Transcription

An Overview of Hazardous (Classified) LocationArea Electrical ClassificationbyDavid WechslerApril 3, 2003Overview EAC by David Wechsler1

Area ElectricalClassification.Installation ofElectrical ApparatusElectrical Equipment Certifications, ListingsHazardous AreaMarkings–Explosion proof–Pressurized–Oil Immersion–Non incendive–Hermetically sealed–Intrinsic Safety2

Area Electrical ClassificationWhat's involved with it?Risk AssessmentOverview EAC by David Wechsler3

What is an Area ElectricalClassification?Risk based methodology used to quantify materialcharacteristics with potential electrical ignitionsources resulting in the objective of reducing afire/explosion potential.Areas found to be applicable are considered“hazardous (classified) locations”.Overview EAC by David Wechsler4

Location Electrical Classification TeamDevelop Classification Team Procedural Planthat defines:Objectives Electrical ClassificationTeam Members and responsibilitiesDocumentation of Classification workOverview EAC by David Wechsler5

The Area Electrical ClassificationTeam Assemble teamMinimum 3 people with expertise levels Operations - processElectrical - maintenance and designProcess SafetyOverview EAC by David Wechsler6

Location Electrical Classification TeamMaintain well documented, complete, area ElectricalClassification information that is readily available.Suggestion: Use dated Classification Drawing to reflectSpecific Materials and their Material Group, AITNotes if the classification is differentfrom “Standard” criteriaNotes to link supportive informationi.e., purged buildingOverview EAC by David Wechsler7

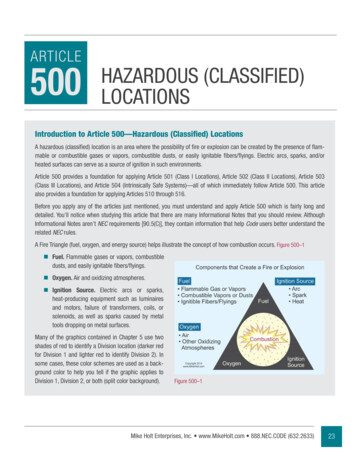

The Fire TriangleThe Hazardous (Classified) Location MethodologyFuelOxygenClass I, II, etc.AtmosphereIgnition SourceElectricalsOverview EAC by David Wechsler8

Data CollectionWhat are the processing conditions?What materials are used?Where are the materials used?How are the materials used?Are there any ignition sources, actual or potential, in the area?Note: Not all potential ignition sources are electrical in nature.Example, High pressure steam lines.Overview EAC by David Wechsler9

Data CollectionExample of some forms for data collection:Overview EAC by David Wechsler10

Assessment of RiskWhat is the Risk?The Fire TriangleNot much control overPresence of fuelin the atmosphereFuelOxygenIgnition SourceMitigation as needed Electrical Apparatus selectionOverview EAC by David Wechsler11

the Standards WorldCanadaCECATEXCENELECUS OSHANECIECOverview EAC by David Wechsler12

ComparisonClassification Methodologies “Class, Division”––––––––Class I, Division 1Class I, Division 2UnclassifiedGroup AGroup B (hydrogen)Group C (ethylene)Group DT Code T1, T2, T2AD, T3, T3A-C, T4-A,T5, T6 (450-85 C) “Zone 0”–––––––––Zone 0Zone 1Zone 2UnclassifiedGroup IICGroup IICGroup IIBGroup IIAT Code T1-T6(450-85 C)13

Division SystemDivision 1Zone SystemDivision 2Zone 1Zone 2Zone 0Division 1Overview EAC by David Wechsler14

HazLoc Classification basedupon the NECI. Definitions and ExplanationsA. Class I, II, III - Define the materialB. Divisions- Address the risk; probability and frequencythe material being present inhazardous (ignitable) concentrations.Division 1 - Present frequentlyDivision 2 - Present only under abnormal operationsUnclassified - Not likely to be present at allOverview EAC by David Wechsler15

NEC Group B(D) ClarificationExample, NFPA 497 Selected Class I ChemicalsMaterialCAS 106-99-0DDB*DFlashpoint C31-54-76AIT 41.9Note: B*D means this material exhibits properties that places it into the Group Bcategory. However, permission to use Group D electrical equipment is given, provided allconduit ½ in. and larger is sealed. This is a design choice and for classification purposesthe area(s) where this material is used should be reflected as Group B*D locations.Overview EAC by David Wechsler16

NFPA 4 9 7 A - Pro c e s s Equipme ntEffe c t s o fSiz eFlo wPre s s ureS O URCEGRADEPro ces sEquipmentPro ce s sSize( gntallo ns) eEquipmeSizPreP res ssuresFloF low wRat e( p s i)( g pm)S m a ll/ Lo w 5 0 0 0Mo de rate5 0 0 0 -2 5 0 0 0 1 0 01 0 0 -5 0 0 1001 00 -50 0La rg e / Hig h 25000 5 0 0 5 0 0S iz ePre s sF lo wOverview EAC by David Wechsler17

25'NFPA 4 9 7 AEffe ct s o fGRADESiz ePre s s ureFlo wS O URCEA{BC{3'15'50'100'BAPro c e s sEquipme ntS iz e10'S m a ll/ Lo wMo de rat eLa r g e / Hig hPro c e s sEquipme ntProc e s sS iz ipe me ntEquPre s sPPrrees ss sF lo wFFlol owwS m a ll / Lo wMod e rate La rg e / Hi g hS iz eCPro c e s sEquipme ntS m a ll/ Lo wMo de rat eLa r g e / Hig hS iz ePre s sF lo wOverview EAC by David Wechsler18

Classification DocumentationClassification Drawing should contain:a) Specific chemical(s), AIT, Group informationb) Notes regarding classification detailsc) Approvals with signatures forProcess EngineeringManufacturingControl Systems/ElectricalSafetyd) Dates for drawing, Revisions, and sign-offsOverview EAC by David Wechsler19

Combustible Dust - Ignitible Fiber ZoneNew NEC proposal( under consideration)Proposed:Existing:NEC Article 502 - Combustible DustsNEC Article 503 - Ignitible FibersClass II, Division 1Division 2UnclassifiedGroups E, F, and GClass III, Division 1Division 2UnclassifiedNEC Article 506 - Zone 20, 21, and 22 Locationsfor Flammable Dusts, Fibers, and FlyingsZone 20Zone 21Zone 22UnclassifiedOverview EAC by David WechslerNo groups20

Area ElectricalClassification.Electrical ApparatusConsiderationsHazardous Area–Explosion proof–Pressurized–Oil Immersion–Non incendive–Hermetically sealed–Intrinsic SafetyElectrical ApparatusCertifications, ListingsMarkings21

URCE BOX"50'CONTROLROOMSTREETPROCESS UNITWITHAREACLASSIFICATIONDIMENSIONSPLOT BOUNDARYCOOLINGTOWER50'Pump lValves,ManifoldEtc.Classified AreasClass I Div 250'STREET50'FIRED HEATERTop of Deck Only (ifreq'd)PLOT BOUNDARYSTREETOverview EAC by David Wechsler22

the Standards WorldCanadaCECATEXCENELECUS OSHANECIECOverview EAC by David Wechsler23

Decisions, decisions.Zone 0DivisionClass IAffecting:Instrumentation Control SystemsArea Electrical ClassificationEquipment, Installation,MaintenanceIntrinsic safetyExplosion- proofPressurizedOverview EAC by David Wechsler24

Equipment Type ComparisonsElectrical Code US Electrical Code Class, Division––––––Explosion proofPressurizedOil ImmersionNon incendiveHermetically sealedIntrinsic safety (partial) IEC Electrical Codes Zone 0––––––––FlameproofPressurizedOil ImmersionNon sparkingEncapsulatedIntrinsic safety (full)Increased safetySpecial protection25

Installation Consideration ComparisonsUS Electrical Code Conduit withExplosionproof seals Cable Tray Thread type andengagement Wire gauge/ampacity Grounding/bondingIEC Electrical Codes Cable, with Cableglands Cable Tray Metric Thread type andengagement Wire gauge/ampacity Earthing26

Equipment selectionSome considerations What is the application?What is the best functional apparatus within cost considerations?Installation and wiring/cabling method?Is the apparatus available as being “suitable” for the AreaElectrical Classification?Overview EAC by David Wechsler27

Is the apparatus “suitable”suitable forthe AreaElectrical Classification?Suitability of identified equipment may be determined by one of the following:(1) Equipment listing or labeling(2) Evidence of equipment evaluation from a qualified testing laboratory orinspection agency concerned with product evaluation(3) Evidence acceptable to the authority having jurisdiction such as a manufacturer'sself-evaluation or an owner's engineering judgmentOverview EAC by David Wechsler28

Cross-Fertilizationof Electrical ApparatusCan IEC electrical apparatus beinstalled as a general rule in a US Class I, Division 2 location?Answer: Highly probableCan IEC electrical apparatus beinstalled as a general rule in a US Class I, Division 1 location?Answer: Only if you are one of those unique folks thatdaily enjoys running 25 miles, when the temperatureexceeds 101F and the humidity exceeds 88%,you might find a way, but not as a general installation rule.Overview EAC by David Wechsler29

Area ElectricalClassification.Electrical ApparatusConsiderationsHazardous Area–Explosion proof–Pressurized–Oil Immersion–Non incendive–Hermetically sealed–Intrinsic SafetyElectrical ApparatusCertifications, ListingsMarkings30

the Standards WorldCanadaCECATEXCENELECUS OSHANECIECOverview EAC by David Wechsler31

Electrical Equipment MarkingsUnited StatesUnderwriter Laboratory ListingFactory Mutual ApprovalULFa c t o ryMu t u a lSys t e mAp p ro v e dCanadaCanadian Standards Approval CertificationOverview EAC by David WechslerCSA32

Equipment MarkingCENELEC & IECCe rt ific a t io n Co d e fo r CENELEC{{{{EEx ia IIC T4Te m p e r a t u re c la s s ific a t io nAp p ar at us Gro up ( g a s )Pro t e ct io n co nc e p t ( IS)Exp los io n p rot e ct e dCe rt ifie d t o t he CENELEC s t an da rdCENELEC Pro te ct io n Co d edFla m e p r o o fiaIn t r ins ic Sa f e t yeInc re a s e d Sa fe t ypPr e s s u r iz a t io nnNo n -in c e n d iv esS p e c ia lIP or Ing re s s P ro t e c t ion Cod e sFirs t n um e ra lP ro t e ct io n Aga ins t0123456S e c on d Num e ra lP ro t e ct io n Ag a ins ts o lid b od ie sNo pro t e c t ionOb je c t s g re a t e rOb je c t s g re a t e rOb je c t s g re a t e rOb je c t s g re a t e rDu s t -Pr o t e c t e dDu s t - T ig h tt hant hant h ant h an50122 .51 .0mmmmmmmm012345678liqu idNo p ro t e c t io nVe rt ica lly d rip ping wa t e rAngle d ripp in g wa t e rSpr aye d wa t e rSpla s he d wa t e rWa t e r je t sHe a vy s e a sEff e ct s o f imme rs io nIn d e f in it e imm e r s io nIP vs NEMA301312323R643651 2 , 1 2 X a nd 1 3664 a nd 4 X33

Equipment MarkingUS - IECCe rt ific a ti n Co de fo rE E{{{{AExEEx ia IIC T4Te m p e r a t ur e c la s s ific a t io nAp pa ra t u s Gro up ( g as )Pr ot e ct io n c o nc e p t ( IS)Exp lo s io n pr ot e ct e dCe rt if ie d t o t he CENELEC s t a nd a rdCENELEC Pro te ct io n Co d edFla m e p r o o fiaIn t r ins ic Sa f e t yeInc re a s e d Sa fe t ypPr e s s u r iz a t io nnNo n -in c e n d iv esS p e c ia lIP or Ing re s s P ro t e c t ion Cod e sFirs t n um e ra lP ro t e ct io n Aga ins t0123456S e c on d Num e ra lP ro t e ct io n Ag a ins ts o lid b od ie sNo pro t e c t ionOb je c t s g re a t e rOb je c t s g re a t e rOb je c t s g re a t e rOb je c t s g re a t e rDu s t -Pr o t e c t e dDu s t - T ig h tt hant hant h ant h an50122 .51 .0mmmmmmmm012345678liqu idNo p ro t e c t io nVe rt ica lly d rip ping wa t e rAngle d ripp in g wa t e rSpr aye d wa t e rSpla s he d wa t e rWa t e r je t sHe a vy s e a sEff e ct s o f imme rs io nIn d e f in it e imm e r s io nIP vs NEMA301312323R643651 2 , 1 2 X a nd 1 3664 a nd 4 X34

ATEX MarkingEquipment GroupID-Number ofNotfied BodiesCategoryGas (G) or Dust (D)0102 II 1 GZone 0EXLUX 6008/142-83Example for type of seriesR. Stahl3Example for ManufacturerEEx de IIB T4 3Example for type of explos. protectionPTB 96 ATEX 2144X 3 Example for test numberATEX 100EN 500140102 II 2 GZone 1EEx ia IIC T4 3Example for type of explos. protectionPTB 96 ATEX 3844X 3 Example for test number0102 II 3 GZone 2EEx n IIA T4 3Example for type of explos. protectionPTB 96 ATEX 3244X 3 Example for test number35

CertificationsCountryUSAApplicable CertificationEuropeNationally Recognized TestingLaboratory (NRTL)- example: FM,UL, ETLStandards Council of Canada certifiedbody- example: CSAATEX- EU Notified BodyAustraliaANZEx scheme for certification bodyCanadaOverview EAC by David Wechsler36

The certification “mark” will drive where theelectrical apparatus may be installed.While an objective is to be able to haveglobally acceptable markings, there currently isnone yet.Overview EAC by David Wechsler37

Area ElectricalClassification.Installation ofElectrical ApparatusElectrical Equipment Certifications, ListingsHazardous AreaMarkings–Explosion proof–Pressurized–Oil Immersion–Non incendive–Hermetically sealed–Intrinsic Safety38

The Speaker - Dave Wechsler is aGlobal Process Safety Technology Leaderlocated at the Dow Chemical Freeport TX facility.He is also the Technical Resource Leader forDow's Global Electrical Area ClassificationTechnical Resource Network which is the coregroup that addresses area classification issues forthe Dow Chemical Company locations, globally.Dave is the Principle American Chemistry Council,formerly CMA, representative on the NEC CMP-14responsible for the Chapter 5 Hazardous (Classified) Locations Articles,and on the Electrical Equipment in Chemical Atmospheres (EECA)that is responsible for NFPA 496, 497 and 499, as its former vice chairman.A senior member of ISA, Dave is also very active on SP12 and many of itshazardous locations committees. He is also a member of theANSI/IEC -Technical Advisory Group working with IEC standardsrepresenting "user" interests.Overview EAC by David Wechsler39

Example, NFPA 497 Selected Class I Chemicals. Overview EAC by David Wechsler 17 Sm all/ Lo w Larg e / Hig h Proces s Equipment Size Pre s s Flo w Mod er t Pressure (psi) Flow Rate (gpm) Size (gallons) Proce s Equipment S OURCE GRADE S iz e Pre s s Flow NFPA 4 9 7 A - Process Equipment Effects of Size Pressure Flow 5 0 0 0 5 0 00 - 2 5 0 0 0 2 5 1 0 1 0 0- 5 0 0 5 1 0 0 1 0- 5 .