Transcription

Lift Tables Hydraulic & Pneumatic Floor Level / Roll-On Heavy-Duty / High Capacity Tandem Wide & Long Extended Vertical Lift Portable & Powered Traverse Popular Options & Accessories Custom Engineered Lift SolutionsFeaturingNow featuring Quick Ship Lift Tablesmaking work faster, safer, and easier since 1890

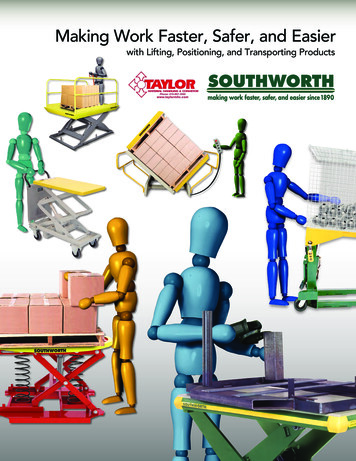

Southworth. The Lift Table ExpertsSouthworth is the world’s leading supplier ofvertical movement and positioning equipmentwith the broadest product lines, largestinventory of stock models, most flexible rangeof modification, most experienced customdesigners and the industry’s leading innovator.Our lift table line is the broadest in the industry.It includes: Standard Duty Lift TablesLite Duty Lift TablesPortable Lift TablesHand Pallet Truck Accessible LiftsPalletizing LiftsTilting Lift TablesCoil and Roll Handling LiftsTandem LiftsExtended Vertical Travel LiftsExtreme High Capacity LiftsTABLE OF CONTENTSLS Series Backsaver Lift Tables . . . . . . . . . . . . . . . . . . . . . 4LST Series Tandem and Wide Base Tandem Lifts . . . . . . 7Backsaver Lite Lift Tables. . . . . . . . . . . . . . . . . . . . . . 4LSH Series Spacesaver Extended Vertical Travel Lifts . . . . 8LS Series Plus High Capacity Lifts - 6,000 - 12,000 lbs. . . 5Pneumatic Lift Tables . . . . . . . . . . . . . . . 9LS Series Wide Base Lifts . . . . . . . . . . . . . 5Palletizing Lifts (ZLS Series, LiftMat & Roll-In) . . . . . . . . .DL Series Heavy Duty Lifts - up to 20,000 lbs . . . . . 6Popular Options & Accessories . . . . . . . . 10-11L-Cam Heavy Duty Lifts. . . . . . . . . . . . . . . . . . . . . . . . . . . 6Custom Lift Solutions Gallery . . . . . . . . . . . 129The World's Best Vertical Work Positioners Shipped in Three Weeks or Less!QualityPriceBest ValueLowest Ownership CostOur SwiftLift initiative employs modern engineering,materials planning and manufacturing technology todrastically reduce production lead times allowing us toship many products in one week or less! But SwiftLiftis much more than just a stocking program. It puts lifttables, palletizers, container tilters, portable lifts and moreinto three availability categories. So now you can createthousands of pre-engineered equipment configurations aswell as some custom variations for shipment in an industrybest three weeks or less.Best PerformanceBest Warranty 2019 Southworth Products CorpWhat You NeedWhen You Need ItStock - Ships in One Week or Less - More than 50configurations of Lift Table, Container Tilter, PalletLevel Loader, and Portable Lift Models.Modified - Ships in Two Weeks or Less - Includes severalpopular options plus any platform size up to 72” x 96”.Modified - Ships in Three Weeks or Less - Virtuallyunlimited configurations including the addition of anystandard option and even light customization.Look for this logo with product families that are part of theSwiftLift program. Many models are available for quick shipment2Availability

Quality Features For Reliabilty and Long LifeContoured LegsComfort Edge DesignWith extra width at thepivot point, Southworth’scontoured legs combinegreat strength with lowercollapsed height.No sharp cornerson table top. Brightsafety yellow stripefor high rque TubesAll pivot points havehardened pins thatoperate in lubricated-forlife, virtually maintenancefree bushings.Torque tubes minimizeplatform twisting anddeflection for high degreeof rigidity and stability.Heavy-Duty HosesTell-Tale ReturnHydraulic Fluid LineAll Southworth liftshave heavy-duty hoseswith burst strength 600%greater than the hydraulicoperating pressure.Oversize, Low-PressureHydraulic CylindersLow operating pressureextends the life of hydraulic components. Chromeplated piston rods arecorrosion resistant, andcylinder walls are honed.Built-In Safety ChockPrevents accidentallowering of tableduring maintenance.Southworth Scissors Lifts are designed andmanufactured to meet or exceed ANSI MH29.1Safety Requirements for Industrial Scissors Lifts.Clear plastic return linefrom cylinder rod bearing to tank gives visualindication of need torepack cylinder andprevents fluid spillagein the event of a bypass. Adjustable Flow ControlPressure compensated flowcontrol valve with lock out.Preset and locked at 10F.P.M. maximum loweringspeed per ANSI Standard,MH29.1 where applicable.Wear Indicating Rollersand Roller RetainersRollers are captured in thebase by means of retainers toprevent accidental separationor misalignment.All oversized widthtabletops also includean upper set of retainers.3

Backsaver Lifts and Backsaver Lite LiftsLS Series Backsaver LiftsSouthworth Backsaver Lifts are extremely ruggedand reliable machines. Thousands of BacksaverLifts are in use throughout the United States formachine feeding, work positioning, assembly,order picking, pallet loading, and a wide rangeof other applications. They are available in manybasic sizes and configurations with capacities upto 6,000 lbs and lift heights up to 56". The widerange of power options, controls, tabletops, andbase configurations that can be specified foreach of the many basic sizes gives the user analmost unlimited choice of variations.LS Series Backsaver LiftsBacksaver Lite LiftsThese industrial grade lift tables arespecifically designed for those applicationsinvolving lighter loads of up to 1,500 lbs.They are available in four standardconfigurations: Stationary, Compact withhigh lift and small footprint, Portable witheasy rolling casters, and Powered Portablewith battery powered drive.SwiftLiftModel No.Capacity(Lbs.)VerticalTravel(Inches)LL & LS Series Backsaver Lite Lifts 0LS05-30WLS1-305501100150055011005005001000LS Series Backsaver Lifts2626352626303030CLL SeriesPortable LiftsLL SeriesLite LiftsCompact LiftsLS05 / LS1HeightMin.Max.(Inches) nches)ElevatingTime(Seconds)51 251 261 49966620 x 3620 x 3624 x 4824 x 4024 x 4012 x 2416 x 2416 x 2436 x 6036 x 6036 x 6030 x 4830 x 4812 x 2424 x 3624 x 3692132713202020311 2311 2411 43535363636LS2-2420002463 4303 424 x 3648 x 6014303 424 x 3648 x 6028LS4-2440002463 4LS6-2460002473 4313 424 x 3648 x 6044LS2-3620003663 4423 424 x 4848 x 7221 LS4-3640003663 4423 424 x 4848 x 7242 LS6-3660003671 4431 424 x 4848 x 7222 LS2-4820004885624 x 6648 x 969 LS4-4840004885624 x 6648 x 9618 LS6-4860004885624 x 6648 x 9627LS2-24W20002463 4303 436 x 3660 x 6014LS4-24W40002463 4303 436 x 3660 x 6028LS6-24W60002473 4313 436 x 3660 x 6044LS2-36W20003663 4423 436 x 4860 x 7221LS4-36W40003663 4423 436 x 4860 x 7242LS6-36W60003671 4433 436 x 4860 x 7222LS2-48W20004885648 x 6672 x 969LS4-48W40004885648 x 6672 x 9618LS6-48W60004885648 x 6672 x 9627Lifts with 3.2 HP three-phase power units available with 1 HP single-phase power units. Rise time increases by a multiplier of 3.3. 4HPStandardVoltage 2 21 21 21 21 21 21 2115/1/60115/1/60115/1/6012 volt DC12 volt 3/6011

LS Series Plus LiftsFor applications that require additional capacity orlarger platforms, LS Series Plus lifts are the perfectchoice. They can be supplied with capacities up to12,000 lbs. and platforms as large as 60”x 156”.LS Series Wide Base LiftsFor even larger platforms up to 8 feet wide,choose an LS Series Wide Base Lift.HeightMin.Max.(Inches) 63 47910108101010101210101430 x 6030 x 6030 x 6024 x 5624 x 5624 x 6624 x 8624 x 8624 x 8624 x 8624 x 8630 x 10230 x 10230 x 10230 x 12030 x 12030 x 12054 x 8454 x 8454 x 8448 x 8448 x 8448 x 9648 x 12048 x 12048 x 12048 x 12048 x 12060 x 13260 x 13260 x 13260 x 15660 x 15660 x 3/60460/3/60460/3/60LS8-36W80003694542 x 6066 x 84213.2LS10-36W1000036104642 x 6066 x 84283.2LS12-36W1200036104642 x 6066 x 84283.2483 442 x 5666 x 84491LS3-42W30004263 4LS5-42W50004274942 x 5666 x 84741LS8-48W80004895748 x 6672 x 96303.2LS2-60W200060107054 x 8684 x 120203.2LS4-60W400060107054 x 8684 x 120203.2LS5-60W50006086854 x 8684 x 120293.2LS6-60W600060107054 x 8684 x 120303.2LS8-60W800060107054 x 8684 x 120423.2LS2-72W200072108260 x 10296 x 132243.2LS4-72W400072108260 x 10296 x 132383.2LS6-72W600072128460 x 10296 x 132413.2LS2-84W200084109460 x 12096 x 156353.2LS4-84W400084109460 x 12096 x 156523.2LS6-84W600084149860 x 12096 x 156563.2Lifts with 3.2 HP three-phase power units available with 1 HP single-phase power units. Rise time increases by a multiplier of 460/3/60460/3/60460/3/60460/3/60460/3/60Model No.Capacity(Lbs.)LS Series Plus 08000200040006000200040006000LS Series Wide Base 27272848484454646483 4495770706870708282849494985

Heavy-Duty DL Series Lifts, L Series Cam Lifts andDL Series LiftsThese heavy-duty lifts are ideal for cargo handling andlifting heavy industrial loads. Built-in hydraulic overloadrelief protects personnel and structures. Heavy-plateplatforms with structural reinforcement minimize deflectionwhile the wide base provides increased rigidity and stability.L Series CAM LiftsExclusive CAM design provides maximum capacities (up to30,000 lbs.) with minimum height clearances.DL Series LiftsL Series CAM LiftsDL Series - Pit MountedDL Series Heavy-Duty LiftsModel 06060606072848484Top ageApprox.ShippingWeight/Lbs.(std. platform 2 81 21 23 83 81 21 21 21 23 83 83 tageApprox.ShippingWeight/Lbs.(std. platform)48 x 7854 x 7860 x 9060 x 9072 x 96283 4 x 60303 4 x 60341 2 x 701 2341 2 x 701 241 x 701 (Inches) nches)16131 4141 41616161622262212161652611 4621 4647676768286949610010060 x 7647 x 7660 x 7660 x 7660 x 10260 x 10260 x 10260 x 12072 x 14472 x 14460 x 12060 x 12060 x 12096 x 10884 x 10896 x 10896 x 10896 x 14496 x 14496 x 14496 x 144108 x 180108 x 18096 x 15696 x 15696 x 156HeightMin.Max.(Inches) (Inches)StandardPlatform(Inches)75 8991 2101 8111 430 x 6032 x 6036 x 7236 x 7243 x 7213L Series CAM LiftsModel 636435 845451 2461 8471 4

Tandem Lifts – Long and Wide BaseTandem LiftsLST Tandem lifts provide level rise for long loads such aslumber, pipes, sheets, bar stock, and assemblies. These liftsare typically used as feeding tables for tube welders, formers,and panel saws as well as for bundling and banding bar stock,lumber, and other materials.Tandem design allows the combination of high capacity andlow collapsed height to support loads up to 7’ x 17’. They areavailable in extra long and extra wide configurations.LST Series Tandem - WideLST Series Tandem - LongLST Series Tandem - Conveyor TopLST Series Tandem LiftsModel )HeightLST 4-36LST 8-36LST 12-36LST 4-48LST 8-48LST 12-48LST 4-60LST 8-60LST 10-60LST 636364848486060606063 463 471 48881010810Max.(Inches)423 4423 4431 eApprox.ShippingWeight/Lbs.(std. platform)24 x 9624 x 9624 x 9624 x 13224 x 13224 x 13224 x 17224 x 17224 x 17224 x 17248 x 12048 x 12048 x 12048 x 16848 x 16848 x 16848 x 20448 x 20448 x 20448 x 0502550270028502850LST Series Wide Base LiftsModel )LST 4-36WLST 8-36WLST 12-36WLST 4-48WLST 8-48WLST 12-48WLST 4-60WLST 8-60WLST 10-60WLST 3636364848486060606063 463 471 rdVoltageApprox.ShippingWeight/Lbs.(std. platform)423 4423 4431 45656567070687036 x 9636 x 9636 x 9648 x 13248 x 13248 x 13254 x 17254 x 17254 x 17254 x 17260 x 12060 x 12060 x 12072 x 16872 x 16872 x 16884 x 20484 x 20484 x 20484 x 35024503250340035503550HeightLifts with 3.2 HP three-phase power units available with 1 HP single-phase power units. Rise time increases by a multiplier of 3.3. The listings above representSouthworth’s most popular tandem lift arrangements, however, practically any lift models can be tandemized end to end or side by side - Consult Factory.7

Spacesaver High Rise Lifts and Personnel LiftsSpacesaver LiftsLSH Spacesaver lifts can be used as personnel work platforms, as cargolifts, between levels as mezzanine lifts, and for positioning test apparatus ortools. These lifts are available with vertical travel up to 12 feet. Capacitiesrange from 1,000 to 12,000 pounds.LSH Series High Rise LiftLSH Series Modified use as Personnel LiftLSH Series Spacesaver High Rise LiftsModel )LSH 1-36LSH 1-48LSH 2-48LSH 4-48LSH 6-48LSH 1-60LSH 2-64LSH 5-60LSH 8-60LSH 12-60LSH 1-72LSH 2-72LSH 5-72LSH 2-84LSH 4-84LSH 6-84LSH 1-96†*LSH 3-96LSH 5-96LSH 10-96LSH 2-114LSH 5-120*LSH 3-128LSH 6-128LSH 2-144*LSH 4-144*LSH 696961141201281281441441441091 291 21214101 2121 2141418121 2123 414171717171 417172017242121242421†811 4” Lateral motionHeightMax.(Inches)46571 2571 26062701 2761 2747478841 2843 4861011011011131 4113113116131144149149168168165*Three sets of legs–All others have pingWeight/Lbs.(std. platform)24 x 3224 x 4024 x 4030 x 4232 x 42**24 x 4824 x 5330 x 5330 x 5436 x 6720 x 5320 x 5332 x 57**33 x 6933 x 6933 x 6924 x 5336 x 7736 x 7736 x 7733 x 8844 x 69***42 x 9642 x 9642 x 7742 x 7742 x 10836 x 4836 x 5436 x 5448 x 6048 x 6036 x 6042 x 6648 x 6648 x 6660 x 8436 x 6636 x 6654 x 7260 x 9060 x 9060 x 9042 x 6660 x 10860 x 10860 x 10860 x 10872 x 9672 x 12072 x 12072 x 10872 x 10872 x 5045004000** Base frame width 30***Base frame width 42

Pneumatic, Floor Height & Palletizing LiftsPneumatic LiftsFor use anywhere that shop air is available. Capacitiesup to 4,000 pounds. No hydraulic fluid means norisk of contaminants in the production process.Floor Height LiftsThese lifts lower to floor height or near floor heightso that they can be fed and offloaded by hand pallettrucks. Capacities range from 2,000 to 6,000 pounds.Lifts for PalletizingSouthworth manufactures a wide variety of Lift Tablesfor use in palletizing applications including LiftMat andRoll-In Lifts. See our Pallet Handling Brochure for acomplete selection.LiftMat Low-Profile LiftPneumatic LiftZLS Floor Height LiftLiftMat with TurntableRoll-In Palletizing LiftPneumatic LiftsModel SI)Free 0242488323236 x 4848 x 4848 x 6060 x 6015 (empty)15 (empty)80 psi/15 cfm80 psi/15 cfm650800(std. platform)ZLS Series Floor Height Lift TablesSwiftLiftModel geZLS2-35ZLS4-35ZLS6-3420004000600035353449 - 671 449 - 671 453 - 711 432-5032-5032-5048484873 473 485 8 83 81 250 x 4850 x 4850 x 48454863111115/1/60115/1/60115/1/60 3Approx.ShippingWeight/Lbs.(std. platform)142514401865LiftMat Series Low-Profile Lift TablesModel 28 1 431 4311 224 x 6648 x 96201115/1/60600(std. platform)LiftMat Series Low-Profile Lift Tables with Built-in TurntableModel ndardVoltageApprox.ShippingWeight/Lbs.LM2.2-28 TT1950281 441 8323 848 x 6048 x 96201115/1/60700(std. platform)Roll-In LiftsModel hippingWeight/Lbs.ROLL-E 2.2-28ROLL-U 2.2-2822002200283 8283 831 431 4311 2311 249 x 571 249 x 571 222221.01.0115/1/60115/1/607007009

Lift Tables Options and AccessoriesPopular Lift TableOptions and AccessoriesWhen you purchase a SouthworthLift Table, you get exactly what youwant, without any compromise.Southworth’s standard line of lifttables offer well over one milliondifferent configurations that meetthe vast majority of applicationneeds. In addition, the wide rangeof options and accessories shownin this brochure allow you tospecify tables that precisely meetyour lifting and positioning needs.Your Southworth distributor willbe happy to assist you in selectingoptions and accessories to meetyour specific application.One Touch/Auto LevelRaise or lower the lift a presetincrement at the touch of abutton. User Programmable.Toe Sensing EdgeSensor automatically reverseslowering motion on contact.Flush Mount TurntablesAre only 3 16” higher than thesurrounding platform. Turntablecan rotationally locked when thelift is in the full down position.Wheels and CastersFor a variety of portabilityrequirements includingpowered and semi-live portableto suit any environment.Bellows SkirtingCover mechanism betweenplatform and base. Protectsvital lift or tilter componentsfrom damage caused by debris.10Popular Lift Table Options for: ControlSafetyConveniencePortabilityMachine Protection

Hydraulic/Actuation OptionsLarger Power Units*Higher horsepower motors andhydraulics used to increasetravel speed.Manual Hand or Foot Pump ActuationLever type hand pump or foot pedalpump for use when manual actuationor precise positioning is required.Minimum Downdrift Valving*Near positive shut-off valving foruse where platform must maintainposition for extended periods of time.Continuous Duty Power Units*Specially designed power units withmotors capable of many motor startsper hour.Air Motor Driven Power UnitsFor use where electrical actuation isundesirable and shop air is available;meets explosion proof requirements.Cross Check Valving*Locks oil in cylinders to eliminatedeflection caused by oil transfer. Usedin certain side loading applications.Continuous Running Power Units*Heavy-duty power units with specialcooling features. Power unit runscontinuously, and valves are actuatedto activate lift. For extreme high cycles.Screw Jack*Lift is actuated by gear motor drivenworm or ball screw. For more precise,repetitive positioning or wherehydraulics are not desired.DC Power UnitsDirect current power units for usewith battery power.Power Units Full JIC StyleContinuous Running Power Units*Continuous running power unit builtto JIC specifications.Double Acting Cylinders*For special applications where it isnecessary to provide both power upand power down.Hot and Cold TemperatureHydraulic PackagingSpecial sealing and hydraulic fluids foruse in hot or cold atmospheres.External Power Unit*Power unit is connected to liftonly by hydraulic hoses.No Coast Valving*Fast acting hydraulic valving, whichdecreases upward coast, for use wheremore precise positioning is desired.Air Bag ActuationInflatable air bag provides limitedtravel lift actuation. Used whereelectrical power is not desirable orwhere only two positions are required.Velocity Fuse(s)/Excess Flow ProtectorsHydraulic control prevents table freefall in the unlikely event of massivehydraulic failure.Electronic Control OptionsWall Mounted Push ButtonPermanent wall mounted controls foruse where a fixed operating stationis desirable.Maintained Contact ControlsUp/down/emergency stop pushbutton control which stops travelautomatically at preset level. (Controlbutton does not have to be held.)Special NEMA Rated Electrical Packages*A variety of electrical packagesdesigned to meet NEMA standardsfor outdoor, explosion proof, and otherinstallation requirements.Electrical Travel Limit Switch(es)Stops travel, provides heightpositioning, and can activate otherequipment. Use with mechanical stopfor fixed lowered height.Automatic Leveling PackageOptical sensing control positions tableand stops travel at any preset height.Electrical Quick DisconnectQuick disconnect plugs for use withportable or frequently relocated lifts.Visual or Audible SignalsLights or bells used to warnpersonnel when lift is in operation.One-Touch Auto LevelingIncrease productivity in repositioningapplications. Raise or lower lifts a specificincrement at the touch of a buttonPortability and Transport OptionsMechanical OptionsNarrow BaseReduced width base to fit specialneeds. Must be lagged for stability.Lifting EyesSteel eye bolts allow table to belifted with hoist. Frequently used inpit mounted applications for ease ofinstallation and maintenance.Wide BaseIncreased width base provides extrastability for wider loads.Lag PlatesPermanently attached plates orangles with bolt holes for laggingtables to floor.Powered TraverseHydraulic motor drives two wheels ona single shaft via a chain and sprocket.Sub BasesExtra base unit increases low height ofstandard designs. Provides a positivestop at predetermined down level.Increased Roll Over CapacityStructural strengthening of tablesupport for use in pit installationswhere trucks or transporters traversethe platform in its lowered position.Vee Groove WheelsSteel wheels with groove for use withinverted angle or Vee track to provideunidirectional horizontal movement.Semi-Live PortableWheels at one end of base and pullplate at the other, plus wheeled jackhandle. Used only for moving table to anew position, not for load transport.Flanged WheelsSteel wheels with flange for use withflat or rail track to provideunidirectional horizontal movement.CastersA variety of casters, mountingarrangements, and floor locks isavailable for use where full portabilityand maneuverability are desired.Push BarHand height bar to facilitate manualmovement of wheeled or casteredportable units.Platform OptionsManual or Powered TurntablesBearing mounted and supportedturntables for rotating or positioningloads of work.Vee Cradle PlatformVee shaped platform providescentering and secure handling ofcylindrical loads,such as rolls.End-Shifting PlatformManual or powered platform end-shiftused to align loads with other handlingsystems or operating equipment.Gravity or Powered Conveyor TopsRoller conveyor tops for integrationwith other handling equipment orsystems.Tilting Tops30 , 45 , and 90 tilting platforms forbetter positioning of certain loads.Fork PocketsStructural fork pockets allow entire unitto be lifted and moved by fork truck.Ball Transfer TopFixed or retractable ball conveyors foromnidirectional movement of loadon platform.Throw-Over PlatesHinged plates used to provide abridge between the platform surfaceand an adjacent fixed height surface.Access PlateRemovable or hinged plate inplatform surface allows access topower unit and hydraulics when liftis in lowered position.Stainless Steel PlatformCorrosion and damage resistant surfacefor use with corrosive materials orwhere frequent wash down is required.Fixed and RemovableHandrails with Snap ChainFor applications involving personnellifting. Removable rails allow accessfrom any side when lift is not in use.Bellows Accordion SkirtingSingle-ply stitched polyester skirtingcovers mechanism between platformand base. Also available as boots tocover cylinders only.Anti-skid Platform SurfacesDiamond tread platform surface orabrasive type paint provide bettertraction for powered vehicles andreduce danger of personnel slipping.Counterweighted Wheel ChockRecessed in table top. Automaticallyengages as lift raises and preventsvehicle from rolling in set direction.Bevel Toeguard30 bevel on platform sides provideswarning contact without abrupt shearpoint when lift table is installed in pit.Toe Sensing EdgeAutomatically reverses lift on contactwith any obstruction.Special PaintCustomer specified paint formulationsand colors. Corrosion Protection similarto that of Hot Dip Galvanizing.Cam Follower Rollers*Low friction leg rollers for increasedefficiency and longer operating life.High Duty Cycle and Greased Manifolds*Special bearing packages andregreasable pivot points for moderatelyhigh and high duty cycle applications.Environmental OptionsExport BoxingMeets special packaging andshipping requirements for exportout of the United States.* Because of the high performance of standard tables, most asterisked options may not be required in normal usage.To avoid unnecessary cost, please consult factory before specifying these options.11

Custom Lifts and Lifting SolutionsNo other manufacturer has as much experience designing and buildingcustom lifting solutions as Southworth. Whether it’s extended vertical travel,massive platforms, or super high capacity, we’ve designed and built it. Butour expertise goes well beyond just higher, bigger and stronger lifts. Wecreate custom solutions with power traverse, computer integration, multi-axispositioning and much more. So whatever your lifting and positioning needs,you can rely on Southworth to provide the best possible solution.making work faster, safer, and easier since 1890Southworth Products CorpP.O. Box 1380, Portland, ME 04104-1380TEL: (800) 743-1000 FAX: (207) 797-4734www.SouthworthProducts.comemail: salesinfo@SouthworthProducts.comLTC 7 2019Printed in U.S.A.

Our lift table line is the broadest in the industry. It includes: Standard Duty Lift Tables Lite Duty Lift Tables Portable Lift Tables Hand Pallet Truck Accessible Lifts Palletizing Lifts Tilting Lift Tables Coil and Roll Handling Lifts Tandem Lifts Extended Vertical Travel Lifts Extreme High Capacity .