Transcription

Sentry Precision SpindlesValue-Priced Sentry PrecisionBelt-Driven SpindlesThe Sentry line is our standard building block spindle and is offered as a low-cost solution for manyapplications that call for a precision, high performance, standard design. Sentry spindles are builttough to deliver years of trouble-free performance. They feature a 100% inch design permanentgrease lubrication, class 7 extra precision steel ball bearings, and can be applied at any attitude:horizontal, vertical, angular, ceiling, and side-mounted attitudes and rotational need.The Sentry line includes 6 models – 1 cartridge and 5 block configurations: C017 Cartridge SpindleB035 Block SpindleB040 Block SpindleB050 Block SpindleB070 Block SpindleB090 Block SpindleSentry C017Cartridge SpindleThe C017 and B035 are the smallest Sentry spindles. Thesespindles are equipped with labyrinth seals. The Sentry C017is our newest cartridge spindle, a drop-in replacement for theGilman 1875.The C017 is available in two basic configurations and offeredwith three spindle nose options and two spindle mountingbrackets. Built to stock, these configurations are offered with1-2 week shipment and a standard one year warranty.The Sentry B035 is our smallest block spindle. Its compact sizemakes it ideal for small work that may require precision boring,drilling, and milling. The B035 is offered with a variety of motordrive packages – up to 3 hp and 9,000 rpm and features 4-6 weekshipment. The B035 is a drop-in replacement for the Gilman 2750.Sentry B035 Block SpindleModels B040, B050, B070, and B090 represent the high end ofthe Sentry precision spindle line. These spindles are equippedwith the patented SETCO AirShield and feature a standard2-year warranty and 6-8 week shipment with standard options.All Sentry block-style spindles are equipped with a cross keywayand jackscrew holes, and can be configured with a variety ofoptions such as triplex and quad front bearing arrangements,a wide assortment of motor drive packages, manual drawbar,and arrangement for through-spindle coolant. Like the B035,these spindles can be equipped with a variety of motor drivepackages – up to 10 hp and 13,500 rpm.Note: Due to continual improvements, specifications are subject to change withoutnotice. For current specifications, request a certified print when placing your order. 2001 SETCO Sales Company.SETCO , SentryTM, and AirShieldTM are trademarks of SETCO Sales Company.2Sentry B035 Spindle withOptional Motor Drive Packagein Motor-front Position

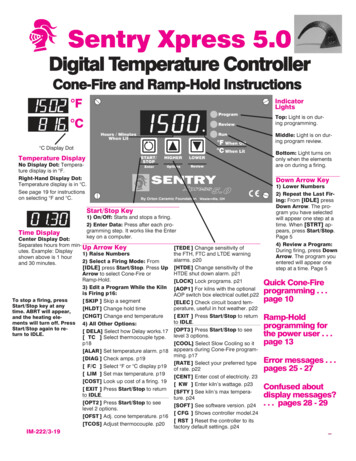

How to Order Sentry SpindlesThe following example identifies the Sentry spindle model code. When ordering a spindle, refer to thischart to specify the desired spindle and option package. The chart below is a matrix of options for thecomplete Sentry spindle Nose TypeNumberof FrontBearingsSpindlerpm/100OptionsMotorrpm/100B BlockC Cartridge1800 183600 36015FMotor hpMotorPosition1.5 hp 01510 hp 100(Block only)(Block only)Example:B - 040 - M - 2 - 50 - D - 18 - 015 - FSentry Spindle ModelFeatures / tridge with Labyrinth SealN/AXN/AN/AN/AN/ABlock with Labyrinth SealN/AN/AXXXXHousing Style/Seal TypeBlock with AirShieldSpindle NoseXN/AN/AN/AN/AN/AArbor (AR)XN/AN/AN/AN/AN/ACollet (CT)XN/AN/AN/AN/AN/AStraight Bore (ST)N/AXXXXXN/AXXN/AN/AN/A#30 NMTB Milling (M)N/AN/AN/AXXN/A#40 NMTB Milling (M)N/AN/AN/AN/AN/AX#50 NMTB Milling (M)Boring (B)Front Bearing ArrangementXXXXXXDuplex (2)N/AXXXXXTriplex (3)N/AXXXXXQuad (4)Brackets, Spindle and Drive Options017 OptionsXN/AN/AN/AN/AN/AClamp S-Type Cartridge Bracket (P)XN/AN/AN/AN/AN/APositioning Nut Cartridge Bracket (N)035 -090 OptionsN/AXXXXXManual Drawbar for Milling Nose (D)N/AXXXXXRotating Coolant Union Arrangement (C)XXXXXXNo Option (N)N/AN/AN/AN/AXXType A – Motor Forward Drive Package (AF)N/AXXXXXType B – Motor Forward Drive Package (F)N/AXXXXXType B – Motor Rearward Drive Package (R)For Details, Call Us Fax Us Log OnTel: 1-800-543-0470 Fax: 1-513-941-6913 www.setcousa.comINDEXAirShield Design. 4Spindle Sizing Chart. 5Spindle Thrust Loads. 6Spindle Models.7Accessories.133

TMPatented AirShield TechnologySETCO’s Exclusive PatentedAirShield Provides the Industry’sBest Spindle Sealing System!TMWith over 600 AirShield-equipped spindles in the field,over 4 years of runtime without a failure, the SETCOAirShield sealing system is the most reliable spindleseal in the industry!As standard, an AirShield-equipped SETCOspindle delivers: 2-year warranty on standard speed spindlesIncreased spindle reliabilityReduced maintenanceIncreased runtimeIncreased productionProtection from coolantingress in dynamicand static modes Corrosion-resistant designU.S. Patent No. 5,727,095, 5,980,115 and 6,217,2192.00 TYP.Standard Precision Run-Outs.001REF. EDGE.001/8" A.0005BCBSee ChartSee ChartSee ChartRUNOUT TOLERANCES (INCHES)BORING PILOTMILLING ameterB035B040See ChartSee Chart.001/8"C

How to Size Your Spindle to the ApplicationSpindle Selection Procedure1. Determine the Power and Speed requirements for the application. Refer to the cuttingdata found in tool catalogs. For assistance, consult the SETCO Application Group.2. Locate the Spindle Speed (rpm) on the chart and follow the line up until it intersectswith the required Power (hp).3. Continue up until it crosses the Spindle Size (model) line. This line is the minimum spindle size.4. Verify that the Tool Overhang, measured from the spindle nose, falls within the maximumfor the 0.5"Ove rhang8.25"4090)B030(in.POWER – hpimTOOLaxOVERMHANG5. For finish bore applications, verify the front spindle bearing is as large as the bore to be machined.20B0701006.0"B 05 00B035 and B040123SPEE4B045D (rp6m x1000)789101112134.75"014B0153 5 3.5"16Note: The maximum rpm noted is based upon grease lubrication and light preload bearing.5

Sentry Spindle Thrust Load vs. rpmThrust Load vs rpmDuplex Bearing – 15 DegreeThrust Load vs rpmDuplex Bearing – 25 B035-0303000Thrust LoadThrust 0150020002500rpm300035004000450050000500THRUST LOAD FORMULADuplex Bearing – 15 40004500500045005000THRUST LOAD FORMULADuplex Bearing – 25 DegreesB035B040B050B070B090TL 7461*rpm- 0.39TL 9640*rpm- 0.39TL 17013*rpm- 0.39TL 26056*rpm- 0.39TL 6545*rpm- 0.33TL 8318*rpm- 0.33TL 15001*rpm- 0.33TL 23592*rpm- 0.33Thrust Load vs rpmTriplex Bearing – 25 DegreeThrust Load vs rpmTriplex Bearing – 15 st LoadThrust 000THRUST LOAD FORMULATriplex Bearing – 15 DegreesB035B040B050B070B090TL 11688*rpm- 0.39TL 15018*rpm- 0.39TL 26618*rpm- 0.39TL 39940*rpm- UST LOAD FORMULATriplex Bearing – 25 DegreesB035B040B050B070B090TL 10634*rpm- 0.33TL 13514*rpm- 0.33TL 24369*rpm- 0.33TL 38325*rpm- 0.33TL Thrust Load6

C017 Cartridge SpindlePlain CartridgePositioning Nut CartridgeShown with Collet NoseShown with .500" Arbor Nose8.904.88Collet Capacity:1/8 to 3/8" Diameter.47Straight Bore 2.508.124.88SET SCREWFLATø 11/32 – THRUø 1/2 C'BORE – .31 DP.4 HOLESPositioning Nut Bracketø 11/32 – THRUø 1/2 C'BORE – .34 DP.4 .00Sentry 017 Specifications34,000 rpm Maximum35 in-lb1/1800 hp/revArbor, Straight Bore, and Collet (1/8" to 3/8")Duplex Class 7, "DB" 17 x 35 mm BallSingle Class 7, 17 x 35 mm Ball140,000 lb/in40,600 lb/inLabyrinth Seal SystemPermanent Grease PackNot Available4.0 lb7.5 lb1 14TYP.38SpeedTorquePower/RevolutionSpindle Nose OptionsFront Bearing ConfigurationRear Bearing ConfigurationStatic Axial StiffnessStatic Radial StiffnessSeal TypeLubricationMotor Drive PackageWeight (Approx.)Spindle CartridgeCartridge and BracketWarranty.471.251.75.69TYP.12 SQ.KEY1.25ø.5000.49951/4-20 SOC.SET SCREW1/4-20 SOC.SET SCREW (3)3.2503.13Mounting:.500" Diameter.50 TYPClamp-Style Bracket.38.12 SQ. KEY1.25ø.5000.49953.38 MIN3.88 MAX.88FLATSERICKSON COLLET NUT ASSEMBLY1" HEX. FOR 200DA SERIES COLLETCOLLET RANGE 1/16 TO 3/8 DIA(COLLET NOT INCLUDED)1.812.00.25 WIDE x .06DP. KEYWAY1.38ø.22.81 FLATS1.75.19MAX.500ø.499.47.50 x 20 RH.FLANGEDHEX NUT11/16 HEX.1.10.82ø1.50.12 SQ. 371.513/32 x 3/64KEYWAY.5000ø .49952.62.75.342.12REF.4.88.50ø2.44 TYP7.88.881.63.375/.376.375/.3761.812.004.00C017 Spindleshown withpositioning nutcartridge andpositioning nutbracket7

B035 Block SpindleSentry Belt-Driven SpindleB035BKeyed Block Style1/4 x 28 THREAD3 HOLES EQ. SPACEDON A ø2.250 B.C.250 SQ. KEY(4) MOUNTING HOLESFOR 5/16 BOLTS1.50.9370ø 000ø.53THRUø 251.384.0004.887.0011.132.75B035M(4) MOUNTING HOLESFOR 5/16 375.633.000.250 SQ. KEY1.50ø0.56THRU2.1262.1243.63#30 NMTB MILLING TAPER2.06ø .6250.6255ø .9370.9365ø1.250GAGEKeyed Block Style2.751.6251.382.75Note: See page 4 for StandardPrecision Run-Outs.4.0004.887.0011.13Note: Erickson 075 collet nose also available.035 TECHNICAL ghtMax.SealType60 in-lb1/1000 hp/rev25 lbLabyrinth*All data is based upon light preload, duplex bearing aticRadialStiffness1 year15,30012.0 lb-in22.46 x 105 lb/inStaticAxialStiffness**2.45 x 105 lb/in**Spindle stiffness calculated using 100 lb radial load applied at the spindle nose.

B040 Block SpindleSentry Belt-Driven SpindleB040BKeyed Block Style(4) MOUNTING HOLESFOR 5/16 BOLTSø 1.50001.5002.375 SQ. DRIVE KEY(2) PLACES 180 APARTON A ø3.500 B.C.3/8 x 16 THREAD(4) HOLES EQ.SPACED ONA ø3.500 B.C.250 SQ. .500.79PILOT5.00.50ø 1.06201.06154.000.500ø4.331.002.5012.4995.00ø .56THRU3.5001.411/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS7.7504.502.0010.0016.38B040MKeyed Block Style#30 NMTB MILLING TAPERø 1.250GAGE(4) MOUNTING HOLESFOR 5/16 BOLTS.250 SQ. KEY2.50.53ø .6250.62551.0001.001.50.500.503.24ø 1.06201.06154.000.500ø4.331.002.5012.4995.00ø .56THRU6.0001.412.500.502.5005.004.383.5001/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS7.7504.5010.0016.382.00Note: See page 4 for StandardPrecision Run-Outs.040 TECHNICAL ghtMax.SealType66 in-lb1/900 hp/rev71 lbAirShield*All data is based upon light preload, duplex bearing ticRadialStiffness2 year13,50017.0 lb-in22.11 x 105 lb/inStaticAxialStiffness**2.57 x 105 lb/in**Spindle stiffness calculated using 100 lb radial load applied at the spindle nose.9

B050 Block SpindleSentry Belt-Driven SpindleB050BKeyed Block Styleø 2.00002.0002(4) MOUNTING HOLESFOR 3/8 BOLTSø .56THRU1.003.000.53ø .0001.001.19KEYS.5005.000.250 SQ. KEY2.50ø4.843/8 x 16 THREAD(4) HOLES EQ.SPACED ONA ø4.000 B.C.3.0012.9996.00.375 SQ. DRIVE KEY(2) PLACES 180 APARTON A ø4.000 B.C.4.0001.331/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS9.0005.002.0011.2517.75B050MKeyed Block Style#40 NMTB MILLING TAPERø 1.750GAGE(4) MOUNTING HOLESFOR 3/8 BOLTS2.501.001.58ø � 1.12451.1240.53.5003.0012.9996.00ø4.84ø .69THRU.63.5005.000.250 SQ. KEY4.504.0001/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS9.0005.0011.2518.002.25Note: See page 4 for StandardPrecision Run-Outs.050 TECHNICAL ghtMax.SealType180 in-lb1/350 hp/rev113 lbAirShield*All data is based upon light preload, duplex bearing taticRadialStiffness2 year11,10030.0 lb-in23.31 x 105 lb/inStaticAxialStiffness**3.20 x 105 lb/in**Spindle stiffness calculated using 100 lb radial load applied at the spindle nose.

B070 Block SpindleSentry Belt-Driven SpindleB070BKeyed Block Style1.00ø ILOT7.00.631.0001.001.19KEYS.500.500 SQ. KEYø 1.99951.99906.000(4) MOUNTING HOLESFOR 3/8 BOLTSø .56THRUø5.833/8 x 16 THREAD(4) HOLES EQ.SPACED ONA ø4.750 B.C.3.5013.4997.00.375 SQ. DRIVE KEY(2) PLACES 180 APARTON A ø4.750 B.C.5.0001.411/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS11.0006.0013.382.1221.12B070MKeyed Block Style#40 NMTB MILLING TAPERø 1.750GAGE(4) MOUNTING HOLESFOR 3/8 BOLTS.500 SQ. KEY3.25.53ø .7500.75051.0001.001.63.500.634.21ø 1.99951.99906.000.500ø5.831.003.5013.4997.00ø .69THRU8.0003.5001.73.503.5007.005.625.0001/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS11.0006.0013.3821.442.44Note: See page 4 for StandardPrecision Run-Outs.070 TECHNICAL ghtMax.SealType974 in-lb1/60 hp/rev187 lbAirShield*All data is based upon light preload, duplex bearing ticRadialStiffness2 year8,00087.0 lb-in27.08 x 105 lb/inStaticAxialStiffness**4.80 x 105 lb/in**Spindle stiffness calculated using 200 lb radial load applied at the spindle nose.11

B090 Block SpindleSentry Belt-Driven SpindleB090BKeyed Block Style(4) MOUNTING HOLESFOR 5/8 BOLTSø 3.00003.00021/2 x 13 THREAD(6) HOLES EQ.SPACED ONA ø6.250 B.C.625 SQ. KEY3.251.007.000.53.500ø7.564.2514.2498.50ø 0.79PILOT8.50.63ø 2.74952.7490.500 SQ. DRIVE KEY(2) PLACES 180 APARTON A ø6.250 B.C.5.7501.551/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS12.5007.5016.0024.002.38B090MKeyed Block Style#50 NMTB MILLING TAPERø 1.06THRU4.13ø 2.74952.7490.53.5001.0001.001.75.750.63ø 1.25001.25057.000.625 SQ. KEY3.25ø7.561.004.2514.2498.50ø 2.750GAGE(4) MOUNTING HOLESFOR 5/8 2.881/2 x 13 THREAD(2) HOLES EACH SIDEADJUSTING BLOCKS16.0024.50Note: See page 4 for StandardPrecision Run-Outs.090 TECHNICAL ghtMax.SealTypeWarrantyrpmMax.(Grease)*2600 in-lb1/25 hp/rev330 lbAirShield2 year6,200*All data is based upon light preload, duplex bearing setup.12SpindleInertiawk 2StaticRadialStiffness273.0 lb-in2 9.65 x 105 lb/inStaticAxialStiffness**6.05 x 105 lb/in**Spindle stiffness calculated using 200 lb radial load applied at the spindle nose.

Accessories: Motor DriveType ‘B’ Belt Drive PackagehpThe Type ‘B’ Belt Drive Packages provide a complete drive systemfor the Sentry series precision spindles. Mounted on the rear of thespindle housing is an integral belt guard/mounting bracket with motormounting plate having screw type belt adjustment. Belt guard/mountingbracket allows for mounting of the motor toward or away from thespindle nose. Belt and pulleys are included to provide a wide range ofincremental operating speeds for the application. The motor plateaccommodates ‘C’ - face mounted motors.1.523Motor AdjustingScrewNote: Specifymotor mountingposition whenordering.ADrive 7.44MForwardRearwardMotorSize Frame Size SpindleSize(max.)SpindleNC*C–1Standard–Vendor Dependent*C Non-NEMA Arbor LengthType ‘A’ BeltDrive PackageDrive PackageThe Type ‘A’ Belt Drive Packages are offered on modelsB070 and B090 for motors of 15, 20, and 25 hp. Mountedon the top of the spindle housing is an adjustable motormounting plate that controls belt tensioning. Belt andpulleys are included to provide a wide range of incrementaloperating speeds for the application. Motor plateaccommodates foot-mounted 070B090B070B090ABB-2M17.386.75 3.38 2.1220.658.50 4.25 2.88N0.1222.65 10.25 5.12 3.8824.91 10.75 5.38 3.88Note: This is a“Custom Option”and may extendlead time.Motor AdjustingScrewMounting PlateBelt DriveRatio (Max.)254T2 to 1256TSpindleType ‘A’ TypicalMounting with HSSeries HardenedWay Slide13

Accessories: Standard Sentry Drive 040540060016750SpeedRatioModel1.5 to 11.25 to 11 to 11 to 1.251 to11 to 1.251 to 1.51 to 1.761 to 11 to 1.121 to 1.251 to 1.3851 to 1.51 to 1.6361 to 1.761 to 1.8751 to 21 to 2.0831 to 2.251 to 2.3641 to 2.5SpeedRatioModel2 to 11.333 to 12 to 11.333 to 11.5 to 11.2 to 11 to 11.714 to 11.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.251 to 1.41 to 1.51 to 1.6671 to 1.8752 to 11.333 to 11.5 to 11.2 to 11 to 11.714 to 11.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.251 to 1.41 to 1.51 to 1.6671 to 1.8751.5 to 11.2 to 11 to 11.714 to 11.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.251 to 1.41 to 1.51 to 1.6671 to 4500482051915400SpeedRatio2 to 11.333 to 11.5 to 11.2 to 11 to11 to 1.1881.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.21 to 1.2671 to 1.3331 to 1.4621 to 1.61 to 1.7311 to 1.8461 to 1.9231 to edRatio2 to 11.3 to 12 to 11.3 to 11.529 to 11.182 to 11 to 11 to 1.1541.444 to 11.3 to 11.182 to 11.083 to 11 to 11 to 1.0771 to 1.251 to 1.3391 to 1.4421 to 1.52 to 11.3 to 11.529 to 11.182 to 11 to 11 to 1.1541.444 to 11.3 to 11.182 to 11.083 to 11 to 11 to 1.0771 to 1.251 to 1.3391 to 1.4421 to 1.51.529 to 11.182 to 11 to 11 to 1.1541.444 to 11.3 to 11.182 to 11.083 to 11 to 11 to 1.0771 to 1.251 to 1.3391 to 1.4421 to 2 to 11.333 to 12 to 11.333 to 11.5 to 11.2 to 11 to11 to1.1881.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.21 to 1.2671 to 1.3331 to 1.4621 to 1.61 to 1.7311 to 1.8461 to 1.9231 to 21.5 to 11.2 to 11 to11 to 1.1881.5 to 11.333 to 11.2 to 11.067 to 11 to 11 to 1.1111 to 1.21 to 1.2671 to 1.3331 to 1.4621 to 1.61 to 1.7311 to 1.8461 to 1.9231 to 2Note: Standard Type ‘B’ drivepackages. For Type ‘A’packages consult factory.Speed based on no-loadmotor rpm. Specificationssubject to change withoutnotice. Custom drivepackages are availableas a “Custom Option.”Consult factory.

Accessories: Coolant Union & DrawbarAccessoriesRotating Coolant Union ArrangementAvailable on all Sentry series super precisionspindles. Rotating coolant unions allow the coolantto enter by way of the rear of the spindle shaft andflow through the spindle to the tooling. Requireshole through and machining of spindle shaft toaccommodate mounting of union (standard iscustomer-supplied, or SETCO can provide).øXTHREADSAvailable as straight through or 90 union. Specifyleft-hand or right-hand thread.THREADX.65565/8 X 18S.28.6560Note: Specify direction of spindle rotation viewing rear of spindle.Other makes and styles of unions are available upon request.Manual DrawbarXX–1Commonly used for manual retention of milling taper adapters per ANSI B5.18.HEXMTHREADM–1SSIZE30THREAD.50 -13M1.2540.62 -111.50501.00 - 61.001.250.502.501.62Call Us Fax Us Log OnTel: 1-800-543-0470 Fax: 1-513-941-6913 www.setcousa.com15

YOUR SINGLE SOURCEFor Repair, Rebuild, Exchange, New – Plus a Total Range ofRelated Services to Enhance Your Just-In-Time ManufacturingPRODUCTSDovetail SlidesLinear RecirculatingBearing SlidesHardened SteelWay SlidesGrinding Spindlesand AccessoriesBoring and MillingSpindlesSentry Belt-DrivenSpindlesSpindle/SlideCombinations3-Axis MachiningModulesProMetrix BeltDriven SpindlesSmart Closed-LoopMotorized SpindlesSERVICESTotal Solution TeamEngineeringField Service andVibration AnalysisState-of-the-ArtSlide RepairComplete In-HouseManufacturing, AssemblyLeading EdgeSpindle RepairHands-On Spindle andSlide Repair TrainingTel: 800/543-0470 Fax: 513/941-6913www.setcousa.comPublication S-0005-1Printed in U.S.A. 5M 1201 MC

Value-Priced Sentry Precision Belt-Driven Spindles The Sentry line is our standard building block spindle and is offered as a low-cost solution for many applications that call for a precision, high performance, standard design. Sentry spindles are built tough to deliver years of trouble-free performance. They feature a 100% inch design permanent