Transcription

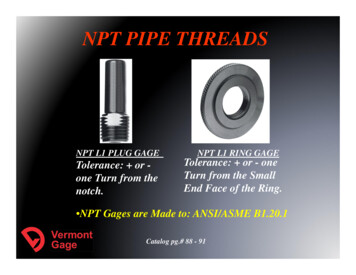

NPT PIPE THREADSNPT L1 PLUG GAGETolerance: or one Turn from thenotch.NPT L1 RING GAGETolerance: or - oneTurn from the SmallEnd Face of the Ring. NPT Gages are Made to: ANSI/ASME B1.20.1Catalog pg.# 88 - 91

NPT PIPE THREADS NPT Threads are Considered “General Purpose”Pipe Threads. NPT Threads Are Intend to be Sealed at the Crest &Root with Teflon Tape, Pipe Dope or Other Types ofSealant. NPT Threads Do Not Require “Crest Check”, L3, orL2 Gages. NPT Gages are Made to: ANSI/ASME B1.20.1

NPTF PIPE PLUGSNPTF L1PLUG GAGEThe L-1 Plug Inspectsthe Pitch Diameter ofthe Hand Tight (L-1)Length of Engagement.NPTF L3PLUG GAGECREST CHECKPLUG (6 Step ) GAGEThe L-3 Plug Inspectsthe Taper and WrenchTight (L-3) Length ofEngagement.The Crest Check PlugInspects the TruncationLimits & Taper of theMinor Diameter. NPTF Gages are Made to: ANSI/ASME B1.20.5Catalog pg.# 88 & 91

NPTF PIPE RINGSNPTF L1RING GAGEThe L1 Ring Inspectsthe Pitch Diameter ofthe Hand Tight (L1)Length of Engagement.NPTF L2RING GAGEThe L2 Ring Inspectsthe Taper and WrenchTight (L2) Length ofEngagement.CREST CHECKRING (6 Step ) GAGEThe Crest Check RingInspect the TruncationLimits & Taper of theMajor Diameter. NPTF Gages are Made to: ANSI/ASME B1.20.5Catalog pg.# 88-89

NPTF PIPE GAGES NPTF Gages are Considered “Dry Seal” Pipe Threads. NPTF Gages are Relationship Gages. NPTF L1 Tolerance is or - One Turn from the, (Notch on thePlug or Small End Face of the Ring). NPTF L2 Ring, L3 Plug Tolerance is or - One Half Turn fromthe Location of the L1 Gage. NPTF Crest Check Gage will be Between one of these Sets ofNotches, ( MN & MNt ,B & Bt ,MX & MX t ). These Notches arein Relation to Where the L1 & ( L3 or L2 ) Gages Measured.

NPTF Classes ofProduct ThreadsClass 1 Threads - “Acceptability is determined by coordinated useof L1 & L2 gages for external product threads and L1 & L3internal product threads. Crest and root truncation is generallyconsidered to be controlled by tooling or other means”.ANSI/ASME B1.20.5Class 2 Threads - Same as above, “however, inspection of rootand crest truncation is required.”, (ANSI/ASME B1.20.3). Thismeans that 6-step root & crest check gages or other methods arerequired to inspect product root & crest truncation.

Dryseal Gage Selection ChartTABLE 1 Gages and TolerancesASME B1.20.5 - 1991Thread to be GagedGaged WithProduct Thread ToleranceApplied to Basic Size[Note (1)]Limits Method of Gaging[Note (1)] TolerancePlus (small) Minus (large)1 turn1 turnL1 or L1 Short and [Note (2)]L2 or L2 short ring gages Plus (small) Minus (large)PTF-SAE SHORT, External0 turn1.5 turnNPTF, ExternalThreads are within thePlus (large) Minus (small) allowable tolerance whenNPTF, Internal1 turn1 turnthe product reference pointL1 or L1 Short and [Note (3)]is on or between theL3 or L3 short plug gages Plus (large) Minus (small)PTF-SAE SHORT, Internalmaximumand minimum0 turn1.5 turnstep of the L1 gage.Plus (large) Minus (small)NPSF, Internal0 turn1.5 turnL1 or L1 Short plug gagePlus (large) Minus (small)NPSI, Internal1 turn0.5 turnNotes:(1) Step limit gages with 4 (or 3) steps should be used.(2) The difference in engagement of the L1 versus the L2 ring gages shall not exceed 0.5 turn. See para. 1.8.4.(3) The difference in engagement of the L1 versus the L3 plug gages shall not exceed 0.5 turn. See para. 1.8.4.Note: Customers usually prefer to measure Dryseal Straight Pipe Threads(NPSF, NPSI, ) with Go & No Go Plug gages. Go & No Go Plug gagesmay be used but, the parts must pass the NPTF L1 Plug gage.

ANSI/ASME B1.20.5 Class 2 Threads - Same as above, “however, inspection of root and crest truncation is required.”, ( ANSI/ASME B1.20.3 ). This means that 6-step root & crest check gages or other methods are required to inspect product root & crest truncation. NPTF Classes of Product Threads . ASME B1.20.5 -1991 TABLE 1 Gages and Tolerances Thread to be Gaged Gaged With Product Thread .