Transcription

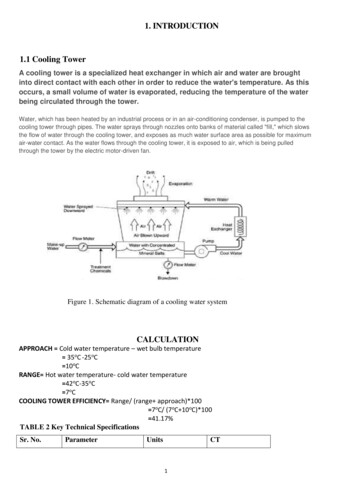

Marco J. Shmerykowsky, P.E.The 5 Times Square tower is a 40-story high-risebuilding located at the intersection of SeventhAvenue and 42nd Street in the “Bow Tie” district of New York City's Times Square. TheAll photos byMarco J. Shmerykowsky, P.E., courtesyof SCE/ShmerykowskyConsulting Engineers.tower, which is approximately 565' tall, contains 1,000,000 rentable sq. ft. of office space and100,000 sq. ft. of retail space.Modern Steel Construction / December 2001

One of the major challenges on this projectwas the foundation system. Just like manyNew York City towers,the 5 Times Square site is bordered bythe New York City subway. The engineers must be very careful in the design of the foundation system to avoidtransferring the tower's foundationloads into the subway structure. Thecloser the building and the deeper thesubway, the more of a challenge thistask becomes.The 41st Street side of the 5 TimesSquare tower foundation wall is approximately 2’-0” from the adjacentsubway structure. The bottom of thesubway, in turn, is approximately60’-0” below grade level and 30’-0”below the second cellar level. Consequently, a deep foundation system wasneeded to safely transfer the towerloads from the tower columns to a levelbelow the subway structure.The 5 Times Square Tower is fortunate to sit on Manhattan Shist bedrock.While it is good from a structural perspective, it is very difficult to excavate.Furthermore, the proximity of the siteto the subway and a historical landmark building on the west propertyline dictated that blasting could not beused. Consequently, the system wentthrough three phases of design evolution. In the initial scheme, the intentwas to use 24” diameter caissons. Although these large caissons had adequate capacity, it became difficult toefficiently locate them while accounting for New York City code and TransitAuthority’s placement requirements.The alternative solution was to excavate large concrete piers down tobelow the bottom of the undergroundsubway structure. While this was a diLeft: Transfer truss on tower’s west side looking north.Above: View of the west face of the tower looking south.rect engineering solution, the highquality of the bedrock on the sitewould have made efficient excavationwithout blasting difficult.The final solution consisted of highcapacity 10” diameter mini-caissons.These caissons were composed of a12” diameter steel shell, high strengthconcrete and a core of reinforcing bars.The small size of the caissons alloweda placement pattern that minimizedthe eccentricity of each caisson grouprelative to the line of the load from eachtower column. Furthermore, the smallcaissons allowed the contractor to usefaster drilling equipment, which delivered less energy to the surroundingrock.The caissons are used along the entire 41st Street side with the exceptionDecember 2001 / Modern Steel Construction

of the southwest corner column adjacent to the New Amsterdam Theater.Due to the high axial loads and its corner location, the placement of an adequate number of caissons under thiscolumn was not practical without imposing a large eccentricity on the foundation system. To address this issue, alarge concrete pier was built at this location down to the bottom of the subway. This direct load path allowed forthe tower’s column load to be transferred below the subway, while avoiding the costly construction whichwould have been required to properlytransfer a large additional eccentricityin tight quarters.Computer AnalysisAs with all modern complex projects, the design of 5 Times Square madeextensive use of computer analysis anddesign techniques. A key aspect to thiscomputerized work was to avoid placing complete reliance on a single tool.In addition to finite element based programs such as SAP90 and ETABS, several custom design programs andcommercially available structural programs were used. This resulted in acompartmentalized approach to theAbove: View of east side elevation.Left: Caisson installation at south end of tower.computer design and analysis and allowed the structural engineer to maintain full control over the designprocess. This approach also allowed fora method of independent consistencychecking where the results of multipleprograms and hand calculations can becompared to ensure that the results arereasonable. For example, the preliminary lateral analysis was accomplishedthrough the use of several two-dimen-Modern Steel Construction / December 2001sional models using the SAP90 analysis program. The final analysis wasdone using a three-dimensional modeland the ETABS program. The initialtwo-dimensional analysis provided anexcellent benchmark for verifying theoverall accuracy of the more complexanalysis.In addition to the various tools usedduring the design of the structural system, extensive use of the computer was

also made in the detailing phase of thebuilding. In order to ensure that thebuilding properly “closed” and that thearchitect’s high complex multidimensional geometric parameters whereproperly achieved, the entire structuralframe was modeled in three-dimensions in the computer. This allowed thedetailer to identify all complex connections in a virtual environment prior tocutting or drilling a single piece ofsteel. In the construction of a buildingwith complicated geometry such as 5Times Square, this approach was extremely beneficial.The Lateral Load Resisting SystemThe structural lateral load resistingsystem selected for this building can bebest described as a “modified perimeter tube system.” Traditionally, a building of this size would use a centralbraced core as part of the lateral loadresisting. The costs for fabricating anderecting a braced system tend to bemuch lower than for a comparably performing moment frame system. Thedown side of such a system is that theamount of usable floor space is reduceddue to the large size of the bracingmembers, which must be installed inthe building’s core. Since rentablesquare footage is such a highly prizedasset in the New York City office market, minimizing the area needed for thelateral system and therefore reducingthe core size became a high priority andchallenge to the design team at the initial stage of the project. By moving thelateral system to the perimeter of thebuilding, the design team achieved thegoal of maximizing the rentable squarefootage.The system itself is a modification ofa traditional “tube” system, which usesclosely spaced columns, typically 6’ to12’ on center, and deep spandrel girders around the entire perimeter of thestructure. The north and south faces ofthe lateral system are composed of W14columns, which are spaced at 10’-0” oncenter and are linked by W36 windgirders.The “modification” to the traditional tube system exists in the east andwest faces. These sides of the toweralso utilize W14 columns and W36girders. Since these sides are longerthan the north and south faces, it waspossible to increase the column spacingon the center three bays to 30’-0”. TheTypical view of perimeter truss system between 2nd and 3rd floor.longer spans allowed the architects toutilize a larger column free viewingarea while still retaining many of thestructural benefits of traditional tubesystem.Some of the columns at the lowerfloors are large built-up members.These sections ranged from 24” deepby 20” wide I-shapes composed of verythick plate material to four 30” deep by20” wide “box” columns. The boxcolumns are located at the northeastcorner of the site and work in combination with the second floor perimetertruss system to transfer the tower’snortheast corner column at the secondfloor. The transfer makes possible thecreation of a column free space, whichlooks out onto New York’s famousTimes Square.The Core and Floor SystemThe selection of the perimeter lateralsystem was not the only component,which contributed to the ability to design such an efficient and tight core. Tominimize column sizes, the majority ofthe core columns consist of W14 sections conforming to ASTM A572, grade65, while the perimeter columns areW14 and built-up sections conformingto ASTM A572, grade 50. Since thetower uses a perimeter lateral system,the controlling factors in the selectionof the perimeter moment frame members are lateral loads and drift control.Foundation excavation looking at southeast corner of site.December 2001 / Modern Steel Construction

Consequently, the perimeter lateralsystem columns and the interior gravity columns tend to work at differentstress levels. This in turn leads to differential shortening of the columnsunder load. In order achieve a desiredlevel floor upon the completion of construction, it was necessary to lengthencertain column lifts. This lengtheningwas designed so that as the building isgradually loaded, the beam-to-columnconnections at a given floor level willarrive at the same final elevation.The typical floor system consists ofa 21/2” of normal weight concrete over3” composite metal deck, which spansbetween W18 floor beams. The maininterior girders, into which the floorbeams frame, were given special consideration in order to produce a cost effective floor design. Since these girdersspan nearly 44’, deep W33 memberswere selected. In order to properly accommodate the mechanical system,which was installed in the ceilingspace, penetrations were provided inthe girders. The cost saving wasachieved by sizing the girders so thatcostly reinforcing of the openingswould not be required.In addition to the typical floor construction, there are several areas wherea heavier floor system was implemented to meet the specific needs ofthe building. The most notable area isthe Con Edison transformer vaults.Due to the tight nature of the site andthe close proximity of the subway lines,it was not feasible to install the transformers in the more typical sidewalkvault spaces. The solution was to construct the six vaults and network protector rooms at the southern end of thethird floor. The concrete vaults themselves were specifically designed as perCon Edison requirements, which stipulated that in addition to other designloads, the concrete structure needed tobe capable of withstanding a heavyblast load should any of the transformers explode. This resulted in a massivereinforced concrete box structure supported on a cradle of W16 and W21beams spaced 5’-0” on center. In addition to the reinforced concrete vaults,various sections of the slab needed tobe constructed in “layers” to accommodate the installation of electro magneticshielding and waterproofing. The basicfoundation of this multi-layered floorconstruction consisted of a 21/2” nor-View of the north side elevation looking south.mal weight concrete on top of 3” composite metal deck.The Transfer TrussAnother key aspect of the tower is afull story high transfer truss whichspans nearly 90’-0” and picks up theload from three of the towers “bustle”columns, located on the west side ofthe building. Below the eighth floor,these “bustle” columns would have become interior columns. In order to create a cleaner column free space, a largetruss was built into the perimeter moment frame between the eighth andninth floors. This allows the overallsystem to continue to benefit from themodified tube system while economically transferring the loads.This 90’-0” transfer truss was designed almost entirely of W14 wideflange sections. The top chord of thetransfer truss consists primarily ofheavy W14 sections of ASTM A572grade 50 steel. The vertical and diagonal members range from small W14sections to large W14 members. Thebottom chord of the truss uses custombuilt-up reinforced wide flange sections, sized to accommodate the truss’sclose proximity to the perimeter facade. The nominal section falls withinthe dimensional parameters of a heavyW14 section. The center span of thebottom chord reinforces this built-upsection through the addition of 2” thickflange plates.A similar system was used betweenthe second and third floors to transfercolumn loads. At this level diagonalmembers, typically consisting of four6x6x3/4 thick angles, were added to theperimeter frame to create a belt andsuspenders system consisting of moment connections and a typical trusssystem. The members which create the“bottom” and “top” chords of this hybrid system consisted of the W36 moment frame girders which form themajority of the tower’s perimeterframe.Transfer FloorIn addition to the transfer truss, thetower has an additional transfer systemat the 25th structural floor level. At thislevel, 12 of the tower’s perimeter moment frame columns at the southeastcorner are transferred through the useof a series of W40 and W36 girders,which average 42” in depth. Thelargest girder in this system is aW36x848. The horizontal shear forcesin the columns are transferred from theupper segment of the modified perimeter tube to the lower segment of the lateral system though the use of ahorizontal truss system.The modified tube system adoptedfor the 5 Times Square tower serves as

a practical structural system for supporting the elegant lines, angles andfolds created by the architect whileminimizing the impact on rentablesquare footage. The construction of the5 Times Square Tower in one of theworld’s most famous and well knowncity centers is an example of the marriage between innovative engineeringand architectural design.OWNER & DEVELOPER:Boston Properties, Inc.,New York CitySTRUCTURAL ENGINEER:Thornton-Tomasetti / Engineers,New York CityARCHITECT:Kohn Pedersen Fox, New York CitySTEEL FABRICATOR:Helmark Steel Inc., Wilmington,DE (AISC member)STEEL ERECTOR:Helmark Steel Inc., Wilmington,DE (AISC member)STEEL DETAILER:DOWCO Consultants, Vancouver,Canada (AISC & NISD members)SOFTWARE:Sap90, Etabs, RAMFrame,RAMAnalysisJanuary 2001 / Modern Steel Construction / 29

Marco J. Shmerykowsky, P.E. All photos by Marco J. Shmerykowsky, P.E., courtesy of SCE/Shmerykowsky Consulting Engineers. The 5 Times Square tower is a 40-story high-rise building located at the intersection of Seventh Avenue and 42nd Street in the "Bow Tie" dis-trict of New York City's Times Square. The tower, which is approximately 565 .