Transcription

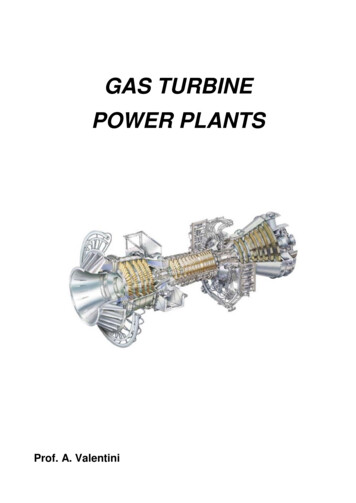

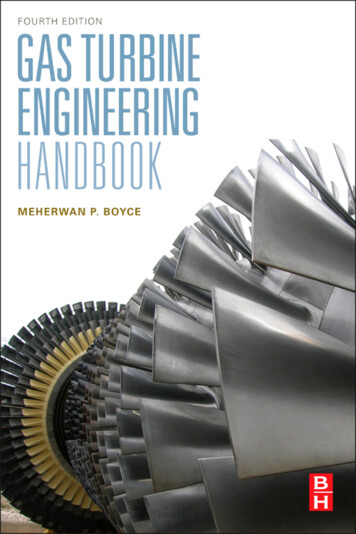

ContentsPreface to the Fourth EditionPreface to the Third EditionPreface to the Second EditionPreface to the First EditionForeword to the First EditionAbout the AuthorPart I Design: Theory and Practice1An Overview of Gas TurbinesGas Turbine Cycle in the Combined Cycle or Cogeneration ModeGas Turbine PerformanceGas Turbine Design ConsiderationsCategories of Gas TurbinesFrame Type Heavy-Duty Gas TurbinesAircraft-Derivative Gas TurbinesIndustrial-Type Gas TurbinesSmall Gas TurbinesVehicular Gas TurbinesMicroturbinesMajor Gas Turbine ComponentsCompressorsRegenerators/RecuperatorsFuel TypeCombustorsEnvironmental EffectsTurbine Expander SectionRadial-Inflow TurbineMixed-Flow TurbineAxial-Flow TurbinesMaterialsCoatingsGas Turbine Heat RecoverySupplementary Firing of Heat Recovery SystemsInstrumentation and 24450515157596162767677788083838587

viContents2Theoretical and Actual Cycle AnalysesThe Brayton CycleRegeneration EffectIncreasing the Work Output of the Simple-Cycle Gas TurbineIntercooling and Reheating EffectsActual Cycle AnalysisThe Simple CycleThe Split-Shaft Simple CycleThe Regenerative CycleThe Inter-cooled Simple CycleThe Reheat CycleThe Inter-cooled Regenerative Reheat CycleThe Steam Injection CycleThe Evaporative Regenerative CycleThe Brayton–Rankine CycleSummation of Cycle AnalysisA General Overview of Combined-Cycle PlantsCompressed Air Energy Storage CyclePower AugmentationInlet CoolingInjection of Compressed Air, Steam, or WaterInlet Cooling TechniquesEvaporative Cooling of the TurbineRefrigerated Inlets for the Gas TurbinesCombination of Evaporative and Refrigerated Inlet SystemsThermal Energy Storage SystemsInjection of Compressed Air, Steam, or Water for Increasing PowerMid-Compressor Flashing of WaterInjection of Humidified and Heated Compressed AirCombination of Evaporative Cooling and Steam InjectionSummation of the Power Augmentation 311321373Compressor and Turbine Performance CharacteristicsAerothermodynamics of TurbomachineryIdeal GasDry- and Wet-bulb TemperaturesOptical and Radiation PyrometersIdeal Gas LawsCompressibility EffectAerothermal EquationsContinuity EquationMomentum EquationEnergy Equation139139140144148149150153153154156

Contents4viiEfficienciesAdiabatic Thermal EfficiencyPolytropic EfficiencyDimensional AnalysisCompressor Performance CharacteristicsTurbine Performance CharacteristicsGas Turbine Performance formance and Mechanical StandardsMajor Variables for a Gas Turbine ApplicationType of ApplicationPlant Location and Site ConfigurationPlant TypeGas Turbine Size and EfficiencyType of FuelEnclosuresPlant Operation Mode: Base or PeakingStart-Up TechniquesPerformance StandardsASME PTC 19.1: Test UncertaintyASME PTC 19.3: Part 3: Temperature MeasurementInstruments and ApparatusASME PTC 19.5: Flow Measurement, Published 2004PTC 19.10: Flue and Exhaust Gas Analyses, Part 10ASME PTC 19.11: Steam and Water Sampling, Conditioning,and Analysis in the Power CycleASME PTC 19.23: Guidance Manual for Model Testing, Published 1980ASME PTC 46: Performance Test Code on Overall Plant Performance,Published January 1, 1996Object and ScopePerformance Test Code on Gas TurbinesASME PTC 22, Published 2006ASME Measurement of Exhaust Emissions from StationaryGas Turbine Engines B133.9, Published 1994ASME PTC 36 Measurement of Industrial Sound (ASME B133.8),Published 2004Mechanical ParametersASME B 133.2 Basic Gas Turbines, Published 1977(Reaffirmed: 1997)ASME B133.3 Procurement Standard for Gas Turbine AuxiliaryEquipment, Published 1981 (Reaffirmed 1994)ASME B133.4 Gas Turbine Control and Protection Systems,Published 1978 (Reaffirmed: 187188188188190190190191191192192192

viiiContentsASME B133.5 Procurement Standard for Gas Turbine ElectricalEquipment, Published 1978 (Reaffirmed: 1994)ASME B 133.7M Gas Turbine Fuels, Published 1985(Reaffirmed: 1992)ASME B133.8 Gas Turbine Installation Sound Emissions,Published 1977 (Reaffirmed: 1989)ASME B133.9 Measurement of Exhaust Emissions fromStationary Gas Turbine Engines, Published: 1994API Std 616 Gas Turbines for the Petroleum, Chemical, andGas Industry Services, Fourth Edition, August 1998API Std 613 Special Purpose Gear Units for Petroleum, Chemical,and Gas Industry Services, Fourth Edition, June 1995API Std 614 Lubrication, Shaft-Sealing, and Control-Oil Systemsand Auxiliaries for Petroleum, Chemical, and Gas IndustryServices, Fourth Edition, April 1999API Std 618, Reciprocating Compressors for Petroleum, Chemical,and Gas Industry Services, Fourth Edition, June 1995API Std 619, Rotary-Type Positive Displacement Compressorsfor Petroleum, Chemical, and Gas Industry Services, ThirdEdition, June 1997ANSI/API Std 670 Vibration, Axial-Position, andBearing-Temperature Monitoring Systems, Third Edition,November 1993API Std 671, Special Purpose Couplings for Petroleum, Chemical,and Gas Industry Services, Third Edition, October 1998API Std 677, General-Purpose Gear Units for Petroleum,Chemical, and Gas Industry Services, Second Edition, July 1997(Reaffirmed: March 2000)Application of the Mechanical Standards to the Gas TurbineGearsLubrication SystemsVibration MeasurementsSpecifications5Rotor DynamicsMathematical AnalysisUndamped Free SystemDamped SystemForced VibrationsDesign ConsiderationsApplication to Rotating MachinesRigid SupportsFlexible SupportsCritical Speed Calculations for Rotor Bearing 05206208215215217218222224226226228230

ContentsElectromechanical Systems and AnalogiesForces Acting on a Rotor-Bearing SystemRotor-Bearing System InstabilitiesSelf-Excited InstabilitiesCampbell DiagramBibliographyix232233236239244250Part II Major Components2516Centrifugal CompressorsCentrifugal Compressor ComponentsInlet Guide VanesImpellerInducerCentrifugal Section of an ImpellerCauses of Slip in an ImpellerStodola Slip FactorStanitz Slip FactorDiffusersScroll or VoluteCentrifugal Compressor PerformanceRotor LossesStator LossesCompressor SurgeEffects of Gas CompositionExternal Causes and Effects of SurgeSurge Detection and ControlProcess Centrifugal CompressorsCompressor ConfigurationImpeller 2742752782792812832892902912922952982997Axial-Flow CompressorsIntroductionBlade and Cascade NomenclatureElementary Airfoil TheoryLaminar-Flow AirfoilsEnergy IncreaseVelocity TrianglesDegree of ReactionRadial EquilibriumDiffusion FactorThe Incidence RuleThe Deviation Rule303303306309311313313315319320321323

xContentsCompressor Operation CharacteristicsCompressor SurgeCompressor ChokeCompressor StallIndividual Blade StallRotating StallStall FlutterCompressor Performance ParametersPerformance Losses in an Axial-Flow CompressorNew Developments in Axial-Flow CompressorsAxial-Flow Compressor ResearchCascade TestsBlade ProfileCompressor Blade 3323333373403423443453453513543558Radial-Inflow TurbinesHydraulic Radial-Inflow TurbinesRadial-Inflow Turbines for Gas ApplicationsTurbine ConfigurationsThermodynamic and Aerodynamic TheoryTurbine Design ConsiderationsPerformance of a Radial-Inflow TurbineLosses in a Radial-Inflow TurbineRadial-Inflow Turbine 13839Axial-Flow TurbinesTurbine GeometryThermodynamic and Aerodynamic TheoryUtilization FactorDegree of ReactionWork FactorVelocity DiagramsZero-Exit Swirl DiagramImpulse DiagramSymmetrical DiagramImpulse TurbineTurbine Blade Cooling ConceptsConvection CoolingImpingement CoolingFilm CoolingTranspiration CoolingWater/Steam 05405405

Contents10xiTurbine Blade Cooling DesignConvection and Impingement Cooling/Strut Insert DesignFilm and Convection Cooling DesignTranspiration Cooling DesignMultiple Small-Hole DesignWater-Cooled Turbine BladesSteam-Cooled Turbine BladesCooled-Turbine AerodynamicsTurbine mbustorsGas Turbine CombustorsTypical Combustor ArrangementsCan-Annular and Annular CombustorsSilo-Type CombustorsCombustion in CombustorsThe Diffusion-Type CombustorAir-Pollution Problems in a Diffusion CombustorSmokeOxides of NitrogenNOx PreventionDiffusion Combustor DesignThe Diffusion CombustorFlame StabilizationCombustion and DilutionFilm Cooling of the LinerFuel Atomization and IgnitionThe Dry Low Emission CombustorsPrimaryLean–LeanPremix TransferPiloted PremixPremixTertiary Full-Speed No Load (FSNL)Silo-Type CombustorsOperation of DLN/DLE CombustorsCatalytic Combustion and CombustorsFeatures of Catalytic CombustionCatalytic Combustor DesignPreburnerMain Fuel InjectorCatalytic ReactorTransition 84487

xiiContentsPart III Materials, Fuel Technology, and Fuel Systems49111MaterialsGeneral Metallurgical Behaviors in Gas TurbinesCreep and RuptureDuctility and FractureCyclic FatigueThermal FatigueCorrosionGas Turbine MaterialsTurbine Wheel AlloysCompressor BladesForgings and Non-destructive TestingCeramicsCoatingsShroud CoatingsFuture 50850850951351351412FuelsFuel SpecificationsFuel PropertiesLiquid FuelsLiquid Fuel Handling and TreatmentHeavy FuelsFuel Gas Handling and TreatmentEquipment for Removal of Particulates and Liquids from Fuel Gas SystemsFuel HeatingCleaning of Turbine ComponentsHot Section WashCompressor WashingFuel EconomicsOperating ExperienceHeat Tracing of Piping SystemsTypes of Heat-Tracing SystemsStream Tracing SystemsElectric TracingStorage of LiquidsAtmospheric TanksElevated TanksOpen TanksFixed Roof TanksFloating Roof TanksPressure 545546548549550550551552552552552552552553553

ContentsxiiiPart IV Auxiliary Components and Accessories55513Bearings and SealsBearingsRolling BearingsJournal BearingsBearing Design PrinciplesTilting-Pad Journal BearingsBearing MaterialsBearing and Shaft InstabilitiesThrust BearingsFactors Affecting Thrust-Bearing DesignThrust-Bearing Power LossSealsNon-contacting SealsLabyrinth SealsRing (Bushing) SealsMechanical (Face) SealsMechanical Seal Selection and ApplicationProductAdditional Product ConsiderationsSeal EnvironmentSeal Arrangement ConsiderationsEquipmentSecondary PackingSeal-Face CombinationsSeal Gland PlateMain Seal BodySeal SystemsAssociated Oil SystemDry Gas SealsTandem Dry Gas SealsTandem Dry Gas Seal with LabyrinthDouble Gas SealsOperating Range of Dry Gas SealsDry Gas Seal MaterialsDry Gas Seal SystemsDry Gas Seal 459459559659959960060060160160160314GearsGear TypesFactors Affecting Gear DesignPressure AngleHelix Angle605607608609611

xivContentsTooth HardnessScuffingGear AccuracyTypes of BearingsService FactorGear HousingsLubricationManufacturing ProcessesHobbingHobbing and ShavingHobbing and LappingGrindingGear RatingGear NoiseInstallation and Initial OperationGear 615615616616616618618619619620622624625Part V Installation, Operation, and Maintenance62715LubricationBasic Oil SystemLubrication Oil SystemSeal Oil SystemLubrication Management ProgramLubricant SelectionOil ContaminationFilter SelectionCleaning and FlushingOil Sampling and TestingOil Analysis TestsTest ProfilesGearboxesClean Oil SystemsCoupling 64164164664664764864916Spectrum AnalysisVibration MeasurementDisplacement TransducersVelocity TransducersAcceleration TransducersDynamic Pressure Transducers651656657657658658

ContentsxvTaping DataInterpretation of Vibration SpectraSubsynchronous Vibration Analysis Using RTASynchronous and Harmonic SpectraBibliography65966066466867217BalancingRotor ImbalanceBalancing ProceduresOrbital BalancingModal BalancingMultiplane Balancing (Influence Coefficient Method)Application of Balancing TechniquesUser’s Guide for Multiplane Couplings and AlignmentGear CouplingsOil-Filled CouplingsGrease-Packed CouplingsContinuously Lubricated CouplingsGear Coupling Failure ModesMetal Diaphragm CouplingsMetal Disc CouplingsTurbomachinery UpratesCurvic CouplingsShaft AlignmentThe Shaft Alignment 971071171819Control Systems and InstrumentationControl SystemsStart-up SequenceCondition Monitoring SystemsRequirements for an Effective Diagnostic SystemMonitoring SoftwareImplementation of a Condition Monitoring SystemPlant Power OptimizationOnline Optimization ProcessLife Cycle CostsDiagnostic System Components and FunctionsData InputsInstrumentation RequirementsTypical Instrumentation (Minimum Requirements for Each Machine)Desirable Instrumentation 42742

xvi20Contents742745Criteria for the Collection of Aerothermal DataPressure Drop in Filter SystemTemperature and Pressure Measurement for Compressorsand TurbinesTemperature MeasurementThermocouplesResistive Thermal DetectorsPyrometersPressure MeasurementVibration MeasurementVibration Instrumentation SelectionSelection of Systems for Analyses of Vibration DataAuxiliary System MonitoringFuel SystemTorque MeasurementBaseline for MachineryData TrendingThe Gas TurbineIdentification of LossesCompressor Aerothermal Characteristics and Compressor SurgeFailure DiagnosticsCompressor AnalysisCombustor AnalysisTurbine AnalysisTurbine EfficiencyMechanical Problem DiagnosticsData 767768Gas Turbine Performance TestIntroductionPerformance CodesFlow StraightenersPressure Measur

ASME PTC 22, Published 2006 190 ASME Measurement of Exhaust Emissions from Stationary Gas Turbine Engines B133.9, Published 1994 190 ASME PTC 36 Measurement of Industrial Sound (ASME B133.8), Published 2004 191 Mechanical Parameters 191 ASME B 133.2 Basic Gas Turbines, Published 1977 (Reaffirmed: 1997) 192 ASME B133.3 Procurement Standard for Gas Turbine Auxiliary