Transcription

TECHNICAL DATA SHEETAirJet 486 CRDCHAMBERREFLOW and SOLDERING PARTS cleaningwww.dct.cleaningwww.dct.cleaning

TECHNICAL DATA SHEETAirJet 486 CRDGENERAL INFORMATIONThe AirJet cleaning systems represent uniqueair-bubbling technology developed and manufacturedby DCT.Air-bubbling technology machines are developedfor gentle yet highly efficient maintenance cleaningof reflow and wave soldering machines suchas soldering frames, filters, heat exchangers, etc.The AirJet “Piano” can also be offered for the removalof conformal coatings. AirJet cleaning systems are availablein several sizes and with different levels of automation of thecleaning process.AirJet 486 CRD including 100% separated processesof cleaning, rinsing and drying technologies.All processes are automated and take place in 3 separateprocess chambers, which are also storage tanks.Cleaning takes place in the first inlet chamber, where theoperator places the basket with parts. Then the operatormanually moves the basket with the cleaned parts into thesecondary rinse chamber. The operator then moves thebasket to the last drying chamber.All 3 chambers can be used in parallel, which increasesthe machine’s cleaning capacity and reduces crosscontamination when compared with single-chamber devices.The AirJet 486 CRD is designed for the maintenancecleaning of reflow ovens and wave soldering machines.Depending on your cleaning requirements, the DCT projectmanager, in collaboration with a local distributor, will adviseyou on a suitable water-based cleaning fluid and the correctsetup of the entire process.Depending on your cleaning requirements,the DCT project manager, in collaborationwith a local distributor, will advise youon a suitable water-based cleaning fluidand the correct setup of the entire process.www.dct.cleaning2

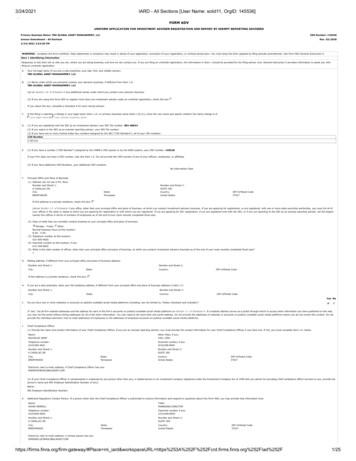

TECHNICAL DATA SHEETAirJet 486 CRD3 INDIVIDUAL PROCESSESCCLEANINGRRINSINGDDRYINGDRCCLEANING low and soldering partsLEGEND:highly recommended*Recommendedtemperature30 – 50 Crecommended86 – 122 FTotal cleaningprocess timeCapacityper 8 hours35 min.192 **applicablePCB eurocards / per 8 hours (calculated for dimension of 100 x 160 mm / 3.94 x 6.3 in)* * Parts in soldering palette / per 8 hours (320 x 500 x 50 mm / 12,6 x 19,7 x 1,97 in)* * * Stencils, pumpprints larger than 736 x 736 mm / 29 x 29 inwww.dct.cleaning3

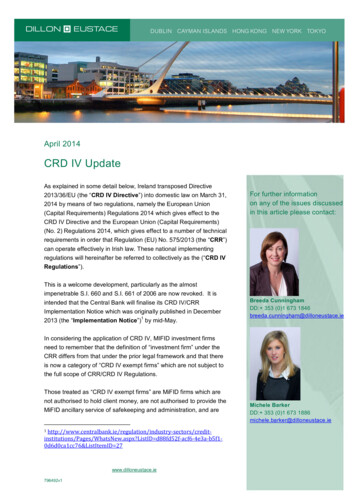

TECHNICAL DATA SHEETAirJet 486 CRDTECHNICAL PARAMETERSmetric unitsimperial unitsDimensions (w x l x h)1800 x 1080 x 1150 mm70.8 x 42.5 x 45.3 inWeight310 Kg683 lbsØ energy consumption per cycle1,65 kWh1.65 kWhCleaning and rinsing fluid consumptionper cycle0,05 – 0,3 l0.01 – 0.08 galCompressed air consumption per cycle83 l / 5 Bar21,93 gal / 72.5 PSIMax. dimensions of the cleaned parts400 x 800 x 600 mm15.75 x 31.50 x 23.62 inTemperature range setting of the cleaningand rinsing fluidFrom ambient temperature to 60 CFrom ambient temperature to 140 FTemperature range setting of the dryingFrom ambient temperature to 80 CFrom ambient temperature to 176 FNoise level 70 dB 70 dBDevice controlPLC 4,3“ touchscreenPLC 4.3“ touchscreenVolume of the storage tanks (clean, rinse)100 l26,42 gal600 mm23.6 in1150 mm600 mm600 mm23.6 in23.6 in45.3 in600 mm23.6 inDIMENSIONSwww.dct.cleaning1800 mm1080 mm70.8 in42.5 inMINIMUM SERVICE SPACEAROUND THE MACHINE4

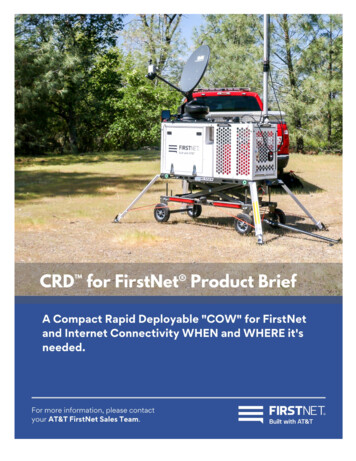

TECHNICAL DATA SHEETAirJet 486 CRDINSTALLATION REQUIREMENTSmetric unitsimperial unitsPower supply400V, 32A, 50Hz* (3 N PE)400V, 32A, 60Hz* (3 N PE)Pmax9,5 kW9.5 kWCompressed air connectionPipe Ø 6 mmPipe ID 0.24Recommended working pressure2 – 4 Bar29 – 58 PSICompressed air quality3. Class **3. Class **Exhaust pipe diameterØ 100 mmID 3.94 inExhaust pipe capacity380 m3/h13 400 ft3/hodMinimum liquid for first run2 x 50 l2 x 13,21 galService space required around the device600 mm23.6 in* When using frequency convertor** According to the norm ISO 8573-1BACKVIEWchimneypressure air inlet 1x Ø 6 mmpressure air inlet 1x Ø 0,2 mm730 mm28.7 in409 mm16.1 inel. power input154 mm6.1 inwww.dct.cleaning5

AirJet 486 CRDTECHNICAL DATA SHEETSTANDARD HARDWARE EQUIPMENT3 process chambers – manual solutionCleaning and rinsing fluid heatingHot air dryingEmergency stop buttonManipulation wheels – lockablePLC controller 4,3“ touchscreen displaySpare parts (base kit)STANDARD SOFTWARE EQUIPMENTStandard software language mutation – CZ, ENGLiquid and filter replacement notification – cycle countingPossibility of 3 programs – setting option3 levels of logging – operator, maintenance, engineerwww.dct.cleaning6

AirJet 486 CRDTECHNICAL DATA SHEETOPTIONAL HARDWARE EQUIPMENTDrip tray – ESD floor protectionControl of external exhaust ventilatorOther optional equipment - the complete list of optional accessories will provide you DCT or the local distributor.OPTIONAL SOFTWARE EQUIPMENTAdjustable timer of cleaning fluid heatingLanguage mutation (CZE, ENG, GER, POL, CHI, RUS, ITA, SPA, MAY, HUN)ONLINE access to cleaning deviceOPTIONAL ACCESSORY – FRAMES AND OTHERSMechanical basket with folding handleMechanical holder for basketMechanical basketwww.dct.cleaning7

TECHNICAL DATA SHEETAirJet 486 CRDDCT QUALITYAll of the InJet , AirJet and Sonix cleaning systemsdeveloped by DCT are characterised by the highestquality on the market, high reliability, ease of use,simple maintenance, an extremely long lifespan, andthe longest warranty on the cleaning system market.These afore-mentioned benefits are achievedby the precise manual production of the machinesin the Czech Republic, and thanks to the superior qualityof the used materials and components.Cleaning systems boast a unique all-stainless-steelconstruction, which is welded manually from AISI 304and AISI 316 stainless steel and then chemically passivated.The cleaning systems are designed and manufacturedwith a focus on ease of use by operators, simplemaintenance, and smart process parameter setting.They are equipped with industrial PLC IDEC, a wellarranged colour touch display with 3-level access (operator,maintenance, engineer), and with 5 adjustable cleaningprogrammes as standard.Monitoring of the cleaning process history, whetheroffline or online, is ensured by an optional traceabilityfunction.A wide range of standard hardware and softwareequipment is available for every cleaning system.However, DCT also excels by its flexibility whenresolving non-standard machines and their accessories.Our machines, together with our cleaning fluidsand local application and technical support, bringyou a long-term reliable, powerful and stablecleaning process, even under the most demandingcontinuous operation conditions.With all its cleaning systems, DCT offers a wide rangeof hardware and software equipment, special frameswith hitches for the parts you want to clean, and countlessvariants in addition to the basic process monitoring optionswhich use traceability.The device automatically and permanently checks allprocesses, operating fluid levels and processtemperatures, and also gives timely notification of theneed to replace individual consumables or fluids.STAINLESSSTEELDESIGN: For more information, a list of optionsand a selection of suitable equipment,please contact a DCT specialist in yourcountry or the manufacturer directly.main support framestorage tanksprocess chambersfluid and air distribution systemsspray arms and nozzlesmechanical high-capacity filtersprocess chamber door frame and handleexternal shieldingactive filters for rinsing DI water100%STAINLESSSTEELDESIGNAISI 304/316Date of issue: 10/2021InJet is a registration trademark of DCT Czech s.r.o.DCT Czech s.r.o., Tovární 85, 679 21 Černá Hora, Czech republice-mail: info@dct.cleaning, www.dct.cleaningwww.dct.cleaning8

The AirJet 486 CRD is designed for the maintenance cleaning of refl ow ovens and wave soldering machines. Depending on your cleaning requirements, the DCT project manager, in collaboration with a local distributor, will advise you on a suitable water-based cleaning fl uid and the correct setup of the entire process.