Transcription

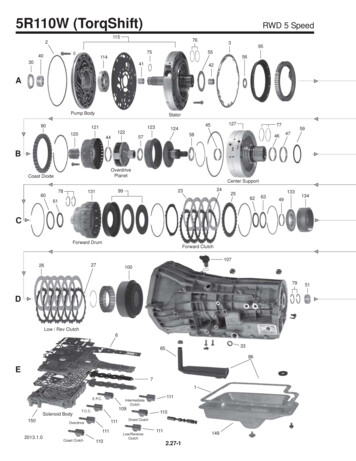

KEEP THOSE TRANNYS ROLLINGFORD’STORQSHIFT 6In this issue of Keep ThoseTrannys Rolling, we’re goingto look at some of the benefitsand problems encountered withFord Motor Company’s TorqShift 6transmission. Ford’s introduction ofthe TorqShift 6 in 2011 ushered in anew era of medium-to-heavy dutytruck transmissions. The TorqShift 6transmission was designed to competewith the Allison, used in mostmedium-to-heavy duty GM trucks.The TorqShift 6 is manufacturedat Ford’s award-winning transmissionplant in Sharonville, Ohio, and wasspecifically designed to partner withthe newly designed 6.7L diesel engineand the 6.2L gas engine.Let’s take a look at some of thebenefits the TorqShift 6 transmissionbrings to Ford’s medium-to-heavyduty truck line.TORQSHIFT 6 BENEFITS SelectShif t — Automaticfunctionality, including progressiverange select and manual functions.SelectShift provides conventionalautomatic operation or a manualshift mode that gives the driverc omplet e c ont rol ove r ge a rselection. The system synchronizes121pete315 v2.indd 12by Pete Huschermembers.atra.comthe engine and transmission speedsto allow fast, crisp shifts. Progressive Range Select — allowsthe driver to reduce the range ofavailable gears in drive, to limit theuse of upper gears when the truckis heavily loaded or while towingon grades. Drivers can also pull theshift lever into M for full manualmode and select the gear desired. Live Drive PTO (Power Take Off)— enabled with Super Duty dieselswith the PTO prep option. Thissegment-exclusive feature allowsthe transmission to power auxiliaryequipment, such as cement mixers,aerial lifts, tow truck lifts, or dumptrucks. Power is available any timethe engine’s running. High Capacity filtration system —provides longer fluid life (150,000service interval). Low speed torque converter lockup— for increased fuel economy andperformance.Now that we’ve seen some of thebenefits the TorqShift 6 transmissionhas to offer, it’s time to take a lookat some of the problems encounteredwith it over the past year on the ATRATechnical HotLine.GEARS March 20152/13/15 2:45 PM

smart blend 11-12-14.indd 212/8/14 2:40 AM

Ford’s TorqShift 6With today’s electronic transmissions relying heavily on computerprogramming, it’s getting harder and harder to differentiate between acomputer control problem and a mechanical problem.PROGRAMMING ISSUESThe TorqShift 6 transmissionrelies heavily on computerprogramming to control its operation,using inputs from both the PCM andTCM. Engine performance problemscan interfere with t ransmissionoperation. Some of the problems we’veencountered specifically related tocomputer system programming are: False codes being set in the PCMand TCM Delayed for ward and reverseengagements Shift problems, such as f lared,harsh, or abrupt shifts, or gearhunting These problems can usually becorrected by reprogramming thePCM and TCM with the latestupdates and resetting the adaptivestrategy.TORQSHIFT 6 PROBLEMS The TorqShift 6 transmission hasalso been plagued with several noncomputer related problems, such as: Solenoid f u nct ion. Solenoidsaren’t interchangeable and must bereinstalled in their correct locations.You can identify solenoids by bodycolor and band-width identificationnumber (2-5) marked on solenoid(figure 1). Torque converter hub and pumpbearing failure (figure 2). Valve body wear.These problems can usually becorrected by replacing the faultysolenoid, wor n torque conver terand pump bearing, or repairing orreplacing the worn valve body.VALVE BODY WEARNow that the TorqShift 6 hasbeen in service for five years, valvebody wear problems are becomingpretty common. Valve body wear can141pete315 v2.indd 14Torqshift 6/6R140 Solenoid Identification (Function)1Shift Solenoid E (SSE) Overdrive (4,5,6) Clutch, Normally High2Shift Solenoid C (SSC) Intermediate (2,6) Clutch, Normally Low3Shift Solenoid A (SSA) Forward (1,2,3,4) Clutch, Normally Low4Shift Solenoid B (SSB) Direct (3,5,R) Clutch, Normally High5Torque Converter Clutch (TCC) Solenoid, Normally Low6LIne Pressure Control (LPC) Solenoid, Normally Open7Shift Solenoid D (SSD) Low/Reverse (1,R) Clutch, Normal LowFigure 1cause numerous transmission-relatedconditions such as: Delayed engagements Flared shifts Harsh or abrupt shifts Shift hunting Neutrals when coming to a stopLet’s take a look at a specificcondition caused by a worn valvebody.HARSH 1-2 UPSHIFTOR 2-1 DOWNSHIFTThis condition was brought toour attention after the repair shop hadexhausted every means at its disposalto correct a harsh 1-2 upshift or harsh2-1 downshift. The vehicle was a 2011F250 with a 6.7L diesel engine and aTorqShift 6 transmission.The customer brought the vehicleto the shop complaining about aharsh 1-2 upshift and a harsh 2-1downshift. After further inspection,the shop determined that the f luidwas discolored and the transmissionneeded to be rebuilt.They removed and rebuilt thetransmission, replacing worn clutches,seals, and torque converter. After theGEARS March 20152/13/15 2:45 PM

Exedy March 2015.indd 12/18/15 11:01 AM

Ford’s TorqShift 6Figure 2rebuild, they installed the transmissionand filled it with the recommendedf luid. They then perfor med theadaptive strategy reset procedure andtook the truck for a test drive.D u r i ng t he test d r ive, t hetechnician noticed that the transmissionstill had a harsh 1-2 upshift and a harsh2-1 downshift at light-to-mediumthrottle. The technician was familiarwith the adaptive strategy reset andknew it might take a few test drives toget the computer system to adapt thetransmission shifts.T h e t e c h n ic i a n p e r fo r m e dseveral lengthy test drives, hopingthe computer system would adapt andcorrect the harsh 1-2 upshift and 2-1downshift. It didn’t.Certain that this was a computersystem problem, the tech nicianreprogrammed the PCM and TCMwith the latest update and then tookit for another test drive. The harsh 1-2upshift and a harsh 2-1 downshift werestill there.161pete315 v2.indd 16At that point the technicianbelieved the condition had to havebeen caused by a valve body problem.VALVE BODY INSPECTIONAfter talking to the technician, Iasked him to send us the valve bodyfor further inspection.The valve body arrived the nextday by special courier. I inspected thevalve body and solenoids for any signsof damage. Then I disassembled it,inspecting each valve and valve borefor wear. I performed three proventesting methods on the valve body.I performed a wiggle test on eachvalve. I used a light source behindeach valve to see if any light wouldpass by and lastly I used vacuum.After all three tests, I discovered theintermediate clutch regulator valve,the forward clutch regulator valve, thesolenoid feed pressure regulator valve,the line pressure regulator valve, andtheir respective bores were all wornexcessively (Figure 2 & 4).Due to the extent of the valveand valve bore wear, I recommendedreplacing the valve body.REPLACING VALVE BODYAfter informing the technicianof our findings, he replaced the valvebody with a new, OEM valve bodyfrom Ford. He installed the new valvebody and downloaded the new solenoidbody strategy into the TCM. Then hewas ready to take the truck for a testdrive.During the first few minutes ofthe test drive, the transmission shiftswere a little firm. As the test drivecontinued, the transmission startedto shift normally. After several milesof driving, the transmission beganworking properly and it appeared thenew valve body eliminated the harsh1-2 upshift and 2-1 downshift.It appeared we had the problemwhooped.GEARS March 20152/13/15 2:45 PM

Our seals can gothousands of mileswithout a leak.Go with the leader in transmission repair for nearly 40 yearsand stop leaky seals from compromising your work and reputation.Some transmission seals just can’t hold their fluid like others. To help keep the transmissions you rebuild on theroad and out of your shop, make sure you use only parts and kits from one of the most trusted and respectednames in transmission repair for nearly four decades – Precision International. We rely on the same topmanufacturers who supply OEMs. We thoroughly inspect each and every incoming parts shipment for propersize, fit, material and appearance. And we constantly monitor OEMs for product changes or updates toeliminate surprises and help keep both of us on top of our game. Even more reassuring, our technical advisorygroup actually tests our kits out on the most current transmission designs before they go to market. So weoften identify and solve potential transmission problems before the OEMs even discover them!The best info and advice in the businessPrecision also offers outstanding tech support andassistance, including www.transmissionkits.com – ourwebsite with continually updated video seminars fromleading transmission expert John Parmenter, questionand answer forums, complete parts information andmuch more.So you can troubleshootany problem and offer yourcustomers the very besttransmission solutionspossible. It’s all part of ourPrecisionInternational March2015.indd 1quality story and uncompromising commitment to you.After all, the last thing we want is a leaky seal drainingyour time and money.For more information, give us a call.www.transmissionkits.comThe Problem Solvers.14 Todd Court Extension, Yaphank, NY 11980(631) 567-2000 Fax (631) 567-2640 Toll Free: 800-872-6649E-mail: 2/24/15 2:24 PM

Ford’s TorqShift 6Figure 3Lower Valve Body Identification1Low/Reverse Latch Valve(1.626 X .363 X .043)2Solenoid Feed Pressure Regulator Valve(1.608 X .365 X .048)3Direct (3,5,R) Clutch Latch Valve(1.626 X .363 X .043)4Forward (1,2,3,4) Clutch Latch Valve(1.626 X .363 X .043)5Intermediate (2,6) Clutch Latch Valve(1.626 X .363 X .043)6Overdrive (4,5,6) Clutch Latch Valve(1.626 X .363 X .043)7Manual Valve8Line Pressure Regulator Valve(3.114 x .719 X .057)9TCC Charge Limit Valve(1.163 X .481 X .056)10Cooler Bypass ValveOrange Spring (1.267 X .492 X .038Yellow Spring (1.263 X .433 X .038CONCLUSIONUpper Valve Body Identification1 Overdrive (4,5,6) Clutch Regulator Valve2 Intermediate (2,6) Clutch Regulator Valve3 Forward (1,2,3,4) Clutch Regulator Valve4 Direct (3,5,R) Clutch Regulator Valve5 Low/Reverse Clutch Regulator Valve6 Torque Converter Clutch (TCC) Regulator ValveW i t h t o d a y ’s e l e c t r o n i ctransmissions relying heavily oncomputer programming, it’s gettingharder and harder to differentiatebetween a computer control problemand a mechanical problem. That’s whyit’s always a good idea to verify thatthe computer system has the latestcalibration updates before jumpinginto a mechanical repair.With a better understanding ofhow the computer system controlsthe transmission, and having therecommended diagnostic equipment— you should have no problemkeeping those trannys rolling.7 TCC Apply Regulator ValveFigure 4181pete315 v2.indd 18GEARS March 20152/13/15 2:45 PM

WHY NOT BUILD YOUROWN CONVERTERS?ATI’s CW3 Converter Weldingand Overhaul System has beenmanufactured in Baltimore,Maryland for over 25 years by thesame people who invented it. Ourconverter rebuilding machines aredesigned specifically to increaseprecision and production in yourshop. We know what you work onand we address your needs. Noother manufacturer offers you thesame level of personal service.Our systems come complete withmany options available and theywill make you money. Talk toan ATI user then order your newprofit center today.ATI’s CW4 COMING SOON!5” more swing and canaccommodate a 3” tallerconverter than the CW3!Why 45º? Gravity pullsthe weld into the pumpand cover seam fornearly 100% leak-freeproduction.CW3 ConverterWelder38” wide x 73” tall x 30” deepAccuBalanceConverterBalancerAll equipment carries a one year parts warrantyFAMILY OWNED AMERICAN MADEQuick Test ConverterLeak TesterClutch PistonBonder(877)298-5003CW3WELDER.COM6747 Whitestone Road Gwynn Oak, Maryland 21207 2015 ATI Performance Products, Inc.ATI Performance March2015.indd 12/19/15 9:45 AM

The TorqShift 6 transmission has also been plagued with several non- computer related problems, such as: Solenoid function. Solenoids aren't interchangeable and must be reinstalled in their correct locations. You can identify solenoids by body color and band-width identification number (2-5) marked on solenoid (figure 1).