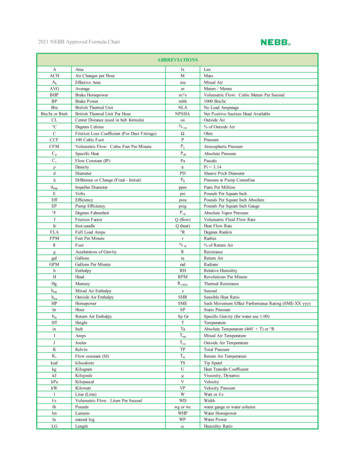

Transcription

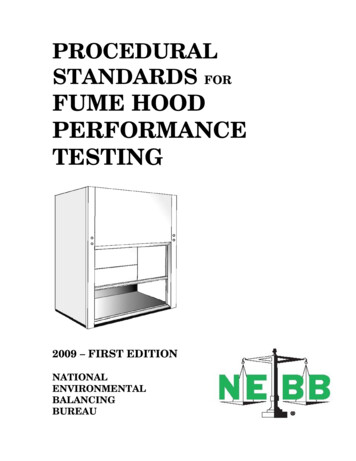

PROCEDURALSTANDARDS FORFUME HOODPERFORMANCETESTING2009 – FIRST EDITIONNATIONALENVIRONMENTALBALANCINGBUREAU

PROCEDURALSTANDARDS FORFUME HOODPERFORMANCETESTING2009 – FIRST EDITIONNational Environmental Balancing Bureau8575 Grovemont CircleGaithersburg, Maryland 20877-4121301-977-3698301-977-9589 FAXwww.nebb.org

PROCEDURAL STANDARD FORFUME HOOD PERFORMANCE TESTING Copyright NEBB, 2009FIRST EDITION – MARCH 2009NEBB DEVELOPS AND SPECIFIES STANDARDS FOR TESTING OF FUME HOODPERFORMANCE. PERFORMANCE OF THESE SERVICES ONLY BY PERSONS THAT ARECERTIFIED OR QUALIFIED FOR ENGAGING IN THIS SPECIALTY IS ONE SUCHSTANDARD. NEBB SOLICITS INQUIRY BY ANY AND ALL PERSONS SEEKING SUCHAPPROVALS. FOR MORE INFORMATION, GO TO WWW.NEBB.ORG.This book may not be reproduced in any form without written permission of thecopyright owner.These Procedural Standards were developed using reliable engineering principles andresearch plus consultation with, and information obtained from, manufacturers, users,testing laboratories and others having specialized experience. They are subject torevision as further experience and investigation may show is necessary or desirable.Fume Hood Testing, which complies with these Procedural Standards, will not necessarilybe acceptable, if when examined and tested, it is found to have other features that impairthe result intended by these standards. The National Environmental Balancing Bureauassumes no responsibility and has no liability for the application of the principles ortechniques contained in these Procedural Standards. Authorities considering adoption ofthese Procedural Standards should review all Federal, State, local and contractregulations applicable to the specific installation.II

FOREWORDThe purpose of the NEBB Procedural Standards for Fume Hood Performance Testing is to establish auniform and systematic set of criteria for the performance testing of fume hoods.This publication is the first edition of the Procedural Standard. Similar to the other NEBB disciplines,the Procedural Standard serves as the anchor for the program. Fume hoods and other safety controlenvironments, such as bio-safety cabinets, offer a distinct set of challenges to the firms andindividuals testing the field performance of these specialized, containment enclosures. The AmericanSociety of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE) has developed anANSI/ASHRAE Standard 110 Method of Testing Performance of Laboratory Fume Hoods. Anotherstandard is ANSI/AIHA Standard Z9.5 Laboratory Ventilation. These publications define the testingprocedures to be used when testing fume hoods and are well recognized and respected in this area ofexpertise. The NEBB discipline builds on these standards and complements them by providing aprogram that combines their testing requirements with a complete package for firm certification.The NEBB Procedural Standard and the NEBB Fume Hood Testing program define the requirementsfor firm certification, for Certified Professional educational and experience requirements, for reportingconsistencies, and for instrumentation requirements.This Procedural Standard is similar to other NEBB Procedural Standards in that it is divided into twodistinct Parts: Standards and Procedures. These FHT procedural standards have been developedusing language defined by “Shall, Should, and May” as it relates to the standards and proceduresdescribed in this manual. It is important to note these particular words throughout this manual andhow they pertain to the NEBB standards and procedures.These standards and procedures are intended as the minimum NEBB requirements that a NEBBCertified FHT Firm shall follow when performing fume hood testing and reporting the results. Contractdocuments may supercede the NEBB requirements. These Procedural Standards have beencarefully compiled and reviewed by the NEBB Technical Committees.Part 1 STANDARDSPart 1, STANDARDS, covers the requirements for Quality Control and Compliance, InstrumentationRequirements, and FHT Reports. The report requirements allow the NEBB Certified Firm moreflexibility in designing their reports by prescribing sets of information that "Shall, Should and/or May"be required to complete an FHT Report.Part 2 PROCEDURESPart 2, PROCEDURES, covers required testing procedures to be followed when using ASHRAE 110and ANSI Z9.5. Part 2 also addresses criteria and testing procedures other than those dictated bythose referenced standards. This Procedural Standard allows that flexibility.APPENDICESThe Appendices includes a suggested NEBB FHT specification, test illustrations, ejectorspecifications references and engineering formulas.This Edition of the FHT Procedural Standards, when used by NEBB Certified FHT Firms, will assurethe building owner of standard, accurate reporting of fume hood performance.Andrew P. Nolfo, P.E.NEBB Technical DirectorIII

FUME HOOD COMMITTEE MEMBERSAND OTHER CONTRIBUTORS FOR CURRENT EDITIONCurrent FHT Committee:Bohdan (Don) Fedyk, ChairmanBuffalo, New YorkMichael J. KellyBethlehem, PennsylvaniaMichael L. LancetteSt. Paul Park, MinnesotaThomas R. McKeen, PESan Antonio, TexasDavid G. McFarlaneGrand Forks, North DakotaDavid MuggahSydney, Nova Scotia, CanadaW. David Bevirt, PETucson, ArizonaAndrew P. Nolfo, PEPhoenix, ArizonaAdditional Contributors to the First Edition:Michael P. DolimGaithersburg, MarylandRandall SilvaSan Jose, CaliforniaIVMichael A. WiederBethlehem, Pennsylvania

TABLE OF CONTENTSPAGEForewordNEBB Fume Hood Testing CommitteeTable of ContentsIIIIVVPART 1 – STANDARDSSECTION 1 Definitions1SECTION 2 NEBB Program, Quality Control and EBB Programs2.1.1 NEBB Disciplines2.1.2 Certification of Firms2.1.3 Certification of Professionals2.1.4 Recertification RequirementsQuality Assurance Program – Conformance Certification2.2.1 Program Advantages2.2.2 NEBB Quality Assurance Program CertificateQuality Control and Compliance2.3.1 FHT Work ComplianceFHT Professional Responsibilities2.4.1 Execution of FHT Procedures2.4.2 Technician Training2.4.3 FHT Procedures Training2.4.4 Instrument Use and Maintenance2.4.5 Coordination / Supervision2.4.6 Project Communication2.4.7 Work Completion2.4.8 Compilation and Submission of Final FHT ReportsSECTION 3 Responsibilities3.13.2IntroductionDesign and Construction Team Responsibilities3.2.1 Design Professional’s Responsibilities3.2.2 Construction Team Responsibilities3.2.3 NEBB Certified FHT Firm ResponsibilitiesSECTION 4 Standards for Instrumentation and Calibration4.14.24.3Minimum InstrumentationRange and AccuracyCalibrationTable 4-1 NEBB Minimum FHT Instrumentation RequirementsV1313131314141515151516

NEBB FHT PROCEDURAL STANDARDSTABLE OF CONTENTSPAGESECTION 5 Standards for Reports and Forms5.15.2ReportsRequired Forms5.2.1 Report Title5.2.2 Report Certification5.2.3 Table of Contents5.2.4 Report Summary / Remarks5.2.5 All Report Pages5.2.6 Instrument Calibration5.2.7 Abbreviations5.2.8 Airflow Velocity Test Report Data – ConstantVolume Systems5.2.9 Airflow Velocity Test Report Data – VAV Systems5.2.10 Airflow Visualization Test Report Data – Local Challenge5.2.11 Airflow Visualization Test Report Data – Large VolumeChallenge5.2.12 Tracer Gas Containment Test Report Data – Static Mode5.2.13 Tracer Gas Containment Test Report Data – Sash MovementEffect5.2.14 Tracer Gas Containment Test Report Data – Perimeter Scan5.2.15 Other Fume Hood Performance Test Report Data191919192020212121212222232323242424PART 2 - PROCEDURESSECTION 6 Laboratory and Cleanroom Safety6.1 Introduction6.2 Designing A Program Policy Health and Safety6.2.1 Designing a Program Policy6.2.2 Designing a Training Program6.2.3 Essentials of the Health and Safety Program6.3 Responsibilities6.3.1 Individual Health and Safety Responsibilities6.4 Elements Of The Program6.4.1 Project Specific Items6.4.2 Health and Safety Program ImplementationSECTION 7 Laboratory and Cleanroom Protocol7.1 Introduction7.2 Laboratory And Cleanroom Procedures7.2.1 Gowning Procedures7.2.2 Equipment Entrance Procedures7.2.3 Laboratory / Cleanroom ConductSection 8 Overview of Testing Requirements8.1 Introduction8.2 Test Setup 31

NEBB FHT PROCEDURAL STANDARDSTABLE OF CONTENTSPAGE8.2.1 Fume Hood Types8.2.2 Fume Hood Sash Configurations8.2.3 Test Setups8.3 ANSI/ASHRAE Standard 1108.4 ANSI/AIHA Standard Z9.58.5 Preliminary Test Procedures313232333434SECTION 9 Airflow Velocity Test Procedures353535353536363636373839399.1 Introduction9.2 Airflow Velocity Tests – Constant Air Volume (CAV) Fume Hood9.2.1 Instruments and Equipment9.2.2 Test Procedures (Average Airflow Face Velocity)9.2.3 Acceptance9.2.4 Reporting9.3 Airflow Velocity Tests – Variable Air Volume (VAV) Fume Hood9.3.1 Instruments and Equipment9.3.2 Test Procedures (Average Airflow Face Velocity)9.3.3 Test Procedures (Response Time)9.3.4 Acceptance9.3.5 ReportingSECTION 10 Airflow Visualization Test Procedures10.110.210.3IntroductionAirflow Visualization Tests – Local Challenge10.2.1 Instruments and Equipment10.2.2 Test Procedures10.2.3 Acceptance10.2.4 ReportingAirflow Visualization Tests – Large Volume Challenge10.3.1 Instruments and Equipment10.3.2 Test Procedures10.3.3 Acceptance10.3.4 ReportingSECTION 11 Tracer Gas Containment Test Procedures11.111.2IntroductionTracer Gas Containment Tests11.2.1 Instruments and Equipment11.2.2 Test Procedures (Static Mode)11.2.3 Acceptance (Static Mode)11.2.4 Reporting (Static Mode)11.2.5 Test Procedures (Sash Movement Effect)11.2.6 Acceptance (Sash Movement Effect)11.2.7 Reporting (Sash Movement Effect)11.2.8 Test Procedures (Perimeter Scan)11.2.9 Acceptance (Perimeter Scan)11.2.10 Reporting (Perimeter 49494949

NEBB FHT PROCEDURAL STANDARDSTABLE OF CONTENTSPAGESECTION 12 Optional Tests and Procedures12.112.212.3IntroductionOther Tests and ProceduresSupplementary Tests and Procedures12.3.1 Room Airflow Velocity Tests12.3.2 Temperature/Humidity Uniformity Tests12.3.3 Sound and Vibration Level Tests12.3.4 Cross Draft Condition Tests12.3.5 Other Tests515151515152525253APPENDICESAPPENDIX AAPPENDIX BAPPENDIX CAPPENDIX DAPPENDIX ESample FHT SpecificationExample Test IllustrationsEjector System SpecificationsReferences and Referenced PublicationsEngineering Formula and ExamplesVIIIIXXIXXVXXIIIXXXV

PART 1 - STANDARDSSECTION 1 DEFINITIONSThese procedural standards have been developed using language defined by “Shall, Should,and May" as it relates to the standards and procedures described in this publication. It isimportant to note these particular words throughout this publication and how they pertain toNEBB standards and procedures.Acceptance Criteria: The value or range of values which is compared to the measured value that willdetermine if the results of the test pass or fail.Accuracy: The capability of an instrument to indicate the true value of a measured quantity.AHJ: The local governing Authority Having Jurisdiction over the installation.Air Supply Fixtures: Devices or openings through which air flows into the laboratory room. For thepurpose of this standard all accessories, connecting duct adapters, or other mounting airways shall beconsidered part of the supply fixture and reported as a unit or an assembly. Some specific supplyfixtures are defined as follows:grille: a louvered or perforated face over an opening.register: a combination grille and damper assembly.diffuser: an outlet designed to mix supply air and room air and to distribute it in varying directions.perforated ceiling: a ceiling with perforated panels used to distribute the air uniformly throughoutthe ceiling or a portion of the ceiling. Filter pads may be used to achieve a similar result.Auxiliary Air: Unconditioned or partially conditioned supply or supplemental air delivered to alaboratory at the laboratory fume hood to reduce room air consumption.Calibrate: The act of comparing an instrument of unknown accuracy with a standard of knownaccuracy to detect, correlate, report, or eliminate by adjustment any variation in the accuracy of thetested instrument.Control Level: The average measured concentration of tracer gas, in parts of tracer gas per millionparts of air by volume (ppm), that is not exceeded at the hood face with a 4.0 Lpm release rate.Deficiency: Any circumstance or operation that affects the measurement results as compared to thedesign criteria required by the contract documents.Design Sash Opening: The position of the sash at which the design team assumes that the fumehood will be operating.Face Velocity: The average velocity of air moving perpendicular to the hood face, usually expressedin feet per minute (fpm) or meters per second (m/s).1

NEBB FHT PROCEDURAL STANDARDSSECTION 1DEFINITIONSFume Hood (sometimes referred to as a laboratory hood): A box-like structure enclosing a sourceof potential air contamination, normally with one open or partially open side, into which air is movedfor the purpose of containing and exhausting air contaminants. A fume hood is generally used forbench-scale laboratory operations but does not necessarily involve the use of a bench or table.Fume Hood System: An arrangement consisting of a fume hood, its adjacent room environment,and the air exhaust equipment, such as blowers and ductwork, required to make the hood operable.Function: For the purposes of this NEBB Standard, function refers to the specific type of datameasurement specified in Section 4, Standards for Instrumentation and Calibration.High Value of Range: The maximum response time divided by the average response time of theVAV Response Time Test. Value is expressed as a percentage.Hood Face: The plane of minimum area at the front portion of a laboratory fume hood through whichair enters when the sash(es) is (are) fully opened, usually in the same plane as the sash for a hoodwith a vertical sash. For a hood with horizontal sash(es) or a comb

ANSI/ASHRAE Standard 110 Method of Testing Performance of Laboratory Fume Hoods. Another standard is ANSI/AIHA Standard Z9.5 Laboratory Ventilation. These File Size: 1MBPage Count: 109