Transcription

Principles of ChemicalEngineering ProcessesMATERIAL AND ENERGY BALANCESSECOND EDITIONNAYEF GHASEMANDREDHOUANE HENDA

Principles of ChemicalEngineering ProcessesMATERIAL AND ENERGY BALANCESSECOND EDITION

Principles of ChemicalEngineering ProcessesMATERIAL AND ENERGY BALANCESSECOND EDITIONNAYEF GHASEMREDHOUANE HENDABoca Raton London New YorkCRC Press is an imprint of theTaylor & Francis Group, an informa business

MATLAB is a trademark of The MathWorks, Inc. and is used with permission. The MathWorks doesnot warrant the accuracy of the text or exercises in this book. This book’s use or discussion of MATLAB software or related products does not constitute endorsement or sponsorship by The MathWorksof a particular pedagogical approach or particular use of the MATLAB software.CRC PressTaylor & Francis Group6000 Broken Sound Parkway NW, Suite 300Boca Raton, FL 33487-2742 2015 by Taylor & Francis Group, LLCCRC Press is an imprint of Taylor & Francis Group, an Informa businessNo claim to original U.S. Government worksVersion Date: 20140930International Standard Book Number-13: 978-1-4822-2230-2 (eBook - PDF)This book contains information obtained from authentic and highly regarded sources. Reasonableefforts have been made to publish reliable data and information, but the author and publisher cannotassume responsibility for the validity of all materials or the consequences of their use. The authors andpublishers have attempted to trace the copyright holders of all material reproduced in this publicationand apologize to copyright holders if permission to publish in this form has not been obtained. If anycopyright material has not been acknowledged please write and let us know so we may rectify in anyfuture reprint.Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced,transmitted, or utilized in any form by any electronic, mechanical, or other means, now known orhereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.For permission to photocopy or use material electronically from this work, please access www.copyright.com (http://www.copyright.com/) or contact the Copyright Clearance Center, Inc. (CCC), 222Rosewood Drive, Danvers, MA 01923, 978-750-8400. CCC is a not-for-profit organization that provides licenses and registration for a variety of users. For organizations that have been granted a photocopy license by the CCC, a separate system of payment has been arranged.Trademark Notice: Product or corporate names may be trademarks or registered trademarks, and areused only for identification and explanation without intent to infringe.Visit the Taylor & Francis Web site athttp://www.taylorandfrancis.comand the CRC Press Web site athttp://www.crcpress.com

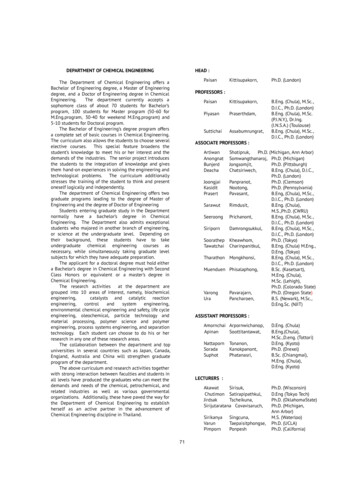

ContentsPreface.xiAcknowledgments.xvAuthors. xviiSystems of Units. xixConversion Factors. xxi1. Introduction.1Learning Objectives. 11.1 Definitions of Chemical Engineering.21.2 Sets of Units and Unit Conversion.31.2.1 Conversion of Units. 31.2.2 Temperature Measurement.51.2.3 Temperature Conversion.61.3 Significant Figures.81.3.1 Multiplication, Division, Addition, and Subtractionof Significant Numbers. 91.4 Dimensional Homogeneity. 101.4.1 Dimensionless Quantities. 111.5 Process and Process Variables. 131.5.1 Process Flow Sheet. 131.5.2 Process Unit. 131.5.3 Process Streams. 131.5.4 Density, Mass, and Volume. 131.5.5 Mass and Volumetric Flow Rates. 141.5.6 Moles and Molecular Weight. 161.6 Compositions of Streams. 171.6.1 Mass Fraction and Mole Fraction. 171.6.2 Concentration. 191.7 Pressure Measurement.221.7.1 Types of Pressures. 231.7.2 Standard Temperature and Pressure. 241.7.3 Pressure-Sensing Devices. 251.8 Process Classification and Material Balance. 381.8.1 Material and Energy Balances. 38Homework Problems. 39References.42v

viContents2. Process Units and Degrees of Freedom Analysis.43Learning Objectives.432.1 Process Units: Basic Functions.442.1.1 Divider (Splitter).442.1.2 Mixer (Blender).442.1.3 Dryer (Direct Heating).442.1.4 Filter. 452.1.5 Distillation Column. 462.1.6 Multieffect Evaporator. 462.1.7 Dehumidification. 482.1.8 Humidifier. 482.1.9 Leaching and Extraction. 492.1.10 Absorber (Stripper). 492.1.11 Partial Condenser and Flash Separator. 502.1.12 Flash Separator. 502.1.13 Crystallizer. 512.1.14 Reactors. 512.1.15 Batch Reactor. 522.1.16 PFRs and PBRs. 532.1.17 CSTR and Fluidized Bed Reactor. 532.2 Process Flow Diagram. 532.3 Labeling a PFD.542.4 Degrees of Freedom Analysis. 552.4.1 Possible Outcomes of DFA. 562.5 Independent Equations. 562.6 Multiunit PFD. 662.7 DFA, Multiunit Process. 68Homework Problems. 71References. 743. Material Balance on Single-Unit Process. 75Learning Objectives. 753.1 Introduction to Material Balance. 753.2 Material Balance Fundamentals.773.3 Mass Balance on Steady-State Processes. 783.3.1 Stream Specification. 783.4 Basis for Calculation.833.4.1 Procedure for Solving Material Balance Problems.83Homework Problems. 100References. 1024. Multiunit Process Calculations. 105Learning Objectives. 1054.1 Multiunit Process. 1054.2 Degrees of Freedom Analysis. 106

Contentsvii4.3Recycle, Bypass, Purge, and Makeup. 1084.3.1 Recycle. 1084.3.2 Bypass. 1094.3.3 Purge. 1094.3.4 Makeup. 110Homework Problems. 132References. 1355. Material Balances on Reactive Systems. 137Learning Objectives. 1375.1 Stoichiometry Basics. 1385.1.1 Stoichiometric Equation. 1385.1.2 Stoichiometric Coefficients. 1385.1.3 Stoichiometric Ratio. 1385.1.4 Limiting Reactant. 1395.1.5 Excess Reactants. 1395.1.6 Fractional Conversion. 1435.2 General Material Balance. 1435.2.1 Differential Balance. 1445.2.2 Integral Balance. 1445.2.3 Formulation Approaches of Mass Balance. 1455.3 Extent of Reaction Method for a Single Reaction. 1455.4 Element or Atomic Balance Method. 1475.5 Molecular or Component Balance Approach. 1475.6 Extent of Reaction and Multiple Reactions. 1575.7 Molecular Species Approach for Multiple Reactions. 1625.8 Degrees of Freedom Analysis for Reactive Processes. 1685.8.1 Chemical Equilibrium. 1695.9 Combustion Reactions. 1725.9.1 Theoretical and Excess Air. 172Homework Problems. 179References. 1826. Multiple-Unit Systems Involving Reaction, Recycle, and Purge. 183Learning Objectives. 1836.1 Multiple-Unit Process Flowcharts. 1836.1.1 Flow Sheet for Reaction with Recycle. 1846.1.2 Reaction with Product Splitter and Recycle. 1846.1.3 Reaction with Recycle and Purge. 1856.2 Degrees of Freedom Analysis for Reactive Multiple-UnitProcesses. 1866.3 Reaction and Multiple-Unit Steady-State Processes. 192Homework Problems. 208References. 214

viiiContents7. Single- and Multiphase Systems. 215Learning Objectives. 2157.1 Single-Phase Systems. 2157.1.1 Liquid and Solid Densities. 2167.2 Ideal Gas Equation of State. 2177.2.1 Gas Density. 2197.3 Real Gas Relationships. 2207.3.1 Compressibility Factor (z). 2217.3.2 Virial Equation of State.2227.3.3 van der Waals Equation of State.2227.3.4 Soave–Redlich–Kwong Equation of State.2237.3.5 Kay’s Mixing Rules.2257.4 Multiphase Systems. 2287.4.1 Phase Diagram. 2287.4.2 Vapor–Liquid Equilibrium Curve. 2287.5 Vapor Pressure Estimation. 2297.5.1 Clapeyron Equation. 2307.5.2 Clausius–Clapeyron Equation. 2307.5.3 Cox Chart. 2317.5.4 Antoine Equation. 2317.6 Partial Pressure.2347.6.1 Dalton’s Law of Partial Pressures.2347.6.2 Raoult’s Law for a Single Condensable Species. 2357.7 Gibbs’ Phase Rule. 2417.8 Bubble Point, Dew Point, and Critical Point. 242Homework Problems. 244References. 2468. Energy and Energy Balances. 247Learning Objectives. 2478.1 Energy Balance for Closed and Open Systems. 2478.1.1 Forms of Energy: The First Law of Thermodynamics.2488.1.2 Energy Balance for a Closed System. 2488.1.2.1 Kinetic Energy. 2498.1.2.2 Potential Energy. 2518.1.3 Energy Balance for an Open System. 2538.1.4 Steam Turbine. 2578.1.5 Heaters and Coolers. 2598.1.6 Compressors. 2618.2 Mechanical Energy Balance. 2638.3 Bernoulli’s Equation. 2678.4 Enthalpy Calculations. 2688.4.1 Enthalpy Change as a Result of Temperature. 2688.4.2 Constant Heat Capacity. 271

Contentsix8.5Enthalpy Calculations with Phase Changes. 2748.5.1 Energy Balance for Open Systems with MultipleInputs and Multiple Outputs. 2768.5.2 Enthalpy Change because of Mixing. 2798.5.3 Energy Balance for Bioprocesses. 2818.6 Psychrometric Chart. 2838.7 Summary. 293Homework Problems. 293References. 2979. Energy Balance with Reaction. 299Learning Objectives. 2999.1 Heat of Reaction. 2999.2 Heats of Formation and Heat of Combustion.3009.2.1 Extent of Reaction.3049.2.2 Reactions in Closed Processes.3049.3 Energy Balance for Reactive Processes. 3079.3.1 Heat of Reaction Method. 3079.3.2 Heat of Formation or Element Balance Method.3089.4 Simultaneous Material and Energy Balances.3099.4.1 Unknown Process Exit Temperature. 3229.5 Combustion Processes. 3279.6 Energy Balance in Bioprocesses. 3329.7 Energy Balance in Membrane Reactors.3349.8 Summary. 338Homework Problems. 339References.34210. Simultaneous Material and Energy Balances.343Learning Objectives.34310.1 Material Balances.34310.1.1 Conversion.34310.1.2 Yield.34410.1.3 Selectivity.34410.1.4 Extent of Reaction (ξ).34410.2 Energy Balances.34510.2.1 Heat of Reaction Method.34510.2.2 Heat of Formation Method.34510.2.3 Concept of Atomic Balances.34610.2.4 Mathematical Formulation of the Atomic Balance.34610.2.5 Degrees of Freedom Analysis for the Atomic Balance.34610.2.6 Implementing Recycle on the Separation Process. 349Homework Problems. 375References. 381

xContents11. Unsteady-State Material and Energy Balances. 383Learning Objectives. 38311.1 Unsteady-State Material Balance. 38311.2 Unsteady-State Energy Balance. 394Homework Problems. 405References. 406Appendix. 407

PrefacePurpose of the BookThe objective of this book is to introduce chemical engineering studentsto the basic principles and calculation techniques used in the field and toacquaint them with the fundamentals of the application of material andenergy balances in chemical engineering. The book is mainly intended forjunior chemical engineers. It exposes them to problems in material andenergy balances that arise in relation to problems involving chemical reactors. The focus is on single and multiphase systems related to material andenergy balances. This material is introduced in a manner that there will belittle lecture content. Most of the material presented covers work on problem solving skills. The material intrusion theory is explained briefly andsimply to make this book more user-friendly. Many examples are includedand solved in a simple and understandable format that explains the relatedtheory. A few examples related to unsteady state material and energy balance are solved using MATLAB /Simulink , and this enables students touse such software in solving complicated problems of material and energybalances. The book can be covered in one semester if based on a four-hourcontact course or two semesters on a two-hour contact course. The new edition contains additional solved examples and homework problems. A newchapter related to single and multiphase systems has been added.Course ObjectivesAt the completion of this course, students will1. Acquire skills in quantitative problem solving, specifically the abilityto think quantitatively (including numbers and units), the ability totranslate words into diagrams and mathematical expressions, theability to use common sense to interpret vague and ambiguous language in problem statements, the ability to make judicious use ofapproximations and reasonable assumptions to simplify problems2. Understand processes typical of those found in the chemical and bioprocess industries3. Know general principles used in process engineering, particularlystoichiometry, material and energy balances, gas laws, and phaseequilibriaxi

xiiPrefaceCourse OutcomesEvery course that a student takes should further his or her knowledge, building on what was previously learned. By the end of this course, each studentshould be able to1. Explain the concepts of dimensions, units, psychrometry, steamproperties, and conservation of mass and energy2. Solve steady-state and transient mass and energy balance problemsinvolving multiple-unit processes and recycle, bypass, and purgestreams3. Solve and understand simple unsteady-state mass and energybalances4. Solve more complicated problems using the software appropriate forthe problem5. Present the solutions to engineering problems in both oral andwritten form in a clear and concise mannerRelationship of Course to Program Outcomes (AccreditationBoard for Engineering and Technology [ABET] Criteria)At the completion of this course, students will have demonstrated the following skills, as described by the ABET:1. An ability to identify, formulate, and solve engineering problems2. An ability to communicate effectively3. An ability to use the techniques, skills, and modern engineeringtools necessary for engineering practiceA Note about the Web DownloadsThe material available via the CRC Web site contains a summary of allchapters in the book, exercises, property estimation software, and psychometric chart parameter estimation software. This material is available fromthe CRC Web site: .

PrefacexiiiPowerPoint presentations that explain the simulations and property estimation using HYSYS are also available to instructors.The website also contains POLYMATH—a software that the user will beallowed to run 200 times free of charge. For the last 50 uses, a warning willbe issued where the software will indicate the number of trials remainingand gives information as to where the software can be purchased. The weblink for this software ishttp://www.polymath-software.com/ghasem/More information about POLYMATH can be obtained at the following link:http://www.polymath-software.comMATLAB is a registered trademark of The MathWorks, Inc. For productinformation, please contact:The MathWorks, Inc.3 Apple Hill DriveNatick, MA 01760-2098 USATel: 508-647-7000Fax: 508-647-7001E-mail: info@mathworks.comWeb: www.mathworks.com

AcknowledgmentsWe are thankful to Allison Shatkin, acquiring editor for this book, andJessica Vakili, the project coordinator, for their help and cooperation. Wealso thank those professors who have given us the chance to see theircourse syllabi and contents. They include Professor Richard Zollarsfrom Washington State University; Professors Prausnitz, Brown, Jessica,Bartling, Koros, and Timothy from the Georgia Institute of Technology;and Professors Palecek, Murphy, Root, and Rawling from the Universityof Wisconsin–Madison. We also extend our thanks to all professors whoare teaching or contributing to this subject. The feedback from ProfessorDouglas R. Lloyd and David Himmelblau and others is highly appreciated.Nayef GhasemRedhouane Hendaxv

AuthorsNayef Ghasem is an associate professor of chemical engineering at theUnited Arab Emirates University, Al Ain, United Arab Emirates. He earnedboth BSc and MSc degrees from the Middle East Technical University,Ankara (Turkey), and earned his PhD from the University of Salford, GreaterManchester (UK). He teaches chemical process principles, natural gas processing, and process modeling and simulation as undergraduate coursesalong with other courses in chemical engineering. Previously, he taughtthese courses at the University of Malaya, Kuala Lumpur, Malaysia. He haspublished more than 40 journal papers, primarily in the areas of modelingand simulation, bifurcation theory, gas–liquid separation using membranecontactor, and fabrication of polymeric hollow fiber membranes. He has alsoauthored Computer Methods in Chemical Engineering, published by CRC Press.Dr. Ghasem is a member of the Institute of Chemical Engineers (IChemE)and a member of the American Chemical Society (ACS).Redhouane Henda is a professor of chemical engineering at the LaurentianUniversity, Sudbury, Ontario, Canada. He earned both MSc and PhD fromthe Institut National Polytechnique de Toulouse (France) and spent a postdoctoral fellowship at the Universität Heidelberg (Germany). He has taughtnumerous core courses in chemical engineering at the undergraduate andgraduate levels. Dr. Henda’s research interests lie at the intersection of chemical engineering and materials science, with a focus on nanoscience andtechnology of thin films and on process engineering of complex systems.He has written a number of journal articles and book chapters in both focusareas and has developed some computer modules for research and education purposes. Among the recognitions he has received are fellowships fromthe French Ministry of Higher Education and the German Alexander vonHumboldt Foundation, as well a scholarship from the Research Council ofNorway. Dr. Henda is a licensed professional engineer in Ontario and hasserved on the editorial boards of numerous journa

Chemical Engineering ISBN: 978-1-4822-2228-9 9781482222289 90000 K22278 Principles of Chemical Engineering Processes: Material and Energy introduces the basic principles and calculation techniques used in the field of chemical engineering, providing a solid understanding of the fundamentals of the application of material and energy balances .