Transcription

Basic Practical ExperienceLogbook1 (98)EASA Part-66 Aircraft Maintenance LicenceDOCUMENTATION of EXPERIENCE1. This documentation of experience logbook is to be used to record details of experience over the practicalperiod prior to the initial issue or amendment of a EASA Part-66 Aircraft Maintenance Licence (AML) and foradditional categories or subcategories.2. Systems and equipment are arranged within this schedule in conformity with ATA 100 specification3. The schedule does not specify tasks but identifies those task areas in which experience should be gained.Such as: Troubleshooting, Maintenance practices, Servicing, Removal/installation Adjustment/check, Inspect/check, Approved repairs4. A signature, date and licence no. recorded against each ”work carried out” entry shall be made bysupervising licenced aircraft maintenance licence holder.5. Supervisors signing in the logbook must fill in information in the logbooks signlist.Page 1Applicant InformationPage 2Example of certifying documentPage 3-7Organisations ATA ChapterPage 8SignlistPage 10Example documentationPage 11-37ATA Experience DocumentationPage 37-46Additional experience documentation sheets

Basic Practical ExperienceLogbook2 (98)Organisation No 1Name of applicantAML licence no and/or Date of birthLicense category B1/B2/B3, tick in the applicable subcategoryB1.1 B1.2 B1.3 B1.4 B2 B2L B3 Part-M /Part145/ Part-CAU maintapproval no or AML licence noCompany /Org/ Certifying LAETraining periodFromToDaysHoursThe signature below signs for the accuracy of this document and that the applicant has met the relevantmaintenance experience requirements of AMC 66.A.30(a) Basic Experience RequirementsDatePart-M /Part145/ Part-CAU maint approval no or AML licence noSignature of Quality ManagerNameOrganisation No 2Name of applicantAML licence no and/or Date of birthLicense category B1/B2/B3, tick in the applicable subcategoryB1.1 B1.2 B1.3 B1.4 B2 B2L B3 Part-M /Part145/ Part-CAU maintapproval no or AML licence noCompany /Org/ Certifying LAETraining periodFromToDaysHoursThe signature below signs for the accuracy of this document and that the applicant has met the relevantmaintenance experience requirements of AMC 66.A.30(a) Basic Experience RequirementsDatePart-M /Part145/ Part-CAU maint approval no or AML licence noPart-M /Part145/ Part-CAU maint approval no or AML licence noName

Basic Practical ExperienceLogbook3 (98)Organisation No 3Name of applicantAML licence no and/or Date of birthLicense category B1/B2/B3, tick in the applicable subcategoryB1.1 B1.2 B1.3 B1.4 B2 B2L B3 Part-M /Part145/ Part-CAU maintapproval no or AML licence noCompany /Org/ Certifying LAETraining periodFromToDaysHoursThe signature below signs for the accuracy of this document and that the applicant has met the relevantmaintenance experience requirements of AMC 66.A.30(a) Basic Experience RequirementsAMC 66.A.30(a) Basic Experience RequirementsDatePart-M /Part145/ Part-CAU maint approval no or AML licence noSignature of Quality ManagerNameOrganisation No 4Name of applicantAML licence no and/or Date of birthLicense category B1/B2/B3, tick in the applicable subcategoryB1.1 B1.2 B1.3 B1.4 B2 B2L B3 Part-M /Part145/ Part-CAU maintapproval no or AML licence noCompany /Org/ Certifying LAETraining periodFromToDaysHoursThe signature below signs for the accuracy of this document and that the applicant has met the relevantmaintenance experience requirements of AMC 66.A.30(a) Basic Experience RequirementsAMC 66.A.30(a) Basic Experience RequirementsDatePart-M /Part145/ Part-CAU maint approval no or AML licence noSignature of Quality ManagerName

Basic Practical ExperienceLogbook4 (98)Organisation No 5Name of applicantAML licence no and/or Date of birthLicense category B1/B2/B3, tick in the applicable subcategoryB1.1 B1.2 B1.3 B1.4 B2 B2L B3 Part-M /Part145/ Part-CAU maintapproval no or AML licence noCompany /Org/ Certifying LAETraining periodFromToDaysHoursThe signature below signs for the accuracy of this document and that the applicant has met the relevantmaintenance experience requirements of AMC 66.A.30(a) Basic Experience RequirementsDatePart-M /Part145/ Part-CAU maint approval no or AML licence noSignature of Quality ManagerName

5 (98)Supervisor signlistName of supervisorEASA Part 66licence numberCompanyauthorizationnumberCompany.Swedish Transport AgencyCivil Aviation and Maritime DepartmentDel-66SE-601 73 Norrköping, SwedenOffice addressOlai kyrkogata 35, portstyrelsen.seTelephoneTelefax 46 771 503 503 46 11 185 256StampSignature

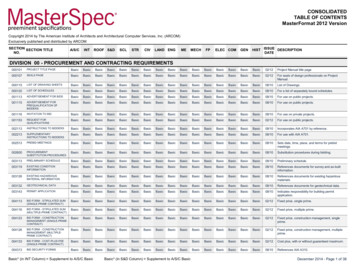

Basic Practical 262728293031323334353637383941454649Task areaPeriodic inspectionsDimensions & areasLifting & shoringLeveling & weighingTowing & taxiingParking, mooring, storage & return to servicePlacards & markingServicing – routine maintenanceVibration & noise analysis (helicopter only)Standard practices – airframeAir conditioningAuto flightCommunicationsElectrical powerEquipment / furnishingsFire protectionFlight controlsFuelHydraulic powerIce & rain protectionIndicating / recording systemLanding gearLightsNavigationOxygenPneumaticVacuumWater / wasteElectrical - electronic panels &multpurpose componentsWater ballastCentral maintenance system (cms)Information systemAirborne auxiliary powerATA515253545556576061626364656667707172 (T)72 (R)737475767778798081828384916 (98)Task areaStandard practices & structures - generalDoorsFuselageNacelles / pylonsStabilizersWindowsWingsStandard practices – propeller / rotorPropellers / propulsorsMain rotorsMain rotor drive(s)Tail rotorTail rotor driveRotor blade & tail pylon foldingRotors flight controlStandard practices – enginePower plant – generalEngine – turbine / turboprop, ducted fan / unducted fanEngine – reciprocatingEngine – fuel & controlIgnitionBleed airEngine controlsEngine indicatingExhaustOilStartingTurbines (reciprocating engines)Water injectionAccessory gear boxes (engine drivenPropusion augmentationCharts

Basic Practical ExperienceLogbookATACHAP05Task areaPeriodic inspectionsAssist and explain ascheduled check(e.g. 100h check or A-check)Perform weekly checkScheduled maintenancechecksPerform pre-flight checkPerform daily checkUnscheduled maintenancechecksSuppose a hard oroverweight landing: Showunscheduled inspectionprocedure according AMMand explain actionExplain the requiredinspection following alightning strike or staticdischargeDemonstrate close-up ofdocumentation followingperformance of maintenancetasksDetermine aircraftairworthiness per MEL/CDLAircraft type /categoryAircraftregWorkorder/Log seq7 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq8 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbook06Dimensions & areasGeneralJackingShoring08Leveling & weighingCalculate Centre ofGravity/Balance limits, userelevant documentsPrepare aircraft for weighingLeveling of aircraftAssist jacking an aircraft09Towing & taxiingPark, chock and groundaircraftAssist in the towing of anaircraftTaxiingPerform long time parking10Parking, moring, storage &return to servicePerform long time parkingPark, chock and groundaircraftMooringReturn to serviceCovers and plugs rem/installPlacards & markingGeneralExterior Color Schemes &MarkingsExterior Placards & MarkingsInterior PlacardsCheck aircraft for correctplacards119 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq10 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP12Task areaServicing –routine maintenanceGeneralReplenishingScheduled ServicingUnscheduled ServicingRefuel aircraftDefuel AircraftPerform pre-flight/dailycheck18Vibration & noise analysis(Helicopter only)Analyse helicopter vibrationproblem.Analyse engine vibration.Analyse noise spectrum.Aircraft type /categoryAircraftregWorkorder/Log seq11 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq12 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP20Task areaStandard practices airframeExplain hazards whenworking with aircraft relatedto noise, heat, movingsurfaces, propellers, rotors,intakes, exhaustsDemonstrate safetyprecautions when usingfluids, gasses and chemicalsCheck validity of calibrationof tools and equipmentDemonstrate the use oflubrication equipmentaccording AMMUse tools and equipment forcutting, forming and joiningcommonly used materials(Ferrous and non-ferrous)Fit and remove thread insertsRemove defective rivetswithout causing furtherdamage to skinSelect and install rivets asinstructed by StructureRepair ManualLubricate aircraft accordingMaintenance ManualLocate components usingreferencing system, e gstation numbersPerform a small repair of acomposite structureExplain methodes to detectdefects/deterioration incomposite materialIdentify the characteristicsand properties of commoncomposite materialsAircraft type /categoryAircraftregWorkorder/Log seq13 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookIdentify a range of sealingand bonding agentsPerform simple solderingtasksSolder cables to single andmultipin connectorsInspect soldered, weldedand brazed jointsExplain constructionmethods used in woodenstructuresDiscuss methods ofpreservation andmaintenance of woodenstructuresDemonstrate repair ofwooden structureExplain I identify defects infabricsPerform refueling/defuelingof aircraftExplain the detection ofdefects in wood material andwooden structuresDemonstrate I explainmethods to repair fabriccoveringAdjust, set and use torquespannersDemonstrate competencewhen wire locking a varietyof assembliesDemonstrate application oftwo-component sealers andcompoundsExplain & implement ESDprocedures (ESD ElectroStatic Discharge)14 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq15 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP21Task areaAir zation ControlHeatingCoolingTemperature ControlMoisture / Air ContaminantControlConnect and use external airsupplyCheck operation of coolingair-conditioning systemCheck operation of heatingair-conditioning systemAircraft type /categoryAircraftregWorkorder/Log seq16 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq17 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP22Task areaAuto flightGeneralCheck operation of autopilotSpeed – attitude correctionAuto throttleSystem monitorAerodynamic load alleviatingWeighing & balancingCheck operation of yawdamperTroubleshoot faulty systemOperational test of theRemote electronics unit(REU)Operational test of the flightcontrol panelCarry out an autothrottlesystem testDemonstrate BITE testpractices on flightmanagement systemPerform an autopilot systemtestReplace an LRU related toair data system, applyassociated BITEForce Trim System Operational CheckAircraft type /categoryAircraftregWorkorder/Log seq18 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq19 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP23Task areaCommunicationsReplace VHF COM unitCheck operation of VHFradiosSatcom operational testData Transmission &Automatic CallingCheck operational check ofPassenger Adress,Entertainment & ComfortsystemDescribe an typical antennareplacement procedureAudio IntergratingStatic DischargingCarry out a VHF RadiocheckIntegrated Automatic TuningReplace cockpit voicerecorderReplace static dischargewickPerform an intercom orpassenger addresscomponent replacement andtestingAircraft type /categoryAircraftregWorkorder/Log seq20 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq21 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP24Task areaElectrical powerReplacement of CBReplacement of generatorAC GenerationDC Generation voltageoperational checkExternal Power syst checkAC Electrical Load DistributionDC Electrical Load DistributionRemove/refit main batteriesCheck an aircraft electricalcircuit for continuity inconjunction with an electricalwiring diagramUse test meters to measurevolts, amps and resistancein practical taskcircumstancesCarry out basic fault findingtechniques using a range oftest metersDemonstrate wire splicingmethodesInsert I extract electricalinserts (pins) in a variety ofelectrical connectorsRepair or replace anelectrical connectorSelect and use appropriatecable stripping toolsUse two crimping systems toprepare cable ends or plug Isocket tenninalsAircraft type /categoryAircraftregWorkorder/Log seq22 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookConnect and use externalelectrical powerDemonstrate disconnectingand reconnecting ofelectrical connectorsDemonstrate replacement ofcircuit breakerConduct a NICA batterycheckReplace an electricalcomponent and run afunctional test according toAMM23 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq24 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP25Task areaEquipment / furnishingsReplace carpetsReplace crew seatReplace pax seatPassenger CompartmentBuffet / GalleyTroubleshoot LavatoriesCargo CompartmentCheck of EmergencyequipmentRemove and install ceilingand sidewall panelsCheck ELT for compliancewith regulationsCheck inertia reels. OpcheckInspect cabin cockpitequipment for serviceabilityPerform replacement of anoven or boilerCheck seat belts forserviceabilityReplace escape slides/ropesAircraft type /categoryAircraftregWorkorder/Log seq25 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq26 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask area26Fire protectionCheck fire bottle contentsCheck/test operation offire/smoke detection andwarning systemCheck cabin fire extinguishercontentsExplosion SuppressioncheckCheck avionic smokedetector systemTroubleshoot faulty system.Perform weight check on fireextinguisher container andreplace, if necessaryCheck/test operation ofcargo fire/smoke detectionand warning system27Flight controlsTroubleshoot faulty systemPerform operation test ofaileron control systemDetailed inspection ofelevator and rudder controlcablesPerform operation test ofelevator control systemPerform operational test ofHorizontal Stabilizer /Stabilator systemExtending/retracting flaps &slats. Op testSpoiler, Drag Devices &Variable Aerodynamic FairingsAircraft type /categoryAircraftregWorkorder/Log seq27 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookOperational check of GustLock & DamperLift AugmentingCheck control range anddirection of movementFunctional test of primaryflight controlsFunctional test of flapsystemPerform lubrication ofbearingsPerform gust lockoperational checkRun a functional check onauto flap retractionTest function ofmechanically operatedailerons, elevators, rudderSuppose a faulty flightcontrol system: Use the onboard reporting system fortroubleshootingRun a functional check on afly-by-wire systemExplain precaution andsafety measures requiredbefore operating flightcontrolsPerform rigging of flightcontrols followingcomponent replacementExplain replacementprocedure for a hydraulicflight control actuatorRun a functional check onhydraulically operated flightcontrol systems28 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq29 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP28Task areaFuelWater drain system(operation)Perform capacitance test offuel quantity probesFuel transfer between tanksOperation check of levelsensorsIndicatingCheck of Indicating systemDefuel the fueltankcheck of the vent systemFuel the aircraftOperational Test of theEngine Feed Shutoff ValvesReplace & test a flexiblehose including clamps andbracketsReplace and test a fuelbooster pumpCheck/calculate fuelcontents manuallyDeactivation/reactivation ofthe fuel valves (transferdefuel, X-feed, refuel).Replace fuel tank cells.Aircraft type /categoryAircraftregWorkorder/Log seq30 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq31 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP29Task areaHydraulic powerCheck filters/clog indicatorsCheck indicating systemsPressurization/depressurization of the hydraulic systemQuantity check accumulatorPerform hydraulic leakchecksCarry out servicing ofhydraulic systemReplace & test a flexiblehose including clamps andbracketsDemonstrate swagingCheck & replenish oil andhydraulic systemReplace a hydraulic systemcomponent according AMMExplain replacement /installation of hydraulicpump (electrical or enginedriven)Inspect hydraulic reservoir,replenish fluid and rechargereservoir if requiredPerform a fuel quantityindicating system testRotor Brake ServicingAircraft type /categoryAircraftregWorkorder/Log seq32 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq33 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP30Task areaIce and Rain ProtectionCheck operation of the IceDetection SystemOperational test of the pitotprobe ice protectionOperational test of the TATice protectionOperational test of the wingice protection systemTroubleshoot faulty systemOperational test of thewindshield and side windowanti-icing systemOperational test of the airdata probes and sensorsanti-ice systemReplacment of deicer bootOperational test of deicerboot systemCheck function of anti-ice orde-icing systemRemove and refit windshieldwiper bladesRemove/intall test wipermotor.Aircraft type /categoryAircraftregWorkorder/Log seq34 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq35 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP31Task areaIndicating/recordingsystemGeneralReplacement of Instrument& Control PanelsIndependent InstrumentReplace FDR RecorderDownload of recorderparametersCentral Warning SystemsReplacement of displays inflightdeckAutomatic Data ReportingSystemsPitot Static operational testOperational test of clocksFDR parameter checkTroubleshoot faulty systemDiscuss maintenancepractices on EFIS(Electronic Flight InstrumentSystem)Identify flight data and voicerecorder locationAircraft type /categoryAircraftregWorkorder/Log seq36 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq37 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP32Task areaLanding GearGeneralFunctional test of the nosewheel steering systemService struts with oil andnitrogenReplace Main Gear & DoorsReplace Nose Gear / TailGear & DoorsCarry out extension &retraction of L/GReplace main wheelSteering operational checkPosition , Warning, &Ground Safety SwitchSupplementary Gear –Check/test emergencyblowdown (emergencylanding gear extension)Operational test of theparking brake systemMLG shock strut extensioninspectionNLG shock strut extensioninspectionCheck tyre pressuresAssist or explainreplacement of seals onshock strutPrepare airplane for landinggear retraction I extensionoperationPerform functional test ofanti skid systemBleed hydraulic brakesAssess shock strut fluid leveland recharge if requiredAircraft type /categoryAircraftregWorkorder/Log seq38 (98)Work carried out andDate workreference toapproved data (AMM) performedSignature &Licence No.

Basic Practical ExperienceLogbookCheck function of landinggear indication systemReplace rotorcraft skids.Pack and check floats.Flotation equipment.33LightsOperational test of the winglanding/taxi lightsOperational test of FlightCompartment & AnnunciatorPanelOperational test ofPassenger CompartmentOperational test of Cargo &Service CompartmentsReplacement of the winglanding/Taxi light-bulbReplacement of EmergencyLighting batteryPerform emergency lightingsystem checksReplace internal andexternal lamps/ bulbsOperational check ofsearchlight39 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq40 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP34Task areaNavigationTroubleshoot faulty systemInspect electrical cablelooms and bundles andcorrect them if necessaryReplacement of Attitude &Direction compOperational test of Air datacomputerOperational test ofIndependent PositionDetermining GPSFunctional check weatherradarLeakcheck of pitot and staticsystemCarry out Navgationoperational testCarry out tansponderoperational system testCarry out DME operationalsystem testADF op syst testFunctional check TCASFunctional check TAWSFunctional check inertialnavigation systemReplacemnet of FluxevalveReplacemnet of AHRScompterReplacemnet of DG gyroReplacement of VG gyroPerform a typical avionic testusing a test equipmentCarry out bonding andinsulation testsAircraft type /categoryAircraftregWorkorder/Log seq41 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookInspect coaxial cableinstallations, correct them ifnecessaryInterpret typical electricalwiring diagrams andschematics circuitsRepair or replace anelectrical connectorRun BITE tests on selectednavigation systems (VOR,ADF, LOC/GS, Marker, DMERun BITE tests on selectednavigation systems ( RadioAltimeter, TCAS, GPWS,ATC, GPS)Run BITE tests on selectednavigation systems (GPWS,ATC, GPS)Run BITE tests on selectednavigation systems (TCAS,TAWS)Discuss weather radarcomponent replacement andfunctional testPerform initialisation checkon inertial reference unit IplatformAssist a compass I standbycompass compensationAssist calibration check of apitot static system using aleak testerCheck operation of on-boardmaintenance system (BITE)42 (98)

Basic Practical ExperienceLogbook43 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq44 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP35Task areaOxygenTest of crew oxygen systemTest of pax oxygenpassenger systemPerform auto oxygen systemdeployment checkCheck of portable oxygenbottlesService of the oxygensystemPurge and recharge oxygensystemReplenish oxygen system, orreplace 02-cylinderAircraft type /categoryAircraftregWorkorder/Log seq45 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask area36PneumaticTroubleshoot faulty systemCross-Bleed valveRemove/InstallCross-Bleed valveAdjustment/TestBleed-air control panelAdjustment/TestPrepare environment forAPU StartTroubleshoot faulty systemCross-Bleed valveRemove/Install37VacuumVacuum pump replacemnetPerform vacuum pumpcheckIndicatingCheck/replace filters.Aircraft type /categoryAircraftregWorkorder/Log seq46 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq47 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP38Task areaWater / WasteTroubleshoot systemAssist in servicing of toiletand potable water system (ifinstalledOperational test of systemReplenish potable wateInspect toilet and galleyunits for serviceabilityReplace water pump.Replace tap.Inspect waste bin flapclosure.Replace toilet pump.39Electrical – Electronicpanels & multipurposecomponentsGeneralInstrument & Control PanelsElectrical & ElectronicEquipment RacksElectrical & ElectronicJunction BoxesMultipurpose ElectronicComponentsIntegrated CircuitsPrinted Circuit CardAssembliesAircraft type /categoryAircraftregWorkorder/Log seq48 (98)Work carried out andDate workreference toapproved data (AMM) performedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq49 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask area41Water ballastGeneralStorageDumpIndication42Integrated modularavionicsGeneralCabinet AFDX maintenanceData Communication NetworkARINC 429 maintenanceARINC 629 maintenanceAFDX maintenanceAFDX fault findingCommon Core System(CCS) maintIntegrated Modular Avionics(if IMA available: Run asystem testAircraft type /categoryAircraftregWorkorder/Log seq50 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq51 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask area44Cabin systemsCabin Systems (if CSavailable: Run a functionaltest)45Central maintenancesystem (CMS)GeneralCMS / Aircraft GeneralCMS / Airframe Systems45 Central MaintenanceSystemsCMS / Airframe SystemsCMS / StructuresCMS / PropellersCMS / Power PlantRetrieve data from centralmaintenance system (CMS, ifinstalled)Aircraft type /categoryAircraftregWorkorder/Log seq52 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq53 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAP46Task areaInformation systemGeneralLoading of New Data BasesFlight Deck InformationSystemsMaintenance InformationSystemsPassenger InformationSystemsMiscellaneous InformationSystemsAirplane General InformationSystemsFlight Deck InformationSystemsMaintenance InformationSystemsAircraft type /categoryAircraftregWorkorder/Log seq54 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq55 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookATACHAPTask area49Airborne auxiliary powerOperational test of the APUReplacemnet of the APUTroubleshooting the APUsystemEngine Fuel & ControlIgnition / StartingAirEngine ControlsIndicatingExhaustOil51Standard practices &structures - generalCarry out assessment ofdamageInvestegation, Cleanup &Aerodynamic SmoothnessCarry out treatment ofcorrosionReplacement of anchournutsReplacement of FastenersSupport of Airplane forRepair & Aligment proceduresControl – Surface BalancingCarry out RepairsCarry out Electrical BondingAircraft type /categoryAircraftregWorkorder/Log seq56 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practical ExperienceLogbookDemonstrate the procedurefor a structural inspection(from nose to tail)Check door seals andreplace them, if requiredSheet metal repair.Fibre glass repair.Wooden repair.Recover fabric controlsurface.57 (98)

Basic Practical ExperienceLogbookATACHAPTask areaAircraft type /categoryAircraftregWorkorder/Log seq58 (98)Work carried outand reference toapproved data(AMM)Date workperformedSignature &Licence No.

Basic Practica

4. A signature, date and licence no. recorded against each "work carried out" entry shall be made by supervising licenced aircraft maintenance licence holder. 5. Supervisors signing in the logbook must fill in information in the logbooks signlist. Page 1 Applicant Information Page 2 Example of certifying document