Transcription

VTT TECHNICAL RESEARCH CENTRE OF FINLAND LTDPotential for Bio-CCS in the pulpand paper industryK. Onarheim, S. Santos (prev. IEA GHG), P. Kangas(VTT), V. Hankalin (ÅF Consult Oy)Market and regulatory issues related to Bio-CCUSWorkshop Brussels, 16 January 2018

Bio-CCS negative CO2 emissions2

Pulp and paper millCookingWashingDelignificationBleachingWood lantLime kilnPowergenerationBleaching chemicalpreparationMulti-fuelboilerCourtesy of Valmet3

Battery limits reference casesIntegrated pulp and board millMarket pulp mill400 000 adt/a800 000 adt/aPulp millBoard mill740 000 adt/aTotal CO2 2.19 Mt/aBiogenic CO2 2.07 Mt/a4

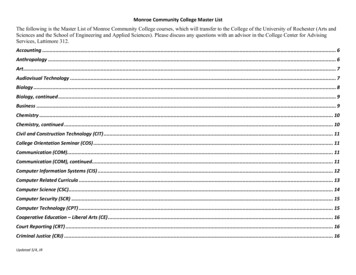

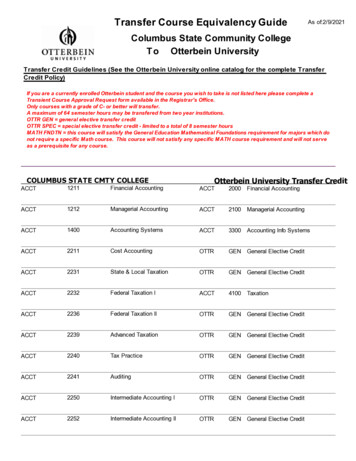

Case studiesTotal emissionsCapture case description(site after CCS)[MTPY]Total CO2 captured[MTPY]Overall CO2Total directNegativecapture rateCO2 avoidedCO2 emissions[%][%][MTPY]KRAFT PULP MILL1. Recovery boiler684 0001 478 00068.468.41 478 0002. Multi-fuel boiler1 892 000271 00012.512.5271 0003. Lime kiln1 965 000197 0009.19.1111 0004. Recovery boiler and multi-fuel boiler413 0001 749 00080.980.91 749 0005. Recovery boiler and lime kiln487 0001 675 00077.577.51 589 0006. Recovery boiler, multi-fuel boiler and lime kiln1216 0001 946 00090.090.01 860 000INTEGRATED PULP AND BOARD MILL1. Recovery boiler2834 0001 478 00064.061.51 478 0002. Multi-fuel boiler1 892 000271 00012.512.5271 0003. Lime kiln1 965 000197 0009.19.1111 0004. Recovery boiler and multi-fuel boiler2646 0001 749 00073.170.11 749 0005. Recovery boiler and lime kiln2706 0001 675 00070.467.31 589 0006. Recovery boiler, multi-fuel boiler and lime kiln2566 0001 946 00077.5373.81 860 0001MP steam at 13 bar to supply CO2 capture plant 2 CO2 compressors driven by backpressure steam turbines. Auxiliary boiler needed5

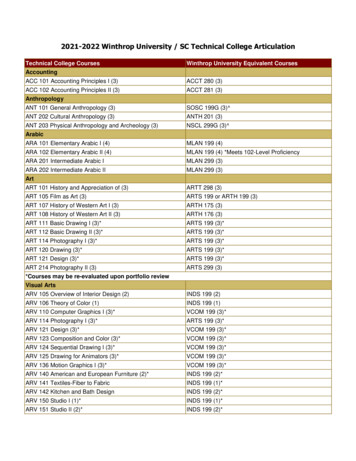

Levelized cost of pulp (LCOP) and associatedcost of CO2 avoidedKraft pulp millIntegrated pulp and board millLCOP /adt pulpCAC /t CO2LCOP /adt pulpLCOB /adt boardCAC /t CO2Reference market pulp mill without CO2 capture523-523680-Capture of CO2 from recovery boiler only6436567168082Capture of CO2 from multi-fuel boiler only5549155668092Capture of CO2 from lime kiln only5438354568084Capture of CO2 from recovery boiler and multi-fuel boiler6596269568084Capture of CO2 from recovery boiler and lime kiln6526268768083Capture of CO2 from all three sources6776371468088Caseadt air dried tonne6

Effect of electricity price on LCOP, pulp millBase CaseRECMFBLKREC MFBREC LKREC MFB LKBreakeven price of pulp [ /adt]700 650 600 550 500 450 10 20 30 40 Electricity price [ /MWh]50 60 70 7

Potential for Bio-CCS with negative emissioncredits, pulp millBreakeven price of pulp [ /adt]750 700 650 600 550 500 450 400 0 20 40 60 Negative CO2 emission credit [ /t]80 100 8

Potential for income with CCU, pulp millRECMFBLKREC MFBREC LKREC MFB LKCO2 avoided cost [ /t]140 120 100 80 60 40 20 -30 -20 -10 0 10 20 CO2 income [ /t]30 40 50 9

Concluding remarks Pulp and paper potential candidate for industrial Bio-CCS demonstration 75-100% biogenic CO2 emissions Low-hanging fruit Negative emissions Feasibility of Bio-CCS is dependent on policy framework CO2 emission tax Renewable energy incentives Negative CO2 emissions ETS for feasible CO2 capture from pulp and paper industry 60 – 70 /t Long-term political instability is detrimental Assessment done for the pulp and paper industry, but the principals are at large thesame for any industry sector emitting biogenic CO2 emissions Waste to energy Biofuel production Biomass-fired power and heat generation Replacing coal or other fossil fuels with biomass (iron and steel, cement)10

Full portsArticle Part 1 (technical 2.008Article Part 2 (economic 09.01011

Thank you for your attention!

Battery limits reference cases Pulp mill Board mill Market pulp mill Integrated pulp and board mill Total CO 2 2.19 Mt/a Biogenic CO 2 2.07 Mt/a 800 000 adt/a 400 000 adt/a 740 000 adt/a. 5 Case studies Capture case description Total emissions (site after CCS) Total CO 2 captured . Replacing coal or other fossil fuels with biomass (iron and .