Transcription

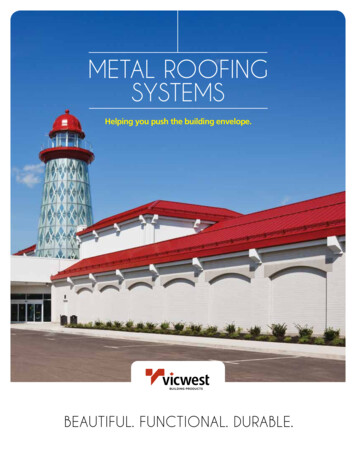

METAL ROOFINGSYSTEMSHelping you push the building envelope.BEAUTIFUL. FUNCTIONAL. DURABLE.1

STANDINGTHE TEST OF TIMEFor over 85 years, Vicwest has been manufacturing premiumquality roofing, metal cladding, and decking in Canada,redefining and setting the standards in metal buildingconstruction and design.With service and manufacturing facilities in Canada and theUnited States providing expert technical support, you canbe confident that, regardless of location, your project willbe covered by the Vicwest umbrella. Vicwest is the leaderin building envelope systems, providing comprehensiveservice, support and ultimate reliability.BUILDING FOR TOMORROW

VICWESTROOF SYSTEMSA metal roofing system by Vicwest will add beauty and characterto your building’s design regardless of size and shape demandsand protect it for years to come with unmatched durability.Vicwest metal roof systems provide the ultimate in design performance.Architecturally attractive and exceptionally functional, they offer the mostcontemporary designs for commercial, industrial, institutional and residentialbuildings. Our comprehensive product selection offers a variety of steel substrates,finishes, and profiles protected by technologically advanced 40-year coatings tocombat corrosion and fading.When you partner with Vicwest, you can be confident you are working with areputable North American company committed to providing you with qualityproducts and services and supported by experienced Vicwest teams from coast tocoast. Our knowledgeable technical and sales staff can assist you with your design,estimating and consulting needs to help you achieve the right solution for your nextbuilding project.Providing solutions for the building envelope is our business, and our metal roofingsystems are our crowning glory.www.vicwest.com3

Metal Roofing SystemsTRADITION 100 AND 150Creative flexibility for unique design possibilitiesDistinctive curved roofs,furnished with the Tradition100 profile in your choiceof material finish make forattractive curved parapets,wall edges or barrel vaultedroofs.TRADITION 100Key AdvantagesThe Tradition 100 panel with the I-style snap-on cap is designedspecifically for straight sloped or curved roof applications over a rigid solidsurface. It can be wrapped across its width to follow a contoured surfaceof wall or curved over its length to form a curved parapet wall edge or abarrel vaulted roof. Tradition 100 can be curved along the sheet length toa radii ranging from a minimum of 1500 mm to full straight.Roof Installation & PreparationAvailable in 400 mm widths, the Tradition 100 profile can be installed asa single skin on a solid surface without installation or as an exterior sheetas a fully insulated roof system design (System 3000). Please refer to theSystem Products Reference Chart on page 14.The surface to which the Tradition 100 is applied must be a solid, smoothsurface, strong enough to provide anchorage for the Snap Clips. The entireroof surface should be covered using a moisture retardant membranelapped horizontally, starting at the eaves, before Tradition 100 is applied.Please refer to www.vicwest.com for additional information.Side LapThe 33 mm (1 9/32”) I-style standing seam with snap-on cap is used onthe Tradition 100 roof profile.4www.vicwest.com400 mm22 mm

TRADITION 100TRADITION 150400 mm (standard)15.75”400 mm (standard)15.75”MinimumLength1.2 m(4’-0”)1.2 m(4’-0”)MaximumLength12.2 m(40’0”)12.2 m(40’0”)Curve Over Length3 **N/AMechanicallySeamedN/A3Requires /ANo ExposedFasteners33MinimumSlope /Degree3 in 1214.04 Deg2 in 129.46 DegAdditionalBarrier1 in 124.77 Deg1 in 124.77 Deg33Panel WidthMetallic FinishesTRADITION 150Key AdvantagesThe Tradition 150 panel with the T-style side lap is recommendedfor straight slope applications. The Tradition 150 is an excellentchoice where the roof design possesses slopes as low as 2 in 12(9.46 deg.) or where snow build-up and water pooling areas areidentified.Roof Installation & PreparationAvailable in 400 mm width, the Tradition 150 profile can beinstalled as a single skin or 3000 system application. Moistureretardant membranes should be considered as a secondaryprecaution in potential problematic areas. Please refer tovicwest.com for additional information.Side LapThe Tradition 150 profile uses the T-style mechanically seamedside-lap which is manufactured with a height of 38 mm (1 1 2”).** Field curving with machine supplied by Vicwest400 mm38 mmBUILDING FOR TOMORROW5

Metal Roofing SystemsMARQUISUncompromising style, matched in durabilityAchieve the distinct boardand batten appearance withthe Marquis roof system.This complete system deliverssuperior insulation values andhigh efficiency for roofs andwall assemblies.Key AdvantagesThe Marquis system possesses superior insulating values as a result of ourthermal clip mounting system which reduces thermal bridges. The battencap provides a structural advantage, results in a more water-tight system,and presents a traditional board and batten appearance.Panel Width450 mm (standard)17.72”MinimumLength1.2 m(4’-0”)MaximumLength12.2 m(40’0”)Gypsum board allows for a thermal barrier within the system, thusreducing thermal bridging. No seamer is required and clips are fastenedthrough the gypsum board to the metal deck below with fasteners. Thenumber of screws to be used depends on:Curve Over LengthN/AMechanicallySeamedN/A1) Magnitude of wind upliftRequires SolidSubstrate32) Spacing of clipsStructuralSpanningCapabilities3Snap Cap RequiredNo ExposedFasteners3Thermal clips come in a variety of depths from flush mount to depthswhich accommodate up to 254 mm of insulating material. Allowance tohave 10” of insulation with thermal clip system.3) Thickness of the inner metal deck.Roof Installation & PreparationMarquis is a fully engineered system. It combines a number of roofingelements that must be properly integrated to ensure good performance.To make sure the selected roof and all its components meet the specifiedperformance needs, contact a Vicwest technical representative. All arewell-trained in assisting architects and engineers to design with Marquis.Please refer to www.vicwest.com for additional information.6MARQUIS 450www.vicwest.comMinimum Slope/ Degree Without Batten Cap2 in 129.46 DegMinimum Slope/ Degree WithBatten Cap1 in 124.77 Deg

MarquisThermalSpringMarquisPanel45 mmMarquisThermalClip450 mm45 mm398 mmMarquis BattenKnee CapBatten Knee Cap CaulkedAround with CaulkingPop RivetButyl TapeMarquis Batten CapThe Marquis batten cap provides a distinctivearchitectural feature by creating bolder shadow lines.With single skin applications, the batten cap providesincreased rigidity. It is also used to provide perfecttransitions from roof to fascia.TransitionsWith the batten cap, Marquis provides a perfect transitionfrom roof to fascia, and even from fascia to soffit.Batten Cap Depth50mm (1.968”).BUILDING FOR TOMORROW7

Metal Roofing SystemsPRESTIGEImpressive for Residential or Commercial RoofsAccomplish a sophisticatedbatten style appearance withPrestige. With a name derivedfrom the prestigious style onlyit can accomplish, Prestigereflects a true artisan quality.A true display of steel roofingmade beautiful.Key AdvantagesThis classic standing seam profile, mimicking abatten style roofing panel, will enrich the appearanceand add value to any commercial or residentialroofing project. Prestige is a snap-in/interlockingprogressive system. Hidden fasteners mean there isno penetration of the metal, thus preventing waterfrom infiltrating the system. Note that the slottedanchoring location allows for thermal expansion ofthe panel.Roof Installation & PreparationIt is recommended that Prestige be installed onlyon single skin applications where a solid base ofplywood, steel deck or concrete is available. Ensurethe decking area is covered with a good qualityair barrier. Prestige uses a hidden fastening and isinstalled using a snap- in-place design and does notrequire seamers. Prestige is a cost effective solutionthat offers trouble free installation. Please refer towww.vicwest.com for additional information.PRESTIGEPanel Width305 mm / 400 mm / 508 mm(12”)* / (15.75”) / (20”)Minimum Length1.2 m (4’-0”)Maximum Length9.2 m (30’0”)Curve Over L engthN/AMechanically SeamedN/ARequires SolidSubstrateStructural SpanningCapabilitiesNo Exposed FastenersMinimum Slope / DegreeWithout Batten Cap* Prestige 12” manufactured in Delta, BC only8www.vicwest.com3N/A33 in 1214.04 Deg

1 1/2"(38 mm)12"(305 mm)1 1/2"(38 mm)16"(406 mm)1 1/2"(38 mm)20"(508 mm)BUILDING FOR TOMORROW9

Metal Roofing SystemsTSRSurprisingly economical and highly functionalThis low slope roofing systemproduces a remarkablyattractive roof with itscorrugated panel appearance.Completely weather proof andsuited for projects in high winduplift zones, TSR stays securewith incomparable quality, longlife, and three separate systemsto provide energy efficiency.Key AdvantagesThe TSR system demonstrates all weather performance in areas of extremewinds, rains and heavy snow. It is engineered specifically for extremely lowslope roof applications common to industrial and institutional buildings.Roof Installation & PreparationTSR is one of our most versatile profiles. It can be installed on single skin,or on the 1000, 2000, 3000 systems, allowing for varying degrees ofefficiency. TSR is an excellent solution for achieving weather tightness onextremely low slope roofs where pooling can be problematic. Please referto www.vicwest.com for additional information.TestingsTSR has UL class 1-90 and ASTM 1592 ratings on both 22 gauge and24 gauge for purlin spacing of 5 feet (1500 mm). And now the TSRsystem is one of the few steel roof systems to have been tested underand passed UL 1897, a stringent wind uplift test standard for roofcoverings. Vicwest’s new rating of 140 pounds per square foot uplift(6.7 kPa) with no visible damage will give owners great confidence inthe integrity of their roof system.10 www.vicwest.comTSRPanel Width610 mm (24”)Minimum Length1.2 m (4’-0”)Maximum Length12.2 m (40’0”)Curve Over L engthN/AMechanically SeamedRequires SolidSubstrate3N/AStructural SpanningCapabilities3No ExposedFasteners3Minimum Slope /Degree1/4 in 121.19 Deg

Tabs8”r1”o.5, 122 or 4 tabsare requiredby design”7.52” to10 3/16”MaterialThickness16 ga.FemaleEdge69 mm (2.72”)51 mm (2.00”) (0.72”)18 mmMaleEdge70.612 mm (2.78”)70.612 mm (2.78”)141.224 mm (5.56”)BUILDING FOR TOMORROW11

Metal Roofing SystemsEXPOSED FASTENERColour-matched fasteners give this profile a sleek lookInstalling Vicwest profilesusing exposed fastenersmakes for a quick installation,therefore becoming a muchmore cost effective alternativeto a concealed fasteningapproach.Key AdvantagesExposed Fastening System is an economical choice for roof designs on a firm budget.Roof Installation & PreparationInstalling Vicwest profiles using exposed fasteners makes for a quick installationtherefore becoming a much more cost effective alternative to a concealedfastening approach. Using the exposed fastening system may also be a favourablechoice if it is suspected that the building may experience future additions or expansionsin which case an exposed fastening system will allow the panel to be easily removed and replacedto accommodate accordingly. Please refer to www.vicwest.com for additional information.Please contact one of our experts to recommend the fastener best suited for your particular application.MacKay-Lyons Sweetapple Architects, Photo by Greg Richardson12 www.vicwest.com

EXPOSEDFASTENERPanel WidthVariesMinimum Length1.2 m (4’-0”)Maximum Length12.2 m (40’0”)Curve Over L engthN/AMechanically SeamedN/ARequires Solid SubstrateN/AStructural Spanning CapabilitiesNo Exposed Fasteners3CL400CL470CL725-RCL622-RN/A3 in 1214.04 DegMinimum Slope / DegreeCL435-TCL840Metal Screwwith WasherCORRUGATED 7/8”Metal RoofPanelStitchFastenerCL938ContinuousButyl TapeCL439SuperVicBUILDING FOR TOMORROW13

Metal Roofing SystemsTECHNICALRoofing SystemsSingle Skin on Rigid DeckingVicwest Roof profiles are ideal in applications where a solid deck isavailable for support. Our roof profiles are adaptable to any solidbase material such as plywood, steel deck or concrete. To preventinternal air leakage, which can cause condensation problems,Vicwest recommends the use of a good air barrier over thestructural material.System 1000For light industrial applications, choose the Vicwest System 1000as an economical and attractive roof. Vicwest roof products can beused as a single skin or with or without metal building insulationas required.System 2000The Vicwest System 2000 roof provides an upgraded system withan L-800 Liner sheet air vapour barrier and a wider range ofinsulation values from which to choose.System 3000The Vicwest System 3000 roof is designed for almost all roofingapplications. It combines all the elements needed for a highperformance weather tight roof. It integrates all necessary roofingcomponents and provides a single source of responsibility for theroof design and construction. For a more economical approach,where the interior humidity of the building is less than 35%, thethermal barrier may be eliminated and deck fillers installed tosupport the side and end laps of the air vapour barrier. Cautionmust be exercised to ensure that humidity conditions duringconstruction also remain below this level.Images reflect the Marquis profile.Actual components will vary dependingon roof profile selected.14 www.vicwest.comRoof SheetThermal ClipAir/Vapour BarrierStructural Roof SupportInsulationRoof SheetPurlin Thermal BlockThermal ClipStructural Roof SupportInsulationRoof SheetStructural Roof SupportAir/Vapour BarrierThermal BarrierThermal ClipInsulationRoof SheetStructural LinerAir/Vapour BarrierThermal BarrierStructural Roof SupportThermal Clip

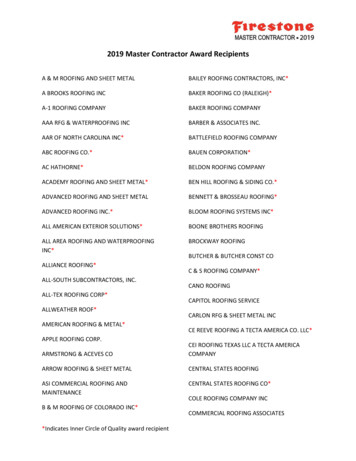

Accessories &Material FinishesRoof Systems &Corresponding ComponentsROOF r Panel3333Panel Clip3333Metal BuildingInsulation3Semi RigidInsulation3Rigid Insulation3Subgirt ClipSystem3L-800 Liner3Asphaltic Air/Vapour Barrier33Gypsum Board3Structural ion 10033*Tradition 3Material FinishesZ275 Galvanized or AZM150 Aluminum-Zinc Alloycoatings are recommended for general installations.WeatherXL is Vicwest’s Silicone Modified Polyester(SMP) coating. With its unique resin system, this SMPtopcoat combines a mix of ceramic and inorganicpigments. Selected WeatherXL colors possessreflectance values that are Energy Star qualified, meetcurrent cool roof standards and help towards earningLEEDTM certification. In addition to outstanding colourperformance, WeatherXL is resistant to stains, abrasionsand metal marking which allows it to endure the physicalstresses of fabrication, transit and construction whileminimizing cracking and marring. Vicwest is confidentin the WeatherXL system and is offering customers anextensive colour palette with exceptional film integrityand color protection. WeatherXL is supported by a40-year limited warranty. Please refer to our colourchart for the tint that best matches your design and ourcompatibility chart for available gauges.Vicwest’s Expressence finishes, utilizing the durable PVDFcoating system in matte, satin or textured finishes, replicatenatural materials like wood, stone and metal. Covered bya 40-year paint performance warranty, PDVF coating isbased on Kynar and Hylar resins to provide maximumprotection and optimal colour retention. Please refer toour Expressence Colour Card for a pattern finish that bestachieves the desired effect.3* Special precautions must be taken, please contact a Vicwest representativeClosuresTypes: 1. Metal closures to match finish of metalcladding. 2. Foam closures.Availability: Both metal and foam closures are availablefor installation over and under panel for most Vicwestprofiles.Application: Metal closures are used to fill the voidsof the exterior panel at peak and eave of roof. Theseclosures allow air circulation within the panel betweenthe exterior sheet and insulation to control condensation.Foam closures are used to seal in weathertight and/orairtight installations.N.B: For availability and colour selection of all theseproducts, please contact Vicwest or visit vicwest.com.15

Metal Roofing SystemsSystem Products Reference ChartTRADITION 100TRADITION 150MARQUIS 450450 mm400 mm400 mm38 mm22 mm45 mm398 mmPanel Width400mm (15.75”)400mm (15.75”)450 mm (17.72”)MinimumLength1.2 m (4’-0”)1.2 m (4’-0”)1.2 m (4’-0”)MaximumLength12.2 m (40’-0”)12.2 m (40’-0”)12.2 m (40’-0”)Curve ate333StructuralSpanningCapabilitiesNo ExposedFastenersMinimumSlope /Degree3Batten Cap Required3333 in 12 / 14.04 1 in 12 / 4.77 (Membrane Required)2 in 12 / 9.46 1 in 12 / 4.77 (Membrane Required)2 in 12 / 9.46 1 in 12 / 4.77 (Batten Cap)* Prestige 12” manufactured in Delta, BC only** field curing required with machine supplied by VicwestNote: For slopes below 2:12 please contact your local Vicwest representative for specific recommendations16 www.vicwest.com3

PRESTIGETSRSUPERVICEXPOSED FASTENER1 1/2"(38 mm)12"(305 mm)762 mm (30")1 1/2"(38 mm)16"(406 mm)69 mm(2.72")610 mm (24.00")19 mm (3/4")254 mm (10")1 1/2"(38 mm)20"(508 mm)508 mm / 400 m / 305 mm(20”) / (15.75") / (12")*610 mm (24”)Varies1.2 m (4’-0”)1.2 m (4’-0”)Varies9.15 m (30’-0”)12.2 m (40’-0”)VariesCall for Details333333 in 12 / 14.04 1/4 in 12 / 1.19 33 in 12 / 14.04 17

Metal Roofing SystemsENERGY SAVINGS & LEED Metal Cladding, Decking and Roofing by Vicwest providesdesign professionals with the ability to design a building withenvironmental sustainability in mind. By incorporating Vicwestmetal building components into your design, the environment ofyour build will continue to function properly and meet the needsof those who occupy it without endangering the health andwelfare of future generations. Vicwest offers a variety of WeatherXL finishes whichare Energy Star qualified. Ask your representative for details. When permitted by local building codes, re-roofingapplications can require little removal of waste from buildingsites resulting less in landfills. Vicwest Metal Roofing and Cladding Systems aremanufactured with recycled content. They are extremelydurable, have a long-life cycle and are 100% recyclable atthe end of their life. Metal Roofing Systems by Vicwest can reduce coolingconsumption during summer months. This results in lessfossil fuels burning in the atmosphere, reducing smogand pollution.Vicwest is committed to revitalizingCanada’s forests and wildlifeby contributing to Canadianenvironmental groups throughvarious eco-gifts and sponsorships. Vicwest’s manufacturing facilities recycle cardboard, paper,wood and steel. We’re always looking for ways to reduceenergy consumption. Vicwest metal roofing profiles can help designers earn LEEDTMcertification. Please visit our website at www.vicwest.com forrecent case studies showcasing these certified buildings. When installed on site, Vicwest Metal Roofing and CladdingSystems will not release VOC’s (Volatile organic compounds)into the atmosphere. This applies to interior installations.For further information on how steel can meet LEED Canadarequirements as outlined by the Canada Green Building Council,please visit our website for our ecoScorecard . The ecoScorecard evaluates and documents the environmental benefits of ourproducts making it easy for you to compile and print submisssiondocuments for LEED and other green building programs.18 www.vicwest.com

OTHER VICWEST PRODUCTSVicwest has what you need to succeedFor over 100 years, Vicwest has beena leading manufacturer of premiumquality metal cladding, roofing anddecking in Canada, redefining andsetting the standards in metal buildingconstruction and design.Wall SystemsVisit vicwest.com for our complete lineof metal building products.Insulated Metal PanelsRoof DecksFloor DecksRoof SystemsSteel Trims & AccessoriesArchitectural PanelsSee more projects at www.vicwest.com19

Up-to-date Information,Best Practices, everything neededto work with Vicwest Steel RoofSystems in the most efficientmanner, from the product lineto specialty coatings, specialprojects and accessories.It’s all here for a completeroofing system.Vicwest Locations:Edmonton, AlbertaSaskatoon, SaskatchewanStratford, OntarioOakville, OntarioVictoriaville, QuebecMemramcook, New BrunswickKensington, PEIThe Vicwest CommitmentFor more than 85 years, we’ve understoodthat people c hoose Vicwest not only becausewe build superior products, but because westand behind them. Every Vicwest product wesell is backed by leading system warranties,comprehensive service, and ultimatereliability. At Vicwest, we’re committed tocontinually improving upon and developingnew building products to protect the placeswhere we live, work and play. At Vicwest,we’re building for tomorrow.Note: For more information about building with steel,please refer to the CSSBI publication on the structuralintegrity of steel building panels.In accordance with ongoing efforts to improve ourproducts and their performance, Vicwest BuildingProducts reserve the right to change without notice thespecifications contained herein.The contents herein are for general information andillustrative purposes only and are not intended to serveas any type of advice. Every effort is made to ensure theaccuracy of the information included in this brochureand it is believed that the information contained hereinis accurate and reliable as of the date of publication.Vicwest Building Products does not warrant or representthe accuracy or reliability of any information included inthis brochure. Any reliance on any information withoutconsultation with Vicwest Building Products or a dulyauthorized representative shall be at the user’s own risk.www.vicwest.comwww.vicwest.comBUILDING FOR TOMORROW 2017 Vicwest Building Products – All rights reservedVW00299EN05/17

A metal roofing system by Vicwest will add beauty and character to your building's design regardless of size and shape demands and protect it for years to come with unmatched durability. Vicwest metal roof systems provide the ultimate in design performance. Architecturally attractive and exceptionally functional, they offer the most