Transcription

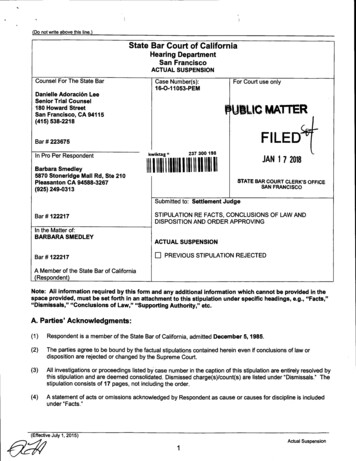

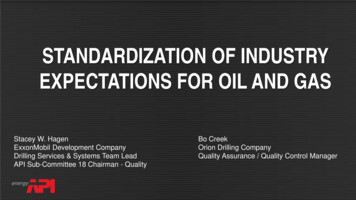

Dowel Bar StandardizationNC 2 Spring MeetingSavannah, GA

Dowel Bar Task ForceMaria Masten, Minnesota DOTMark Snyder, ACPA PennsylvaniaMatt Zeller, Concrete Paving Association of MinnesotaTom Cackler, CP Tech CenterGlen Eder, WG BlockJohn Staton, Michigan DOTMark Brinkman, Construction Materials Inc.Jenne Imholte-Decker, Simplex Construction Supplies

Dowel Bar Diameters:Summary of Current ichiganMinnesotaMissouriNorth d on NC 2 March 2009 dowel bar questionnaire, question number 9 1.5001.5001.5001.5001.5001.5001.500

Proposed dowel bar size and dowelbasket height to center of dowelPavement6” – 7.5” 7.5” – 10” 10” – 12” 12”ThicknessDowel Bar1”DiameterHeight tocenter ofdowel**3”1¼”1½”4”5”1 ½”6”**Elect to have thinner cover in bottom of slab vs. top ofslab

Proposed Dowel Bar Diameters“Engineering behind it” Proposed dowel diameters are essentially the samediameters that have been used as standard (for the topend of each pavement thickness range) since the AASHORoad test: D T/8.The load transfer capacity will be at least the same (orslightly better) for all proposed designs, meaning thatperformance will be equal or better than standard in allcases.There should be no need to perform an engineeringanalysis of the proposed systems unless the proposeddowel sizes are smaller than their current standards.

Proposed Dowel Bar Diameters“Engineering behind it” Any required engineering analysis would have to bedone on case-by-case basis (using agency-specificassumptions for slab geometry and structural designparameters) and could be done one of two ways:– The hard/complex way– The easier/simpler way Again, these two approaches shouldn’t be necessaryunless the proposed dowel diameters represent adecrease from current practices, which should not be thecase for most agencies.The real justification should be in terms of ease ofconstruction and fabrication (which should translate intolower costs).

Proposed dowel bar size and dowelbasket height to center of dowelPavement6” – 7.5” 7.5” – 10” 10” – 12” 12”ThicknessDowel Bar1”DiameterHeight tocenter ofdowel**3”1¼”1½”4”5”1 ½”6”**Elect to have thinner cover in bottom of slab vs. top ofslab

Dowel Bar Length –How did we get to 18 inches? As a bit of background, the first pavement dowels usedconsistently in this country were ½-in diameter, 24-inlong bare steel bars, 4 per lane back in the 1920s, Ibelieve.Dowel diameter increased and spacing decreased untilwe got the use of 1-in dowels on 1-ft centers asstandard in the 40s and 50s. The 18-in length cameabout mainly because it was determined that this wasthe length (9 inches of embedment) that would result indowel behavior (for a 1-in dowel) that was close enoughto the assumptions of Timoshenko’s analysis, whichassumed a semi-infinitely long dowel embedded inconcrete and loaded on the exposed end.

Dowel Bar Length –How did we get to 18 inches? In order to maintain the validity of his analysis withlarger dowels, dowel length should actually increase withdowel diameter, so a 1.5-in dowel might require 24inches or more of length to behave consistently withTimoshenko’s model! Fortunately, we don’t require that.Current rationale: We need that length in order to makesure that the joint is formed somewhere that providesadequate embedment on both sides of the joint.In reality, we probably need only a few inches ofembedment to make the system work properly (TomBurnham concluded in his paper).Dowel bar length - Individual DOT decision

Dowel Bar Material Dowel bar steel – AASHTO M 227 Grade 70-80 (ASTM A 615Grade 40 or 60) 7–13 mil epoxy coating thickness on dowel bar Alternate Dowel Bar Materials – may need to be consideredDowel Bar Material Comparison (#9)ASTM A615 Grade 40ASTM A615 Grade 60xxAASHTO M227 GR 70-80AASHTO ouisianaxMichiganxMinnesotaxxMissourixNorth CarolinaxNorth DakotaOhioTexasxWisconsinxxASTM A615 Grade 40 is recertifiable as AASHTO M227, 99% of time, ASTM A615 Grade 60 is alsobecoming re-certifiable as AASHTO M227 Grade 70-80 (Eder NC 2 March 2009)Not Specifiedxx

Dowel Bar Configuration(May affect basket length) Innovative Concrete Pavement Dowel DesignGuidelines fromACPA: http://www.pavement.com/dowelcad/

Wires and Basket StyleWire Gauge Comparison (#5)Top Bottom Side ShippingRecommended0.306 0.306 0.306 0.177CaliforniaW10W10NGNGIowa0.306 0.306 0.306 0.135Illinois0.306 0.306 0.306 0.177IndianaW7.5 W7.5 W7.5NGLouisiana0.306 0.306 0.306NGMichigan0.306 0.306 0.306NSMinnesota0.306 0.306 0.243 0.177Missouri#0(.306) #0(.306) #0(.306) NGNew York0.306 0.306 0.243NGNorth Carolina0.276 0.276 0.276 0.192North DakotaNSNSNSNSOhio0.306 0.306 0.306 0.177TexasNGNGNGNGWisconsinNGNGNGNGNG Not GivenNS Not SpecifiedCut Shipping (Spacer) Wires (#11)YesNo Contractor's Optionxxxxxxxxxxxxx(must cut every 4th)Basket Leg Style (#4)U-leg V-legJ-leg Choked V-leg Not SpecifiedxxxxxxxxxxxxxxxxxxxxxxxxxFrom NC 2 March2009 Survey

2001 Universal Basket

Dowel Bar StandardizationRecommendationsRecommendationsThe following recommendations are based on the informationreceived from 22 states as well as contractors andmanufacturers. Basket frame Basket/frame wire diameter of 0.306 in. Side rail wire diameter of 0.243 in. Spacer wires Spacer wire diameter of 0.177 in. Number of spacer wires required – 3 minimum Leg configuration U-leg and V-leg

Epoxy Coating ThicknessEpoxy Coating Thickness ssouriMontanaNebraskaNevadaNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaPennsylvaniaSouth CarolinaSouth DakotaTennesseeTexasUtahVirginiaWashingtonWest inNo coating requiredMinMin

Implementation Benefits Fabrication will be simplified knowing the frames could besupplied to many different DOTs.Standardization will reduce the lead time needed to supplybaskets to projects.When projects are delayed, baskets that are being storedoutside in manufacturing yards could be shipped to otherprojects, reducing the time they sit in the yard anddecreasing the potential for degradation of the epoxycoating.Epoxy coating thickness standardization will eliminate therisk of sending the wrong dowels to a project and willstreamline the epoxy coating process since plants will nothave to modify options to adjust for varying coatingthicknesses.

Future discussion points Dowel basket anchoring methods and materials– We should recommend the industry work with the manufacturer’s todevelop and propose the best systems for DOT’s to ensure basketsare sufficiently anchored into the underlying material Lubrication material used as bond breaker on dowels– Several states are allowing the baskets to be pre-coated prior toshipment with Tectyl 506 which eliminates a construction operation– Consideration of the value of the Tectyl material protecting the epoxycoating from nicks caused by handling and placement and ultravioletexposure to the elements (UV rays) during outdoor storage– We should recommend the industry show us the benefits of precoating the dowel bars with a Tectyl type material

ASTM A615 Grade 40 is recertifiable as AASHTO M227, 99% of time, ASTM A615 Grade 60 is also becoming re-certifiable as AASHTO M227 Grade 70-80 (Eder NC 2 March 2009) Dowel bar steel – AASHTO M 227 Grade 70-80 (ASTM A 615 Grade 40 or 60)