Transcription

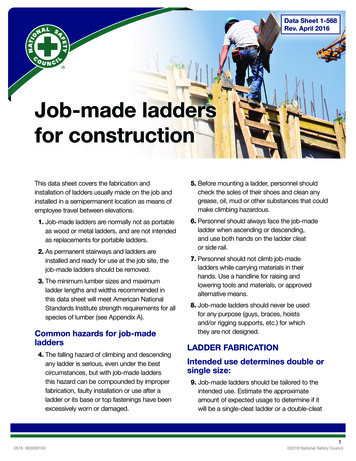

Data Sheet 1-568Rev. April 2016Job-made laddersfor constructionThis data sheet covers the fabrication andinstallation of ladders usually made on the job andinstalled in a semipermanent location as means ofemployee travel between elevations.1. Job-made ladders are normally not as portableas wood or metal ladders, and are not intendedas replacements for portable ladders.2. As permanent stairways and ladders areinstalled and ready for use at the job site, thejob-made ladders should be removed.3. The minimum lumber sizes and maximumladder lengths and widths recommended inthis data sheet will meet American NationalStandards Institute strength requirements for allspecies of lumber (see Appendix A).Common hazards for job-madeladders4. The falling hazard of climbing and descendingany ladder is serious, even under the bestcircumstances, but with job-made laddersthis hazard can be compounded by improperfabrication, faulty installation or use after aladder or its base or top fastenings have beenexcessively worn or damaged.5. Before mounting a ladder, personnel shouldcheck the soles of their shoes and clean anygrease, oil, mud or other substances that couldmake climbing hazardous.6. Personnel should always face the job-madeladder when ascending or descending,and use both hands on the ladder cleator side rail.7. Personnel should not climb job-madeladders while carrying materials in theirhands. Use a handline for raising andlowering tools and materials, or approvedalternative means.8. Job-made ladders should never be usedfor any purpose (guys, braces, hoistsand/or rigging supports, etc.) for whichthey are not designed.LADDER FABRICATIONIntended use determines double orsingle size:9. Job-made ladders should be tailored to theintended use. Estimate the approximateamount of expected usage to determine if itwill be a single-cleat ladder or a double-cleat10516 900009150 2016 National Safety Council

ladder. For example, if the ladder will providethe only means of access to or egress from amain working area for 25 or more workers, or ifsimultaneous two-way traffic is expected, install adouble-cleat ladder.Proper ladder length10. Determine the height the ladder is to reach andthen add approximately 36-42 inches to allowthe side rails to extend adequately above the toplanding to provide a hand-hold for mounting anddismounting.11. The maximum length of single-cleat laddersshould not exceed 24 feet between supports(base and top landing). If ladders are to connectdifferent landings, or if the length requiredexceeds this recommended maximum length, usetwo or more separate ladders, staggered, witha protected platform between each ladder. Themaximum length of double-cleat ladders shouldnot exceed 24 feet.Ladder width12. The width of single-cleat ladders shall be atleast 16 inches, but not more than 20 inches,between rails at the top. The width between railsof double-cleat ladders shall not be less than 18inches or more than 22 inches. Cleats shall becontinuous members between the outside parallelrails (see Figures 1 and 2).13. The width shall be uniform in the total length of theclimb.Lumber selection14. ANSI A14.4, Safety Requirements for Job-MadeLadders, permits many species of lumber for cleatladder fabrication. See Appendix A for variousspecies of wood for use in job-made ladders.15. All wood parts shall be seasoned to a moisturecontent of not more than 19 percent, reasonablystraight-grained (no steeper than a 1-in-12 slope),dressed on all sides, and free from sharp edgesand splinters.Figure 1. Scale drawing of a single-cleat ladder. It shows how the cleats are attached. All lumber sizes shown are nominal.2

16. Side rails must be free of knots. Cleats maycontain knots providing the knots are sound, in thewide face, 0.75 inches or less in diameter, and notmore frequent than two per cleat span or closerthan 6 inches on center. Knots are not permitted inthe narrow faces of the lumber used for job-madeladders. Note: Glossaries of wood defects aregiven in Appendices B and C.Side rails17. It is preferable that side rails be continuous.Structural finger-jointed lumber is permissible whenfull-length rail members cannot be procured. Ifsplicing is necessary to attain the required length,however, the splice must develop the full strengthof a continuous side rail of the same length.18. The load-carrying capacity of side rails is a functionof working length and pitch. The minimum rail sizesfor various combinations of length and pitch forsingle- and double-cleat ladders shall comply withTables I and II. Handrails should be prohibited onjob-made ladders.Cleats19. Nominal 1-inch by 4-inch board material is notnormally subject to stress grade rules and shallbe used after close site inspection ensurescompliance with the materials requirementsdescribed in paragraphs 18 and 19. Nominal2-inch by 4-inch stress-grade dimension lumberlisted in Appendix A will be acceptable without siteinspection prior to use.20. Cleats should be evenly spaced throughout thelength of the ladder between supports except onmasons’ ladders, on which the cleats should runthe full length (height) of the ladder. Spacing, fromtop to top of cleats, should be 11.5-12.5 inches.Each cleat should be continuous members andextend the full width of the ladder on double-cleatladders.21. Cleats should be attached to the narrow faceof rails, using three 10-penny nails for 1-inch by4-inch lumber, and three 12-penny nails for 2-inchby 4-inch lumber. The nails shall be staggered toreduce splitting. Filler strips (blocks) of the sameFigure 2. Cleat attachment for a double-cleat ladder.3

thickness as the cleats shall be cut snug andinserted between cleats and nailed to the side rails.22. Do not permit dapping (or cutting into) the rails tohouse cleats.Ladder installation23. Set rails on level, even and solid footing; anduse foot blocks or mud sills if necessary. Placejob-made ladders at locations where there will beno danger of being struck by passing vehicles,equipment or falling objects. When laddersmust be placed in passageways or other suchthoroughfares, they should be protected bysubstantial barricades around their bases.24. The permissible pitch shall range from vertical to1 in 4 depending upon site conditions and ladderrail sizes (see Tables I and II). In other words, thehorizontal distance from the base of the ladder tothe supporting surface shall not be greater thanone-fourth the ladder working length. Ladders withspliced side rails shall be used at a pitch fartherthan 1 in 8.25. Tops of ladders should extend approximately36-42 inches above the top landing so workersgetting on or off will have a solid handhold.26. Horizontal handrails, mid-rails and toe-boards arenecessary on either side of the job-made ladderside-rail extensions when the ladder is used foraccess to an elevated work area.27. Secure ladders to prevent displacement. At thetop, nail the ladder or lash it with wire or rope toa secure object. At the bottom, secure it againstmovement by blocking, tying or another suitablemethod.28. Solidly decked landings should be provided at thetop of all ladders.Table I. Minimum rail size for single-cleat ladders (nominal-dimension lumber)Pitch (H/L)Working x6(See Note 1)Table II. Minimum rail size for double-cleat ladders (nominal-dimension lumber)Working 2x42x6Pitch 202x42x62x62x6(Note 2)22242x42x42x62x62x62x62x62x6(Note 2)(Note 2)Notes: 1) Pitch is defined as H, the horizontal distance from the base of ladder to supporting surface, divided by working length L,length of rail from base to point of bearing at the top. 2) Stresses exceed capacity of 2x6 rails for this combination of height and pitch.4

29. If protective coatings are considered desirable, onlytransparent coatings or wood preservative shouldbe used. Ladders shall not be painted with opaquecoating.Inspection and maintenance30. All job-made ladders, landings and lashings shouldbe inspected daily or before each use, and anydefects that have developed (or damage that hasoccurred) should be corrected immediately.Sources of informationAmerican National Standards Institute, 1819 L St.,N.W., 6th Floor, Washington, DC 20036. SafetyRequirements for Job-Made Ladders, ANSI ASCA14.4-2009. Some material in this data sheet isreproduced (with permission) from this standard,copyright 2009 by the American National StandardsInstitute. Copies of the standard may be purchasedfrom the American National Standards Institute.Appendix A: Acceptable stress-grade lumber for job-made ladders (note 1)Species groupCoast sitka spruceDouglas fir-larchDouglas fir-southEastern hemlock-tamarackEastern spruceHem-firLodgepole pineMountain hemlockNorthern pinePonderosa pine-sugar pineRed pineSitka spruceSouthern pineSpruce-pine-firWestern hemlockMinimum grade (Note 2)Select structural [Note 3(f)]No. 2 [Note 3(c), (d), (f)]No. 2 [Note 3(d)]No.1 [Note 3(a), (b), (f)]Select structural [Note 3(a), (b)]No. 1 [Note 3(c), (d), (f)]Select structural [Note 3(d)]No. 1 [Note 3(c), (d)]No. 1 [Note 3(a), (b)]Select structural [Note 3(d), (f)]Select structural [Note 3(f)]Select structural [Note 3(c)]No. 2 [Note 3(e)]Select structural [Note 3(f)]No. 1 [Note 3(c), (d)]Notes:(1) Used at 19 percent maximum moisture content.(2) Minimum fiber stress in bending fb 1200 lbf/in2 [pound-force per square inch 9psi)](3) A ll lumber shall be identified with a grademark of an ALSC-approved inspection agency under the rules setforth by the following rules-writing agencies:a. Northeastern Lumber Manufacturers Associationb. Northern Hardwood and Pine Manufacturers Associationc. West Coast Inspection Bureaud. Western Wood Products Associatione. Southern Pine Inspection Bureauf. National Lumber Grades Authority - Canada5

Appendix B: Permissible defects inwood used for laddersCleats - The slope of the grain for this lumbershould be not less than 1 in 15. Knots are notpermissible in the narrow faces of the ladder cleatsand knots in the wide faces should not be biggerthan 0.25 inch in diameter.Side rails - This lumber should be as straight aspossible, with a slope of the grain not steeper than 1in 12. Knots are not permissible in the narrow facesof the lumber. Tight and sound knots of 0.5 inches orless in diameter are permissible in the wide faces if notmore frequent than one in three feet and at least 0.5inch back from a narrow face. Pitch and bark pocketsnot more than 0.125 inch wide, two-incheslong, and0.5 inch deep are permitted in side rails, if they arenot more frequent than one in every three feet. Blackstreaks in western hemlock are not considered anirregularity, except that chambers present in the streaksare limited by the specifications for pitch and barkpockets.Appendix C: Glossary of wood detectsKnots - A knot is a segment of a branch or limb thatwas embedded in the tree and has been cut through inthe process of manufacturing. An encased knot and anintergrown knot are shown in Figure 6.Checks - A lengthwise separation of the wood thatmost often occurs across the annual growth rings.Compression failure - A deformation (buckling) of thefibers due to excessive compression along the grain.This may appear as a wrinkle across the surface.In some cases compression failure may be presentbut not visible as wrinkles; in such cases it is oftenindicated by fiber breakage on end-grain surfaces.Compression wood - An abnormal growth, primarilyfound in soft wood, characterized by relatively wideannual rings, usually eccentric, and comparatively largeportion of summer wood (usually 50 percent or more)that most often merges into the spring wood withoutexhibiting a marked contrast in color.Figure 6. Examples of an encased knot (left) and anintergrown knot (right). (Photo Courtesy of Forest ProductsLaboratory, U.S. Forest Service)Decay - The disintegration of wood due to theaction of fungi. (This is also known as dote or tor.)Pitch and bark pockets - A pitch pocket is anopening extending parallel to the annual growthrings that contains or has contained pitch in a solidor liquid form. A bark pocket is an opening betweenannual growth rings that contains bark. Barkpockets appear as dark streaks on radial surfacesand as rounded areas on tangential surface.Shakes - Separation along the grain, mostcommonly occurring between annual growth rings.Wane - Bark or the lack of wood on the corner of apiece of lumber. The cause is not important.Copyright 2016 National Safety Council. Allrights reserved.Although the information and recommendationscontained in this publication have been compiledfrom sources believed to be reliable, the NationalSafety Council makes no guarantee as to, andassumes no responsibility for, the correctness,sufficiency, or completeness of such informationor recommendations. Other or additional safetymeasures may be required under particularcircumstances.6

ANSI A14.4, Safety Requirements for Job-Made Ladders, permits many species of lumber for cleat ladder fabrication. See Appendix A for various species of wood for use in job-made ladders. 15. All wood parts shall be seasoned to a moisture content of not more than 19 percent, reasonably straight-grained (no steeper than a 1-in-12 slope),