Transcription

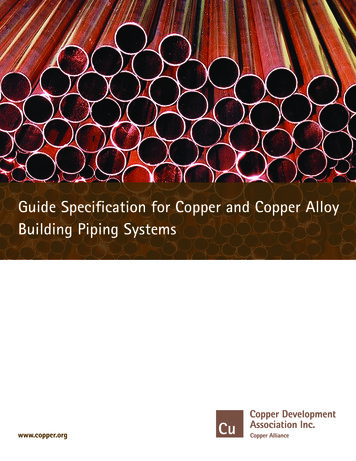

07/19/9509:50NW,ll:l!:l 1"1.::1"' {!dl,!:DOCU11ENTENGINEERIN!3C.O. INC. .; 5 5 892 1159"" .ICl,41I D"lgnltlon: 8 458 . 94,c.; .Jr'-J.:.AMlIllIc:AHIClClITV1'01' 'l'!lnt.O AI«) MA AI.I:'111. fIIaee Sl f'1I18d81pIllt,I"AI.,C13"'U,11II8' 110111IPII AM., IIooh' AtN IIta,.j.",., "';'18111 AI N(It 1lll11io.1ItIillIh. 'IIIf.1I .""'II\IcIIIIft.111"""'11111"" .",".10.:.,St.ndard Specification 'orElectrodeposlted Coatings of Copper Plus Nickel PlusChromiumand NIckelPlus Chromium1Tb. 8Iund.rd Is iuucd ul'd r Ihi flud GealinallOIl a S61,hi number1"""01118\.1)'Ibllillllln Ibt CltII",allOlllnClhlllCSth' r,orll'n.' Idoplioll or. in ,tit ca. or ".Ision. Ih. yeit 6( lu, revllinn.It.IIU",.' IIIpaNn'blllft MIlII/PO"""P' .il.n hI '"dlcl4,. III ,di'8ri.1 thllna. Ii,," ,he Iii' ""lllon or tCI,ptO,/II., 'ScopeJ." J This specincatlon covers reQuircmenu(ar Slveraltypes and arudes of eJl!ctrodepo itedcopper plus nickel plus hromium or nickel plus chromium coatin&t on'teel, nickelph 5chromium coatin.- on copper and copper aUo)l',andC'opperP'UI nickel plus f:hrontillm eoatinp on zinc8J10)'1torapplicationl where both appearanceand. protecllan of thebasil me&lllllinst carro.ion are imponant. Five artdes ofcoltin,s .ra pravldedto correspond with the set'Yiceconditlonl underwhichneh is eJtpccted to provide sad.factoryperformance:'namely. extended "cry severe,very severe,Ryer,. modetate, ,nd mild. Dennidon and typical eumplesof ,hlle leJ'\lict conditions are pro\'ldltd in Appendi XI.1.2 The rullowift&huards Clveatpenain. only tD the teatmothods'ponions. Append;".Xl, X3. and X4. or thisDrIII' ,lIr arloft nlppro".,I, It.B 487 T.11MethodI'or M.alufement of Metal and OltideCoatlnsThlekn*C8 by MicroscopIcsl uminatlon oraCrollSoction'.8 499 Teat Method (or Me.uremtat of Coadn. Thi,k. nO&8by the Maane\icMethod: NOftllllllftoticCo.t.iltllon Ma.netic Jnstt; M,tallI'fbr Mcu rnmlSln uf Thickn/:ss ofMetallic Coat'n. by the CoulomlJlric:Method'8 530 T.lt Me\hod for Mouurtmont of Coatins Tbi lc.a 504 Test Methodneuee by &heMapede Memed: I!lecirodeposi NIckelCoatln. Oft Mnlnetlc aDd Nonml8netic SubsltttesJB 537 Pra!rticcfor Ratin, of Elt.ctroplatedPanels Subjectedto AtmollphericExposurel14554Guide for M urcJ!tent of 1'h.lclcneuof MeWllcCOltln. on Nonn1CtaJllcSubstrate,',specification: This s'QltdtJ,d dots """purpOrt to addre:u d'i (Jjitl,/iIJI CQn( rnl. if alf)'. tl S(Jcf4ted with iu wcf. II is thertJpOltilbi/ilJ' (Jf the JlICf ()f this IltJ.nda,d 10 ellfJblish fJpproprill" stlltt.\' I2nd hefl/th prattle,.s tJnd de"",,;n, the applica.bility 0/ r t l/tllO"J'limiUll;()n.s prlfJr tQ uSt.Non I-The tSO stand rd&1436&ftd 145' are no! requir.tI\cntlbutun b; rcf8l',nctd,rot additionallnrormatiOIl.B 568 Tut Method ror Mellurement of Coa\ina Thick.nell by X-Ray Spcunrometry3B 571 Tesl Methacil for AdhtlioJl ot MehllJi Coati".'e 602TeAtMethodfot AttributeSlamplinlJaf Metallic:andJnorpnic Coati11&1:1'IS659 Ouldo ror MeBSurin Thickneas of Metallic and2. Refcrtnc:o(1Document B 691Quid! (or Selectionor SampllnaPIanofor h,.pee:.110n of I,elrodeposited Metallic: aDd Inorpnle2.1 ASTM Stflndllras;8 11,. rCSt Method ror Sal,t Spray (Faa) TOitina2B 183Praeticcror P,reparationbf Low-CarbonSteelrarElecuL Ialina'.B 242 P"'t;tice for PrepatutitJn of Hip-Carbon \011rorElectrapJatina'B 252 Practiceror ' eparalion of Zinc:AllOYDie CUtin.for EleetropJatina and Conver'ion Coatinp'8 281 Prac1,jcefal' Preparauon of Copper and Copper baseAlla '1for EJec:uoplatlnaand Conversion Coatings'B 287 Method of Acetic:Aeid.Sal\ Spra)'.(Foa) Tesung. '.B 320 Prattice, fbr Jlrepl\ration ot Iron CUtin. ror,Coatinga),,a 762 Mtthod 01'VariablesSampLinlof M.ta11i andlnol'pnlc COAdlllpJa 764 Method tor SimultaneousThicknessand ayers'n Multilay.r NicklslD.po.h (STEP Te:ln)3D 1193 Speclncationtor a.a,.nt Wa1er'S 380 Methodof Corro.lon Tc.th\1 of DecorativeEleetro.pla\edeoltinas by tht: Cl)I'1'QdkoteProcedur.'ISO I." Metallic lcoatinss-Electroplated coati"r ofcopperplus nickel jpJuachromium 'iirtln or,lteelIThil Iptclfia.lioll il unlltr lilt Jvri84/CIID"of ASTMComlllineeB.8 onMtullic ""tllnOlplllc CO&tin81Ind f8 1111"j,., IIIIOnll"lIIl or Ivbeoml'll'""IOLO) 011DteortllYt COIIIIII',Nlcklf. OI'Ol'llilllll, I"d Nitk,loChromlloll'll COI'.11\81.tV""'1 Idilioll . ,tO.c.cI Ma,cll I. 1994. Publlslled Mo, 1994. Oniinill Plllali"',I1.Sf. U. w, "'twiO",' 4i,io" 1\45. - 9311. "'It'/ifli .,101; qf .tSrM S'lfnda,tI,. YOI03.0 . '''''It/alS.& rl( .1.'1'101 . la"Jfltfl.r. Vol 02.0 ." Dlaro/niny.,I-Sa11/116AItIl'HlIIJI)(JJ;,1 A5"1'M I.IIII.,dy.VOl0).02. C3. T.rmlnOI IJ.Che3.1 Dt/iIflIiD". /I17fTesJ(jll". ""'ltIlIl Sault 01ASTM ,f//lllfit/fl/"Vol 11.01,lYe.---j. """lUll&4OIt0/A TH .'ftlltlj.,I,.Volls,ot. LI vle ,A"nUM8DO tt&T",,Tttmft,4"VOl0).05. "I/ped /:).,,""fJFch.- -------.,'V DeqrchoJ. ,4".illl l,1i,I'IIIn"",aU8Mlllllldafd.Cttillllllhti'/i{ll drfjttll1l11.(lelltVII20, Swl\q,IIIId." ', 9 19.ra'/:'6S11-268S0S N3A31S 'l' 21:21 S6. 61 lnrp'd."D39S' PractJ (or C.ommerctaJPj&cka&!ul\'1:50 Pra llcesfor Apparatus, R lelllll, and Safety'Pre-B 368 Method for Copper-Acceterated Acetic!Acid-SaltSpray(Fal) TcsUna',---loarpnlc CoatinpJcautionstor Chemica! Analyaiaelt Meulls'2.2 ISO StaMQ,ds:JSO1456M.callic cOtunas-ElIIIC1rod,potijtedcoadnpofnickel plus chromhlM and ot copper 1)lusnickel pluschromium'EleetroplBtinA'3',

J.1S6DOC\J1'1EtiTENGINEERIN CO. I INC. 505 892 1159217/19/95 09:51411}tpa 3/0128 456TAIL! 1 SUMMa" of tile Aequlram."la lor Double- ",II T"pl.-La HI.lctl C aalJllU') 0." 11'1""TOil"'1 O,O."'In'1D':'28"I.' "Trill01 NIC'l8II 'ie1I0IIgI,lon.BoIIOlllT M. a. .XI.111111' Coftt8ll'-AtltiiYiiOTOj; NICI(1t Tr\;;;'". . 1-; eo.-'5o4DiJli101- :lDI'0 0INOI.I'1II0te40,A Copper WIdline:,lAMlr."1 .". tfttIt a I. 'or NOI'I ., aM . . Seotlon e.d -doubt. ortripl.I. .rfliek 1 oalin&S uqalu thollsurflcunormallyvisible3.1.1 J/",I/II:,.1I'r -",1I11t (thilla, CCnYflllllollal)ehtomilolm(direc\Jyor byrcnecdon)thatareessentialto theappearanceme -mictOCllcltld chromhlmor .ervfceabllltyof the anicle when 811CmbledIn normalmJl-mlotQporo". chrornlumposition:or that can belthe sourceor CtltiO"NumbtrJ-A coat.defice visible sul'f8CC ou the assembledarticle. Whennec:elllry,the II.nlOcant surracesshall be speeinedby the in. on Iteel comprilin. I' j.Lmminimum(ductileacid)c:apperplus 2' 11mminimum (duplex)nickelplul0.25 mpurchuer and shall beIndicatedon the drawinp of the parts.minimum (mlc racked) chromiumhu the (:Iaulftcatlonor by the pravilioft of lultabl)l markedsample.number: Fe/tu15a NI2Sd Cr mc (- 4.3 and 6.1 for. pl.n.tion or Iymboll),4. ct.,U1car1oft,4.1 FIvearaclol orcoatinas desiaoatod by service conditionftumben and .v.tI! types of coetin.dcO edby classlfica. S. OrderinllnfoflDadolS,S.I When ordenq uUcl. to b. electroplated in conformtion numberaatecovuedby thi. speeincation.4.2 Smlt, COlldillDnNumb":aneewith this standard, the puroha.ser shall IIlIItethe rol.lowing:4.2.1 The 8trvlce condition numb.r indicatel the .verity'.1.1 The!ASTM de iSnAtionnumber of thl Stt\ndatd.of ejtpo ure ror which the gradeor cOltlnaII Intended:SC j extended .eycr CJ'\tiec,. '.2 Either theclUllOcaUonn&&mber or &fteIpcctnccoatIn, required (see 4.3) D' the lubltrlle maceri.a1 and thelOrvlt:e:sC 4 very.,vert Hrvicc,conditio" "\lmbet denotiq the Beyerityof the conditionsitSC J "VIr. .'rYiCt,is required to wlthltlnd (lee 4.2). If ttte !IOl'Vlce oncUtioftSC 2 modentf. Ilf\llce.andSC 1 mild service.number is quoted alld not Ihe ellllint:ation nunlbet, the4.2.2 Typical serviClcondition. for which the varioul manufacturer '5 free to supply Iny or the tYp6!1of cO8llnasc:ot1'l!spcndin.toservicecondition number! Ife appropriate are Jiven in d.lan.ted by thl claasificationnloJmbel'll,'Appendix X I.4.3 Comi", Claslijlc:atiQfINumb,r- The coAtil\8clwin.cationnumbereomprtses:4.3.1 The cliemlcal symbolrorthebui. meJaI(orfortheprincipIImew It.n aUoy) nowedby . .Iashmark.".3.2 The chemlcals)'mbol ror copper(Cu)(If capporIsU& d).'TABL.!I NI.tl "lullCllremlumCoolIl\g' elt lta,lND'. 1-Au\IIt, 01. "" 1II'IIf1/ll1rlGlla1'Ultr't 18II)1\IImil'" wMUWIlI8bII,IliII!a "y.'I""S,.am.indicatln.theminhDumthicleness of the4.1.1 A num rcoppercoalinain micrometret(U'copper il used),IIrvIot4.3.4 A lower-cue letter designatlns tho t)'J)Cor co perdeposit(ir Gopperil used) (se. 4." and 6.2.3),4,3.5 The chernlcaJ uymbol ror nickel (Ni).4,3.6 A number indic:atlnathe I'I\h'limumthickneaaorIhenickel coalin" in mic:rurnetre.,4.1.7 A. lower cuelete.rdelianatln.thotypt of nickeldCPQlit(see 4.4 find 6.2.4),4.3.8 The cl\cmlcilsymbol rarchromium(Cr), and4.3.9 A lotter (or leuors)deaianatin.thetypoofchromham, and it. minimum thlckn. in micrometrCl(He 4.4and 6. .5)., .4 )Jmbo/Jji),E.qJtlls/nt CltUl(j1tmIDfI-Th.faUowln,.lowor-tase letten shall be used in c:OItln8c:laullic8tionnumbersto describetho ty. ot coatinil:deposit.b,.dfllItIIlI6dby IJ'II c .slftca'iatlnllmlj.,.II'\w II'D 'UClutll cIwomillm .,. uli'factorY for SC 4 IIId C 3.Non 2-WhtnpennllttCI till Ih. II\IfCNIIf, cop!* mill)' Illed . 811undercoal/Of ttk:ktl bII' It noC !tuGtlih.1aDIefar ."y wt 01 "'" IIlcMj Iftj,knest,pecllIed. If \l1li 01 /!Oppel t. pCImIilttd, T.bIIt 3 till, 118ullOO10 oIal8in tho-duc:tlle tc) I t,dej:lOSltedr,orn.cid.t1fP8 baths-sinllt-1aye1 I\lOkcldeposited in the fbllY.brialucondition-dull or ltift\:-h"'ah. n "cl rCQllirini pal:lhi. '0' &I-. tlil/brisJuneu"ro. 1IOn.CIfIGIIiM No.Clt.IIIcI'1On NO." --NIck811'1I1CICnIII.1'1118CIso'.seaCrmaFu/NI3 cfCt m ,;F"/N 011Of rFol"ll30c1Ct mePII/NI OCIer mp.0'o/Nidd351203DFClINI OtCf,3021Ffl/NIIIOCrIl1O"'/Nlllei Cr"' 'IIF./NMCJCt,8ca.Ie,." WIIaIIa &dItit .d"40II"NI O.C,mo'II/NI:.OpCt 'e/NI20110, rf:'JNII' Cr1M:1030:tol'Fefl'4l's.Cr 1'1111.0/,-Ft/NIIOI"""" IIIr"'.""""'.,10 Dnldtl/ IIU, D8IIID8ulllt8lflOt a b ftlckll or lor IN IriOn' lI,er 01 d 1IIokII. p 014 lI!ellal m.y De lutI"IMICII«/\ICk. In SIniceCeIIcdllonHOt. I andI, m: ormpClVotnIwl'ln'I8)'., lloIIIIcll\II8Grill, CftlanlumIn NO,I. tJOft2.6S11-268 S0SS'd -N3A31S 'l' E1:21 S6. 61 lnr-----------

07/19/95D I8NT ENGINEERINGco., INC. 505 892 11 09:514t ClassIllCatlOnNo.TABLE 5 NiCk.' Pltll t:hromlumCoaUng'"on r.ap .' or COlllpt,Alloy,.NIcktI'nIicknn.,pm.SO 1\sc.SC3"1/Cu'S.N"t3Od Cr "' Fe/Cu'S. NI3Od Cr mp1ft/CutS. Ni25d Ct II'rC303025Fe/OU'S, Ni25dcr "'PFI/Cu,2a NJ2OdCf meF8lCu12aNi:lOOOr mil252020. WhIrl a d.11or lIalin 'InlShlslor lhe bf"IGI'lIIIy8'( 01 IS nlck.l.required.""buffedN TI!-AItIICIu;h hdUliftcltlan are lIuarnctcry for UCft cf iI8InCIiCIttel aervIcecandltICIn n\IIIW. """'"'are ;1I,.,.an IUperIor in ocrroCIIan ralltani:8SMvieeCct1dItlcnNo.SC4UIinQn'iCJctRI nI/n . Iumto 11'1010ua1118Ng!Aat ctIraINum.Cl8WllcltIOnNo,ACU/N13OdOr,II nickel may be IUI'ISliluled1SC3N1dc., nolll.TABLE 4 CO"," PlUINick,1P/ul ChromiumtOltinlll' onZInc.AlloyNOTi-Result 01. tosl program iMitate Ihal8 ill lome dOl/i'll wl'lttl'l.t lhecoating systems de.etj CI 1'1,th8 dll8lificedon IIlImllerS itIVOlvingrogutar C/UooServfoeConCli.tOIiNo,SC S. -Clessl'lcatiOn No. .Nk1kel ThIcIInns.2n/CIISsetSC3N'135d Ci' nipINCuS Ni351SCr rZn/Cu5 NI3OdCr mc3530Zft/CIISNI3011 Ct mp30%n/CII51I/'25C1 CI' r25Zn/Cu5 Ni2DuCr meZn/Cu5 NI2OdCr mpasCU/Nl2Sd Cr 1111)25.Cu/Nl25dCr,25.SC2'tn/CuS Ni2SpC'. mcZnJCu5 N125pCr I'll)25Ni3SP Cr rtn/Cull NI2QbCr rZn/C5 Nasl'I Ct me2n/Cu5 Ni1Sb Cr "'II1. and I'N:or mpdlromlun\OulNi25p Cr rCu/N12OpCr meCII/NI20p Cr Inp20CwJNi30bCr rCuJNt2lib(irme302525Cr mpCIIJNI15DC, ,SOl' Cu/Nl5bCr,Whena dvllor otintllllllllt, 8d,-- .28201S10:105Ullbutlacsp nlC*f' may beIUrJ8UIllt t« tI niCkel or for tI1t Clrlfht 11)'" 01 d n1cIcll.I P cr G nIt:okeimay be subllIMeCI fer b nlckll h SIW\riCI8CcnditIan NoI. 2 and1 me 01'mp cI1rcml\llllMat t)fraubstllUI8d fDr t ct\romILnTI InService IOIINo.t.in accordance with Method B 764 within the limits Bivenin'56.7.15.5.1.1J Adhesion Test-The6.3).'0" When . Gull Of sat!r'i FinIsh IS roqu.rOd. uJ\lIIIn p'niekelllllY1:18lubSlit1.lttdfor b nICkel or for the brigMt llyer 01 d nlc:kel. p or ISnlck.1 t"tI., be IWbslitutlCl'OI b nldwlln Service ConditlOtt NOs. 2 andNo.t.20CuJNi10D Cr meCU/NI10b Or mp.20.%/l/Cu&Ni'DbCr,so ,.SC;!O20Cv{NI2Od Cr nipCujNl25b20352SnlCl/ JIM3535ZnlCuSNi35dCt I'IC:SOC\I{NI25dCrmeCu/N12Od C, me:mum 8f1Ut!SIICtC/YlorSC. InllSC3.1"'Id\O4/\Ql":B 456TABLE3 Copper Plul Nick., Plul Ch,omillm CoaUngl an Bt.,StrvIceCondltiC1llNU.ll:Jbadhe lon test to be used (see6. Product Requirements6.1 VisualDdtcu:6.1.J The sisnific.antsurfacesof the electroplated articlemly be substituted 'Of r tIIromlum In ServIcI Cl:lndluonshaJJbe freeof cleatl)'visibleplatinsdefects,suchas blisten,the specified,. service conditionnumber,as JiveDin Tables2.3, 4, or ::i. On request, the manufacturer shaJJ infonn thepurch8JC!:ofthe classification number of the coating applied.5.1.3 The appearance required, roOrexample,bright,dull,ot Btin.Ahemalively, samples showina the required finishor RInge of fini h shaJl be supplied or approved by thepurchaser.S.I.4 The IIlanHicantsurfaces, to be indicated on drawingsof the parts. or by !.he provision or suitably marked speci-pits, rouihncsS. tracl( . aDduncoatedlUgs and shalldot besWncd or diSCDlored.On articles where a visible conlictmark's unavoidable, its posi\ion shall be specHied by thepurchaser. The electroplated article shall be clean andfreeofdamale,6.1.2 Defects in the surface of thc basis metal, such asscratches, porosity, no conductin8 Inclusion , roll and diemarks, cold shuts, and cracks, ltIay advu l)' affect theappearance and the perfonnance Df coatings applied theretodespite the observanc!: of the best electroplating practices.AccordinsJy, the plater's responsibility for defects in tbecoatins resultins frorn such conditions shall1:e walv d.mens (see 3.1).S.1.S The poshions on significantsurface

C'opper P'UI nickel plus f:hrontillm eoatinp on zinc 8J10)'1tor applicationl where both appearance and. protecllan of the basil me&lllllinst carro.ion are imponant.