Transcription

Fluid Power SealDesign GuideCatalog EPS 5370

Catalog EPS 5370/USA!WARNING:Failure, improper selection or improper use of the products and/orsystems described herein or relateditems can cause death, personalinjury or property damage.For safe and trouble-free use of theseproducts, it is important that you readand follow the Parker Seal Group ProductSafety Guide. This Safety Guide canbe referenced and downloaded free ofcharge at www.parkerseals.com and canbe ordered, without charge, as ParkerPublication No. PSG 5004 by calling1-800-C-PARKER.This document, along with other information from ParkerHannifin Corporation, its subsidiaries and authorized distributors,provides product and/or system options for further investigationby users having technical expertise. It is important that youanalyze all aspects of your application and review the informationconcerning the product or system in the current product catalog.Due to the variety of operating conditions and applications forthese products or systems, the user, through his or her ownanalysis and testing, is solely responsible for making the finalselection of the products and systems and assuring that allperformance, safety and warning requirements of the applicationare met. The products described herein, including withoutlimitation, product features, specifications, designs, availability andpricing, are subject to change by Parker Hannifin Corporation andits subsidiaries at any time without notice.OFFER OF SALEThe items described in this document are hereby offered for saleby Parker Hannifin Corporation, its subsidiaries and its authorizeddistributors. This offer and its acceptance are governed by the provisionsstated on the separate page of this document entitled “Offer of Sale.” 2007, 2008 Parker Hannifin Corporation. All rights reserved.

Fluid Power SealDesign GuideTable of ContentsSee Appendices A through G for:Introduction11Engineering2Materials3Fluid Power Applications4Rod Seals5Symmetrical Seals6Piston Seals7Wipers8Wear Rings / Bearings9Back-ups10Urethane O-Rings / Head Seals11A Design Action Request FormB English / Metric ConversionsC Custom Groove CalculationsD Chemical CompatibilityE ASTM D2000 CompatibilityF ISO Gland TolerancesG Other Parker EPS Products.Parker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000Fax: 801 973 4019www.parkerseals.com

1IntroductionParker Hannifin is theindustry leaderfor sealing systemsolutions for the fluidpower industry.Catalog EPS 5370/USAParker EPS Division provides the most complete selection of dynamicseals for both OEM and MRO hydraulic and pneumatic applications.Our expertise and complete product offering means Parker is your onesource manufacturer and sealing solution partner. Our innovative technology and value added services allow us to engineer your success withleading edge material development, experienced design, high qualitymanufacturing, and outstanding customer service.Rod SealsRod Seals, which guard against external leakage, are one of the mostvital components of the sealing system. In recognition of their criticalnature, Parker is pleased to offer the most complete range of materialsand profiles in the industry. Our advanced plastic, rubber and PTFEmaterial development delivers the highest performance in a wide varietyof rod seal applications. Cutting edge technologies include multiplesealing lip systems, shock-load resistance, low friction and ultra-drycapability.Symmetrical SealsWith thousands of available size and material combinations, Parkersymmetrical profiles are designed to act as either rod or piston seals,allowing one part number to function in two applications. Often copiedbut never equaled, the PolyPak for hydraulic applications and the8400 u-cup for pneumatic applications have revolutionized the fluidpower industry and become trusted standards. Symmetrical u-cups andsqueeze seals are available in a variety of lip shapes and materials.Piston SealsOur diverse product line of piston seal profiles suits a broad rangeof hydraulic and pneumatic applications. Whatever the need, from lowpneumatic pressures to extreme hydraulic shock loading, Parker has thesolution. Profiles are available to meet the demands of uni-directionaland bi-directional pressure, low friction, easy installation, port passing,and zero-drift scenarios.WipersJust as rod seals are designed to keep fluid in, Parker wipers performto keep contamination out. Wipers work in conjunction with rod sealsto form the first line of defense in protecting a system and keeping itfree from dirt, mud, water, and other contaminants. Incorporating thelatest technology in aggressive wiping lips and OD exclusion, Parker hassolutions in press-in, snap-in, and double lip profiles.09/01/071-2www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Wear Rings and BearingsParker offers a complete line of wear rings and bearing productsto fit any application. The product offering meets the full spectrumof needs, from heavy duty hydraulic cylinders operating under thehighest temperatures and pressures to pneumatic applicationsrequiring low friction, long life and self-lubrication. No matter what theapplication demands, Parker’s diverse bearing product line ensures thatperformance requirements are met with maximized value.Back-up RingsParker back-up rings offer simple solutions to safely increase systempressure or solve an existing seal extrusion problem. Standard profilesare available in a variety of materials to complement virtually any Parkerrod or piston profile.O-rings & Head SealsParker is pleased to offer the material advantages of the Resilon family of urethanes in standard and custom o-ring sizes. With hightemperature Resilon o-rings, the need for back-ups can be eliminated,simplifying installation and reducing damage due to spiral failure. Statichead seals are ideal for replacing o-rings and back-ups in hydrauliccylinder heads, fool-proofing installation and eliminating failures due toback-up pinching and blow-out.09/01/071-3www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Rod Seals (See Section 5)Application cProfilePageBDPremium non-symmetrical o-ring energized rod seal with a knifetrimmed primary lip and molded secondary lip. Standard materialsare 4300, 4700, 5065. Available with positively actuated back-up.5-5BTPremium non-symmetrical u-cup rod seal with a knife trimmedprimary lip and molded secondary lip. Standard material is 4300family.5-7BSNon-symmetrical u-cup rod seal with knife trimmed primary lip andmolded secondary lip. Standard materials are 4300 family, 4700,5065.5-9B3Non-symmetrical u-cup with knife trimmed lip. Standard materialsinclude 4300, 4700, 5065.5-11URStandard non-symmetrical u-cup with trimmed lip. Standard materialis 4615.5-13E5Non-symmetrical low friction rounded lip pneumatic rod seal.Standard materials include 4274, 4180, 4208, 5065.5-21TRBi-directional rod “T-seal” available in no back-up, single back-up, andtwo back-up groove sizes. Standard energizer materials include 4115,4274, 4205, 4259. Back-ups available in PTFE, Nylon, PEEK.5-24ONBi-directional, rubber energized PTFE rod cap seal. Full range ofenergizer and PTFE materials available.5-28CRBi-directional, low profile, rubber energized PTFE cap rod sealdesigned to fit standard o-ring glands. Full range of energizer andPTFE materials available.5-32OCStandard bi-directional rubber energized PTFE rectangular cap rodseal. Full range of energizer and PTFE materials available.5-39BRPremium knife trimmed buffer or secondary seal designed towork with a primary rod seal for heavy duty or zero-leak systems.Standard material is 4300.5-45ODUni-directional rubber energized PTFE rod seal, typically used asa buffer or secondary rod seal. Full range of energizer and PTFEmaterials available.5-48V6Pneumatic cushion or check valve rod seal used to cushion thepiston using internal pressure. Standard materials include 4622,4180, 4181, 4208.5-54ORBi-directional rubber energized PTFE rod seal used in rotary oroscillating applications. Full range of energizer and PTFE comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Symmetrical Seals for Rod or Piston Applications (See Section 6)Application HydraulicPageSPPStandard PolyPak. A square shaped symmetrical squeeze seal witha knife trimmed scraper lip. Standard materials include 4615, 4622,4651, 4263, 4207, 4266.6-6DPPDeep PolyPak. A rectangular shaped symmetrical squeeze sealwith a knife trimmed scraper lip. Standard materials include 4615,4622, 4651, 4263, 4207, 4266.6-8BPPType B PolyPak. A rectangular shaped symmetrical squeeze sealwith a knife trimmed beveled lip. Standard materials include 4615,4622, 4651, 4263, 4207, 4266.6-10SLA dual lip seal created by the combination of a standard PolyPaksquare shell and a rubber lip seal/energizer. Standard materials area 4615 shell and 4180 lip seal/energizer. Also known as SCL-Pak.6-39USStandard symmetrical u-cup with trimmed beveled lips. Standardmaterial is 4615.6-42Symmetrical rubber u-cups used primarily in pneumatic applications.8400 series feature knife trimmed with a beveled lip. 8500 seriesfeature a scraper lip. Standard materials include 4180, 4274, 4208.6-4984008500Piston Seals (See Section 7)HeavyMediumDescriptionSpiral v-packing rings typically sold in sets, also known as chevronpacking. Made from a wide range of materials, v-packing may becut to size, machined, or net molded. Most dynamic v-packing hasbeen replaced with PolyPak seals or ion (Duty)PneumaticIndustry standard symmetrical u-cups per the old Army Navy (AN)specification. Standard material is 4295.AN6226Page6-59Piston Seals (See Section 7)BPPremium bi-directional rubber energized urethane piston cap seal.Standard material is 4304.7-5PSPStandard bi-directional rubber energized urethane piston cap seal.Standard materials include 4300, 4622.7-8CCChemCast is a heavy duty bi-directional rubber energized hard plastic, step-cut piston cap seal.7-11OKPIPBi-directional rubber energized nylon step-cut piston cap seal.Bi-directional piston seal created by the combination of a PressureInverting Pedestal (PIP) back-up ring and Type B PolyPak. Standardmaterial is a 4615 PolyPak with a 4617 PIP ring.7-137-1509/01/071-5www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Piston Seals (See Section 7)Application HydraulicPageB7Premium non-symmetrical u-cup with knife trimmed lip piston seal.Standard materials include 4300, 4700, 5065.7-19UPStandard non-symmetrical u-cup with trimmed beveled lip pistonseal. Standard material is 4615.7-23E4Non-symmetrical low friction rounded lip pneumatic piston seal.Standard materials include 4274, 4180, 4208, 5065.7-26Low friction bumper and round lip seal profile for use in pneumaticapplications. Standard materials include 4274 and 4208.7-29TPBi-directional piston “T-seal” available in no back-up, single back-up,and two back-up grooves. Standard energizer materials include 4115,4274, 4205, 4259. Back-ups available in PTFE, Nylon, PEEK.7-31S5Economical medium duty bi-directional o-ring energized PTFE piston seal. Standard material is 15% fiberglass-filled PTFE with nitrileenergizer. Split option available.7-35R5Medium to heavy duty bi-directional lathe cut energized PTFE pistonseal. Full range of energizer and PTFE materials available. Splitoption available.7-39CTFour piece capped “T-seal” piston seal made from molded rubberenergizer, PTFE cap, and Nylatron back-ups.7-43CQBi-directional three piece lathe cut energized PTFE cap piston sealwith an integrated quad seal for zero drift. Also available with dualo-ring energizer.7-48OEBi-directional, rubber energized PTFE piston cap seal. Full range ofenergizer and PTFE materials available.7-53CPBi-directional low profile, rubber energized PTFE cap piston sealdesigned to fit standard o-ring glands. Full range of energizer andPTFE materials available.7-62OAStandard bi-directional rubber energized PTFE rectangular cap piston seal. Full range of energizer and PTFE materials available.7-68OQBi-directional rubber energized PTFE piston seal used in rotary oroscillating applications. Full range of energizer and PTFE ls.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Wipers (See Section 8)Application HydraulicPagePremium snap-in wiper with OD exclusion lip and a knife trimmedwiping lip. Standard material is 4300.8-5SHDSlotted heel snap-in wiper for pneumatics and light to medium dutyhydraulics. Standard materials are 4615, 5065, 4263, 4208, 4207.8-6SHXSlotted heel snap-in wiper with OD exclusion feature. Designedto upgrade SHD wipers without changing the groove. Standardmaterials are 4615, 5065.8-7SH959An industry standard slotted heel Army Navy (AN) wiper designedto fit MS-28776 (MS-33675) grooves. Standard materials are 4615,5065, 4263, 4208, 4207.8-11SX959An industry standard slotted heel Army Navy (AN) wiper with an ODexclusion feature designed to fit MS-28776 (MS-33675) grooves.Designed to upgrade SH959 wipers without changing the groove.Standard materials are 4615, 5065, 4263, 4208, 4207.8-12AHDouble-lip, press in place, metal canned wiper with knife trimmedsealing lip for heavy duty hydraulics. Standard materials are 4300,4700, 4615.8-15JStandard single-lip, press in place, metal canned wiper with aknife trimmed lip for medium and heavy duty hydraulics. Standardmaterials are 4300, 4700, 4615.8-17YDAYH/8600KADSGPremium snap-in place double-lip wiper for hydraulic applications.Standard materials are 4300, 4301, 4700.8-19Standard snap-in place double-lip wiper. Standard materials for Hwiper are 4615, 5065. Standard material for 8600 wiper is 4181.8-21Light load snap-in wiper with double-lip designed for low friction,light load applications. Standard material is 4615.8-27Double acting, double-lip, rubber energized PTFE wiper. Full rangeof energizer and PTFE materials available.8-30Metal scraper with rubber energizer for excluding s.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Wear Rings / Bearings (See Section 9)Application HydraulicPageWPTTight tolerance piston wear ring with chamfered corners. Standardmaterial is 4733 WearGard .9-7WRTTight tolerance rod wear ring with chamfered corners. Standardmaterial is 4733 WearGard.9-11WNStandard commercial wear ring for rod and piston applications. .Standard material is 4650 MolyGard .9-14PDTPTFE wear strip/bearing available cut to length or in bulk rolls. Avariety of PTFE compounds are available.9-18PDWPrecision cut wear ring/bearing machined from PTFE billet material.Rod and piston chamfer may apply.9-27Back-ups (See Section 10)MBHeavy cross-section modular back-up for PolyPak seals. Standardmaterials are 4617, 4652.10-48700Light cross-section back-up for PolyPak and u-cup seals. Standardmaterials are 4651, 4729.10-105100Back-up rings designed for o-ring grooves. Standard materials are4651, 4729.10-13PABPositively actuated back-up ring incorporated into common sealprofiles to extend a seal’s pressure range. Sold as an assembly withthe seal.10-21PDBAnti-extrusion PTFE ring offered in solid and split configurations.Full PTFE material range applies.10-22Urethane O-Rings & Head Seals (See Section 11)568High performance urethane o-ring made from the Resilon familyof high temperature, low compression set urethanes.11-2HSStatic head seals designed to replace o-rings and back-up in staticapplications. Standard material is 4700.11-1509/01/071-8www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

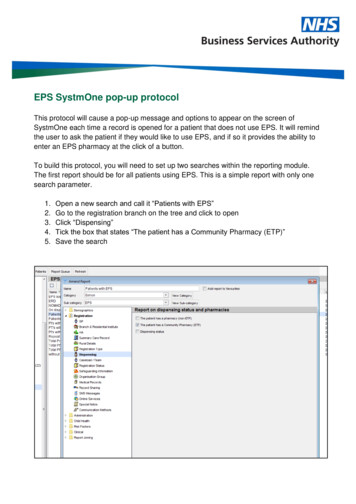

Catalog EPS 5370/USAIntroduction1General Application GuidelinesParker’s selection of products is the broadest offering in the industry for hydraulic and pneumatic sealingsystems. Table 1-1 provides “General Application Guidelines” to help define possible differences between light,medium and heavy duty applications. The product profile charts beginning on page 1-4 show correspondingapplication duty recommendations for each profile.Table 1-1. General Application ressureRangeLight DutyMedium DutyHeavy DutyLight DutyHeavy Duty 1200 psi( 83 bars) 3500 psi( 241 bars) 3500 psi( 241 bars)1 to 200 psi(0 to 14 bar)Above 200 psi(Above 14 bars)Not to exceedtwice the systempressure. Shortduration such asvalve shifting.Pressure spikesthat may beseveral timesthe systempressure and ofa longer duration.These are oftenmechanicallyinduced by forcingthe rod in or out.Because of thecompressivenature of gasespressure spikesare typically not aproblem.Because of thecompressivenature of gasespressure spikesare typically not aproblem.-20 F to 200 F(-29 C to 93 C)-45 F to 225 F(-43 C TO 107 C)0 F to 72 F(-18 C to 22 )Cryogenic to450 F(232 C)None or lowPressureSpikesTemperatureRangeContaminationSide Loading0 F to 160 F(-18 C to 71 C)Low or nonexistingModerate withcylinder inhorizontal orinverted position.Moderate to highwith the cylinderupright - verticalLow or nonexistingModerate to highwith the cylinderupright - verticalNone to lightwith shorterstroke andverticalcylinder mount.Moderate sideload with cylindermounted towardsthe verticalposition. Mediumstroke.Longer strokelengths. Cylindermountedhorizontal, heavyside loading.None to light withshorter stroke andcylinder mountvertical.Longer strokelengths. Cylindermountedhorizontal, heavyside loading.It is not uncommon for the requirements of a sealing system to fall into multiple duty columns. When thissituation occurs you should select the majority of your components from the lesser duty range.When selecting a wiper, focus on contamination section.In selecting a sealing component you will evaluate the temperature, pressure and pressure spike variables ofthe application. With a wear ring, you will want to look at the temperature and side loading section. This doesnot preclude the need to consider such things as fluid being sealed and stroke speed.09/01/071-9www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1The Parker AdvantageParker is the world’s leading diversified manufacturer of motion and control technologies and systems,providing precision-engineered solutions for a wide variety of commercial, mobile, industrial and aerospacemarkets. The Engineered Polymer Systems (EPS) Division of Parker Seal Group, has over 40 years experiencedesigning and manufacturing elastomeric, polymeric and plastic seals, materials, and sealing systems fordynamic applications. Working with Parker EPS Division gives you access to all of Parker’s Seal Group in NorthAmerica, Europe, and Asia.Worldwide ManufacturingParker Seal Group and EPS Division’s manufacturingfacilities for dynamic seals include:North America:EPS Division Salt Lake CityDivision HeadquartersPlastic & Rubber Operations2220 South 3600 WestSalt Lake City, UT 84119EPS Division Salt Lake City OperationsEPS Division NacogdochesClipper OperationsOilfield Rubber OperationsExpansion Joint Operations403 Industrial Blvd.Nacogdoches, TX 75964Ph: (800) 233-3900EPS Division Chicago (Elgin)EPS Division PTFE Operations:EPS Division, Elgin Operations2565 Northwest ParkwayElgin, IL 60124Ph: (847) 783-4300EPS Division NacogdochesEPS Division, Marion Operations3967 Buffalo StreetMarion, NY 14505Ph: (315) 926-4211EPS Division, Baja OperationsBaja, MexicoPh: (619) 671-3257EPS Division MarionEPS Division Baja09/01/071-10www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Europe:u opePacking Operations::Prädifa,, Bietigheim,BiettiBtighheimim GermGermanyPh: ( 49)499) 71427 4422 351351-03515 051PTFEFEE Operations:OperaPolarr Seals ApS,p Espergaerde,Espergp gDenmarkm kmarPh: ( 4545) 49 12170041 170BietigheimAdvanceded Products NVNV, Boom,Boom BelgiuBelgiumgiumPh: ( 32) 3 880 818 50Sadska, Czech RepublicepublicPh: ( 420) 325 55555 111Asia:Parker Hannifin Motion & ControlCoCo.,, Ltd.Shanghai, ChinaPh: ( 86) 21 28995181DenmarkBelgiumCzech Republic02/15/081-11www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Manufacturing ExcellenceParker’s manufacturing capabilities accommodatea wide range of dynamic sealing needs, providing thefollowing value benefits to our customers:s All manufacturing operations offer state of the artprocesses and procedures that enable Parker toprovide world class products, in both standard andcustom profiles.s Specialized cellular manufacturing and lean concepts enable Parker to handle both low and highvolume runs with equal efficiency.s Breadth of tooling capability produces diametersas small as 1/16 inch and as large as 9 feet without splicing.s Custom high speed trim machines ensure a sharpsealing edge for the ultimate seal performancewherever possible.performance of any urethane in the industry. Ourcommitment to quality and research and developmentremains a top priority to ensure leading edge status innew material development. With in-house processing,from manufacturing the plastic pellet to molding thefinished product, Parker maintains strict controls whichensure the delivery of quality products from qualitymaterials — start to finish.Rubber OperationsWith over 400 unique rubber compounds, Parkerhas the largest selection of materials available in theindustry. Our material offering includes custom blendsof nitrile, ethylene propylene and fluorocarbons,among others. If an application demands uniquematerial specifications, our in-house chemists havethe expertise and capability to assist in specifyingand validating optimal materials to meet systemrequirements. State of the art rubber moldingprocesses such as compression, transfer, injectionand injection-compression are used to manufacturethe highest quality products.Plastic ManufacturingPTFE OperationsParker’s PTFE operations manufacture highquality machined seals from ¼ inch to 72 inches indiameter, utilizing virgin and proprietary blends of filledPTFE. A wide variety of PTFE fluid power seals aremanufactured on state of the art CNC equipment withlive tooling and multi-axis capabilities. Automatedprocessing allows the efficient handling of both lowand high volume runs. PTFE production at Parkeris entirely an internal system, from material blendingand molding to sintering and CNC machining. Ourcommitment to quality and service is supportedby investment in advanced technology, test andinspection methods.Rubber Injection PressPlastic OperationsOur plastics material offering includes such sealindustry standards as Molythane , PolyMyte ,WearGard , MolyGard , and many more. Parker’sResilon family offers the highest temperaturePTFE Manufacturing09/01/071-12www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Applications EngineeringOur team of application engineers can help youfind the most reliable, cost-effective sealing solutionfor your product. These engineers are experts,combining decades of sealing experience in real-worldapplications with a full complement of technologydriven tools to produce the answers you need.FEAUtilizing advanced non-linear Finite ElementAnalysis (FEA) software our engineers can performextremely accurate virtual simulations of materialperformance based on actual physical test data. Thesesimulations eliminate the need for multiple iterationsof costly prototype tooling, and dramatically reducedevelopment lead times. They also ensure first-timeselection of the best material and geometry for yourapplication.Low pressure life cycle testingMechanical Test LabParker’s mechanical test lab is an important assetfor validating new designs and qualifying sealsto customers’ performance specifications. Oursophisticated mechanical testing lab utilizes severalbreakthrough technologies, enabling engineers tovalidate seals and sealing systems for hydraulic,pneumatic and rotary systems. All product testingis carried out in accordance with ASTM andSAE specifications as well as customer-specificrequirements.Pneumatic cylinder testingHydraulic testing capabilities include pressuresup to 10,000 psi with environmental chambers tocontrol temperatures from -40 to 300 F. Tests canbe performed on assembled cylinders or can beconfigured on test stands which isolate performance ofrod seals, piston seals and wipers for troubleshootingand fine tuning. For heavy contamination situations,our dust chamber can be used to simulate the mostrigorous operating environments, putting seals to theultimate test.High pressure hydraulic leakage testingPneumatic testing is also environmentally controlledto simulate a variety of operating conditions.Endurance and life cycle tests can be performedon applications of all speeds and pressures, fromautomation and assembly cylinders to high speedpneumatic hand tools.Rotary testing capabilities range from low speed,high pressure hydraulic swivels to high speed gearbox and bearing applications in extreme operatingconditions, validating seal performance across a widerange of industries.Rotary hydraulic testing09/01/071-13www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

Catalog EPS 5370/USAIntroduction1Premier Customer SupportWorldwide and local support is just a phone callaway. Our local Parker sales representatives providea single point of contact for local sealing support. Ourestablished worldwide network of over 300 distributorand service center locations combined with factorydirect representatives, including global sales andengineering, ensures access to quality products andengineering services anytime, anywhere.Customer service is a key component of theParker package. Electronic ordering systems suchas EDI and PHconnect make placing and trackingorders easy. Our knowledgeable customer servicerepresentatives are only a phone call away at801 972 3000.CMM: Coordinate measuring tool inspectionParker is consistently willing to explore newideas with the companies and individuals we serve.Customers come to Parker for different reasons, butour role is always the same . . . working to use ourexpertise and help our customers engineer theirsuccess.SmartScope inspectionQuality CommitmentParker is committed to consistently deliveringexcellence in quality and service through continuousimprovement of our people, products and systems.Our manufacturing facilities are registered to eitherAS9100, ISO/9000, or TS16949 standards.Our commitment to quality and service is supportedby our investment in advanced test and inspectionmethods and equipment. Parker constantly strivesto improve customer satisfaction and product qualitythrough the implementation of:s Six Sigmas Lean manufacturings Kaizen eventss TQMs Advanced product quality planning (APQP)s Feasibility studies09/01/071-14www.parkerseals.comParker Hannifin CorporationEngineered Polymer Systems DivisionPhone: 801 972 3000

EngineeringCatalog EPS 5370/USA2ContentsSealing Theory . 2-1Static vs. Dynamic Sealing . 2-1Leakage Control . 2-2Lip vs. Squeeze Seals . 2-2Effects of Lip Geometries . 2-3Friction. 2-3Parker Fluid Power Seals for All ApplicationTechnologiesSeals have been used since ancient times and have evolved into awide variety of shapes and materials. For those who are not familiar withsealing technology, the number of options available can be confusing.Selecting the most suitable product for a given application can bedifficult. This engineering section will assist in product selection byexplaining the fundamentals of seal design and material technology.Pressure Effects & Extrusion. 2-4Seal Wear. 2-5Seal Stability. 2-6Sealing TheorySurface Speed. 2-6Static vs. Dynamic SealingCompression Set. 2-7Every seal, whether static or dynamic, must seal against at least twocontacting surfaces. In static applications, both surfaces are non-movingrelative to one another. In dynamic applications at least one surfaceis in motion relative to the other sealing surface(s). For example, in astandard hydraulic cylinder, the rod and piston seals would be classifiedas dynamic seals, while the seal between the bore and the head glandwould be considered a static seal.Influence of Temperature. 2-7General Guidelines for HardwareDesign . 2-8Hardware Surface FinishSurface Finish Guidelines . 2-9Surface Finish FAQs. 2-13InstallationConsiderations . 2-14Installation Tools - Piston. 2-16Installation Tools - Rod . 2-17In both static and dynamic applications, a certain amount of squeezeor compression is required upon installation to maintain contact withthe sealing surfaces and prevent fluid leakage. Dynamic applications inparticular involve other variables and require that additional factors beevaluated to ensure proper system performance. These variables arediscussed in the following sections.Finite Element Analysis . 2-18Fig. 2-1. Hydraulic

Bi-directional rubber energized nylon step-cut piston cap seal. 7-13 PIP Bi-directional piston seal created by the combination of a Pressure Inverting Pedestal (PIP) back-up ring and Type B PolyPak. Standard material is a 4615 PolyPak with a 4617 PIP ring. 7-15 Symmetrical Seals for Rod or Piston Applications (See Section 6) Profile Description