Transcription

The Strongest Hybrid Pool on theMarket TodayThe UltimateGrecianPoolInstallationManualRev: 02/11/19

IntroductionCongratulations on your decision to purchase thetruly unique and superior Ultimate Grecian pool.The 14- Gauge powder coated steel wall system isthe strongest hybrid pool on the market today.Important!- This pool must be buried at least 18”below grade and have a concrete collar pouredaround it.As you read through this manual, you will noticethat we stress the importance of properinstallation to ensure a long lasting and safeinvestment for your family. This pool is designedto be installed by the ‘do-it-yourself’ homeowneror a professional pool installer. Rebar stakes(provided) MUST be installed in every hole at thebase of the pool wall or the manufactureswarranty is void.The Ultimate Grecian pool carries a lifetimewarranty on the steel panel system as well as apro-rated warranty on the liner. To protect yourinvestment, please fill out and send back yourwarranty cards when this pool is constructed.2

CONTENTSTable of ContentsPAGE INTRODUCTION2 SAFETY INFORMATION4 TOOLS AND MATERIALS NEEDED5 SITE LOCATION AND PREPARATION6-7 POOL AND WALL LAYOUT7-8 OPTIONAL WALK-IN STAIR9 SETTING THE WALLS10-12 INSTALLING COPING OPTIONS12-14 MOUNTING THE SKIMMER AND RETURN FITTINGS14-15 POURING THE CONCRETE BONDING RING16 INSTALLING THE POOL BOTTOM17-18 INSTALLING THE LINER18-20 CUTTING IN THE SKIMMER AND RETURN FITTINGS20-22 INSTALLING THE FILTRATION EQUIPMENT22 POOL DRAWINGS23-283

SafetyA pool is a wonderful investment for years of fun andrelaxation for you and your family. Proper safetymeasures should always be followed to ensure a safeand fun environment in your backyard.Every Ultimate Grecian Pool kit is supplied with safetypacket including information about the swimming poolsafety and a no-diving/no jumping sign to be placed ontop rail of the pool near the ladder entry/exit.The Ultimate Grecian pool is not safe for diving orjumping of any kind. For your safety and the safety ofyour family and friends, please read the safetyinformation thoroughly.Also supplied in the pool kit is a locking/removableladder that should always be locked or removed whenthe pool is not in use.4

Tools & Material Needed Site Prep Transit or similar leveling deviceEarth moving tools; Shovel, rake, wheelbarrow String lineHammerSpray paint or similar ground marking productTwo tape measures Pool Assembly (2) 9/16” wrenches/ratchet sockets2’ or 4’ levelDrill with 5/16 nut driver head & #2 Phillips bit#2 & #3 Phillips screw driverDuct tapeDrift PinsHammerSharp razor knifeShop vacuumRounded (Bottom) trowelSand Bottom Mix (see chart below)(1) 36” flat board 1X3 (to level bottom mix) Pool Bottom Base 7.5 cubic yards Footer Mix7 cubic yards (walls under ground)5

Site Location and PreparationSite location in the yard is a very important part of building aswimming pool. It is vital to locate the pool within the currentbuilding code requirements for your local municipality. Abuilding permit may be required for the installation of yourswimming pool and it is important to follow all guidelinesassociated with the local municipality.The location selected should be virgin or compacted groundfree of overhead power lines and other dangerousobstructions. If the pool is placed at the bottom of a largeslope, a surface water management system may need to beadded when landscaping around the pool.Unlike other hybrid pools, the Ultimate Grecian pool can beburied completely in the ground, set into a hill or slope, andthe ground can be backfilled against the pool wall if needed.Once the location of your pool is determined begin the layoutprocess by locating the center point of your pool. Refer to thepool drawing in the back of this manual that coincides withyour pool.The first thing you need to do is to create a center line for thepool. Run a string line through the length of the pool locationyou have chosen. Drive a stake into the ground several feetbeyond each end of the pool dimension and tie your string lineto them. Locate the center of your pool and drive a stake intothe ground. This center pin will be used to pinpoint all thelayout points for the pool and wall assembly. DO NOT REMOVETHIS CENTER STRING UNTIL ALL THE WALL PLACEMENT PINSARE LOCATED6

Mark the ground to represent the over-dig area of the pool.This over-dig is located 24” outside the perimeter of the pool.If a walk-in stair is installed, the over-dig for the stair is 4’6”.With the ground marked for the outline of the over-dig, beginremoval the dirt to a minimum depth of 18”. It is importantthat the pool is built on undisturbed earth not fill dirt. Fill dirtwill settle over time causing your pool to sink and becomeunleveled.Remove the dirt until the ground is level, and free of rocksand/or sharp objects. A transit or laser level is the best tool forthis job. These items can be rented at any tool rental store ormass merchant rental department.Pool and Wall LayoutNow that the dirt is removed and the ground is level it is timeto begin laying out the pool and wall panel placement.From the center pin you can establish the four points thatidentify the end of the straight walls. Place a stake at each ofthese points. Check diagonal measurements to assure thesepins are square with each other. Place a stake along thecenter string line to establish your points using themeasurements noted on your drawing.7

Place a stake at each panel seam location as noted. For easeof installation, countersink a patio block behind each panelseam steak and confirm proper elevation by using the transitand story pole. The next step is to establish where theskimmer panel will be placed. It is important that the skimmerpanel be placed next to the straight wall as shown in thediagram below. This position will play a crucial part wheninstalling the liner. This panel also should be positioned so theprevailing wind will help push the surface water into theopening. Another suggestion is that the skimmer panel beplaced out of sight toward the back of the pool because this iswhere the filtration system will set.There are several steps thatneed to be followed beforeplacing the panels intoposition. Each panel mustbe marked on the insideface with a line 1 ½”upfrom the bottom. This linewill mark the finished levelfor the pool bottom underthe liner.8

Optional Walk-In stairThere is an option to install an eight foot 5-tread walk-in stairin the Ultimate Grecian pool. This stair must be installed in thenarrow end of the pool. Be sure to order the stair that matchesyour coping selection.First locate the stairplacement at the site.When using the“synthetic wood” topseat, the coping mustbe flush with the top ofthe cantilever stair asshown in photo B.BWhen using the Bendable Aluminum Coping, you should bringthe elevation up to or near the top of the bullnose stair asshown in photo C. As you can see in photo A, there will be avoid below the stair shell thatmust be framed out to holdback the concrete bondbeam that will be pouredbehind and under the stairshell. After the finishedelevation is established, drillthrough the stair flange ateach bolt hole location usingCa 1/2” drill bit and bolttogether.9

Setting the WallsBegin moving your wall panels intoplace.Make sure you place theskimmer panel in the proper location.Photo D. Remember when installingthe pool on-ground, the filtrationequipment will be placed behind thiswall section. That said, it will be visibleand an electric service will be requiredto operate the pump.DAfter all of the wall panelsare placed around the site,it is time to begin the wallerection. Starting with thecorner skimmer panel,align the front edge of thepanel with the layoutstakes in the location ofyour choice.ESecure the panels by using the 9/16” Galvanized nuts and boltsthat were supplied with this package. Begin bolting the panelstogether using only the top two and the bottom bolt on eachseam, until you have closed the perimeter. NOTE: Keep thepanel connection on the outside of the layout stakes. Wesuggest that you hand tighten the panel bolts until the entirepool wall is erected.10

The use of a drift pin photo F,will help to align the bolt holesand keep the panels in positionuntil the bolts are in place. An“A” frame buttress is alsoinstalled at every panel joint.FDo not use the two round holes at thebase of the buttress support for plumbingruns. These holes are designed to allowthe concrete bond beam to flow throughfor added support. Photo GGAs you tighten the bolts make sure the panels are flush on theinside, this will ensure a smooth liner installation at the joints.Use a level to make sure that the pool walls are both plumband level.Do not remove the insideperimeter pins. They willbe needed to attachstring lines for the poolbottom.If any sections of the poolwall are going to beburied completely intothe ground, we highlyrecommend a concretebond-beam be places behind all of these panels.11H

After the wall is assembled double check the position of thewall matching the wall seam to the perimeter layout stakes.Finish the wall positioning; by driving the 12” rebar spikes intothe ground through all of the holes at the base of each panel.These rebar stakes must be installed in every hole at the baseof the pool wall or the manufactures warranty is void.Installing the Top Seats and CopingThere are three top seat/coping options for the Ultimate pool.There is the (I) brown “synthetic wood” with the aluminum sidemount bead receiver, and the (J) white bendable aluminumcoping. Each option will be covered in the following pages.IJ“Synthetic Wood”The top seat is a brown “synthetic wood” with mountingbrackets on the underside. Center the top seat on top of eachpool wall panel. The 90º angledbracket hooks under the outsideof the panel top as shown inphoto K.KIn your pool kit you will findsections of “dual track” white aluminum coping. To install the12

coping you will need your power drill and a 5/16 hex headsocket bit. Each section of coping should be positioned tightagainst underside of the top seat and attached to the poolwall using the self drilling self tapping hex head screws. Thesescrews should pass through both the coping and the top seatbracket.It is very important to makesure the top seat is pressedagainst the top of the panel andboth the coping and top seatare centered on the panel andbefore mounting. These selftapping screws should beinstalled a maximum of 6”Lapart to insure the coping issecure to the panel and theliner will not “pull down” the coping. These screw heads will behidden after the liner is installed.Locate the top cap joint covers andposition them over each miter joint.Each cap hooks in the front first andsecured to the top seat with colorcoated nails as shown.MBendable Aluminum Coping13

The bendable aluminum coping isprimarily used when a pouring aconcrete deck. This coping comesin 10ft sections and preformedGrecian corners that are predrilled for mounting to the top ofthe pool panel.NAfter the coping is mounted,place a support bracket, onthe back side, in the middleof each panel and behindeach coping joint. Lock thebracket into the back of thecoping and fasten it to thetop of the panel using one ofthe self drilling screws.Finish the installation bysnapping a coping cap overeach butt joint.14

Mounting the Skimmer and Return fittingsEvery Ultimate pool issupplied with a pre-punchedwall panel to mount theskimmer and returnplumbing fittings. To mountthe skimmer, simply insertthe face of the skimmerthrough the rectangleopening in the wall andsecure it using the two set screws supplied with the skimmer.If you have any questions, please refer to the manufacturesinstallation instruction in the skimmer package.To install the return fitting, youneed to un-thread the retainingnut from the fitting. Insert thethreads through the prepunched hole from the insideof the pool and tighten theretaining nut to the back of thefitting. Be careful not overtighten this nut.15

Pouring the Concrete Bonding RingIt is necessary to pour aconcrete bonding ring atthe base of the straightwalls. This mix should beon the dry side so it can bepiled on a mound. Whenplacing the concretebehind the wall, it needsto be piled high enough tocover the last two bolts atthe base of the panels andcontinue beyond the support angles as shown.The concrete bondbeam needs to be aminimum of 2500 PSItruck mix.DO NOT USE A BAGMIX.16

Installing the Pool BottomSee sizing chart list on page #8 for bottom mix infoThe first thing you need to do is to remove any loose rocksfrom inside the pool and level the ground as flat as possible.Make sure the pool walls are clean then run a piece of ducttape down the face of each panel joint to cover the entireseam.Remember that pencil line we drew on the bottom of thepanels? Now you need to tie a string line to the perimeter pinsinside the pool at the level of the pencil mark or 1½” up fromthe bottom of the panel. Now run a series of string lines acrossthe pool to another pin. Continue doing this so you haveseveral pie sections of string lines. The lines need to be taughtso they will hold the level height of the finished bottom. Thegoal is to have at least 1½” of space between the string lineand the virgin ground. Begin to transfer the bottom materialinto the pool.The bottom mix should be damp but not wet. There areseveral materials that can be used to make up the poolbottom. Mason sand is the easiest but you can also mix a7 to1 sand to Portland cement mixture to create a harder bottomthat will not shift with foot traffic during the swim season. Ifyou choose to go with a hard bottom mixture and the sand isdamp, don’t add water; just mix them together for a “SandCastle” consistency. See your pool dealer for additional poolbase options.17

Spread the bottom material around the floor of the pool andcompact it to just cover the string lines as you go. Use theedge of a flat board (about 36” long) to scrape the excessbottom material to expose the string lines. Run a trowelacross the surface to smooth it out. A rounded bottom trowelworks best. Remember to pull your pins and fill in their divotsas you progress. “The last one out has to cover their tracks.”Installing the linerRemove the liner from the box and if possible, unroll it (end toend) in a clean, safe area near the pool. This will allow thevinyl to relax and the sun tosoften the material as well. DoNot Unfold the liner at this time.A warm flexible liner will beeaser to install than a cold stiffone. Also be sure to save thesafety/warranty packet forlater.18

Before installing the liner, double check the pool walls and thepool bottom for any dirt or sharp objects that could damagethe vinyl material. Last but not least, make sure the skimmerand return gaskets are in place.Find the seam in the side wall of the liner and position theliner so it will align over the skimmer opening inside the pool.We do this incase the pattern at the seam does not matchwell. This tilesection will becutout wheninstalling theskimmerfaceplate. Withseveral people inplace, pick upthe unrolled linerand rest it on thetop seat of thepool. The liner isfolded so that it can be pulled across the pool area as itunfolds. Try not to drag the liner across the pool bottom anymore that you have to.The top of the liner has a vinyl bead welded to it. Install theliner by inserting the liner bead into the bottom track of thewhite aluminum coping.19

The weight of the vinyl pulling down will keep the bead in thecoping. Make sure that the points around the perimeter of theliner floor match up with the panel joints of the pool wall. Allwrinkles must be removed before filling with water.If you have a soft “push broom” you can tap the bristle endagainst the base of the liner wall to help move the bottommaterial and remove any wrinkles.Another trick is to insert a shop-vac hose through the top ofthe skimmer and down the pool wall through the rectangleopening behind the liner. Keep the vacuum hose at least 15.inup from the floor. Turn on the vacuum and suck the liner backagainst the wall. If your suction is poor, you may need to tapethe skimmer lid closed where the vacuum hose was inserted.If you are satisfied with the fit of the liner, start filling it withwater. After you have between 6” and 8” of water in the pool,you can remove the vacuum hose and prepare cut in theskimmer and return fittings.Cutting in the Skimmer and Return openingsNow that the water level in the pool is at least six inches deep,the side wall vinyl should be stretched tight enough to installthe skimmer and return face plates. You will need a #3Phillips head screwdriver and a good razor edge to installthese plates. Note: Do not use a power screwdriver to installthese screws. Over tightening can cause the holes to strip orthe face plate to crack. If you have any questions, please referto the installation instructions supplied with each fitting.20

Find the twelve flat head skimmer screws that came with theskimmer along with the rectangle face plate and gasket.To start the mounting of the skimmer face plate, you mustfirst find the four corner holes. Push your finger against theliner to find the round depression of the screw sockets foreach corner screw. Push the tip of the #3 Phillips screw driveragainst the depression and turn the screwdriver to mark thevinyl. Insert one of the top corner screws through the faceplate and gasket and drive it through the vinyl liner into theskimmer. Make sure the gasket is attached to face platebefore mounting. Continue installing the other corner screwsand fill in the blanks to complete.After the plate is mountedinsert the razor edgethrough the vinyl at theinside edge of the faceplate. Slowly run theblade around the insideperimeter and remove thesection of material. Youmay want to keep thissection of liner for futurepatch material.The return fitting face plate isinstalled in somewhat the manneras the skimmer. First find the roundface plate and the pack of fourfaceplate screws supplied with thefitting.21

Note: there is no gasket installed between the liner and thereturn face plate. Press your finger against the liner to locateand mark the (4) holes. Screw down the faceplate with the #3Phillips screw driver and cut out the center section of vinylwith the razor edge.To finish, snap on the face plate escutcheon to hide the screwheads. The return fitting has a directional eye ball that threadsinto the fitting. Thedirectional eye should bepositioned in an upwardposition away from theskimmer. The purpose ofthis fitting is to move thesurface water around thepool and back to theskimmer. This fittingshould not be tightenedcompletely, only positionedfor easy adjustment.Installing the Filtration EquipmentThere are many types of equipment designed to filter theswimming pool water. Please check with your local pooldealer for the proper sizing andfilter media to meet your needs.When installing the plumbinglines, make sure that the skimmeris connected to the front (suction)of the pump and the return fittingis connected to the discharge sideof the filter. Shut off valves arerecommended for service andmaintenance on this equipment.22

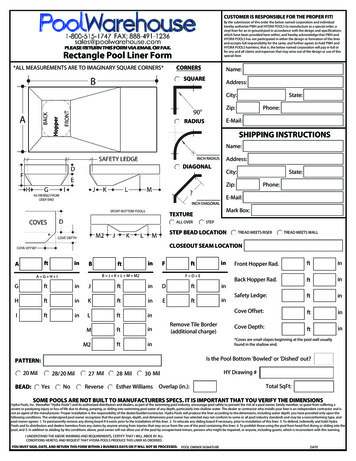

12x24 Grecian23

14x30 Grecian24

14x30 Grecian With Stair25

16x32 Grecian26

16x32 Grecian With Stair27

18x36 Grecian28

18x36 Grecian With Stair29

20x40 Grecian30

20x40 Grecian With Stair31

Notes32

of the pool wall or the manufactures warranty is void. Installing the Top Seats and Coping There are three top seat/coping options for the Ultimate pool. There is the (I) brown "synthetic wood" with the aluminum side mount bead receiver, and the (J) white bendable aluminum coping. Each option will be covered in the following pages.