Transcription

Funded by Departmentof Employment and IndustrialRelations, Workplace Health andSafety QueenslandOffice of Education and EmploymentHazardous SubstanceRisk Assessment Guidefor the CompositesIndustry

Risk Assessment GuideIndex2Hazardous Substance Risk Assessments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Hazardous Substance Risk Assessment Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Appendix A: Risk Assessment Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Appendix B: Chemical Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Specific Risk Assessment Forms:nnnnnnnnnnnnnReferencesPolyester Resin and Gel Coats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Methyl Ethyl Ketone Peroxides (MEKP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Glass & Carbon Fibre (Mat, Fabric, Continous Strand Rovings) . . . . . . . . . . . 35AcetoneFillers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43Cobalt 6% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47DMA (N,N-dimethylanaline) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51Epoxy Resin Part A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Epoxy Resin Part B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Polyamine-Based Hardeners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Polyurethane Resins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67Polyurethane Curing AgentsMould Release Agents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75Queensland legislationWorkplace Health and Safety Regulation 1997 – Part 13 Hazardous SubstancesWorkplace Health and Safety Code of Practice – Risk Management 2007Workplace Health and Safety Code of Practice – Hazardous Substances 2003Dangerous Goods Safety Management Regulation 2001nnnnAustralian Standards/New Zealand StandardsAS/NZS 4360:2004 - Risk managementHB 436:2004 - Risk management guidelines – Companion to AS/NZS 4360:2004AS 1319:1994 - Safety signs for the occupational environmentnnnMaterial Safety Data Sheets (MSDS) – for various products.This booklet has been produced through funding by the Queensland Government– Department of Employment and Industrial Relations and in collaboration withComposites Australia.

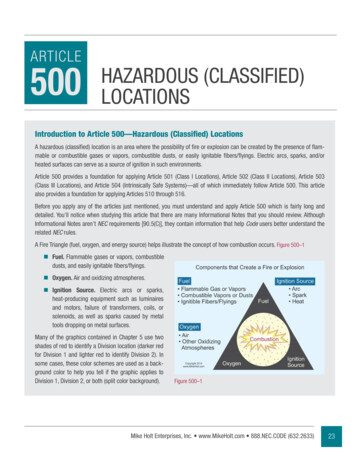

Risk Assessment GuideHazardous SubstanceRisk Assessments3Queensland Workplace Health and Safety legislation requiresthat the risks from using a hazardous substance at work beassessed. A record of this assessment be made and keptand communicated to all personnel using the substance.A hazardous substance risk assessment is a process of applying information aboutthe substance to the way that it is used. The risk assessment will help you work outif the substance is being used safely, and if not – how to use it safely.The benefits of preparing a written hazardous substance risk assessment are to:nnnnProvide the obligation holder with all details of chemicals used atthe workplaceSet the framework on information and training for workersEstablish systems of workCreate a safe environment in which to work.This guide has been designed for the Composites Industry to provide:nnA step-by-step approach on how to do hazardous substance riskassessmentsA risk assessment template (Appendix A).The supplement to this guide ‘Generic Hazardous Substance Risk Assessments’provides example risk assessments on many hazardous substances used in thecomposites industry to assist operators in that industry. These risk assessments aregeneric only. Circumstances are different in every workshop therefore your riskassessments may be significantly different.A register listing all hazardous substances must be kept in the workplace.A form for this purpose is also included (Appendix B).Note: There may be hazardous substances used at your workplace that are notincluded in the supplement.

Risk Assessment GuideWhen to do a HazardousSubstance Risk Assessment:4Current hazardous substances used in the workplace:Do a risk assessment:nnnnnnNow, if a risk assessment has not yet been doneWhen there are significant changes to the way in which the substance is usedWhen new information about the substance becomes available(refer to changes in the Material Safety Data Sheet – MSDS)When health surveillance or monitoring shows the control measuresare inadequateWhen there are changes to control measuresIf it is more than 5 years after the last risk assessment was done for asubstance.New hazardous substances introduced to the workplace:nBefore doing yourHazardous SubstanceRisk Assessment:Before using the substance.Before starting on your hazardous substance risk assessments, you will need:nnnnnA current (less than 5 years old) Material Safety Data Sheet (MSDS) for eachhazardous substance used at your workplace. If you don’t have an MSDSask the supplier for a copyThe job tasks where this substance is used. This should include: How it is used. It may be necessary to do multiple risk assessmentfor the one substance if it is used in different ways and the exposures vary.For example, one risk assessment may be needed for mixing a substanceand one for applying the substance How much is used How often it is usedInformation on any safety controls currently used in the workplace. This may be: Engineering controls such as ventilation or dust extraction systems Personal Protective Equipment (PPE)Recorded information on any injuries or illnesses caused by use of thesubstance. This may be from your workplace or other workplaces usingthe substanceInformation on like or similar products.It is possible to group substances that are similar in their ingredients and howthey are used. Therefore one risk assessment may cover a number of hazardoussubstances.However it is essential to carefully check the MSDS for each substance to ensureall potential exposures and ingredients are covered in the risk assessment.The Supplement to this guide provides risk assessments for generic productsused within the composites industry. Information for the specific substancesused in your workplace will need to be used for any risk assessment developed.

Risk Assessment GuideBefore doing yourHazardous SubstanceRisk Assessment (Cont):The generic risk assessments are:nnnnnnnnnnnnnnnHow to do a HazardousSubstance RiskAssessment:5Polyester Resin and Gel CoatsMethyl Ethyl Ketone Peroxides (MEKP)Glass and Carbon Fibre (Mat, Fabric, Continuous Strand Rovings)AcetoneFillersCobalt 6%DMA (N,N-dimethylanaline)Epoxy Resin Part AEpoxy Resin Part BPolyamine-Based HardenersPolyurethane ResinsPolyurethane Curing AgentsMould Release AgentsTo check the MSDS for hazardous substance classification.Check the MSDS for wording like “Hazardous according to the criteriaof NOHSC”. If the substance is not classified as ‘hazardous’ it can still haveeffects on the health of people using it. The obligation on an employerto ensure the health and safety of employees are protected still applies.Therefore you will still need to assess and control the risks.To observe what is actually done.A risk assessment cannot be done by sitting at a desk. You will needto observe employees completing tasks and activities to collect sufficientinformation to complete a risk assessment. This may need to be donein stages.Using the risk assessment form attached to this guide (see appendix A) is oneway of keeping a suitable hazardous substance risk assessment record.However you can make your own record if you prefer (refer to the WorkplaceHealth and Safety Regulation for what must be recorded and for further details onthe risk assessment record).The following guidance is provided to assist in completing the risk assessmentform attached to this guide.

Risk Assessment Guide6(Insert the name of your business here)Business Name:ExampleBusiness Name:ABC Marine CompanyHazardous Substance Risk AssessmentsName of SubstanceInsert the name of the hazardous substance.If you are grouping a number of substances, write the ‘group’ name hereand refer to an attachment where each substance is listed.If you are doing more than one risk assessment for the one substance,e.g: one for mixing and one for application, you may refer to this in the name.For example, Mixing Epoxy Resin Part A.You should also record the name of any related risk assessments to the oneyou are doing.You may also select the relevant dangerous goods symbols and insert it belowthe name of the substance.ExampleName of Substance:Epoxy Resin Part ARelated Risk Assessments:Epoxy Resin Part B1. How is the substanceused?Describe the task in which the substance is used.If the substance is used for a number of different tasks a risk assessment maybe needed for each task.Write a brief statement on how the substance or group of substances is usedby employees.Remember you must observe what your employees actually do with the substance.Example1. How is the substance used?– i.e. describe the task?(If the chemical is used for a numberof different tasks a risk assessmentmay be needed for each task).Mixed with Epoxy Resin Part B and then sprayedor brushed onto finished surfaces.

7Risk Assessment Guide2. How are peopleexposed to thesubstance?Tick or mark the applicable routes of entry on exposure. Refer also to the MSDS.There are four ways (routes of exposure) a hazardous substance can entera person’s body:Skin – absorbed through the skin and affects other parts of the body or can affectthe skin directly. The substance may be splashed straight onto the skin or ontoclothes and then soaks through to the skin. The skin may come into contactwith the substance through vapours, mists, fumes or dusts etc.Eyes – This is the same as for skin. That is via splashes, vapours, fumes, mists ordusts. The substance may affect the eyes directly or can be absorbed throughthem.Inhalation – the most problematic route of entry. This can be via vapours, mists,fumes or dusts etc which are breathed in and either do damage where they hita surface in the respiratory system or are absorbed by the body and causehealth problems.Ingestion – the least common type of exposure and is caused by swallowingthe substance.Example2. How are people exposed tothe substance?(Tick or mark applicable routes ofentry)Skin (splashed onto or absorbed through)Eyes (splashed onto or absorbed through)Inhalation (breathed in)Ingestion (swallowed)3. How much of thesubstance are workersexposed to during thetask?3333Record the actual amounts e.g: millilitres, milligrams, kilograms or grams, etc.Observe several tasks being performed and record the amounts to whichemployees are exposed.Example3. How much of the substanceare workers exposed to duringthe task?(e.g: in litres/millilitres, kilograms/grams)0.05millilitres per task

Risk Assessment Guide4. For how long areworkers exposed to thesubstance?8Record the actual hours in a day and the number of days per week employeesare exposed to the substance.Do they use it every day for most of the day or is the substance usedonly occasionally?Example4. For how long are workersexposed to the substance?6 minutes per day 5 days per week(How often is the chemical used. e.g:in hours per day and days per week)5. Briefly, what are thehealth effects ofexposure to thissubstance?Read through the MSDS and in particular the Health Hazard Information section.The information in this section will relate directly to the routes of entry explainedabove in Question 2. Summarise and record the health effects from exposureto the substance.You should also refer to the Poison Schedule on the MSDS for additional information.(Refer to the MSDS)Example5. Briefly, what are the healtheffects of exposure to thissubstance?Skin:May cause irritation, drying and cracking.Eyes:Mild to moderate irritation on enteringeye, if in eye for sometime productcould swell and redden the eye.(Refer to the MSDS)Inhalation: Harmful if inhaled. Inhalation over longperiods may cause nervous systemimpairment.Ingestion:6. What engineeringcontrol measures arerecommended?Harmful if ingested.Read through the MSDS and in particular the Precautions for Use section.Summarise and record all relevant information on the risk assessment.(Refer to the MSDS)Example6. What engineering controlmeasures (e.g: extraction,ventilation, dilution ventilation)are recommended?(Refer to the MSDS)nnUse in well-ventilated areaLocal ventilation is usually required to removesolvent fumes from areas.

Risk Assessment Guide7. Are any other controlmeasuresrecommended?Read through the MSDS. Summarise and record all relevant informationon the risk assessment.Other controls might include:n(Refer to the MSDS)9nnnnRotation of employees to minimise the length of exposure to each individualusing the substanceUsing the substance out of hours to decrease how many people willbe exposedWriting procedures on how to do the task safelyTraining and supervision of employeesClear access to fire fighting equipment and first aid equipment such aseye wash stations or first aid kits.In this section of the Risk Assessment you may also insert the relevant fireextinguisher symbol and record other appropriate information.Dangerous Goods Safety Management courses (Course No. 30308 and 30309)are available in Queensland.Example7. Are any other controlmeasures (e.g: procedures,rotation of people, using thesubstance after hours tominimise how many peopleare exposed) recommended?On combustion, product may emittoxic fumes of Carbon Monoxide (CO).n Fire fighting equipment suppliedand serviced

n AS/NZS 4360:2004 - Risk management n HB 436:2004 - Risk management guidelines – Companion to AS/NZS 4360:2004 n AS 1319:1994 - Safety signs for the occupational environment Material Safety Data Sheets (MSDS) – for various products. This booklet has been produced through funding by the Queensland Government – Department of Employment and Industrial Relations and in collaboration