Transcription

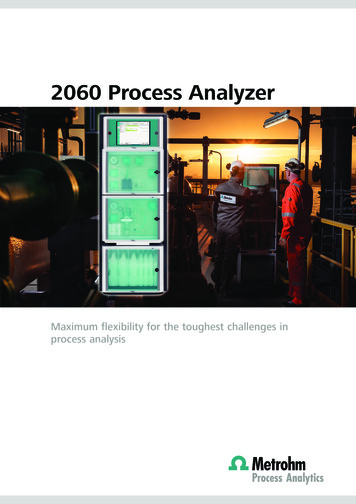

2060 Process AnalyzerMaximum flexibility for the toughest challenges inprocess analysis

2060 Process Analyzer Our most versatile analyzer ever02Metrohm Process Analytics is known as a pioneer inprocess analysis and has become one of the globalprocess industry’s preferred solution providers formonitoring key parameters in large scale industrialmanufacturing processes.The 2060 Process Analyzer is the most versatileanalyzer in the Metrohm Process Analytics productportfolio and on the market. It enables 24/7 online oratline monitoring of chemical industrial processes, water,wastewater or other liquids.The first multipurpose procress analyzer was developedby Metrohm in the 1970’s, with a limited range to handlefour sample streams. Since then, Metrohm ProcessAnalytics has continued to push the limits together withour customers by providing the best customized onlineanalytical solution on the market.The 2060 Process Analyzer will help you to: Monitor and safeguard your process 24/7 Optimize process efficiency Increase plant safety Improve the profitability of your operationsFully remote controllableThe upper part of the analyzer houses the touch screencontroller, which enables users to easily check trendgraphs for a clear overview of the process. Additionally,The new 2060 Analyzer can be controlled remotely toevaluate results immediately, inspect diagnostics fromthe safety of a control room, or connect to our onlinesupport.Robust design: Industrial IP66 ratingDual compartment enclosure ensures a completeseparation between the electronics and the wet part.Hence, maintenance and daily checks are possiblewithout the need to manipulate the electronic part,which overall increases uptime and plant safety.Additionally, the analyzer is splash proof and water tight,which makes it the perfect solution for harsh industrialenvironments.Virtually unlimited sampling optionsCustomized preconditioning systems can be designed forchallenging samples such as those with high temperature,high pressure or solids. We also offer custom madeshelters to protect your investment in especially harshenvironments.2060 Basic cabinet

2060 Process Analyzer Features and Benefits03New configurable softwareThe new software of the 2060 Process Analyzer has anew, modern and user-friendly layout, based on «timeprogramming sheets». The software enables users toreduce analysis time and conduct smart diagnosis on thecomplete analyzer system. Also, users can fine-tunemethods for any changes to the process, set limitconditions and alarms to control the analyzer.Multiple analysis techniquesWith a single 2060 Process Analyzer, you can performmultiple analyses to monitor several parameters in manysample streams. The 2060 Process Analyzer can beconfigured with up to 4 wet parts in one system tohandle the most challenging process applications.Application flexibilityThanks to the modular architecture of the wet part andthe possibility to combine multiple cabinets and evenplaced different cabinets in different locations, a widerange of applications are possible with this new analyzer.Additional optionsThe 2060 Process Analyzer is configured inside a holdingframe which can be placed in various ways: wall mount,table stand, floorstand, and on wheels.Build-in reagents detectionThe additional cabinets can be configured in such a waythat each wet part cabinet can be combined with anreagent cabinet with integrated (non-contact) leveldetection to increase analyzer uptime2060 Fully configured

Maximum flexibility for countless applications04Metrohm Process Analyzers are well known for theirmodular configuration concept, and we have nowtaken that modularity one step further. The Metrohm2060 Process Analyzer not only offers modularitywithin one cabinet, but also can combine up to fourindividual cabinets to create a single analyzerconfiguration.The IP66 rated cabinet modularity allows maximumflexibility to solve complex challenges that contribute tosophisticated plant automation.Multiple Analyses with a single analyzer«The 2060 process analyzer is like noother process analyzer available on themarket»2060 Basic cabinet2060 Fully configured

Basic 2060 Process Analyzer cabinetThis module consists of two parts. The upper partcontains a touch screen and an industrial PC. The lowerpart contains the flexible wet part where the hardwarefor the chemical analysis is housed.1Flexible housingIf the basic cabinet is not sufficient for your particularanalytical challenge, then the basic cabinet can beexpanded. This new flexibility concept guaranteesenough space to solve even the most challengingapplications with a single process analyzer.2Remote wet partsThanks to this new modular architecture, the individualwet parts can be separated from the basic cabinet andplaced at a different location of the process for morerepresentative sampling (which yields more accurate results).34*Images are not to scale05Preconditioning systemsTo satisfy all needs for the most demanding projectrequirements, sample preconditioning systems can beprovided to guarantee a robust analytical solution.

Intuitive software Freely programmable and user-defined06The intuitive new software is designed to efficientlyprogram and control the analyzer. Using a new featurecalled «time programming sheets», the analyzerprogram execution is displayed in a clear graphicaltimeline representation.Alarms can be programmed to inform the user aboutthe current status of the analyzer. Low reagent levels,calibration errors, and loss of sample are a fewexamples of alarms that can be logged into thedatabase. Also, multiple user levels are offered in thesoftware which are suitable for any operator.Modular screens allow the user to freely configure thedisplay, for example to control hardware for maintenancepurposes or to show analysis results at a glace.Easy operation, «time programming sheets» and remote control from any location

Diverse data communication possibilitiesTo ensure safer working environments and «real-time»monitoring of the system, remote control options arepossible from nearly any location. Results can also beexported to USB.Timesheet control programThe new software comes with the implementation oftimesheets for program control. Also, the new softwareallows the user to program different sequences of analysis and set conditions and alarms.Highlights Simple and user-friendly menus and functions Flexible software for straightfoward control Ethernet TCP/IP Network Communication and remote operation Real time titration curves, trend graphs and result databases07

Experience you can trust Solutions for all major industries08Take a look at any of the major manufacturing industries and even beyond at power generation, mineralextraction, and wastewater treatment. World-leading companies rely on our robust process analyzers acrossmany industries. Applications are numerous; here is an overview of some of the most typical and challengingones in each market segmentPetrochemistry / Refining Salt in crude oil Hydrogen sulfide and ammonia insour water TBC in styrene according to ASTMD4590Chemicals Hardness in brine Hydroxyl number in polymer production Low-level moisture in propyleneoxideSurface finishing Acids, bases, and aluminum inetching/anodizing processes Acids and iron in pickling baths Chromium [Cr3 ] in chromic acidelectroplating bathsPower Boric acid in cooling water andpressurized water reactors Trace analysis of cations and anions in the primary circuit Silica in boiler feed water

09Semiconductor Nickel and hypophosphite contentin plating baths Monitoring tetramethylammoniumhydroxide (TMAH) in developer Hydrogen peroxide in CMP SlurryPharmaceuticals Moisture analysis in the granulation process Active Ingredients (API) / contentuniformity Monitoring moisture levels in thefluid bed dryerMineral extraction Free, Total & WAD Cyanide in goldleach slurry and wastewater Zinc, sulfuric acid and iron in zincproduction Bayer aluminate liquors using thermometric titrationWastewater treatment Simultaneous analysis of ammonia, nitrate, and nitrite Ortho- and total phosphate analysis according to DIN EN ISO6878:2004-09 (formerly DIN38405-D11) Hexavalent Chromium [Cr6 ] inwaste water effluentPulp and Paper ABC Titration in pulping liquors

Problem solver Preconditioning and integrated systems10Besides the chemical analysis, sample preparation, preconditioning, and location of the analyzer are decidingfactors for the success of online & atline analysis. We canprovide a full solution for almost any application: an analyzer in combination with sample preparation or even acomplete package with a shelter, piping, wiring, andinterfacing. This allows seamless startup and integrationof the instrument on site.With more than 40 years of experience, Metrohm ProcessAnalytics can provide a complete and exact solution foralmost any application. Projects range from one analyzerin combination with simple sample panel preparation tocomplete complex turn-key packages. On site, only thenecessary utilities and the sample stream need to beconnected, saving significant time and energy in the startup phase of the instrument.Metrohm Process Analytics can engineer and supply virtually any «unit operation» for sample preconditioning: Pressure reduction Cooling Heating, heat tracing (Ultra) filtration Precipitation and settling Dilution (to avoid crystallizatio) Degassing Homogenizing Flow metering Phase separationConsultation and design of acustomized preconditioningsystemCustomized preconditioningsystem on siteSample preconditioning withshelter on site

Local offices worldwide –We are there for youMetrohm Process Analytics is represented in more than50 countries. Every subsidiary has its own service organization, spare parts warehouses and trained ServiceEngineers. Distributors are either equipped with thesame infrastructure or re ceive service and repair supportfrom Metrohm regional support centers (RSC) or evendirectly at our headquarters in the Netherlands.Wherever you need us, we’re there to help.A high standard for us – and a promise to youThe high standards we maintain are also a promise toyou. Regardless of when or where in the world you relyon our services, they are performed to the same exactingstandards. The core elements of our global service promiseare: Clearly defined system maintenance Implementation with specially developeddiagnostic instruments Uniform maintenance agreement with clearlydefined services tailored to customers’ needs Training and courses with customizeduser-specific content Uniform documentation of all services executed11

8.000.5321EN – 2019-08Subject to change without prior noticeLayout by Andrea Ferreira, Metrohm Applikon B.V.www.metrohm.com

within one cabinet, but also can combine up to four individual cabinets to create a single analyzer . Ethernet TCP/IP Network Communication and remote operation Real time titration curves, trend graphs and result databases . Timesheet control program The new software comes with the implementation of