Transcription

TROUBLESHOOTING GUIDECOOLING SYSTEM

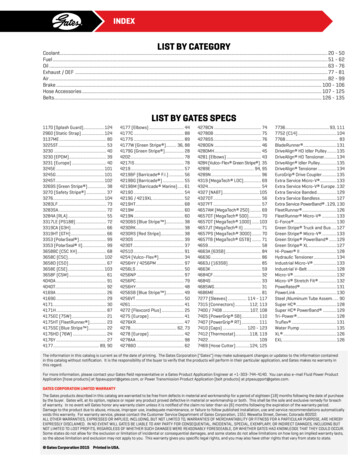

1TROUBLESHOOTING GUIDETABLE OF CONTENTSWHAT YOU SHOULD KNOW BEFORE YOU STARTSelecting the correct replacement part is easy. 6Specialist tools make your job easier. 6The right training gives you the right know-how. 6Introduction to the cooling system and to understanding failure of the system. 7DIAGNOSING COOLING SYSTEM PROBLEMSAlways start by determining the correct part application. 9Using the proper cooling agent. 10Inspecting the hoses. 12Hose failure patterns. 14Inspecting the thermostat. 18Thermostat failure patterns. 20Inspecting the water pump. 24Water pump failure patterns. 26Inspecting the radiator, the expansion tank and their caps. 32Cap function check. 36REPLACE WORN PARTS WITH PREMIUM PRODUCTS BY GATESGates coolant hoses. 39Guidelines for replacing hoses. 41Stant thermostats. 43Guidelines for replacing thermostats. 44Gates Timing Component Kits with Water Pumps. 45Guidelines for replacing water pumps. 46Gates radiator and expansion tank caps. 47Gates Power Clean Flush Tool. 49Special case: How to properly drain, flush and refill the cooling system. 50LET’S RECAPThe importance of the system. 53A reputation depends on satisfied customers. 53Review quiz. 55

4A ROADSIDE FAILURE IS THE LAST THINGYOU OR YOUR CUSTOMERS NEED.ESPECIALLY WHEN THE CAR HAS JUSTBEEN IN THE WORKSHOP FOR A SERVICE.The information Gates has included in this troubleshooting guide willhelp you detect cooling system component weaknesses on liquid-cooledengines before failure, so you can keep your customers on the road.

3TROUBLESHOOTING GUIDE

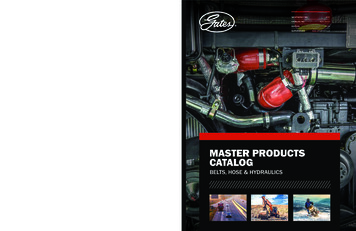

4WHY PROFESSIONALS CHOOSE GATESTHE ONLY THING MISSING WILL BE THAT NEW CAR SMELLNo matter where you travel around the globe, chances are when you look under thebonnet, Gates is there. Gates is one of the world’s largest manufacturers andsuppliers of original equipment (OE) belts and metal parts. With a century of globalinnovation and technology in every component, you can feel confident that Gatesproducts will restore your customers’ vehicles to factory-original condition.Gates is the world’s largest supplier of OE belts. The world’s leader in OE drivedesign technology.Global manufacturers that Gates supplies to includes: Alfa Romeo Audi BMW Chrysler Citroën Fiat Ford Holden Honda Hyundai Jaguar Kia Land Rover Lexus Mazda Mercedes Mitsubishi Nissan Opel Peugeot Porsche Renault Saab Seat Subaru Suzuki Toyota Lada Volkswagen VolvoIf all major car manufacturers use Gates parts, why shouldn’t you?TIPS AND TRICKS FROM YOUR AUTOMOTIVE SPECIALISTSo Gates provides the aftermarket with products that are of original equipment (OE)quality. But that’s not all. Drawing upon our OE knowledge we anticipate the needs ofthe aftermarket and offer true customer support: superior cataloguing, specialisttools, hands-on training seminars, comprehensive technical bulletins, detailed fittinginstructions and so on.LET US SHOW YOU HOW WE ARE THERE TO HELP YOU.

5TROUBLESHOOTING GUIDE

WHAT YOU SHOULD KNOW BEFORE YOU STARTGATES IS THERE TO GUIDE YOU . EVERY STEP OF THE WAYCorrect installation of the right replacement part. That’s where it all begins.Selecting the right replacement part is easy thanks to superior cataloguingGates offers a better market coverage than any other automotive market player.By constantly scanning the market for new developments, our specialised applicationresearch team ensures we have the widest range. What’s more, our team alsoprovides up-to-date application data on virtually every car on the road.All this information is freely and readily available in the Gates application cataloguerange, including catalogues for Drive Belts & Components, Water Pumps, TimingBelts & Timing Component Kits and Radiator Hose.Specialist tools ensure perfect installation and easy maintenanceIn order to ensure that installation can be achieved correctly and according to thevehicle manufacturer’s recommendations you also need the right tools. Withoutthese tools, installation errors can occur. Consequences include prematurecomponent failure, damaged components or even the complete destruction of theengine itself. The last thing you want is your customer left stranded on the roadsidewith a vehicle failure. So, rely on our wide range of professional tools for properinstallation, tensioning, alignment and maintenance.The right training gives you the right know-howYou aim to keep your customers satisfied and eliminate costly comebacks. To do thisyou need more than just quality products and specialist tools. With ever-changingtechnology, proper training has never been more important in the automotiveindustry. Our technical team develops training initiatives and technical servicebulletins to help keep you up to speed with the latest changes and to deal withcomplex problems.WHAT YOU SHOULD KNOWBEFORE YOU START6

7WHAT YOU SHOULD KNOWBEFORE YOU STARTINTRODUCTION TO THE COOLING SYSTEMModern engines produce more horsepower per cubic inch than they ever have in thepast. The thousands of explosions in the engine each minute generate tremendousheat. In most engines however, thermal efficiency is only about 35%. Thermalefficiency is the percentage of fuel energy taken from the combustion that is actuallyconverted into mechanical energy to power the vehicle. The rest of the energy islost, primarily as combustion heat. About 70% of that waste heat exits through theexhaust system. The remaining 30% must be controlled by the engine’s coolingsystem. So the primary job of the cooling system is to prevent the engine fromoverheating and thus avoid catastrophic engine damage. But that’s not all. Enginesare designed to operate within a specific temperature range for optimum efficiency.In the time it takes to reach this optimum operating temperature a car consumesmore fuel, therefore emitting more CO2 and engine parts ultimately endure morewear. Therefore, another important job of the cooling system is to make sure theoptimum engine operating temperature is obtained as rapidly as possible andis then kept constant. All the parts that make up the cooling system serve bothpurposes and ensure the system properly absorbs, transports and dissipates heat:1The heater core:uses the hot coolant to generate hot air to heat the car interior.2The radiator:cools off the hot coolant through the process of heat dissipation.3The expansion tank:stores the coolant reserve and accommodates the changes in coolant volume as thecoolant goes through its cycle of heating up (expanding in volume) and cooling down(reducing in volume) by holding expanded coolant from the cooling circuit.4The fan:draws external fresh air onto the radiator as necessary to assist in heat dissipation(e.g. during idling time in traffic).5The thermal switch:operates with the coolant temperature variation and switches on the fan as necessaryto support the cooling by airflow.6The cooling system hoses:carry the coolant through the entire cooling circuit. The coolant acts as either anengine-cooling or interior-heating source, depending on the part of the circuit it is in.7The thermostat:regulates the coolant flow to obtain and maintain the optimum engine operatingtemperature.8The water pump:constantly circulates the coolant throughout the entire cooling circuit, regulatingthe coolant flow rate.9The radiator cap and the expansion tank cap:seal off the filling hole of the radiator/expansion tank gastight; ensure that theprescribed pressure on the system is maintained at all times during operationby allowing air to escape in case of overpressure.

1937548962WEAR PARTS / HARD PARTSUNDERSTANDING FAILURE OF THE COOLING SYSTEMAnything that decreases the system’s ability to absorb, transport and dissipate heatcan cause the engine to operate at reduced efficiency or even overheat: a low coolantlevel, kinked hose, defective thermostat, corroded water pump, worn pressure cap In other words, the engine can only be kept safe from overcooling or overheating whenevery single cooling system component functions perfectly. The coolant has to get ridof the heat it absorbs while passing through the hot engine block. This requires awell-functioning radiator to make sure the heat absorbed by the coolant is dissipatedto the outside air. But also the hoses, thermostat and water pump are essential.A kinked hose will reduce the flow of coolant. A defective thermostat can block thecoolant circulation. A corroded water pump will be ineffective in moving the coolant.Even a component as small as the pressure cap is critical. A worn pressure cap willnot properly pressurise the system which can compromise the proper functioningof the entire system.The main objective of this guide is to identify cooling system componentweaknesses before failure, so you can prevent your customers from sufferingtroubles such as poor cabin heater power on a freezing winter morning, bad fuelmileage or even worse a roadside breakdown on a hot summer day.Expensive, inconvenient repairs can be avoided as Gates tells you where andhow to look for potential issues!All of which is good news for you, since this improves the customer satisfactionlevels for your garage.WHAT YOU SHOULD KNOWBEFORE YOU START8

9TROUBLESHOOTING GUIDEDIAGNOSING COOLING SYSTEM PROBLEMSDIAGNOSING COOLING SERVICE PART RELATED PROBLEMSNow we are ready to go into more detail.When experiencing any operational issues, use the following troubleshooting methodsto resolve the problem.Always start by determining the correct part applicationAlways double-check all parts to ensure that the proper coolant hoses, thermostat,water pump etc. are installed for the particular vehicle and engine in question.Parts which are not made to the proper specifications may cause the entire systemto malfunction. Be certain that all parts are designed for the specific applicationand installed properly. If any component within the cooling system has beenrecently replaced, check that part for correct installation. Any component installedimproperly can result in less than optimum performance.

10As the cooling agent is the “fluid connection” between the cooling system components,it is to be considered as a vital “part” of the system deserving your full attention. Enginecoolant has several functions: absorb engine heat, provide freeze protection, and helpraise the boiling point (engine cooling is based on the principle that pressurised fluidstarts to boil at higher temperatures than non-pressurised fluid, see also page 34).In addition to protecting the engine from extreme temperatures, the coolant protectsthe cooling system from rust and corrosion as it contains anti-rust agents, corrosioninhibitors and a lubricant for the water pump, all of which keep the cooling systemcomponents operating smoothly.Understanding coolant technology and selectionAs with engine oils, modern vehicles now require vehicle-manufacturer-specificcoolants. The cooling system is considerably more complex than it once was, andincorporates components made from many different materials. The need to protectthese components from rust and corrosion is the key reason behind the growth ofvehicle-manufacturer-approved coolants.Coolants fall into four non-interchangeable types, as each type is designedto work differently:TYPEPROTECTION TECHNOLOGYInorganic Additive TechnologyIATsilicate / phosphateOrganic Acid TechnologyOATorganic acidHybrid Organic Acid TechnologyHOATorganic acid with silicatePhosphate Hybrid Organic Acid TechnologyPHOATorganic acid with phosphateInorganic additives are used to plate cooling system surfaces as they form a thickprotective layer but deplete over time. They are not very selective, which means theycover all surfaces regardless of what these surfaces are made of. Organic additivesform chemical bonds with vulnerable surfaces, making a thin though extremely stableprotective layer offering longer protection. They are selective, targeting only the areasthat need protection.Coolant selection would be easy if all vehicle manufacturers developed their systemswith the same materials. But as that is not the case, each manufacturer developsa factory fill coolant based on the cooling system component materials it contacts.So, choosing the proper replacement coolant is impacted by the cooling systemdesign. That is why Gates recommends to always replace the vehicle’s coolantwith the coolant recommended by the vehicle manufacturer.One coolant cannot work for all vehicles!DIAGNOSINGCOOLING SYSTEM PROBLEMSUsing the proper cooling agent

11DIAGNOSING COOLING SYSTEM PROBLEMSCoolant level check and changeCheck the coolant level whenever a car comes in for service. A low coolant level has aharmful effect on the cooling system components, and can result in engine-damagingtemperatures. The level should be filled between the “maximum” and “minimum”marks on the side of the reservoir. If the level is near or at the marked minimumlevel, top up the system with the vehicle manufacturer’s recommended coolant, or ifnot available, distilled water (max. 2% of the total coolant volume). Don’t top up withtap water or non-compatible coolant. Tap water varies in pH and mineral content;it throws the coolant chemistry out of balance and, when heated, percolates out andforms deposits that block cooling system passages. Non-compatible coolant reducesthe original protection level. Also, always look for the root cause of coolant loss(see also pages 15, 20, 26-27 and 33).When doing a coolant change, Gates recommends a complete change with the vehiclemanufacturer’s recommended coolant. Mixing different types of coolants or puttingthe wrong type of coolant in the system may void car warranties. Always drain andflush the system – using an approved flush tool (see also page 50) – before refilling.Use pre-mix coolant or mix new coolant with distilled water in the ratio recommendedby the vehicle manufacturer.And last but not least, coolant should be changed at least every two years or 50,000 km(31,000 miles) as a good preventive maintenance procedure, or it will lose effectiveness.Also, if you are unsure of the coolant in the system, drain and flush the system and refillwith new coolant.Special note: Looks can be deceivingSometimes coolant may look clean, but if the system has never been flushed andmileage is high, it is probably contaminated. Not all contaminants make the coolantlook dirty. Sand and other abrasive debris particles, aluminium corrosion particlesand mineral content in the water, to cite three examples, won’t be obvious. Also,do not rely on the coolant colouring to make your pick. Coolants may have the samecolour, even though ingredients are different. The function of the dye is to help youspot a coolant leak. The right answer to what coolant to use when, is: always usethe vehicle manufacturer’s recommended coolant.Keep in mind that a cooling system drain, flush and refill is meant to preventproblems, not to fix them!Changing the coolant is good preventive maintenance but will not be sufficient.Gates advises a thorough inspection of all cooling system components at eachservice interval to identify component weaknesses before failure.RefractometerEnsures adequate freeze and boil-overprotection by accurately testing glycolconcentrations of radiator coolant.Maintains effective cooling systemperformance and eliminates risks ofengine damage from electrolysis,cavitation and corrosion. Alsomeasures state of charge and specificgravity for electrolyte in lead-acidbatteries.Part # 91001

12DIAGNOSINGCOOLING SYSTEM PROBLEMSInspecting the hosesWhen engines used to be less complicated, a typical workshop had to carry onlya few sizes and types of coolant hoses. But with today’s smaller engine compartments,coolant hoses come in all shapes and sizes to fit specific applications and tight enginespaces. They carry coolant to a variety of under-bonnet equipment and not just to theradiator, thermostat, water pump and heater core. In addition to the traditional upper,lower, by-pass and heater hoses, vehicles are also equipped with small coolant hosesthat carry coolant to the fuel injection throttle body, turbocharger, oil cooler andother components.Although coolant hose applications have changed over the years, basic hose designhas not. Hoses consist of three parts: the tube, reinforcement and cover. The tubeconveys the coolant, and the reinforcement prevents the tube from rupturing underpressure. The outer cover protects the entire hose assembly from harsh externalenvironments and contaminants. These three components are bonded togetherby special adhesives.

13DIAGNOSING COOLING SYSTEM PROBLEMSExpected hose lifeWhile basic hose design has remained relatively unchanged over the years, hosematerials have improved substantially. Thanks to these improvements hoses lastlonger today than before. Yet, their harsh working environment will inevitably affectthem and over time even the best hoses will wear. And when they do so, they usuallyfail from the inside due to electrochemical degradation (see also page 14). As there isno way to tell from a simple visual inspection if a coolant hose has internal damageand statistics show that failures increase dramatically after the fourth year of service,Gates recommends that coolant hoses be replaced at least every four yearsor 100,000 km (62,000 miles).Hoses can fail fasterWhile the four-year replacement interval is a basic rule of thumb, it is not exact.Vehicles operating under severe conditions or vehicles that are not driven oftenmay require more frequent replacements. Therefore, it is imperative to periodicallyinspect hoses – even hoses less than four years old – for damage from the majorhose enemies electrochemical degradation, leakage, heat, ozone, abrasion, and oilcontamination whenever a vehicle comes in for service. If the hose exhibits any ofthe tell-tale signs of wear, it should be replaced immediately. See pages 14-17for failure patterns.Don’t forget the clamps and connectorsCheck each clamp and connector, and replace any that are defective. Gates recommendsreplacing clamps and connectors each time a new coolant hose is installed. Hose clampscome in very different types, each designed to meet different hose specifications. It isimportant to make sure you have the correct style and size of hose clamps at hand whenyou install new hoses.Gates has coolant hoses in its range that are electrochemical resistant (ECR),delivering longer-lasting service for your customers and building a reputationof reliability for your shop!Not all OE manufacturers use ECR hose, so if you choose a Gates ECR hoseas a replacement you are using the highest quality product on the market.This will strengthen your reputation with your customers.Read more about Gates extensive line-up of coolant hoses on pages 39-40.Cooling System Pressure TesterThe Stant Cooling System and CapPressure Tester is a precisioninstrument designed to locate leaksand pressure cooling systemproblems. It has the ability to test upto 30 pound cooling systems andpressure caps. Adapters for mostvehicles and trucks are alsoavailable separately.Part # 12270

14Hose failure patternsSome general guidelines to start your hose inspection:› Additional tip: checking the hose temperature can reveal if the system is functioning properlyLet us give you some examples. Use an infrared thermometer to read the hose temperature.If the heater is on, both the ingoing and outgoing heater hoses should be close to the sametemperature. If not, it might be time for a repair. If the upper radiator hose already gets hotbefore the engine has properly warmed up, it means the thermostat is not closing properlyor even is constantly open. If it does not get hot at all, it means the thermostat is blocked.In both cases, the thermostat should be replaced immediately.The following signs indicate that a hose needs to be replaced:The engine should be cool before any repair work is started!1. Electrochemical degradation (ECD) – internal damageAppearance: Electrochemical degradation is the number one cause of hose failure. ECD weakens thehose from the inside and is therefore not obvious by visual inspection. Do the “squeeze test”: ECD initiallyattacks the hose 5 to 10 cm (2 to 4 inches) from the ends so first squeeze both end sections using yourthumb and one or two fingers. Then squeeze the middle straight section of the hose, checking for adetectable difference between the ends and the middle. If the ends feel more soft and mushy or if youfeel gaps or channels inside the hose, the hose is most likely under attack by ECD.Cause: ECD occurs when different kinds of metals in the cooling system generate an electrical charge,which is carried from one component to another by the coolant. In case of high concentration, thiselectrical charge will affect the hose tube, creating tiny internal cracks, which weaken the hose.Solution: Replace the damaged hose immediately. The best way to avoid ECD failure is to installa hose that fights ECD. Gates electrochemical resistant hoses are your best protection againstelectrochemical degradation.DIAGNOSINGCOOLING SYSTEM PROBLEMS› Always check for kinkingWhen inspecting a coolant hose for damage, make sure that it is not kinked, and is not touchinghot or moving engine parts or sharp edges. A kink can reduce the flow of coolant and cause theengine to overheat. A sharp surface may eventually cut or abrade through the hose, resulting ina loss of coolant.

15DIAGNOSING COOLING SYSTEM PROBLEMS2. LeakageAppearance: Moisture, drips or coolant bleed marks on or around the hose clamps,connectors or on the hose itself.Cause: Leakage is usually caused by insufficient clamp torque or a deterioratedconnector. Heat causes metal to expand. If a new hose is installed while the engineis still warm, the expanded diameter of the inlet or outlet tubes prevents the clampfrom tightening as much as it needs to. Heat also causes the rubber hose to expand– about 20 times more than the metal. The clamp holds the hose on the tube, butthe hose “sets” in this expanded state. Then when the engine cools off, a gap appearsbetween the “set” ID of the hose and the contracted OD of the metal tube, and thecoolant leaks. Other than clamp or connector failure, leakage can be caused bya deteriorated hose itself.Solution: Hose suggestions: Replace with the recommended Gates hose. Gates usescompounds that offer better resistance to the negative effects of compression set.Clamp torque suggestions: To avoid cold water leaks, adjustable tension clamps mustbe retightened after a brief run-in period. Another solution is to use constant-tensionclamps, which automatically adjust with the heating and cooling of the system.Connector suggestions: A beaded connector offers better sealing and retentioncharacteristics. The smoother the finish of the connector, the less tendency to leak underthe clamp. Brass and cast iron fittings adhere to common rubber compounds after time,which reduces possibility of leaks, as does the use of sealants and viscous gels.

16Appearance: Heat damage can occur both internally and externally. Slight swellingis one sign of internal damage. If the interior yarn has been severely damaged bythe heat, the hose will feel soft and may even bulge in places. External heat damageis easier to detect since heat-damaged hoses typically have a hardened, glossy coverthat is covered with cracks.Cause: As engine compartments become smaller and more compact, temperaturesunder the bonnet increase. Ambient temperature from nearby hot engine parts,low coolant levels and/or temperature spikes also contribute to deterioration.Solution: Replace with the recommended Gates hose. Gates hoses are speciallydesigned to resist deterioration from heat.4. Ozone damageAppearance: Tiny, parallel cracks in the cover, usually at hose bends.Cause: Increased concentrations of ozone, caused by pollution, attack the bonds incertain rubber compounds. Tiny cracks occur, primarily where the hose experiencesstress: curves, bends and at clamping surface areas. These cracks allowcontaminants to invade and destroy the hose.Solution: Replace with the recommended Gates hose. Gates hoses are madeof EPDM and are unaffected by ozone.DIAGNOSINGCOOLING SYSTEM PROBLEMS3. Heat damage

17DIAGNOSING COOLING SYSTEM PROBLEMS5. Abrasion damageAppearance: Abrasion can be identified by rubbing marks on, or damage to, the hose cover.Cause: Abrasion damage is caused by hose rubbing against other engine parts or against objectsin the environment. A hose can, for example, be abraded by coming into contact with a part thatwas accidentally moved during maintenance or repair, or after hitting a speed bump. In othercases, abrasion occurs after the OE hose guiders have broken or after a hose is no longer properlyseated in the guider.Solution: Replace the hose. If the hose is resting on or will come into contact with a sharp surface,or is near a heat source, try one of the following:1. Reroute the hose away from the point of contact or replace/repair the hose guiders if needed2. If that is not possible, slightly twist the hose on one or both spouts to reroute the hose away fromthe surface3. As a last resource, wrap a protective sleeve around the new hose at the point of contact– Gates advises against using a slit piece of an old hose, as this will negatively influencethe system’s overall temperature.6. Oil contaminationAppearance: The hose feels soft or spongy to the touch. Bulges and swelling are readily apparent.Cause: Oil reacts chemically with the hose compounds and weakens the molecular bonds.This causes the hose to soften, swell and separate, layer by layer, leading to failure.Solution: Replace the hose and eliminate any source of oil. If this is not possible, reroute the hose.

18DIAGNOSINGCOOLING SYSTEM PROBLEMSInspecting the thermostatDifferent combustion engine technologies call for different thermostat types, butbasically all thermostats do the same thing. They are the watchdog of the engine’scooling system, as they constantly monitor the temperature of the coolant andaccurately regulate the coolant flow through the radiator to obtain and maintainthe optimum engine operating temperature.In its starting position, the thermostat is closed and blocks the flow of coolantto the radiator until the engine has warmed up. Once the engine rises to runningtemperature and the coolant reaches the thermostat’s activation temperature,the thermostat opens, allowing the hot coolant out of the engine and startingthe circulation loop to and from the radiator. The hot coolant passes to the radiatorand the cool coolant enters the engine to absorb more heat. The thermostatcontinues this opening and closing as long as the engine requires.

19DIAGNOSING COOLING SYSTEM PROBLEMSScenarios for thermostat failureThermostats, like any other part, don’t last forever. There are two scenariosfor failing thermostats:1. If the thermostat becomes stuck in the open position, there is continuous flowof coolant

BEEN IN THE WORKSHOP FOR A SERVICE. The information Gates has included in this troubleshooting guide will help you detect cooling system component weaknesses on liquid-cooled engines before failure, so you can keep your customers on the road. 4