Transcription

SUPRAREX SXE.Better than ever. Versatile asnever before.M O R E P E R F O R M A N C E . M O R E P R O D U C T I V I T Y.MORE PROGRESS IN CUTTING.

The SUPRAREX SXE.Your productive interfacein the manufacturing process.Earth moving machinery for example.Or state-of-the-art shipbuilding technology.Even steel bridges or in plant and mechanicalengineering: ESAB is always there. Withprofessional solutions for welding andcutting, thus makes us number one inmany industries worldwide. Oursector-specific experience and all ofour technical skill are now combined inthe SUPRAREX SXE to form a machineryconcept with an unbeatable variety ofprofitable applications.

SUPRAREX SXE. The evolution.How good gets even better.Pure dynamism, power right down the line.The new SUPRAREX generation convinces users with impressive accelerationand deceleration values helping you toachieve even more productivity and precision. As a high-performance, heavy-dutygantry machine with a rail span of 3,000to 8,500 mm, the SUPRAREX SXE thus formsthe solid foundation for economical cuttingand marking with plasma and oxyfuel.What’s more, with a VISION control systemand COLUMBUS programming softwarefrom ESAB it is perfectly equipped forthe integrated, automated productionprocess.Every detail of the SUPRAREX SXE satisfieseven the most stringent quality requirements,whilst the extremely low maintenance costsand long service life make for a surprisinglyfavorable cost-benefit analysis. Trust inthe power of evolution, invest for the bestSUPRAREX of all time.

The SUPRAREX SXE.A concept that adapts itself.Freedom is the basic requirement for theexpansion of your productivity. Flexibility isthe key to sustainable process integration.With the innovative, modular SUPRAREX SXEgantry machine system, you have completefreedom to configure the perfect solutionof your individual application.Which cutting technology do you wantto work with? How many cutting toolswould you like to use and combine?Which metals and what plate size need tobe processed? ESAB gives you the rightanswers to these and many other questionswith the SUPRAREX SXE!The users and their requirements arethe measure of all things here; the cuttingtechnology adapts itself harmoniously,grows with the user demands and isalways easy to update.

Flexibility and versatile capabilityat a high level.With the SUPRAREX SXE, the options forcombining the diverse range of systemmodules are almost limitless. From thecutting table and the power supply all theway to the peripheral environmental techno-logy: everything comes from ESAB,everything works together optimally,everything satisfies our internationallyrecognized high quality level. Of courseat the same time we have also thoughtabout the ease and safety of use of yourcutting line as well as loading and unloading.For example, the special track conceptallows rapid, trouble-free material feed inthe whole cutting area.That is also an effective way to help savevaluable time and increase your operatingefficiency.

Fit for all processes. With plasma,oxyfuel and combined.The SUPRAREX SXE is ready to receive amultitude of different tools for cutting, weldpreparation and marking with advancedplasma technology or tried and testedoxfuel cutting. Even combinations of theseprocesses or plasma cutting and markingwithout changing tools is easily achievedwith the SUPRAREX SXE.The SUPRAREX SXE from ESAB:everything for your success.High-precision plasma cuttingEven for accurate bevel cutsPlasma bevel cutting with the VBA ExpertPlasma cutting and marking withthe same torchLeft: Powder markingright: Compressed air markingLabeling and marking with InkJetOxyfuel cutting up to 200 mm materialthicknessOxyfuel bevel cutting with VBA-IRGrid cutting with oxyfuel

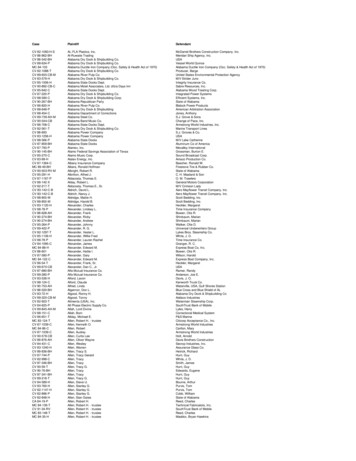

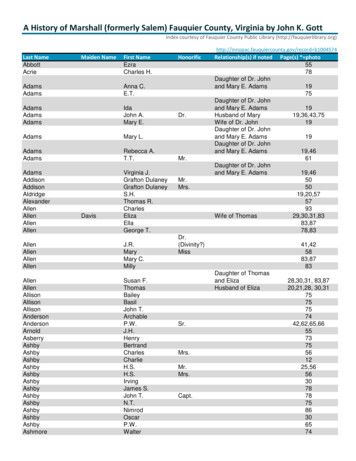

Data and facts about theSUPRAREX SXE.SUPRAREX SXE Technical Specifications SummaryTrack width3,000 – 8,500 mmCutting processesPlasma and oxyfuelPlasma cutting thicknessaccording to plasma generatorSingle-torch plasma cutting equipment1 – 4 torchesOxyfuel cutting thicknessup to 200 mm as standardSingle-torch oxyfuel cutting equipment1 – 12 torchesMachine speed (m/min.)24/40 mMachine length2,000 mmMachine width3,650 – 9,150 mmMachine height2,000 mmWorkpiece support height, table700 mmOther possible processesand combinations:Combined plasma and oxyfuel cuttingWeld preparation with plasmaWeld preparation with oxyfuel cuttingGrid cuttingMarking and labelingThe right to make technical modifications and improvements is reserved.Products may vary from those illustrated.

ESAB. Your partnerin welding and cutting.Includes manufacturing facilities of ESAB North America,a wholly owned subsidiary of Anderson Group Inc.ESAB CUTTING SYSTEMS GmbHRobert-Bosch-Str. 20 · D-61184 Karben, GermanyTel.: 49(0) 60 39 / 40-0 · Fax: 49(0) 60 39 / 40-301E-Mail: info@esab-cutting.comwww.esab.comReg. no. SUPRAREX EN 2007 01 · Technical modifications and errors excepted.Seven decades of experience and the consistent focuson the needs of our customers are the foundations for thesuccessful and comprehensive product range of our cuttingmachines. In keeping with the thermal cutting processes– plasma cutting, oxyfuel cutting and laser cutting –ESAB has developed a range of machines that efficientlycombine the highest cut quality with high cutting speeds,allowing intelligent integration into automated productionprocesses. So in many sectors, the SUPRAREX SXEmachine series also helps to optimize production andincrease the operating efficiency of our customers.

So in many sectors, the SUPRAREX SXE machine series also helps to optimize production and increase the operating efficiency of our customers. ESAB CUTTING SYSTEMS GmbH Robert-Bosch-Str. 20 · D-61184 Karben, Germany Tel.: 49(0) 60 39 / 40-0 · Fax: 49(0) 60 39 / 40-301