Transcription

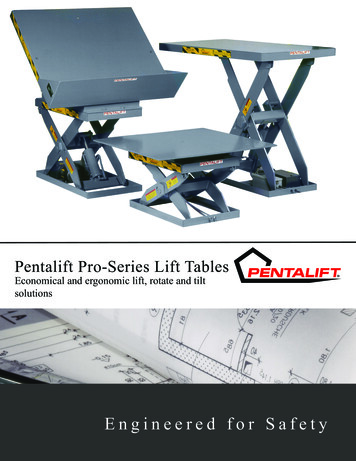

Pentalift Pro-Series Lift TablesEconomical and ergonomic lift, rotate and tiltsolutionsEngineered for Safety

Pentalift Pro-Series lift, rotate and tilt tablesPentalift equipment corporation, the recognized industry leader in the manufacturing of positioning solutions, manufacturesthe Pro-Series line of lift, rotate and tilt tables. Pentalift Pro-Series lift, rotate and tilt tables are a streamlined range of tablesavailable for quick delivery. They create a safe, efficient workplace that increases productivity and reduces the potentialof cumulative trauma disorders. Cumulative trauma disorders result when employees perform repetitive motions or workin awkward positions for extended periods of time. They are the leading occupational hazard for workers. Cumulativetrauma disorders lead to increased medical and workers' compensation costs, high absenteeism and low employee morale.Using Pentalift Pro-Series lift, rotate and tilt tables in the workplace immediately increases safety, productivity andemployee morale while preventing costly injuries. Pentalift manufactures the highest quality equipment in the industry. Awarranty is the reflection of a company's confidence in a product and their commitment to customer satisfaction; compareour extensive warranty, design and construction features with others and you will discover another reason why Pentaliftis your best choice. To immediately gain the benefits of a Pentalift ergonomic solution, simply provide the maximumweight, the physical size of the product to be handled and your product positioning requirements.Adjustable height Pro-Series lift tables fit a multitudeof applications. They increase the overall efficiency andsafety of the work station by maintaining an appropriateheight in relation to the operator and the process.Awkward repetitive bending and stretching motions thatcause cumulative trauma disorders are eliminated.2

Pro-Series lift table incorporating a manual rotating topHaving both lifting and rotating features at a palletizing station enhances efficiency, safety and worker morale. Productpositioning eliminates repetitive bending, stretching and worker maneuvering actions which lead to fatigue and injury.Pro-Series lift table incorporating a platform-mountedtilt tableProduct is lifted and tilted into the most advantageous ergonomic position. A wide range of positioning capabilities eliminatesbending, stretching or reaching to load/unload product.Pro-Series tilt table installed on a structural floor standassembly.3

Pentalift Pro-Series Lift Table Construction FeaturesDesign ContinuityPentalift Pro-Series lift tables are engineered with "component compatibility" logic. Each component isdesigned and utilized in relation to all other components and how they work together to increase the tables'performance. The end result is the most reliable and superior lift table available in the industry.Platform assembly: High tensile steel, formed platformwith rounded edges is supported by heavy-dutystructural beam sections. Beams are positioned toprovide superior strength and load distribution.Scissor legs: Hightensile, ASTMA572, 50 ,000 PSIyield, heavy steelplate, one piececonstruction scissorlegs are engineered formaximum strength andplatform rigidity.Shipped complete: Finished product,power unit, controls (standard pushbutton control shown to right) and allother components are factory load testedand shipped fully assembled, completewith hydraulic fluid.4Pivot points: are precisionreamed for accuratealignment and inspected forquality conformance. Allpivot points utilize precisionpins and lubricated-for-lifebearings for the industry'smost maintenance-free,reliable operation.Base frame assembly:Structural angle base-frameassembly with pre-drilledlag down provisionsprovides rigid support andallows simple and safeinstallation.

Pentalift Pro-Series lift table model and sizing selection chartModel 777-1/2777-1/2VerticalRaisedTravelHeight 55-1/2Platform size (in)W X L (in)StdMax24 x 3648 x 6024 x 4848 x 7224 x 6448 x 8824 x 3648 x 6024 x 4848 x 7224 x 6448 x 8824 x 3648 x 6024 x 4848 x 7224 x 6448 x 88FrameSizeW X L (in)24 x 3624 x 4824 x 6424 x 3624 x 4824 x 6424 x 3624 x 4824 x 64Lift Time(sec)approx111924142431284961No 60870Included in base units: self-contained hydraulic power unit 1- 1/2 Hp 208-230-460-575/3/60 c/w TENV motor, pre-wired NEMA 12motor controls, PentaFLOW bypass cylinder(s), pre-wired NEMA 12 push button on 10 ft of straight cord, reservoir filled with oil,lagging brackets on frame. All Pro-Series lift tables are to be fastened to floor. If these models and sizes do not fit your specificneeds, contact a Pentalift Sales Representative for information about our application designed equipment.Exclusive PentaliftHydraulic CylinderThe lift cylinder is the heart on any hydraulic lift system, Pentalift’sexclusive design ensures the longest cylinder life, reduces maintenance andeliminates oil spills.Here’s How it works:Pentalift’s PentaFLOW cylinder is completely sealed from thesurrounding atmosphere and all components are continuously bathed infresh oil. Contamination and deterioration of the cylinder cannot occur.When the cylinder reaches full extension, the bypass valve opens andallows oil to flow through the piston to the rod side of the cylinder, outthe port, and back to the reservoir. This prevents the cylinder from deadending and building high stresses in the cylinder, equipment structure andhydraulic system. Air in the cylinder is automatically removed throughthe bypass valve eliminating the need for manual bleeding which oftenresults in oil spills and contamination.Note: Precision turned, ground, polished and chrome plated cylinder rodand “drawn over mandrel” precision honed barrels are standard on allPentaFLOW cylinders.Oil under medium pressure Port P (oil from Pump)Oil under low pressurePort T (oil to Reservoir)Pentalift Pro-Series lift tables optionsToe sensor:Positioned around the bottomperimeter of the platform, electrically interlockedcontact sensor bars instantly stop the downwardplatform movement if any objects are contacted inthe lowering path.Accordion bellows: Steel reinforced , pleatedyellow vinyl barrier minimizes the entry of debrisunder the lift table.Other options (not shown with photo) Non standard platformsHydraulic velocity fuse Larger power units forincreased lift speedsPneumatic power units Up / down travel limit switchesBevel toe guards for pitmountingRemote power units Single phase power units Semi-portable:(Table not to be moved whenloaded.) Frame mounted rollers and removabledolly handle allow easy lift table movementto various work stations and more thoroughwork station clean-up. Semi-portable designconfiguration does not allow side/end edge loadingand is to be used with evenly distributed loads only.Guarded foot pedalcontrol: Guarded foot pedalcontrol station, designed to freeoperator's hands.5

Pentalift Pro-Series manual rotating topErgonomic solution which smoothly and safely rotates the work to theworker. Ideal solution to eliminate reaching or unnecessary operatormovements during palletizing, depalletizing, work station assembly ormanufacturing operations. Unlike other manufacturers ' designs , PentaliftPro-Series manual rotating tops incorporate a countersunk central capscrew to ensure the top platform cannot be accidentally lifted, removedor misaligned during load positioning or removal.Available options (not shown) Manually operated platform stop. Metal shaftlocks rotating top at 90 increments.Spring activated detent stops clw spring loadedball transfer. Automatically engages every 90 to stop rotation of platform.Spring loaded rotator lock. A positive springand lever style detent will lock every 90 .Note: Manual rotating top to be fastened to stablesurface through four mounting holes suppliedin the base plate.Guidelines for selecting Pro-Series manualrotating tops for Pro-Series lift tables: Manual rotating tops can be installed onstandard Pro-Series lift table platform sizes. Pro-Series manual rotating tops shall beinstalled on Pro-Series lift tables by Pentalift. All manual rotating tops designed to work withevenly distributed loads (center of gravity ofload within 10" of deck center). When specifying a manual rotating top forinstallation on a Pro-Series lift table , reducethe Pro-Series lift table capacity by 500 lb toaccount for the weight of the manual rotatingtop.6Shown with optional Accordion Bellows.Heavy duty central thrust bearing and a minimum of 8 rollerbearings ensure quiet and low effort operation.A countersunk central cap screw to ensure the top platformcannot be accidentally lifted, removed or misaligned duringload positioning or removal.Pentalift Pro-Series manual rotating top model and sizingLowModel CapacityHeightNo(lb)(in)RP36252- 7/16RP4225 2,5002- 7/16RP48252- 7/16RP36402- 7/16RP4240 4,0002- 7/16RP48402- 7/16RP36602- 7/16RP4260 6,0002- 7/16RP48602- 7/16Platform SizeW X L (in)MinStdMax36 x 3636 x 3641 x 4136 x 4242 x 4247 x 4736 x 4848 x 4848 x 4836 x 3636 x 3641 x 4136 x 4242 x 4247 x 4736 x 4848 x 4848 x 4836 x 3636 x 3641 x 4136 x 4242 x 4247 x 4736 x 4848 x 4848 x 48FrameSizeW X L (in)31 x 3131 x 3131 x 3131 x 3131 x 3131 x 3131 x 3131 x 3131 x d in base units: 2-7/16" overall height, 360 dual-direction rotating steelplatform, minimum of 8 roller bearings ensure quiet and low-effort operation. Centerpivot consists of heavy duty thrust roller bearing and countersunk cap screw to holdtop platform down , preventing accidental lifting and removal of platform duringload positioning or removal.If these models and sizes do not fit your needs, contact a Pentalift salesrepresentative for information about our application designed equipment(highlighted on back page).

Pentalift Pro-Series tilt tablePentalift Pro-Series lift table with Pro-Series tilt tableinstalled . Pro-Series tilt table pivots on rolling end ofPro-Series lift table platform for maximum safety andstability.Ergonomic design positions components within easy reach ofthe operator. By eliminating repetitive bending and reaching,cumulative trauma disorders are reduced and productionefficiency is immediately increased. Tilt up to 6,000 lbs withease, efficiency and safety.Pentalift Pro-Series tilt table top models and sizingModel ltLowCapacity AngleHeight(lb)(Deg) (in) Min2,5004,0006,00030 30 45 45 30 30 45 45 30 30 45 45 777777777777Platform SizeW X L (in)Std30 x 4430 x 4830 x 4430 x 4830 x 4430 x 4830 x 4430 x 4830 x 4430 x 4830 x 4430 x 4844 x 4450 x 5044 x 4450 x 5044 x 4450 x 5044 x 4450 x 5044 x 4450 x 5044 x 4450 x 50Max48 x 4850 x 5448 x 4850 x 5448 x 4850 x 5448 x 4850 x 5448 x 4850 x 5448 x 4850 x 54Frame TiltShipSize Time WeightW X L (sec)(lb)(in)Approx24 x 44 952024 x 44 962024 x 44 1454524 x 44 1464524 x 44 954524 x 44 964524 x 44 1457024 x 44 1467024 x 44 1257024 x 44 1267024 x 44 1859524 x 44 18695Pro-Series Tilt Table with structuralfloor stand.Included in base units: 7" low height, 1-1/2 Hp 208-230-460-575/3/60 clw TENV motor, selfcontained under table, pre-wired NEMA 12 motor controls, PentaFLOW bypass cylinder, pre-wiredNEMA 12 push button on l0 ft of straight cord, reservoir filled with oil, lag holes on frame, 12" highbackstop.If these models and sizes do not fit your needs, contact a Pentalift sales representative for informationabout our application designed equipment (highlighted on back page).Note: Pro-Series tilt tables and Pro-Series lift tables with Pro-Series tilt tables installed are to befastened to the floor for maximum safety and stability.Guidelines for installing Pro-Series tilt tables on Pro-Series lift tables: Pro-Series tilt tables shall be installed on Pro-Series lift tables by Pentalift. Pro-Series tilt table can be installed on standard Pro-Series lift table platform sizes, Pro-Series tilttable platform width not to exceed 50 inches. When installed on a Pro-Series lift table, the Pro-Series tilt table's power supply cord will be routedto the base of the Pro-Series lift table by Pentalift. Capacity of the Pro-Series lift table must be equal to or greater than the Pro-Series tilt table capacityplus the weight of Pro-Series tilt table. When tilting, consideration must be given to the load being tilted. Unusual loads with unfavorablecenters of gravity when tilting could create a safety hazard.Available options (not shown) Non-standard platforms. Special height backstops. Larger power units for fastertilt speeds. Remote power units. Pneumatic power units. Guarded foot pedal control. Hydraulic velocity fuse. Accordion bellows. (See descriptions on Page 5)7

An ergonomic solution for every applicationIn addition to the Pro-Series line of lift, rotate and tilt tables featured in this brochure Pentalift Equipment Corporationoffers positioning solutions to suit unique applications. Contact a Pentalift sales representative for details. To view ourspecial positioning equipment capabilities use this internet link www.pentalift.com/lift-tables/lift-tables.php"Our Primary Goal is to engineer and build the best products to ensure the ultimate in user safety and product reliability"Paul PedersenPresidentPentalift Equipment CorporationIndividual product catalogs are available and can also be found on our website.Pentalift also manufactures a complete line of loading dock equipment.Note: Some photos may reflect products with optional features. All Pentalift Equipment Corporation products are subject todesign improvement through modification without notice.Pentalift Equipment CorporationP.O. Box 1060, Guelph, ON N1H 6N1 Canada P.O. Box 1510, Buffalo, NY 14240 – 1510 USAPhone: (519) 763 3625 Fax: (519) 763 2894www.pentalift.com0214L040 Printed in Canada

Pentalift Pro-Series lift tables are engineered with "component compatibility" logic. Each component is designed and utilized in relation to all other components and how they work together to increase the tables' performance. The end result is the most reliable and superior lift table available in the industry. Shipped complete: Finished product,