Transcription

MultiCam 3000 Series CNC RouterFeature and Specification GuideVersatile, Feature-RichProduction Routing!The MultiCam3000Series CNC Routers areloaded with standard featuresnormally associated withmore expensive machines.The automatic tool change(ATC) option gives the usermaximum machining flexibility,and the all-steel, moving-gantry designallows machining of large parts whilemaintaining a small, space-saving footprint. Designed for a wide range of panel processingapplications, the 3000 Series is the perfectsolution for companies looking for both valueand high performance in a CNC router.Ideal for Cutting: WoodMultiCam, Inc.1025 West Royal LaneDFW Airport, TX 75261972-929-4070 Fax: 972-929-4071www.multicam.com sales@multicam.com Plastics Non-Ferrous Metals Composite MaterialsAnd MoreAll specifications subject to change. 2010 MultiCam, Inc. All Rights Reserved.1Innovation. Quality. Performance.

3000-R Series SpecificationsNo machine offers more features than the innovative and versatileMultiCam 3000 Series CNC Router. Heavy, all-steel gusseted plate frame construction25-mm linear ball-bearing profile rails for maximum stiffnessMultiCam EZ Control user-friendly operator interfaceHigh-speed three-axis motion-control system12-MB memory with unlimited file sizetransfer capabilitiesStandard Ethernet or RS232 direct connectionsBrushless digital ac servo drive systemAutomatic tool calibrationEZ Suite softwareAutomatic Tool Changer (ATC)Choose from two 3000 Series CNC Router ATC options: Linear Automatic Tool Changer: This option offers alow-cost alternative to automatic tool changing. It featuresa linear tool rack holder mounted at the end of the materialprocess area. An extended frame design on the 3000 Seriesdoes not reduce the standard process area. Width of this areadetermines the number of tool locations. The 3100 Series (50"wide) has six tool locations while the 3200 Series (60" wide)has eight, and the 3300 Series (80" wide) has 11 locations. 12-Tool Rotary Turret Automatic Tool Changer: Thisoption mounts on the end of the 3000 Series gantry thatmoves along the X axis. It is beneficial on dual-zonependulum processing configurations. This accessoryaccommodates tool changes without crossing zones during theidle cut zone loading process.All ATC options come standard with automatic tool calibration.Tool change routines built into MultiCam EZ Control simplifyintegration with your favorite CAM software. An Automatic ToolChanger solution will help reduce job times, improve accuracyand reduce setup errors.2

3000-R Series SpecificationsBase FrameThe MultiCam 3000 Series base is a rigid, all-steel plate framethat is welded, stress relieved and precision machined. Thistype of construction allows for a very accurate and smoothcutting system while reducing installation time greatly. It alsoessentially removes the possibility for installation errors thatcould affect the performance and accuracy of the system.Dual X axes feature 25-mm linear rails, ac brushless servos, precisionplanetary gearboxes, rack and pinion.GantryMade of a 3 8" thick steel tube, the gantry is welded, stressrelieved and precision machined. MultiCam engineered it toprovide a smooth, vibration-free cut.Y axis features 25-mm linear rails, ac brushless servos, precision planetarygearboxes, rack and pinion.Gantry SupportsIn conjunction with wide X-axis bearing spacing, cast-irongantry supports help dampen vibration and give thestructural tube gantry extremely rigid support.Linear BearingsThe 25-mm ball linear bearing profile rails with stainlessspring steel strip covers are standard in all axes. 3High rigidity and top-load capacities in all load directionsLowest possible noise level and best runningcharacteristicsHigh torque-load capacityFour bearing packs per axis4000-pound load capacity per bearing

3000-R Series SpecificationsStandard Working SurfaceThe standard working surface is 1" thick 80-82 Durometerphenolic with a machined grid pattern utilizing .500" x .250"foam gasket tape. Phenolic makes an excellent work surfacebecause of its dependable mechanical strength and dimensionalstability. In addition, phenolic has low-moisture absorption,resists heat and wear and is easy to repair as needed.Precision Planetary GearboxesAlpha Precision Planetary Gearboxes are the top of the line inthe industry. Case-hardened and finished ground high-carbonalloy steel gears guarantee the highest service life available.These gearboxes are among the many components that makethe MultiCam 3000 Series a smooth, accurate and long-lastingcutting system. Single Stage: 10:1 gear ratioEfficiency: 97%Low noise levelIntegrated thermal compensationDesigned for continuous operationRegulator UnitsMachines equipped with tool-changing spindles come standardwith SMC filter regulator units that include an ambient air drier.Ball Screw AssemblyThe 3000 Series ball screw assembly has 12" of Z stroke tohandle a wide variety of tooling. Precision dual angular contactball bearings support the 12-mm ball screw in a steel housing.The top of the screw is mounted to a spring-actuated fail-safebrake system. Gantry riser blocks are available to increase thethroat of the machine by 4".4

3000-R Series SpecificationsEZ Control MultiCam EZ Control is one of the most powerful yeteasy-to-use motion-control systems available onmachine tools today. No wonder MultiCam named itsmotion system EZ Control! Hand-held operator interface with graphic icons12-MB memory with unlimited file-size transfercapabilitiesMultiple home positionsAutomatic Z surfacingElectronic depth safety systemProximity restartTool compensationCut speed overrideSpindle rpm overrideStandard Ethernet TCP/IP connectionDrive AssemblyHigh-torque, brushless digital ac servo motors coupledto zero backlash Alpha gearboxes drive both the X andY axes. This results in high acceleration of the gantry aswell as excellent cut quality.Digital Servo Drive SystemDigital servo drives and brushless digital ac servomotors form a digital vector servo drive system that isstandard on all MultiCam Digital Express machines.This drive system integrates position, velocity andtorque loops seamlessly to provide uncompromisedtracking accuracy, smoothness and reliability.MultiCam servo-driven machine drives are the latest inhigh-performance technology. They advance the state ofthe art by utilizing seamless coordination and allowinginformation sharing in real time so all system functionscooperate in any situation. Realize tighter tracking,smoother motion and faster rapid traverse — all ofwhich yield superior machine throughput and reliability.5

3000-R Series SpecificationsStandard FeaturesLeveling FeetOperation Manual6Tool BoxElectrical Schematics

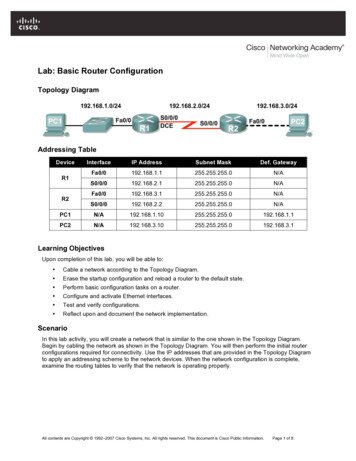

3000-R Series Specifications3000 Series Specifications (Inches) Z-Axis Clearance: 6"; Optional: 10" Z-Axis Travel: 12" Repeatability: /- 0.001 Positional Displacement Accuracy: /- 0.005"over 10' Maximum Cutting Speed: 1400 IPM* Maximum Rapid Traverse: 2500 IPM* Drive System X and Y Axes: Rack and Pinion Drive System Z Axis: Ball Screw Standard Work Surface: 1" Phenolic* 600-IPM Cutting and Rapid Traverse for Stepper SystemsSize Chart 1171832013-304R3-305R3-306RL1 W76126861521708585959595W1 H65657575757777777777WORKING WEIGHTLBS.AREA50 x 5050 x 10060.5 x 6060.5 x 12260.5 x 145297041503260517056305920183 152 115 95 77 80 x 122201 170 115 95 77 80 x 1456310224 193 115 95 77 80 x 1686520Increase W by 13" for Optional Second Carriage or Wide Gantry.3000 Series Specifications (Metric) Z-Axis Clearance: 152 mm; Optional: 254 mm Z-Axis Travel: 304 mm Repeatability: /- 0.025 mm Positional Displacement Accuracy: /- 0.125 mmover 3 m Maximum Cutting Speed: 35.5 MPM (592 MMPS)* Maximum Rapid Traverse: 63.5 MPM (1050 MMPS)* Drive System X and Y Axes: Rack and Pinion Drive System Z Axis: Ball Screw Standard Work Surface: 25-mm Phenolic* 15.2-MPM (254-MMPS) Cutting and Rapid Traverse for Stepper SystemsSize Chart (Metric)3000 SeriesSpecifications subject to 116511651190519054318 2413 1905HWORKINGAREA195619561956195619561270 x 12701270 x 25401524 x 15241524 x 30991524 x 36573-304R 4369 3860 2921 2413 1956 2032 x 30993-305R 5105 4318 2921 2413 1956 2032 x 36583-306R 5689 4902 2921 2413 1956 2032 x 4267Increase W by 330 mm for Optional Second Carriage or Wide Gantry.WEIGHTKg13501886148123502553269028682957

MultiCam 3000 Series CNC Router. Heavy, all-steel gusseted plate frame construction 25-mm linear ball-bearing profile rails for maximum stiffness MultiCam EZ Control user-friendly operator interface High-speed three-axis motion-control system 12-MB memory with unlimited file size transfer capabilities