Transcription

People creatinga better tomorrow.2018 SUSTAINABILIT Y REPORT

Table of ContentsLetter From the CEOAbout Graham PackagingOur BeliefsMission Statement6Pillars of Excellence8Core Values9Our PeopleCommunity Involvement11Training & Development12Ethics & Compliance14Our ProductsWhy Plastic Packaging16PET & HDPE17Bio-Based & Biodegradable Resins18Our InitiativesSustainability Factors20Recycling Overview21Recycled Content24Graham Recycling Center26Lightweighting29Customer Colocation30Case Studies31Our OperationsGRAHAM PACKAGING SUSTAINABILITY REPORT 2018Health & Safety35Environmental Management37Materials38Energy Usage39GHG Emissions40Waste & Water Consumption42Our Partnerships43Looking Ahead45

LETTER FROM THE CEOMessage From Mike KingGRAHAM PACKAGING CEOFor years, plastic has played a vital role in keeping consumer goods safe. It extendsshelf life, preserves food, prevents product loss and even childproofs householdand pharmaceutical products. However, we understand the realities of plasticpackaging and the challenges our industry faces moving forward.With these new challenges, we’ve found a new drive — one that’s pushed us to takea closer look at our business in terms of sustainability, design innovations andleadership. In this report, we’ll detail Graham Packaging as it operates today, aswell as our vision for a more sustainable future.Part of that vision is the belief that preserving our planet should be a shared, globaleffort, and we realize that we need to be a major contributor to that effort. Westarted by signing the Ellen MacArthur Foundation’s New Plastics Economy GlobalCommitment, pledging that our full line of packaging will be recyclable or reusableby 2025. We’ve also joined the Department of Energy’s Better Plants Program withplans to reduce our energy usage by at least 25% over the next 10 years. As welook ahead to 2025, we will continue to implement sustainability programs and findopportunities to make a lasting contribution to the betterment of our planet.But while these are positive steps, formal commitments aren’t the only way we’reshowing progress. Our team members are partnering with our customers to helpthem achieve their sustainability goals for 2025 and beyond — goals that includeexploring alternative solutions like bio-based resin and developing strategies tominimize ocean-bound plastic. In the short term, we’re focused on three primarygoals that directly impact our customers: increasing post-consumer resin contentin our bottles, improving recyclability in all categories and decreasing ourcarbon footprint.It’s this spirit of collaborative, creative problem-solving that has always definedGraham Packaging. For more than 50 years, we’ve made plastic packaging forbeloved consumer brands, from juice and ketchup to cleaning products andautomotive lubricants. But we recognize that to remain successful, we must evolve.Together with our customers and suppliers, we will continue to refine ourprocesses and products. And while there are still barriers to overcome, our teamis steadfast in its commitment to bring sustainable packaging solutions to themarkets we serve around the world.We’re optimistic about the future, and we hope you are, too. We hope you’ll join uson our ongoing mission to preserve our planet for future generations.Mike King, Chief Executive OfficerGRAHAM PACKAGING SUSTAINABILITY REPORT 2018 LETTER FROM THE CEO3

ABOUTGraham PackagingABOUTFounded more than 50 years ago, Graham Packaging is a globalpackaging company dedicated to the design and manufacturingof environmentally friendly packaging solutions.Our company started with the design of the firstplastic motor oil container and has since expandedinto other packaging categories, including food andbeverage, personal care, household and healthcare.We work with Fortune 500 companies, as well assmall independent businesses, to createone-of-a-kind packaging solutions.Headquartered in Lancaster, Pennsylvania, withour flagship manufacturing facility in nearby York,Pennsylvania, we produce more than 16 billioncontainer units annually at almost 70 plants in NorthAmerica, Asia, Europe and South America.In 2011, we were acquired by Reynolds GroupHoldings, a leading global manufacturer andsupplier of consumer food and beverage packagingand storage products.At every Graham facility, you’ll have access to adedicated team of designers, engineers and otherpackaging professionals who are obsessed withsolving the industry’s biggest packaging challenges.We’re confident that through close collaborationwith our customers and manufacturing partners,we can bring stability, innovation and customizableservices to our ever-changing industry.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 ABOUT GRAHAM PACKAGING4

OURbeliefsWe are committed to minimizingthe impact of our manufacturing bydesigning innovative products, creatingoperational and recycling efficiencies,empowering our employees to beinformed stewards and leading theongoing mission to preserve ourplanet for future generations.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR BELIEFS5

OUR BELIEFSWHAT WE DOBuilding on a LegacyWe have a long history of providing environmentallyfriendly packaging solutions to our customers.But to remain the partner of choice, we mustcontinuously evolve, keeping social, environmentaland economic sustainability at the forefront ofour daily lives.In our drive for excellence, we have made sustainability a top priority, and welook at everything we do through that lens. When developing a new product, webalance the delivery of a world-class, profitable solution for our customers withthe creation of a product that will have the lowest environmental impact. Whenbuilding our team, we treat every interaction as an opportunity for employeedevelopment and an investment in our future.We believe that every one of us is part of something bigger — from our familiesand communities to wider society and the global environment in which we live.These relationships are interconnected, and any impact on the environment hasthe potential to affect each of us today, tomorrow and in the future.So, as a packaging company — and more importantly, as human beings — wemust consider our planet’s future in everything we do, every day. Whether we’reshaping a bottle, contracting with a customer, sourcing a new resin or hiring a newemployee, we believe it’s an investment in our future and the future of our planet.OUR MISSION IS TO BEAN INDUSTRY-LEADINGSOLUTIONS PROVIDER FORSUSTAINABLE PACKAGING.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR BELIEFS6

OUR BELIEFSNEW OPPORTUNITIESCreating a Circular EconomyWith the technologyavailable today, we canmake a positive globalimpact both sociallyand environmentally.Our packaging already protects andpreserves our customers’ products.Now, we must take a step forward toconsider how it can protect and preserveour planet. Knowing the potential impactour operations and products may haveon today’s environment and that of futuregenerations, we are focused on being partof a broader solution for our employees,customers and communities.We acknowledge the need for a circulareconomy. To be part of the solution, wehave embraced the idea that a responsiblecompany must exist and grow in anenvironmentally, socially and economicallysustainable way. We build success by beingaccountable for bridging the gap betweenprofitability and the ever-changing needsof our planet.In the face of today’s challenges, we believein the relevance of a circular economyand understand that the best outcome forplastics is the reuse of this valuable, finiteresource. Therefore, our first — and mostimportant — contribution to the circulareconomy is to collect and reuse bottlesthat exist today through vigorous recyclingefforts. We’re also committed to workingwith suppliers and customers to test andvalidate chemically recycled and bio-basedplastics. We can use these resourcesto build new packages, both to furtherpreserve nonrenewable resources andto support a circular economy.However, there are bigger steps to be takenon this long, evolving journey. We needto help educate the public on how we canovercome barriers to recycling and pushfor solutions, understanding that withoutdeveloped infrastructure and governmentsupport, it is up to us to look for the bestpossible environmental outcomes.MANUFACTURINGDESIGNESUREReduced environmentalimpact through innovativepackaging solutions.THReduced carbon footprintthanks to everything fromplant-wide operationalsolutions to an increaseduse of recycling.PPL IERLETA IRBest-in-class repurposingefforts that work to helpsave our planet.CO N SUMERONTHE CERRECYCLINGSUGRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR BELIEFSM7

OUR BELIEFSRESPONSIBLE GROWTHFocusing on AccountabilityOur responsibility to our planet and our communities exists inthree intertwined pillars: social, environmental and economicopportunities that we must leverage to carry out our mission.Each of these pillars is itself critical and important, but combined,they underpin the very basis of a sustainable society and planet.ECONOMICDesign for RecyclabilityUse shapes, process technology and designtechnology to promote recyclability, advocatelightweighting and create functional featuresthat minimize the environmental impact ofour packagingInnovationExplore new technologies to reduce oreliminate barriers to recyclability, chemicallyrecycled plastics and bio-based plasticsEfficiencyContinuously improve our operationsby reducing our carbon footprint, whiledeveloping operational initiatives thatpromote more efficient and environmentallyresponsible outcomesENVIRONMENTALSOCIALRecycled ContentPush the boundaries on recycled plasticcontent in our productsSafetyMaintain and improve on our world-classsafety recordAdvocacyLead the ongoing environmental dialogue onplastic packaging and be a constant advocateto increase the recycling infrastructureEmployee GrowthSupport career development, advancementand work-life balancePartnershipDeliver on customers’ sustainability goals,while helping customers and suppliersreduce their environmental footprintReduced Carbon FootprintWork across our organization to minimize ourenergy and water usage, as well as reduceand eventually eliminate our waste to landfillFreight SolutionsExplore freight initiatives that limitgreenhouse gases by reducing the numberof trucks and trains needed to move ourproducts and materialDiversityPromote inclusion and diversity in ourteamIntegrityComply with local laws and regulations,maintaining the highest ethical standardsEducationWork to educate our customers, suppliers,employees and the public on theenvironmental benefits of plastics, and onproduct recyclability and how to recycleWe will continually reexamine this mission and challenge ourselves to produceconcrete and achievable solutions that advance our industry, grow our business andbetter our planet. As we move forward, we will continue to value our people, honor ourcommitments, embrace the highest standards and act with integrity in all that we do.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR BELIEFS8

OUR BELIEFSCore ValuesVALUE OUR PEOPLECreate a safe environment for our team above all. Build our organizationaround a diverse group of innovative people who want to make a positivedifference and create value for their customers. Identify, promote, investin and reward those who do.HONOR OUR COMMITMENTSAct with integrity. Earn the trust of our partners both inside and outside thecompany. Do what we say we will do and deliver what we commit to deliver.BE THE PARTNER OF CHOICEStrive to be a “destination company,” where people want to work, withwhom customers and suppliers want to do business. Be proud, contributingmembers of the communities where we operate.DRIVE FOR EXCELLENCEHold ourselves to the highest standards and never be complacent. Strivefor continuous improvement, learning from our mistakes and the mistakesof others. Add value in everything we do.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR BELIEFS9

OURpeopleCollaborative. Creative. Committed.Our organization is made up of a diversegroup of people who leverage these keyattributes to make a positive differencein the workplace and in their communities.By building strong relationships andcreating value for our customers throughyears of experience, our people embodythe innovative spirit that’s inherent toGraham Packaging.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PEOPLE10

OUR PEOPLECOMMUNITY INVOLVEMENTMaking a Local ImpactAs a global company, we’re fortunate to be able to make an impact in manydiverse communities. To further these initiatives in 2019, we’re creatingsustainability teams that will focus on community outreach to promoterecycling, reduced energy usage and sustainable living. See what ourteams have been up to recently to help their local communities.Mexicali Plant, Mexico Collects food and water for people in needduring earthquakesBelford Roxo Plant, Brazil Raised 440 pounds of food and put together75 gifts for children in a nearby orphanageTlalnepantla Plant, Mexico Donates pieces of outdated equipmentto Fidel Velazquez School for low-incomestudents seeking technical trainingCorporate Office, Lancaster PA Raised 3,100 for the Children’s Miracle Networkin honor of the son of a Graham employee whowas born with complex medical needs C ollected clothing and food items forhomeless veterans in the communityMason Plant, Ohio Participates in the annual Shared Harvest Groupfood drive to help those in the local community,donating 3,089 pounds of food, which created2,574 meals for those in need in 2017GPC International Participated in a tree-planting activityin Portugal during our kickoff meeting E ncouraged employees to commute towork on e-bikes for Earth DayGPC International, Poland Challenges employees to fill up a VolkswagenTransporter for a local food bankTolleson Plant, Arizona Collects food for St. Mary’s Food BankHouston Plant, Texas Has partnered with the Houston Fire Department’sOperation Stocking Stuffer for the past twoyears, and in 2018, their donations helped thefire department collect over 45,000 toys forunderprivileged childrenElwood Plant, Indiana Committed to donating 10,000 toward a 5Kand chili cook-off yearly through our partnershipwith Red Gold Ketchup Participates in an annual blood drive Donates used printer cartridges to local librariesGRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PEOPLE11

OUR PEOPLETRAINING & DEVELOPMENTFocusing on GrowthWe expect our employees to go above and beyond to create value for ourcustomers, and in turn, we want to create value for them. By identifying,promoting and investing in employees who step up, we’ve built a culturethat rewards hard work and encourages our people to grow their skills.Pay-for-Skills ProgramIn 2018, we began a cutting-edge Pay-for-Skillsprogram for our hourly employees. Beginningat our Bowling Green and Altavista facilities, across-functional team of Graham Packaging leadersidentified the specific tasks associated with planthourly employment. From there, they assessed theskills needed to perform each task and determinedthe progress required to be successful at each one.The benefits of the Pay-for-Skills program aretwofold. For our employees, it allows them to taketheir career development into their own hands.They are rewarded for their motivation to completetraining and acquire/validate their skills.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PEOPLEFor our company, it fosters an environment ofengaged management and helps us further developour talented employees. This program also gives usa competitive advantage when recruiting new talentat our many locations.The concept of Pay-for-Skills is based on the modernparticipative management philosophy that today’semployees can’t be recruited, trained and retainedby traditional time-based compensation systems.Rewarding today’s talented candidates requires aprogressive and intrinsic approach that rewardspeople based on their individual talent and skillsacquisition, not how long they’ve been employed.12

OUR PEOPLELitmos Learning Management SystemTo help our employees learn and grow, we needed to find aworld-class e-learning management system that could maximizeengagement and retention, satisfy facility safety initiativesand ensure legal and regulatory compliance. Plus, as a globalcompany, we needed a platform that allowed our employeesaround the world to take courses in many different languages.We selected Litmos as the best option for our organization.What we can do with Litmos: Use the online course builder to create training materials Schedule and track classroom training sessions Develop learning paths, from multiple courses to group trainingsessions Provide assessment to benchmark knowledge retention Get real-time notifications from teams and learners Review performance and gain insight onto training impacts withreports and dashboards Provide surveys to employeesFrontLine Leadership Developmentand FundamentalsWe believe that a company is only as effective as itsleadership. So, we follow the general rule of focusing70% of our leaders’ development on job-relatedexperiences, 20% on interactions with others and10% on formal education.Our FrontLine Leadership program falls into the formaleducation category and consists of an instructor-ledcourse or a three-day session with subject matter expertswithin our organization. This program provides all plantleaders who are new to their role or new to Graham withthe opportunity to develop a deeper understanding of theirrole, including how to drive standardization, reduce cost,build trust and encourage involvement at all levels ofour business.As a result of their participation in this program, ourplant leaders have become more effective in their roles.They’ve built motivating relationships with their teams,while actively dealing with personnel challenges likestagnation and turnover.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PEOPLE13

OUR PEOPLEEthics & ComplianceHonoring our commitments and acting with integrity are two principles that are built intoour company’s core values. We know we must earn the trust of our partners, both insideand outside our company, and to do that, we must comply with all local laws and regulationswhile maintaining the highest ethical standards.We have a well-developed Ethics & Compliance Program embedded in our company cultureand supported by our Litmos e-learning platform. We use both Litmos and in-persontraining to train all relevant employees on our code of conduct, fraud policies and otherspecific training topics, like anti-corruption, anti-bribery, antitrust and privacy. By offeringthis standardized training, we can be sure every employee receives the same information.We also use this platform to periodically reinforce our compliance focus.In addition to our Litmos platform, we have an ethics hotline available, which canbe accessed globally in the languages of the countries where we operate. The hotlineis accessible by phone or online and provides a platform for employees and third partiesto report any potential ethics or compliance concerns. Those concerns are then fed intoour case management system and thoroughly investigated.We take ethics and compliance violations seriously, and we strive to handle any breachof conduct with the utmost care and professionalism.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PEOPLE14

OURproductsThe packaging we make helps popularbrands deliver their goods in a safe,convenient way. From highly creativedesigns to innovative childproofing optionsand everything in between, our team willenvision and produce a customized solutionthat exceeds expectations.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PRODUCTS15

OUR PRODUCTSPLASTIC PACKAGINGUsing Our ResourcesResponsiblyIn recent years, plastic packaging, particularlysingle-use plastic, has received negative attentionin traditional media and on social media. Much of theconversation has been centered around the amount ofplastic in the ocean, the growing number of cities banningor taxing single-use plastics and what steps companiesare taking to reduce their environmental impact.However, when used responsibly, plastic packagingcan lead to reduced pollution and lower energy usagethan other forms of packaging available today.Glass, for example, has been consideredas an alternative, but the energy involvedin producing glass, as well as the freightand fuel costs involved with shipping sucha heavy material, has been a deterrent. Notto mention, glass packaging can lead tobreakage, which results in an increase inproduction downtime and product loss.It’s important to note that some plasticsare easier to recycle than others. PET andHDPE are two of the most common, easilyrecycled plastics. Both PET and HDPEare lightweight, durable and offer designflexibility not found in other plastics. Plus,because of their reduced weight and size,PET and HDPE products can be transportedin higher volumes on fewer trucks.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PRODUCTSThe use of recyclable and reusable plasticpackaging helps create a circular economywhere valuable resources are conservedrather than wasted. By working togetherto preserve these finite resources, we cancontinue to enjoy the many benefits of plasticpackaging, including safer products, moreconvenience, lower prices, reduced energyuse and less product loss.16

OUR PRODUCTSPolyethylene Terephthalate (PET)PET is widely used for packaging food and beverages, like juice, water and saladdressings, as well as personal care and cleaning items like hand soap and spraycleaners. It’s also an approved material for use in pharmaceutical and medicalapplications. PET won’t react with foods or drugs and is resistant to the growthof microorganisms and biological degradation.Though clear and lightweight, PET is also strong enough to endure shippingwithout danger of breakage. Because it’s both lightweight and strong, it resultsin lower transportation costs and more energy efficiency for facilities thatproduce it. Thus, it’s considered more sustainable than glass, aluminum andother packaging materials.Bottle-grade PET is one of the common plastics we use, and it’s our goal that100% of our PET packages be recycled back into bottles or be recovered for use inother plastic products. In 2018, we processed over 550 million pounds of PET resinacross our global facilities.High-density Polyethylene (HDPE)HDPE is used in a variety of applications, from snowboards and outdoor decking tofood and beverage packaging. Thanks to its high strength-to-density ratio, HDPEis ideal for packaging gallons of milk, laundry detergent and other heavy liquids.Plus, its light weight keeps transportation costs low.This material has a high melting point, allowing it to be sterilized by boiling beforebeing used for food and beverages. It also naturally resists mold, microorganisms,acids and even chemicals. Highly malleable, HDPE can be molded into countlesscreative shapes for more shelf appeal.Bottle-grade HDPE is another common plastic we use, and it’s our goal that 100%of our HDPE packages be recycled back into bottles or be recovered for use inother plastic products. In 2018, we processed over 670 million pounds of HDPEresin across our global facilities.IN 2018, WE PROCESSED OVER 550MILLION POUNDS OF PET RESIN ANDOVER 670 MILLION POUNDS OF HDPERESIN ACROSS OUR GLOBAL FACILITIES.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PRODUCTSSPOTLIGHT ONFood WasteEvery year, approximately one-third ofall food produced in the world for humanconsumption is lost or wasted. In fact,when the greenhouse gas emissionsfrom the top 20 countries in the worldwere compared to the emissions fromoverall food waste, it was found thatif food waste were its own country,it would be the third largest emittingcountry in the world.11 This large volumeof waste affects not just the world’s foodsupply, but also the supply of criticalresources like water, land and energy.While food waste may seem like aproblem independent of plastic recycling,these two key issues are closelyintertwined. By replacing glass and othernon-durable types of packaging with rigidplastic solutions, food manufacturers anddistributors can cut down on food wastedue to breakage. Plastic packaging alsoextends the shelf life of foods that wouldotherwise expire.17

OUR PRODUCTSBio-based ResinsBio-based resins are derived either partially or completely from renewable rawmaterials that undergo a chemical reaction to create a new synthetic material.They take the place of traditional resins like polyester, epoxy and polyurethane.We are continuing to research and experiment with bio-based resins that do notcompete with the food chain.Biodegradable ResinsBiodegradable resin is plastic that is actively metabolized by microorganisms likebacteria when left in the natural environment. For example, we have exploredusing potato starch compounded into HDPE. This unique mixture creates a newalloy-like polymeric compound that is recyclable, but for those containers thatslip outside the recycling stream into the environment with microorganisms,the intention is that the entire container will 100% biodegrade. Although we’veexperimented with biodegradable resin, and it sounds like an ideal packagingoption, there are currently several challenges with this technology.First, many of these products are not truly biodegradable. They won’t biodegradenaturally if they slip out of the waste stream into the environment. Most of theseresins need special industrial facilities to process them, and these facilities arenot consistently available. Even where such facilities do exist, many industrialcomposters won’t take biodegradable plastics because of the problems they cancause, like not composting adequately, introducing contamination and hurtingresale quality.Second, the global supply chain is not yet equipped for industrial compostingbecause most facilities can’t adequately sort materials and avoid questionableproducts. For example, some packaging is being produced with compostableresins, but because there is still a mix of materials being used, compost facilitiesare refusing all these containers.8SPOTLIGHT ONGreen Resinat GrahamAbout seven years ago, we partnered with acustomer to create a resin made mostly ofsugar cane, and we became one of the firstcompanies to take this type of product intolarge-scale production. We made roughlythree billion bottles using this bio-basedresin, which is now widely used in the industry.And third, large-scale composting disrupts the recycling stream by promotingthe degradation of plastics that would otherwise be recycled and reused. It isworth noting that biodegradability is a proper solution for packages that are notrecyclable or for those that may slip out of the waste stream into the environment.We believe that biodegradable resins are a second- or third-tier sustainabilitysolution. Our preference is to enable virgin polymers to be used as many times aspossible via recycling and through the management of our internal scrap, whetherthe polymer is from fossil fuels (nonrenewable) or bio-basedmaterials (renewable).GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR PRODUCTS18

OURinitiativesFor us, sustainability is about thinkingglobally and acting locally. We constantlyask ourselves what we can do to makethings better for our customers, ourcommunity and the world. It’s clear thatit will take a collective effort to preserveour planet for future generations, andwe’ll continue to support that effort inevery way possible.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR INITIATIVES19

OUR INITIATIVESSUSTAINABILITY FACTORSMinimizing Our ImpactWe strive to be responsible, purposeful and sustainable at every level of our business.That means taking a hard look at where we are and where we want to go over the nextfive to 10 years. We’ve identified several areas of opportunity that will help us reachour sustainability goals going forward.DESIGN FOR RECYCLABILITYINNOVATIONMinimize the environmental impact of ourpackaging through design focused on recyclability,plus lightweighting and freight optimization.Explore new technologies to reduce or eliminatebarriers to recyclability, chemically recycledplastics and bio-based plastics.PARTNERSHIPEFFICIENCYPartner with customers and suppliers to helpthem reduce their carbon footprint by advocatingfor on- or near-site partnerships.Work tirelessly to develop operational initiativesthat promote more efficient and environmentallyresponsible outcomes.RECYCLED CONTENTCARBON FOOTPRINTPush the boundaries on how much recycledcontent we use in our products.Work across our organization to reduce ourenergy and water usage, as well as reduce andeventually eliminate our waste to landfill.GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR INITIATIVES20

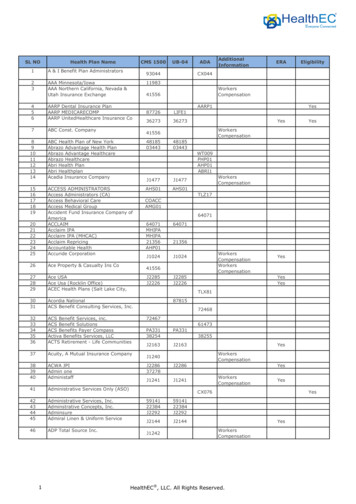

OUR INITIATIVESTHE IMPORTANCE OF RECYCLINGUnderstanding the Big PictureThe plastic boom began in the 1940s when mass-producingplastic items became necessary to support the war effortduring World War II.Since that time, roughly 9.1 billion tons of plastic have been produced across the world.Seventy-nine percent of that plastic has made its way into landfills or the naturalenvironment, while a meager 9% has been recycled.1In the face of those numbers, it’s clear to see that, as a global community, we’ve fallen shortin our efforts to preserve our planet through good recycling practices. It’s time for a change,and getting better at recycling is an easy first step.Recycling Rates Around the World*U.K.43.5%DenmarkWales46.3%63.8%South KoreaGermany66.1%Belgium53.5%59%SwitzerlandHong alySingapore61%Australia41.6%*Global Data2*U.S. Data3GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 OUR INITIATIVESNOTE: Data i

GRAHAM PACKAGING SUSTAINABILITY REPORT 2018 Letter From the CEO About Graham Packaging Our Beliefs Mission Statement 6 Pillars of Excellence 8 Core Values 9 Our People Community Involvement 11 Training & Development 12 Ethics & Compliance 14 Our Products Why Plastic Packaging 16 PET & HDPE 17 Bio-Based & Biodegradable Resins 18 Our Initiatives