Transcription

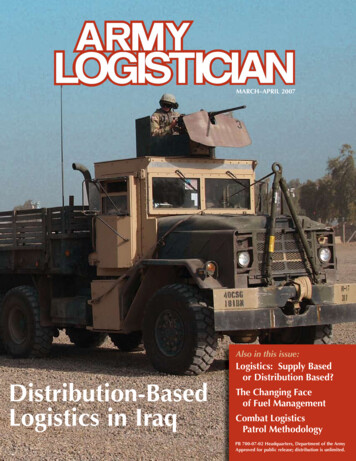

MARCH–APRIL 2007Also in this issue:Distribution-BasedLogistics in IraqLogistics: Supply Basedor Distribution Based?The Changing Faceof Fuel ManagementCombat LogisticsPatrol MethodologyPB 700-07-02 Headquarters, Department of the ArmyApproved for public release; distribution is unlimited.

PROFESSIONAL BULLETIN OF UNITED STATES ARMY LOGISTICSPB 700–07–02VOLUME 39, ISSUE 2MARCH–APRIL 20071News2Distribution-Based Logistics in Operation Iraqi Freedom—Colonel C. Brandon Cholek andChief Warrant Officer (W–5) Matthew A. Anderson, Sr.9Commentary—Logistics: Supply Based or Distribution Based?—Eric PeltzMembersThe Honorable Claude M. Bolton, Jr.Assistant Secretary of the ArmyAcquisition, Logistics, and Technology12Combat Logistics Patrol Methodology—Major Julian H. Bond, CAARNGLieutenant General Ann E. DunwoodyDeputy Chief of Staff, G–4Department of the Army14Army Reduces Tactical Supply System Footprint—Thomas H. Ament, Jr.General Benjamin S. GriffinCommanderArmy Materiel Command16Medical Logistics Interface Tab for FBCB2—Captain Cody R. Roberson19Midnight Run—Captain Michael J. Rainis22The Active Guard/Reserve Instructor Share Program—Major Paul Wakefield24The Changing Face of Fuel Management—Major Vincent C. Nwafor30BOARD OF DIRECTORSPolymer Advances in the Interwar Period:The Impact of Science on World War II—Major Paul Wakefield33Resources for Convoy Battle Drills—Captain Christina A. Polosky40Resourcing the Force in the Midst of Complexity:The Need to Deflate the ‘ppb’ in PPBE—Dr. Christopher R. Paparone49Writing for Army LogisticianChairmanMajor General Mitchell H. StevensonCommanderArmy Combined Arms Support CommandARMY LOGISTICSMANAGEMENT COLLEGEColonel Shelley A. RichardsonCommandantBarbara G. MroczkowskiAssistant CommandantSTAFFRobert D. Paulus, EditorJanice L. Simmons, Assistant EditorApril K. Morgan, Assistant EditorLouanne E. Birkner, Administrative AssistantGraphic arts and layout byRCW Communication Design Inc.This medium is approved for the official dissemination of material designed to keep individualswithin the Army knowledgeable of current andemerging developments within their areas ofexpertise for the purpose of enhancing their professional development.By Order of the Secretary of the Army:PETER J. SCHOOMAKERGeneral, United States ArmyChief of StaffOfficial:Cover: During Operation Iraqi Freedom 05–07, the 3d Corps Support Command (COSCOM) provided support to over 220,000 coalition Soldiers andcivilians and backup support to the emerging 300,000-man Iraqi SecurityForce. In order to perform their corps sustainment mission, 3d COSCOMunits traversed almost every main supply route and most alternate supplyroutes throughout Iraq. Their story begins on page 2. In the cover photo,Soldiers of the 181st Transportation Battalion prepare to provide security fora departing combat logistics patrol. (Photo by SGT Mary E. Ferguson, 3dCOSCOM PAO.)JOYCE E. MORROWAdministrative Assistant to theSecretary of the Army0 35503World Wide Web address:www.almc.army.mil/alog

ALOG NEWSLIFE CYCLE MANAGEMENT COMMANDCREATED FOR MUNITIONSThe life cycle management command (LCMC)concept was extended to munitions with the activation of the Joint Munitions and Lethality (JM&L)LCMC in November. The JM&L LCMC is thefourth of the Army Materiel Command’s (AMC’s)LCMCs, joining the Aviation and Missile LCMC, theCommunications-Electronics LCMC, and theTACOM [Tank-automotive and Armaments Command] LCMC. The creation of the LCMCs is designedto reduce life-cycle costs and deliver better productsto Soldiers more quickly by improving the relationship among AMC, its major subordinate commands,and the program executive offices (PEOs).Headquartered atPicatinny Arsenal,New Jersey, the JM&LLCMC integrates theArmament Research,Development, andEngineering Centerat Picatinny; the PEOfor Ammunition, alsoat Picatinny; and theJoint Munitions Command at Rock IslandArsenal, Illinois.JM&L LCMC logo.ARMY SPEEDS UP BCT SCHEDULEThe Army announced in December that it willestablish two more Active-component brigade combatteams (BCTs) ahead of schedule in order to increasethe number of combat and combat support units available for combat and homeland-defense missions.VETERAN ARMY LOGISTICIANEDITOR RETIRESJanice L. Simmons, a staff writer-editor at ArmyLogistician since 1995, retired on 3 January after34 years of Federal service. During her 12 yearsat Army Logistician, Ms. Simmons consistentlyperformed according to the highest standards ofThe 3d Brigade, 1st Armored Division, at FortRiley, Kansas, will convert to a heavy BCT in April,11 months earlier than planned. Its transition teammission and resources will be assumed by the 1stBrigade, 1st Infantry Division. The BCT will reflagnext September as the 2d Brigade, 1st InfantryDivision, bringing all Fort Riley units under the 1stInfantry Division.The 3d Brigade, 1st Infantry Division, at FortHood, Texas, will convert to an infantry BCT inApril, 17 months ahead of schedule. When facilities become available, the unit will relocate to FortKnox, Kentucky. However, if the unit deploys, itwill return from combat to Fort Hood before movingto Fort Knox.The conversion to BCTs is in keeping with theArmy’s decision to transform the total force froma Cold War-structured organization to one thatis prepared to operate in conflicts ranging fromfull-scale combat to stability and reconstructionoperations.Increasing the number of BCTs also will helpreduce stress on the current force by giving Soldiersa few more months at home than they now have.Currently, the ratio is 1 year deployed to sometimesless than 1 year at home station. The Army’s goalfor the Active component is 1 year deployed to 2years at home station.Most of the Soldiers affected by the acceleratedcreation of the two BCTs will receive permanentchange of station orders this summer.HANDBOOK OFFERS LOGISTICS CAPTAINSINTRODUCTION TO ARTILLERY SUPPORTThe Army Logistics Management College (ALMC) at Fort Lee, Virginia, has prepared a handbook designed to prepare logistics captains forsupport positions in field artillery battalions, particularly in forward support companies. The handbook, Field Artillery Logistics: Munitions Support,Army journalism. The hallmarks of her work weremeticulous attention to detail and devotion toaccuracy. She combined the skills of a painstaking researcher with the discernment of a mastergrammarian. Her excellence was recognized at theArmy level when she received the Army Editor ofthe Year Award in 2003. Her judgment, advice,and humor will be missed greatly.(continued on page 46)ARMY LOGISTICIANPROFESSIONAL BULLETIN OF UNITED STATES ARMY LOGISTICS

Distribution-BasedLogistics in OperationIraqi FreedombyColonel C. Brandon Cholek and Chief Warrant Officer (W–5) Matthew A. Anderson, Sr.The lifeline to the Army’s combat power is its distribution networkand demand-supported, on-hand stocks for all classes of supply.In the summer of 2005, Brigadier General RebeccaHalstead, the Commander of the 3d Corps SupportCommand (COSCOM), directed our unit, the 3dCorps Distribution Center (CDC), to analyze, optimize,and refine the distribution architecture of the Iraqi theater. Her charter to the CDC was: Increase the velocityand quality of support to the warfighter, optimize effectiveness of scarce distribution assets, keep Soldier andcontractor force-protection paramount, and improveunity of effort across the many disparate organizationsto enhance tactical, operational, and strategic distribution enablers for supporting a transforming Army.In order to reduce the millions of dollars worth of“insurance stocks” and increase the confidence ofsupported units in the distribution network, the variability of supplies and equipment must be limited. Atthe same time, the operational readiness and visibilityof unit equipment must be increased. While the processes of requisitioning, distributing, and receiptingmateriel, supplies, and commodities are interrelated and integrally linked to readiness, each process isstraightforward when individually scrutinized. In Iraq,the CDC team analyzed all distribution modes andnodes while using the Army distribution managementphilosophy: define, measure, and improve. From thetactical level through the strategic level, the distribution process involved numerous agencies and manydisparate teams of professionals.Command and Control for Echelons Above BrigadeUnity of command greatly facilitated the logisticssuccess of 3d Corps units on the battlefield duringOperation Iraqi Freedom (OIF) 05–07. Previous rotations operated under the Army of Excellence organizational structure, in which the divisions were supportedby their assigned division support commands. For OIF05–07, transformed and transforming modular unitswere employed at various levels of manning, with allof the division’s logistics capabilities residing in thebrigade combat teams (BCTs).MARCH–APRIL 2007

A 317th Maintenance Company Soldier directs aforklift operator to move a pallet of tires that isbeing staged for retrograde. (Photo by SGT Rachel A.Brune, 101st Sustainment Brigade PAO.)During our deployment, the 3d COSCOM’s supportbrigades assumed the missions of the former divisionsupport commands as well as those of the supportingcorps support groups. Brigadier General Halsteadwas in direct command and control (C2) of all logistics assets above the BCT level and could effectivelyflex to meet the Multinational Corps-Iraq (MNC–I)commander’s intent. The tremendous logistics capabilities of 20,000 COSCOM Soldiers and 5,000Logistics Civilian Augmentation Program (LOGCAP)contractors encompassed materiel management, fieldmaintenance, automated logistics systems operation,and distribution.The 3d COSCOM’s C2 reach extended to everycorner in Iraq, and, unlike any single division or coalition force headquarters, 3d COSCOM units traversedalmost every main supply route and most alternatesupply routes nightly in support of their corps sustainment mission. The depth and breadth of the 3dCOSCOM span of control over the combat servicesupport echelons-above-brigade units, coupled withits ownership of direct support and general supportstocks, enabled the 3d COSCOM to manage all of itsresources seamlessly and effectively in a coordinatedand synchronized manner. Providing support to over220,000 coalition Soldiers and civilians and backupsupport to the emerging 300,000-man Iraqi SecurityForce was a mission the 3d COSCOM embraced withconviction.The 3d COSCOM comprised two sustainment brigades, three corps support groups, a theater securityBCT, an area support group, and two rear-area operations centers arrayed across Iraq on diverse, inhospitableterrain in an area the size of Texas. Almost 40 percentof the 3d COSCOM’s force was committed to providingforce-protection duties for 5 bases and serving as theatersecurity escorts for 2,000 trucks organized into approximately 70 nightly combat logistics patrols (CLPs).These 70 CLPs were in addition to the 30 CLPs (over1,000 trucks) from the theater transportation group thataccompanied deployments, redeployments, and theatersustainment from Kuwait. During surge periods, the3d COSCOM had to track up to 4,000 trucks movingin more than 130 CLPs. During our yearlong rotation,corps, theater, and contractor trucks moved in more than37,000 CLPs (over 1.1 million truckloads) throughoutIraq and endured over 1,400 enemy confrontations onthe dangerous supply routes.The 3d CDC, composed of commodity analysts,distribution and movement control experts, and futureARMY LOGISTICIANoperations planners, served as the logistics nerve center for the 3d COSCOM. The CDC fused the supplyexpertise of the 19th Materiel Management Centerwith the transportation, distribution, and movementcontrol functions of the 27th Movement Control Battalion under the supervision of the 3d COSCOM support operations staff to achieve a logistics commonoperating picture. Enabled by logistics automationsystems and supported by movement control and distribution management teams throughout Iraq and atthree borders, the CDC was ideally postured to synchronize seamless, continuous support.The CDC maintained continuous visibility andoversight of all commodities and common-user landtransportation assets in Iraq. The CDC had real-timesituational understanding and was fully integrated inthe operational and mission planning of the MNC–I,so it was able to apply resources to operations rapidly and effectively while continuing to balance thecomplex theater sustainment mission. Having singleoperational logistics C2 reside with the 3d COSCOMalso provided the MNC–I commander and his staffcomplete logistics situational awareness, flexibility,responsiveness, and sustainability in the allocation ofresources in the dynamic joint and coalition theater.While achieving unity of command for the corps’logistics assets, the 3d COSCOM served as the primary logistics integrator and conduit for leveragingthe capabilities of our in-country strategic partnersto achieve unity of effort. Working with the MNC–IC–4, the Multinational Force–Iraq (MNF–I) DeputyChief of Staff for Resources and Sustainment, the377th Theater Sustainment Command, and the Coalition Forces Land Component Command C–4, the 3dCOSCOM coordinated logistics unity of effort byleveraging the capabilities and resources of the ArmyMateriel Command (AMC); the Defense LogisticsAgency (DLA) and subordinate DLA organizationssuch as the Defense Energy Support Center and theDefense Reutilization and Marketing Service, the U.S.Transportation Command and its forward-deployedU.S. Central Command Deployment and DistributionOperations Center (CDDOC), the Joint ContractingCommand, and our LOGCAP and contractor partners.The 3d COSCOM’s unique single logistics C2 structurefacilitated the synchronization of vertical and horizontal coordination of all logistics required for simultaneous protracted theater sustainment, deployment, andredeployment and enabled operational support.OperationsThe Iraqi Theater was a hotbed of activity. Routine sustainment and operational support missionsoccurred simultaneously and continuously throughoutIraq. During our rotation, but most notably for thePROFESSIONAL BULLETIN OF UNITED STATES ARMY LOGISTICS

Ramadi and Baghdad operations, the 3d COSCOMrapidly conducted parallel and multiechelon missionanalyses to implement flexible, effective complexmission sets. The 3d COSCOM was able to balancethe fight carefully with the right enablers to implement proactive measures for countering or mitigating enemy actions, the friction of competing events,and natural challenges. Employing and managingthe critical assets of each of the support brigadesin Iraq as a single, seamless logistics capabilityresulted in a logistics effort greater than the sum ofits many parts.For both the Ramadi and Baghdad missions, onlythe 3d COSCOM could plan, coordinate, assemble,and allocate the Soldiers and the resources necessary to ensure that these operations succeeded inthe required timeframe. Both missions requiredcommon-user land transportation, field services, andmateriel exceeding the capabilities of the respectivesupport brigades in the battlespace. The CDC’s futureoperations planners, who were attuned to corps anddivision planners, developed effective concepts ofsupport for using Soldiers, equipment, and materielfrom all five support brigades. The timely movementand repositioning of over 2,000 truckloads of equipment enabled the maneuver commanders to executetheir missions and postured the corps for logisticssuccess. For each of these missions, planning andexecution were accomplished seamlessly within a2-week timeframe and without adversely affectingthe nightly sustainment missions. Fortunately for theBaghdad mission, the theater transportation truckswere already in Iraq in preparation for the redeployment of the Stryker brigade, so the corps movementcontrol battalion, along with the corps and theaterplanners, diverted the convoys to Baghdad.The 3d COSCOM, in concert with all of its partnersand subordinate units, planned and coordinated to provide the right amount and type of transport needed tobalance the operational requirements effectively withits capabilities. Single C2 for synchronizing transportresources, timing, and the ability to leverage existinginfrastructure and processes, coupled with the robuststocks on hand, provided unprecedented flexibility,agility, and responsiveness.Defining and Refining the Distribution ProcessAs the CDC team studying the theater distribution system identified the key nodes through whichmateriel would travel from end to end, the term“partnering” took on new meaning. Identifyingtasks, applying measurable, standardized metrics forsuccess, and assigning responsibilities at each nodewere prerequisites for refining a common distributionoperating concept. Essential for process improvement was identification of an individual who was directlyresponsible for each task and who could make achange in the process.The CDC team also had to identify what thechange to the distribution process should be and,more importantly, how the system components shouldbe modified and measured. The entire system had tobe analyzed holistically, because an improvement inone segment could affect the functionality in anothersegment and impede its established performancemetrics. Although distribution systems in the theaterhad matured significantly over the course of OIF, individual distribution nodes and segments were underconstant and often dramatic transformations thataffected other segments. Changes to automated logistics systems, advances in radio frequency identification technology, improvements in in-transit visibility(ITV) devices and systems, new air and ground systems, and modular organizational structures for tablesof organization and equipment were some of the manyvariables affecting distribution. Although we encountered constant challenges and constraints with thedistribution system, we were able to refine the systemin order to provide a complete range of supplies andservices to a hard-fighting, demanding force.Different rotation polices and support solutionsamong the services could adversely affect supportif not carefully orchestrated among strategic, operational, and tactical units and critical strategic logisticsproviders. The inevitable disruptions along mainand alternate supply routes by improvised explosivedevices or complex attacks could result in delays andan increase in the supported units’ requisition waittime (RWT) if not properly considered. To ensureseamless support to the warfighters, we developedmitigating strategies and compensating mechanisms.For example, by adjusting days of supply for fuel andfood and relocating tankers and refrigerated storagevans at key nodes in order to implement more flexible redistribution measures, the 3d COSCOM wasable to absorb the variables inherent in the friction ofwar without any impact to the warfighter. [“Frictionof war” is a term coined by Major-General Carl vonClausewitz, a renowned Prussian military theorist, torefer to unforeseen circumstances that frequently ariseand routine tasks or expectations that often becomeextremely difficult.]Reducing Requisition Wait TimeTo measure RWT, we used weekly supply pipelinereports produced by AMC’s Logistics Support Activity(LOGSA). These reports provided RWT and pipelinesegment processing times for requisitions receipted inIraq by class of supply, priority, mode of transportation, and source of fill.MARCH–APRIL 2007

Personnel from the 155th Cargo TransferCompany winch an M1A2 Abrams tank onto aheavy equipment transporter at Camp Taji, Iraq.(Photo by SGT Joshua Salmons, 4th SustainmentBrigade PAO.)Near the beginning of OIF 05–07, the 85th percentile RWT measurement was below the Army CentralCommand’s standard of 20 days. However, there wereseveral weeks during which RWT fluctuated between22 and 23 days, which exceeded the standard. Factorscontributing to higher RWT were unit transitions, strategic transportation demands outside the theater, competing demands for in-theater transportation, supplysupport activity (SSA) personnel turnover, and limitedperiods of movement during critical Iraqi constitutionreferendum and national elections.We formed a process action team (PAT) to exploreways to reduce the time required to process a unit’srequisition from the time the requisition reached theSSA until the requested item was received in the SSA.The PAT was a cross-section of subject matter expertsfrom the tactical, operational, and strategic distribution levels. We examined ways to improve processesthroughout the supply chain, assigned responsibilityfor each process, and identified the individual whocould impact specific areas for improvement. The PATstudied intratheater airlift and the ground lines of communication at the operational and tactical levels. Weanalyzed trends, routes, the current number of CLPs,the volume of transportation movement requests, andthe priorities of the MNC–I in relation to the abilityof 3d COSCOM, division, and theater transportationassets to meet those priorities.Part of the PAT’s charter was to increase the visibility of requisitions throughout the supply chainand to instill confidence in the distribution system inour customers. Increasing visibility and reliabilitywould greatly reduce the counterproductive cycleof redundant ordering, which further burdened analready constrained distribution system and taxed thesupply nodes.The PAT conducted a detailed support-to-supportingunit analysis, and each Department of Defense Activity Address Code (DODAAC) was aligned with theunit position on the battlefield and further alignedwith the closest SSA. We reorganized operationally and reallocated and repositioned transportationassets. We also reduced the number of ground linesof communication and implemented measures to varyroutes in order to reduce the predictability of convoysto the insurgents. Using a variety of statistical toolsand reviews, we constantly scrutinized the logisticshierarchy at all levels, which improved the utilizationrates of the subordinate logistics brigades.ARMY LOGISTICIANAs a result of these detailed efforts, the CDC andits key enabling partners were able to reduce the RWTfrom 22 to 23 days to 12 to 14 days over the courseof 6 months. Quarterly, we studied the changes thatwere implemented and made incremental adjustmentsto ensure maximal support to the units with negligibleimpact on the distribution resources at all levels.As a part of our supply chain analysis, we implemented mitigation strategies that would reduce thethreat to Soldiers and contractors traversing the dangerous roads of Iraq and, at the same time, enhancedistribution. For example, we maximized the use ofairlift, built water-bottling plants, and increased ITV.For every four pallets flown, one truckload was displaced. For every CLP not sent out, up to 35 personnelwere kept off the road.Maximum Use of AirliftThe 3d COSCOM partnered with the Air Force andArmy aviation units to ensure maximum use of theirpallet- and cargo-carrying capabilities. The Air Forceand the CDDOC team embedded forward at the theaterlevel were highly supportive of our efforts. Their mantraPROFESSIONAL BULLETIN OF UNITED STATES ARMY LOGISTICS

became “Load the pallets into GATES and the aircraftwill come.” [GATES (Global Air Transportation Execution System) is the Air Force Air Mobility Command’saerial port operations and management informationsystem designed to support automated cargo and passenger processing.] GATES provided the much-neededvisibility of cargo and the accompanying workload dataneeded to schedule channel missions and opportune lift.Cargo usually was moved within 72 hours.In addition to the usual gray Air Force cargo planes,the CDDOC contracted commercial aircraft—mostnotably Russian IL–76 cargo planes. Starting out asa proof-of-concept principle, use of the cargo planesproved reliable, flexible, and predictable throughoutthe entire rotation. These planes moved more than15,000 pallets (the equivalent of over 3,700 truckloads). Monthly, the CDC Air Cell, in conjunctionwith the CDDOC and the Air Force, reviewed aircraftutilization statistics to assess requirements and adjustflight route channel frequencies and locations.Army CH–47 Chinook helicopters proved criticalin moving repair parts and major assemblies. Initially,the 3d COSCOM received only one mission (requiring two helicopters) on alternating nights; but ourworkload soon quadrupled, which meant that we hadsufficient workload to justify two missions (requiringfour helicopters) nightly. Integrating global contractorrepair parts into the 3d COSCOM theater distributionnetwork was essential to effectively distributing uniquerepair parts for equipment that had been fielded rapidlythroughout the theater. During OIF 05–07, the Armyhelicopters proved to be adaptable for this mission, andthey could be dispatched readily to the remote locations from which many requirements originated. Thehelicopters transported over 3,000 pallets, which madeit unnecessary to dispatch more than 770 trucks.The C–23B Sherpa aircraft was an indispensableworkhorse for moving medical cargo and personnel.More than 98 percent of medical supplies were distributed by aircraft. These small, agile, and reliable aircraft transported over 10,000 pallets, or the equivalentof 1,200 truckloads.Water-Bottling PlantsSoldiers and contractors operating in desert environments need large amounts of potable water fordrinking, dining facility operation, and sanitationand hygiene. Despite advances in reverse-osmosiswater-purification unit (ROWPU) technology andthe Army’s significant investment in personnel andequipment to prepare water for consumption, bottledwater is preferred by the troops.Bottled water was trucked in from Kuwait, Turkey, and Jordan; this required thousands of line-haultruckloads and exposed drivers and escorts to lethalenemy actions. In order to take advantage of an opportunity to mitigate the Soldiers’ exposure to danger whilehauling water and the obvious cost effectiveness ofbuilding potable water-bottling plants directly on U.S.bases in Iraq, logisticians and representatives of theDefense Contracting Command solicited contractors tobuild six water-bottling plants.The first plant was constructed at Logistics SupportArea Anaconda. It quickly proved its worth and servedas a source of lessons learned for constructing thefive other plants. In a 7-month period, the Anacondafacility produced the equivalent of 3,500 truckloads ofwater and saved millions of dollars because the averagecase price was reduced by almost 70 percent. Everymonth, the five completed plants displaced over 3,100A water-bottling specialist prepares water for packaging at water-bottling facility number 6 in Iraq.The plant produces 450,000 one-liter bottles a day. (Photo by SFC Guadalupe Stratman, 4th SustainmentBrigade PAO.) MARCH–APRIL 2007

trucks that had been required to haul water. Whenfully operational, the six plants will displace morethan 16,000 truckloads and yield a potential savingof over 100 million a year. In addition to mitigatingrisk to Soldiers and saving the Army money, the plantsafforded increased operational flexibility because wecould adjust production levels and rapidly change thedistribution schedule to coincide with requirements.In-Transit VisibilityTo increase effectiveness of the distribution system,the 3d COSCOM, MNC–I, and MNF–I embarked on acampaign to “tag everything that moved” to make betteruse of the maturing ITV infrastructure. With over 90fixed interrogators at key nodes throughout Iraq and theavailability of the upgraded Standard Army Retail Supply System (SARSS) at SSAs to write radio frequencytag content, ITV provided us an opportunity to assist allstakeholders. Teams of logisticians throughout our areaof responsibility relied on the data feeds, data integrity,and data latency to conduct their day-to-day operations.The 3d COSCOM’s readiness analysts were trained touse logistics automation enablers, such as the Movement Tracking System (MTS) and the Battle CommandSustainment Support System (BCS3), to track andreport on the status of shipments. Control of situationalinformation allowed us flexibility in providing supportand enabled us to use a variety of modes to move keyitems of materiel to their ultimate destination.Redistribution and RetrogradeRedistribution and retrograde of equipment becameadditional missions for all units in Iraq, most notably forAMC’s Field Support Brigade-Iraq (AFSB–I), the Military Surface Deployment and Distribution Command’s840th Transportation Battalion, and the 3d COSCOM.These processes reversed the paradigm of bringingeverything into Iraq, as had been done for the last 3years. Instead, we began a momentous paradigm shifttoward moving equipment and materiel out of Iraq whileredistributing other equipment to other combat, sustainment, deployment, and redeployment operations.Redistribution and retrograde were key componentsof the Army’s transition from limited wartime property accountability to stricter peacetime accountabilitystandards. Redistributed equipment was allocated tocoalition forces and provided to the Iraqi SecurityForces (ISF) as significant military equipment. [“Significant military equipment” is defined as articles forwhich special export controls are warranted because oftheir capacity for substantial military utility or capability.] The remaining equipment would be retrogradedto reconstitute the Army pre-positioned stocks in theater or redeployed out of theater for refurbishment toreset the Army.ARMY LOGISTICIANThe equipment to be retrograded ran the gamutof all classes of supply and equipment. Major enditems were under the purview of AFSB–I’s redistribution property accounting teams and accounted forusing Property Book Unit Supply Enhanced (PBUSE).SARSS was the primary system used to account forother classes of m

HANDBOOK OFFERS LOGISTICS CAPTAINS INTRODUCTION TO ARTILLERY SUPPORT The Army Logistics Management College (AL-MC) at Fort Lee, Virginia, has prepared a hand-book designed to prepare logistics captains for support positions in field artillery battalions, par- . Distribution-Based Logistics in Operation Iraqi Freedom.