Transcription

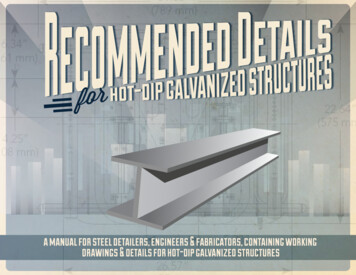

fora manual for steel detailers, engineers & fabricators, containing workingdrawings & details for hot-dip galvanized structures

lbTafoestentnCoRecommended Details forHot-Dip Galvanized StructuresDrawing #Title1Framed Beam connections2 Combination Section - Flange & Channel3 Combination Section - Two channels4 Combination Section - Wide Flange & Channel5 Combination Section - Channel & angle6 Combination Section - Channel & Angle7 Gusseted Connection - Welded8 Gusseted Connection - bolted9Double Angles10moment splice at ridge (Field Bolted)11 Simple Column base (base plate shop welded)12 Simple Column base (base plate field welded)13moment resisting column base (base plate field welded)14moment resisting column base (base plate shop welded)15 Web Stiffener16column splices - bolted17 butt plate coumn splice - bolted18 butt plate coumn splice - welded19Bracket plate20 box truss 2012 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabricationhot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verificationas to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of thisinformation assumes all liability arising from such use.

1. The contents of this publication are the result of a widespreadsurvey conducted among AGA members. Some galvanizers may preferdifferent details, based upon their own experiences, to achievedesired results in the galvanized product.2. Certain details call for welding after galvanizing. More informationconcerning welding and subsequent touch-up of galvanized steelis available in the American Galvanizers Association’s (AGA) Welding& Hot-Dip Galvanizing publication. If possible, steelwork should bedesigned to be bolted rather than welded after galvanizing.3. Welding symbols are those defined in AWS A2.4-2012 Welding &hot-dip galvaning publication. Shop welding symbols are usuallyaccompanied by a notation “intermittent” or by “Cont.” meaningcontinuous. in the absence of any other notation, it is assumed theweld will be continuous (AWS A3.0-2010 includes standard weldingterms and definitions.)4. Class IDetails are those consisting of parts joined together by a fullseal weld, or parts which are bolted together after galvanizing.This class represents the highest degree of corrosion protectionattainable, but does require more fabrication cost.5. Class IIDetails are those consisting of overlapping parts joined together byseal welding and which have an overlap area large enough to needventing in accordance with the appropriate guidelines of Note 7. A veryhigh degree of corrosion protection is available with these details,although not quite equal to Class I. More work is required than iscustomary for normal fabrication standards. It should be notedClass II can be upgraded to Class I by plugging vents after galvanizing. lass III6. CDetails do not include seal welding and may require only slightlymore fabrication effort than normally employed on a non-galvanizedstructure. Class III details enable the galvanizing to provide adegree of corrosion protection that meets or exceeds the protectionprovided by most industrial coatings to identical details.7. Pin holes may exist in seal welds around overlaps inClass I details. Liquids from galvanizer’s cleaning bathsmay pass through the pin hole and enter the overlap area,where it will remain as it is immersed in the molten zinc.Possibility of explosion exists as the trapped liquid vaporizes andexpands at a temperature of approximately 850 F. Danger of explosionis more acute for larger overlapped areas. It is recommended thefabricator provide a vent in one of the overlapping plates accordingto the following guidelines. Location of the vents need not be exact,provided they are in the same general location as shown on thedrawing. Arrangements may be made for installation of vent holes bythe galvanizer.2Overlapped Area (IN )Venting Requirements 16None 16 and 64when steel is 1/2” thickOne 3/8” Dia. hole, orleave 1” of weld undoneadjacent to same location 16 and 64when steel is 1/2” thickNone 64 and 400One 1/2” diameter hole, orleave 2” of weld undoneadjacent to same locationEach increment of 400One 3/4” diamenter hole, orleave 4” of weld undoneadjacent to same location8. Emissions from the unsealed overlaps of class II and Class III detailsmay cause a stain on the surface of the coating. This applies whetherthe coating is paint or galvanizing. The stain is usually superficialand will disappear in time as the galvanizing weathers.9. moisture steaming from unsealed overlaps in class II and Class IIIjoints may result in slight bare spots along the line of the exhaust.If touch-up of these is required it may be accomplished by any of thematerials described in ASTM A780 Standard practice for repair ofhot-dip galvanized coatings.10. After galvanizing, finished ends of column sections shall beground smooth to remove projections.

aFramedszerican galvanirem est. 1935Beam connectDrawing1asso c i a tio nion

astraightening after galvanizing. To minimize warpage,refer to the recommendations of the AGA and ASTM A384.ican galvanirem est. 1935szerCaution: This section is subject to warpage and may requireCombinatioFlange n Section& ChannelDrawing2asso c i a tio n

aszerican galvanirem est. 1935Combinationtwo ch SectionannelsDrawing3asso c i a tio nCaution: This section is subject to warpage and may requirestraightening after galvanizing. To minimize warpage,refer to the recommendations of the AGA and ASTM A384.

Caution: This section is subject to warpage and may requirestraightening after galvanizing. To minimize warpage,refer to the recommendations of the AGA and ASTM A384.aszerican galvanirem est. 1935CombinaWide Fl tion Sectionange &ChannelDrawing4asso c i a tio n

Caution: This section is subject to warpage and may requireican galvanirem est. 1935szerastraightening after galvanizing. To minimize warpage,refer to the recommendations of the AGA and ASTM A384.CombinatioChanne n Sectionl & AngleDrawing5asso c i a tio n

Caution: This section is subject to warpage and may requirestraightening after galvanizing. To minimize warpage,refer to the recommendations of the AGA and ASTM A384.aszerican galvanirem est. 1935CombinatioChanne n Sectionl & AngleDrassawing6o c i a tio n

aGusseteszerican galvanirem est. 1935d connewelded ctionDrawing7a sso c i a tio n

aszerican galvanirem est. 1935gusseted connebolted ctionDrawing8asso c i a tio n

aszerican galvanirem est. 1935DoubleAnglesDrawing9asso c i a tio n

aszerican galvanirem est. 1935moment splic(field b e at ridgeolted)Drawing10asso c i a tio n

aszerican galvanirem est. 1935Simple(base PL Column baseate shop welded)Drawing11asso c i a tio n

aszerican galvanirem est. 1935Simple(base PL Column baseate field welded )Drawing12asso c i a tio n

aszerican galvanirem est. 1935moment res(base PL isting Columnbate field weld aseed)Drawing13asso c i a tio n

aszerican galvanirem est. 1935moment res(base p isting columnlate shop wel baseded)Drawing14asso c i a tio n

Note for both Classes: Bevel weld may be used instead of fillet weld, at designers option.aszerican galvanirem est. 1935Web StiffenerDrawing15as so c i a tio n

Laszerican galvanirem est. 1935Column splices - BoDrawing16asso c i a tio nlted

aszerican galvanirem est. 1935Butt plate column spliceboltedDrawing18asso c i a tio n

aszerican galvanirem est. 1935butt plate column spliceweldedDrawing19asso c i a tio n

aszerican galvanirem est. 1935bracket plateDrawing17asso c i a tio n

aszerican galvanirem est. 1935box trussDrawing20asso c i a tio n

American Galvanizers Association6881 S Holly Circle Suite, 108Centennial, CO t.org

welD will Be conTinuous (aws a3.0-2010 incluDes sTanDarD welDing Terms anD DeFiniTions.) 4. Class I DeTails are Those consisTing oF parTs joineD TogeTher By a Full seal welD, or parTs which are BolTeD TogeTher aFTer galvanizing. This class represenTs The highesT Degree oF corrosion proTecTion aTTainaBle, BuT Does require more FaBricaTion cosT. 5. Class II DeTails are Those consisTing oF .