Transcription

Space Bio-ManufacturingBio-Manufacturing forDeep Space ExplorationNASA’s Space Technology Research Institute:The Center for the Utilization of BiologicalEngineering for Space (CUBES)John A. Hogan Ph.D. (CUBES COR)Bioengineering BranchNASA Ames Research CenterMoffett Field, CA12/05/2017NASA/NAC Meeting11

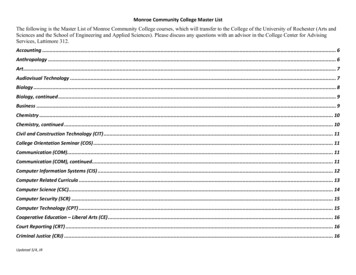

Presentation TopicsBackground NASA’s needs for In situ manufacturing, In situresource utilization and life support The potential of biological systemsCUBES – Center for the Utilization of BiologicalEngineering in Space Team members Project goals and research strategy Expected outcomes12/05/2017NASA/NAC Meeting2

Life Off EarthTemperatureRadiation ProtectionAirFoodWaste RemovalWaterGravityPressure12/05/2017NASA/NAC Meeting3

Future Missions Need aDifferent Approach Short crew duration Frequent resupply of food,water, O2, medical supplies,replacement parts Emergency return to Earth No ET planetary protectionrequirements12/05/2017 Extended crew durations Infrequent or no resupply offood, water, O2, medicalsupplies, replacement parts No emergency return to Earth Possibly strict planetaryprotection requirementsNASA/NAC Meeting4

Future Mission Sustainability In situ Resource Utilization (ISRU) generatessupplies from local resources. In situ Manufacturing (ISM) provides capability tomake needed chemicals, fuels, building materials,pharmaceuticals, etc. on-site and on-demand. Closed-loop life support systems treat andrecover valuable resources via regenerative air,wastewater and solid waste processing systems. Food production will be required to supplynutritional needs not met by current foodprovisioning systems. Eventually all food may beproduced in situ. Space medicine systems will require the ability tomonitor and maintain the health of the crewunder very adverse conditions. These systems require increased reliability andself-sustainability, and decreased mass, power,volume and consumable use.12/05/2017NASA/NAC Meeting5

In situ Production of Mission Products12/05/2017NASA/NAC Meeting6

Potential of BiologyPotential Biological Products: Food – plants and microbial productsVitamins, nutraceuticalsEnzymes, flavors, preservativesTherapeutics/pharmaceuticalsPolymers – plastics for parts, habitat construction, radiationprotectionFuels – hydrocarbons, nitrogen-basedPrimary chemicals for various product synthesisAdhesives/biocement - constructionSpecialized function biomolecules:- e.g., Carbonic anhydrase for CO2 management12/05/2017NASA/NAC Meeting7

BioManufacturing ResearchChallengesResearch Challenges:Novel, high efficiency, engineered microbes/plantsUse of unique substrates – In situ media generationNovel bioreactor designsProduct harvesting and purification strategiesMinimization of inputs/wastesReduction and consolidation of separate unit operationsEnhanced microbial storage and reanimation techniquesMaintaining pure cultures/controlled consortiums with minimalintervention Increased genetic and phenotypic stability Interfacing biology with inanimate components 12/05/2017NASA/NAC Meeting8

Bio-Manufacturing forDeep Space Exploration – STRI Goals1. In situ Microbial Media Production Conversion of carbon dioxide, water, and other needed resources to microbial substrates (“Insitu media” production) - supports rapid heterotrophic growth Supporting physico-chemical and biological methods that process local resources2. In situ Production of Mission Products Developing microorganisms with targeted metabolisms to producetarget products using In situ media Novel systems for growth and harvesting of target products Demonstration of manufacture of products for mission applications3. In situ Food Production Increase yield, volume efficiency, and photosynthetic efficiency Enhance overall nutritional attributes Enhance secondary product recovery from inedible biomass12/05/2017NASA/NAC Meeting9

NASA AlignmentResearch alignment with NASA Technology Roadmaps: TA07 Human Exploration Destination Systems - TA7.1 In Situ ResourceUtilization (the MMFD, BBMD, and FPSD will all use such inputs), TA7.2Sustainability and Supportability (the MMFD, BBMD, and FPSD will all usesustainable resource recycling), TA7.4 Habitat Systems (CUBES will develop a semiautonomous proof-of-concept biomanufacturing demonstration), and TA7.6 CrossCutting Systems (the BBMD additive manufacturing technology will be designed forscaling assembly). TA06 Human Health, Life Support, and Habitation Systems - Enabling long-duration, deep-space human exploration through the minimization of resupplyconsumables and increased Earth independence via Martian In situ resourceutilization, synthetic biology, and biomanufacturing. The FPSD will address TA6.3Human Health and Performance, and the MMFD will address TA6.1 EnvironmentalControl, Life Support Systems and Habitation Systems, and TA6.4 EnvironmentalMonitoring, Safety, and Emergency Response through remediation of toxicperchlorate in the Martian regolith.12/05/2017NASA/NAC Meeting10

CUBESThe Center for the Utilization ofBiological Engineering for SpaceLead Institution:University of California BerkeleyCollaborating Institutions:Stanford UniversityUniversity of California – DavisUtah State UniversityUniversity of FloridaPhysical Sciences Inc.5 years - up to 3M/year budgetNASA/CUBES Kick-off Meeting held 10/19-20/201712/05/2017NASA/NAC Meeting11

CUBES TeamCUBES Investigators:Adam P. Arkin, PI, UC BerkeleyAmor A. Menezes, Co-I (Science PI), U Florida*Craig S. Criddle, Co-I (Institutional PI), Stanford U*Karen A. McDonald, Co-I (Institutional PI), UC Davis*Lance C. Seefeldt, Co-I (Institutional PI), Utah State U*Aaron J. Berliner, Other Professional, UC BerkeleyBruce Bugbee, Co-I, Utah State UDouglas S. Clark, Co-I, UC BerkeleyDevin Coleman-Derr, Co-I, UC BerkeleyKalimuthu Karuppanan, Co-I, UC DavisSomen Nandi, Co-I, UC DavisRobert M. Waymouth, Co-I, Stanford UPeidong Yang, Co-I, UC Berkeley* Research Division Leads12/05/2017NASA/NAC Meeting12

CUBES VisionVision Statement:The Center for the Utilization of Biological Engineering in Space (CUBES) willleverage partnerships between NASA, other federal agencies, industry, andacademia to: Support biomanufacturing for deep space exploration; Create an integrated, multi-function, multi-organism biomanufacturingsystem for a Mars mission; and Demonstrate continuous and semiautonomous biomanufacture of fuel,materials, pharmaceuticals, and food in Mars-like conditions.12/05/2017NASA/NAC Meeting13

CUBES GoalsResearch Objectives: Harness Mars atmospheric and regolith resources fordownstream biological use; Create outputs like propellants and building materialsthat are fundamental enablers of any space mission; Synthesize food and pharmaceuticals in situ, to allowthese long-duration space missions to be manned; Perform space and complex systems engineering, toanalyze, guide, test, improve, and integrate the above.12/05/2017NASA/NAC Meeting14

CUBES StrategyApproach: Four integrated research divisions Systems Design and Integration (SDID): optimally allocate and utilize Marsresources, to tightly integrate and automate internal processes, and tosatisfactorily achieve performance per mission specifications (Menezes) Microbial Media and Feedstocks (MMFD): harness in situ resources,decontaminate and enrich regolith, and transform human/mission wastes tomedia and feedstocks for utilization by downstream processes (Seefeldt) Biofuel and Biomaterial Manufacturing (BBMD): produce propellants,biopolymers, and chemicals from media and feedstocks, recycle products atend-of-life, and use generated biopolymers in 3D-printing (Criddle) Food and Pharmaceutical Synthesis (FPSD): engineer plants and microbesfor use by astronauts. (McDonald)Y1Design, unittesting12/05/2017Y2Test individualoutputsY3Integrate/testoutputsNASA/NAC MeetingY4Learn andconsolidateY5Build/testdemo systems15

CUBES – Impact/OutcomesCUBES’ individual approaches to media production, mission productmanufacture, and food and pharmaceutical synthesis, amplified by a focus onintegration and optimization, will lead to a strong data-driven, technologicallybacked platform for space biomanufacturing. Engineered microbes to convert limited, marginally accessible Martianfeedstocks, such as atmospheric gases at low partial pressure and nutrientsfrom contaminated/toxic land, into commodities; Novel biologically-coupled nanotechnologies to fix available carbon andnitrogen and to transfer energy into biosynthetic processes; Refined plants and plant microbiomes that grow in restricted space, light,water, and nutrients, and that can still provide substantial yields of nutritivefoods; Biologically-produced pharmaceuticals, cellular treatments/therapeutics, andmaterials for on-demand diverse 3D-printing applications; Optimized, integrated operation of these processes.12/05/2017NASA/NAC Meeting16

Questions?12/05/2017NASA/NAC Meeting17

NASA's Space Technology Research Institute: The Center for the Utilization of Biological Engineering for Space (CUBES) John A. Hogan Ph.D. (CUBES COR) Bioengineering Branch NASA Ames Research Center Moffett Field, CA 12/05/2017. NASA/NAC Meeting. 12/05/2017. NASA/NAC Meeting. 2. Presentation Topics. Background