Transcription

SAE-J429ADOPTION NOTICESAE-J429, "FASTENERS, EXTERNALLY THREADED, MECHANICAL ANDMATERIAL REQUIREMENTS FOR", was adopted on 03-OCT-94 for use bythe Department of Defense (DoD). Proposed changes by DoDactivities must be submitted to the DoD Adopting Activity:Commander, Defense Supply Center Philadelphia, ATTN: DSCP-ITAA,700 Robbins Avenue, Philadelphia, PA 19111-5096. Copies of thisdocument may be purchased from the Society of AutomotiveEngineers 400 Commonwealth Drive Warrendale, Pennsylvania, UnitedStates, 15096-0001. http://www.sae.org/Custodians:Army - CR4Navy - SHAir Force - 99DLA - ISAdopting Activity:DLA - ISReviewer Activities:Air Force - 84FSC 53GPDISTRIBUTION STATEMENT A: Approved for public release; distributionis unlimited.Copyright SAE InternationalProyided by IHS under license with SAENo reproduction or networking perrnitted without license from IHSSold to:INFORMATION HANDLING SERVICES, 01874946No' for Resale,2011/9/1 16:56:18 GMT

CIAThe Engineering Society— For Advancing Mobility‘1111011K Land Sea Ah. and Space INTERNATIONAL400 Commonwealth Drive, Warrendale, PA 15096-0001SURFACEVEHICLESTANDARDSubmitted for recognition as an American National StandardREV.ISA Ei J4291., IssuedRevisedJAN19991949-011999-01Superseding J429 MAY1998Mechanical and Material Requirements for Externally Threaded Fasteners/.Scope—This SAE Standard covers the mechanical and material requirements for inch-series steel bolts,screws, studs, sems l , and U-bolts 2 used in automotive and related industries in sizes to 1-1/2 in inclusive.The term "stud" as referred to herein applies to a cylindrical rod of moderate length threaded on either one orboth ends or throughout its entire length. It does not apply to headed, collared, or similar products which aremore closely characterized by requirements shown herein for bolts.1.1The mechanical properties included in Table 1 were compiled at an ambient temperature of approximately20 C (68 F). These properties are valid within a temperature range which depends upon the material gradeused and thermal and mechanical processing. Other properties such as fatigue behavior, corrosionresistance, impact properties, etc., are beyond the scope of this document and responsibility for ensuring theacceptability of the product for applications where conditions warrant consideration of these other propertiesmust be borne by the end user.2.References2.1 Applicable Publications—The following publications form a part of the specification to the extent specifiedherein. Unless otherwise indicated, the latest revision of SAE publications shall apply.2.1.1 SAEPUBLICATIONS—Availablefrom SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.SAE J121—Decarburization in Hardened and Tempered Unified Threaded FastenersSAE J123—Surface Discontinuities on Bolts, Screws, and StudsSAE J403—Chemical Compositions of SAE Carbon SteelsSAE J404—Chemical Composition of SAE Alloy SteelsSAE J409—Product Analysis—Pernnissible Variations from Specified Chemical Analysis of a Heat or Castof Steel1.2.Sems—Screw and washer assembliesU-bolts covered by this SAE Standard are those used primarily in the suspension and related areas of vehicles. For specification purposes,this standard treats U-bolts as studs. Thus, wherever the word "studs" appears, "U-bolts" is also implied. (Designers should recognize thatthe "U" configuration may not sustain a load equivalent to two bolts or studs of the same size and grade; thus, actual load-carrying capacity ofU-bolts should be determined by saddle load tests.)SAE Technical Standards Board Rules provide that: "This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirelyvoluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user."SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.QUESTIONS REGARDING THIS DOCUMENT: (724) 772-8512 FAX: (724) 776-0243TO PLACE A DOCUMENT ORDER; (724) 776-4970 FAX: (724) 776-0790SAE WEB ADDRESS http://www.sae.orgCopyright 1998 Society of Automotive Engineers, Inc. "— grved.Copyright SAE InternationalProvided by IHS under license with SAENo reproduction or nelworking permilled without license from IHSPrinted in U.S.A.Sold to,INFORMATION HANDLING SERVICES, 01874946Not for Resele,2011 /9/1 16'56'18 GMT

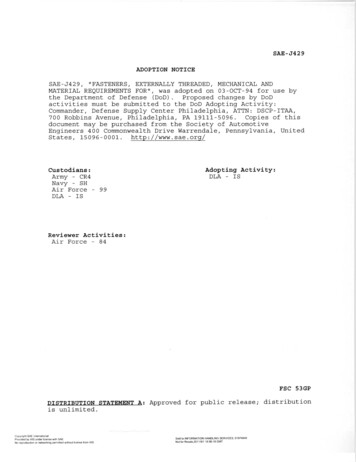

SAE J429 Revised JAN1999SAE J411—Carbon and Alloy SteelsSAE J417—Hardness Tests and Hardness Number ConversionsSAE J1061—Surface Discontinuities on General Application Bolts, Screws, and StudsSAE J1086—Numbering Metals and AlloysSAE J1268—Hardenability Bands for Carbon and Alloy H Steels2.1.2 ASME PUBLICATION—Available from ASME, 22 Law Drive, Box 2300 Fairfield, NJ 07007-2300.ASME B18.2.1ASME B18.18.1M—Inspection and Quality Assurance for General Purpose Fasteners2.1.3 ASTM PUBLICATION—Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.ASTM E 18—Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials2.2 Related Publications—The following publications are provided for information purposes only and are not arequired part of this document.2.2.1 SAE PUBLICATION—Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.SAE J995—Mechanical and Material Requirements for Steel Nuts2.2.2 ASTM PUBLICATION—Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.ASTM F 1470—Guide for Fastener Sampling for Specified Mechanical Properties and Performancelnspection3.Designations3.1 Designation System—Grades are designated by numbers where increasing numbers represent increasingtensile strength, and by decimals of whole numbers where decimals represent variations at the same strengthlevel. The grade designations are given in Table 1.3.2 Grades—Bolts and screws are normally available only in Grades 1, 2, 5, 5.2, 8, and 8.2 (see Appendix A).Studs are normally available only in Grades 1, 2, 4, 5, 8, and 8.1. Grade 5.1 is applicable to sems which maybe heat treated following assembly of the washer on the screw, and to products without assembled washer.4.Materials and Processes4.1 Steel Characteristics—All fasteners shall be made of steel conforming to the chemical compositionrequirements in Table 2 for each grade.For the definition of carbon and alloy steels, see SAE J411. Refer to SAE J403, J404, J1086, or J1268 for thechemical composition limits of standard steel grades. Standard H grade steels are acceptable substitutes asare nonstandard steels which fit the definition of carbon and alloy steels in SAE J411. For Grades 5, 5.1, 5.2,8, 8.1, and 8.2 the maximum content of bismuth selenium, tellurium, or lead shall be 0.02%.Steel for Grades 8 and 8.2 fasteners shall be fine grained steel with sufficient hardenability to provide hardnessequivalent to 90% minimum martensite at the center of a transverse section one diameter from the threadedend of the fastener after quenching. Minimum as-quenched hardness required for steels in the carbon range0.15 to 0.55% is shown in Table 3.Copyright SAE InternationalProyided by IHS under license with SAENo reproducten or networkIng perautted without license from IHSSold to.INFORMATION HANDLING SERVICES, 01874946Not for Resale,2011/9/1 16,56 18 GMT

SAE J429 Revised JAN1999Too1:0)CT,oCLICCE c ".1OCooz z/Ia -oo//o-z.9CO1/ 77.,U)oz1o(31 21Zar 1 1.1 fiy, .00-q-0ll)-C07Cr)COCO0 0Ir 0)C2COCDCOLOa)u-)CONCOC ICO,--CNCOCOm CO 0 0 0 U 0Ot-mCDCOCOMCO0-)COUCr)COe)1O U1a) uIl1.,r .).,r)1cr;tc)23bwLoociu,cc;LOozi13LOu.51. ,-) -1. ,- , -1LC)egLoni1,r ,r) -,)coL17r')frsll7co15rr̀g. 1"aNoLJ-17d N wrg0 EZIwrC, EU)17O1d.u -D g, 11-,,, .s o . o.E 00z1 u/z al 1.12 cr' cu .- c(7) Sft ru ui -2 i-' -15̀ -.ton'V .0E rT, 1 2 -. 5 2' 2 O.E -,T, o2 E o 5, e 1.-, E-5 ar, á -2ti,- T. zm1 WoLLCOn—CO COO'4. ctN.7CD1--MiO.—.-Sc11 M11 '›o11f. s:,, 1, 61 j2el .21 5g 7): 7,az29oooOCO--6oc)CO«,-0CDCDCD0 CDV ON. COO 0 OO O CDO O CDLON Oo G" oOOOOO0LOn—0ONea U) "15"o ooo '7,5O O Oo o oOON oN.Na—oO) COco1I0O00COOnO)-CDCDCDCOa—wN-2U ECD2,020-91zmE21:131CCD ' -C1LiOPr.1r)oro .92 orǹco ecN2oEw"0 13 528oozc1IIa JEVE2122o.2cm wc11).L?J2Oc‘r„.07001O.CCID (3O-CCONu")2CID '7c.1CI 0 LOCO4C'' -coD' 2O o111111-J1- ""r0C0-0„;s7oo oO 00000000"FM11171CDOCDOO CDCDCDLOLOO O 0 O CD O CDOCDCDo oCDCDCDCDCDLOOOni. oCOCDCOCOco11J5aCOCDCO.c.1ea l'-' u) .E. ',7),i,o -a -0 .- 2mo1z(OO.,i, E -8 3 . r, ,.1——1ozCO0OCO0g U) v 5 O0".zco,1-rtU)LLNCO01 x1 1,'oi m1.- 2-ot 11,1wN82N7,E t 1 .cU)YO1—ICS' 2 -1 1U 12C0 OOCD.—.--.COT6VI'1-412oa.17—J1:13E OO a,OC2,,i.i- g 2,75.207 U)b (/)«;1.0- 1 -2Ó1507 CO U)2CO-au)U)2VV-3o2 0 -a"3 i.5 .9mcomL17coEa)U)en-Ir 2oc.)mm51''CO .:.,4 ct -1(31.5.P.Mmm,,,17,7,m.9.) 75, co -0 112 0,t, .z 1 2 1,2 . D. 1:,' ' O' 2 E Et I 1,5 r) P a 2 a 's.' .52 'ce',CO),)-o mtp-05EÑ 0 Ñ -6 2 a) 1.5. or 29051 0)Z0-57 0 1 07s'-c,1CO7L17CO1—CO4 LO «5 N.COái111-3-

SAE J429 Revised JAN1999u)n5tr)Cl1.61kZ1,I 1,›Z2Z—/—1‘1/2.\'575.-c.) G-o 0:61/\ to 12'11(fiWrtI'Uo.:rm-Q4PF:1cli9.1 om-,,-“,,,,,o0O LLr.-- oI'L1,roNO'O CO0 L,roN Oni- GONO'o WMW7Et., río20 — EJ'W, 0 2g 1 b9,1 .- 2-1.Om IT115 ,5--w.uan2 -Imo z t ts"*-. .,--.7,1 Za -,a,, 1O2 21Cro!La 2-1uIn.l z. .w ego W dr, 2ocn .5oo ,5ood oo .5'Nod'WMOciM.óN O'od d W. —.47,2-e e c11.1,2-Igi,tddE511 3'. --isa. . 2 '''. 10 .OLONóu,.oCOóc5.inoLoc.,óLO.O t¿TiF1.".-1.- fl tS 1, 1 :-. 7,; 11.a.1 1-.5---l u ,SWI—.,,,.dUc .COd1a.Ir:W,,1 E1g11 (2Wd.CO.óóoz.521O. 1122oE(10.1.5(1 I.1, E-II. Az i.2O0E.5tv''wil aEou;UalaII'.5.0 o-5 1.'5 Esil?.0O-ii.,F7-2ozo1E c-15EcE c,.?, E c,.7,-Etct5I-l'igItg-I1 70 l'f 2-3I .:.- 53IJ ,. 5 13,1131 '2231',,,,,,,1-'72,o2b5 20,7/5 20 woLE - gs :1.12n2:1.111a.,,2Za3Q-E1aE.2,41'112122 2-vi.24--O1 2,6z1111 ltól 11,11PD0 1,-.1,2' o61, 'o2 12E5 21b§11t'O'2, 11EPI,,,1„72,o1.11:11183 21 ' ,2-2 2 :15,2,321 eg, IlEn,s2E121I2o2o 2 p11.'1 a o- E'cl- P /3' ,„- /3" 45 1 . zE15E-e5.11,.2.Q,r19 11 1!.1 .1,' 12 EIo.á1111J.22 ,133 -oz ,.71,S.11 -9 58 13«,5g2g51 (VCW:2„:ÉlÉt ,1,,. a c1 51J,-,5OU-1EZ1I -c,1 0EL1Zwo1 O21E ,.11.EO‹,10 -51,-, '1- 17,;ozOE-oc.roO -oo 8',r 1 E .1. 1 -2 11o2I—-.u c" -- 1 UwelEO,0nE Eeti:tí 3 7,) 7, oZ 15E"Ood1 o 791,21a.g enc.z O. 0‹. 21-1.1oEd5-,-2od2«,0 d12 11 ;1g5Oui,41-215-2mZ 00-.1I-9N f%)COÉ(75,11'E2 á ,' in-( 1o 72: ,,EIP. á'-4-1- I' S'm 5 i Y)-1.732.(OoWÉTDEea ( t5nu111111.5 -cp .yr 57,. 1. :5 -5 gzi1,1,131Z,,,r ,d COwithou tlicense fron IHSF-,i1— i!O0 1-2.1'SE.Ea. S

SAE J429 Revised JAN1999TABLE 3-CARBON CONTENT VERSUS MINIMUM AS-QUENCHEDHARDNESS FOR 90% MARTENSITECarbon (%)Hardness HRC0.15 through 0.19350.20 through 0.24380.25 through 0.29410.30 through 0.34440.35 through 0.39470.40 through 0.44500.45 through 0.55534.2 Heading Practice-Methods other than upsetting and/or extrusion are permitted only by special agreementbetween purchaser and supplier.Grade 1 bolts and screws shall be hot or cold headed, at option of the manufacturer.Grades 2, 5, 5.2, 8, and 8.2 bolts and screws in sizes up to 3/4 in, inclusive, and in lengths up to 6 in, inclusive,shall be cold headed, except that by special agreement they may be hot headed. Larger sizes and longerlengths shall be hot or cold headed, at option of the manufacturer.Grade 5.1 sems screws shall be cold headed.4.3 Threading Practice-Grades 2, 5, 5.2, 8, and 8.2 bolts and screws in sizes up to 3/4 in, inclusive, and lengthsup to 6 in, inclusive, shall be roll threaded, except by special agreement. Grade 5.1 sems shall be rollthreaded. Threads of all sizes of Grade 1 bolts and screws, and Grades 2, 5, 5.2, 8, and 8.2 bolts and screwsin sizes over 3/4 in and/or lengths longer than 6 in shall be rolled, cut, or ground, at option of the manufacturer.Threads of all grades and sizes of studs shall be rolled, cut, or ground, at option of the manufacturer.4.4 Heat Treatment Practice-Grades 1 and 2 bolts and studs need not be heat treated. Grades 1 and 2 coldheaded carriage bolts and other bolts and screws with thin heads shall be stress relieved at 468 C (875 F)minimum. (Prior agreement with purchaser will be required if mechanical properties are affected). Additionally,when specified by purchaser, Grade 2 cold headed hex head bolts and screws shall be stress relieved at 468 C(875 F) minimum. Grades 4 and 8.1 studs are manufactured from pretreated material and the studs, asmanufactured, need no further heat treatment. Grades 5 and 5.2 bolts, screws, and studs shall be heat treated(fully austenitized), oil or water quenched, at option of manufacturer, and tempered at a minimum temperingtemperature of 427 C (800 F). Grade 5.1 Sems shall be heat treated (fully austenitized), quenched, andtempered at a minimum tempering temperature of 343 C (650 F); quenchants whose principal constituent iswater shall not be used, unless specifically approved by the user. Grade 8 bolts and screws and studs shall beheat treated (fully austenitized), oil quenched, and tempered at a minimum tempering temperature of 427 C(800 F). Grade 8.2 bolts and screws shall be heat treated (fully austenitized), quenched in oil or water, andtempered at a minimum temperature of 340 C (650 F).Under no circumstances should heat treatment or carbon restoration be accomplished in the presence ofnitrogen compounds, such as in carbonitriding or cyaniding.4.5 Decarburization-Unless otherwise specified, Grades 5 and 5.2 bolts, screws, and studs shall conform toClass C, and Grades 8, 8.1, and 8.2 bolts, screws, and studs shall conform to Class B as described inSAE J121.4.6 Surface Discontinuities-Grades 5, 5.1, 5.2, 8, 8.1, and 8.2 bolts, screws, and studs in sizes up to 1 ininclusive, and lengths up to 6 in inclusive shall be in conformity with the requirements of SAE J1061.Copyright SAE InternationalProyided by IHS under

SAE J429 Revised JAN1999 SAE J411—Carbon and Alloy Steels SAE J417—Hardness Tests and Hardness Number Conversions SAE J1061—Surface Discontinuities on General Application Bolts, Screws, and Studs SAE J1086—Numbering Metals and Alloys SAE J1268—Hardenability Bands for Carbon and Alloy H Steels 2.1.2 ASME PUBLICATION—Available from ASME, 22 Law Drive, Box