Transcription

LOGISTIC SYSTEM INTEGRATION WITH ENVIRONMENTAL MANAGEMENTSYSTEM: A CASE STUDY OF INTERNATIONAL COMPANYA. TAMBOVCEVS1, T. TAMBOVCEVA2Riga Technical University, ata2000@inbox.lv2Riga Technical University, tatjana.tambovceva@rtu.lv1The aim of the research is to investigate potential of integrating environment issues into logistic system by literature review and casestudy of international company. In recent years, consumers and governments have been pressing companies to reduce theenvironmental impact of their activities. The activities which are mostly related to the environmental performance need to be pointed,especially how logistics systems influence on environmental performance. This paper analyses how company could lead the initiativein this area by incorporating environmental management principles into their daily activities. The analysis is based on literaturereview about logistics and environment, the information from company R website as well as face-to-face interviews. A case study isgiven to show how they can turn practices into green while simultaneously meet the efficiency objectives. In order to becomecompetitive on the international level, it is necessary to change ways of thinking and to adopt contemporary global standards in thearea of organization management. The research results show that the adoption of EMS and ISO 14001 certification is an effective toolfor the logistics management. Such practices simultaneously reduce the negative impacts of company’s activities on the naturalenvironment and contribute to better company performance. The results also show that the emissions to air and water, and energyconsumption are the main logistics impacts to the environment. These results can be used to measure the potential issues and minimizelogistic system influence on environmental performance. The application of the concept of sustainable development and corporatesocial responsibility is one of the basic prerequisites for the achievement of business excellence. Consequently, how to implement EMSsystems successfully in an effective and efficient manner is an imperative issue in the field of sustainable enterprise development. Thispaper presents a review of the successful implementation of EMS system and green logistics within the international company. Thispaper also argues that EMS systems are an increasingly important source of organizational change with major implications for thecompany's environmental performance.Key words: green logistics, sustainable logistics, environmental management system, sustainable development1. INTRODUCTIONToday, there are many aspects of human life on earththat are moving in a positive direction. Improvingenvironmental performance becomes more and moreimportant to an organization’s success. Through thepaper, which focuses on the interaction betweenenvironmental performance and logistic system, it aimsto find a way which helps organizations to reach theideal condition that getting the cost efficiency andenvironmental responsibility at the same time. The bestchoice for organizations to reach sustainabledevelopment is to effectively control the costs, as well asto reduce the waste of resources and environmentalpollution. This is a twofold effect that once theorganizations adopt environmental management system(EMS), they can examine the possibilities of enhancingtheir logistic system performance while reducing thenegative impact on the ecosystems in the logisticoperation, as well as finding out the proactive solutionsin order to optimize their cost use.The purpose of this paper is to investigate potentialof integrating environment issues into logistic system.The possible impacts between logistics and environmentare the first knowledge aspect needs to be studied.Authors collected a lot of information from the relevantliteratures from Journals and database, such as EBSCO,Springer, ScienceDirect and Google Scholar to deepenour knowledge and try to create the own approaches forthe analysis. Our literature review focuses upon English-speaking peer-reviewed journals, since they are the mostcommon resources for information exchange amongresearchers. To establish a time span, a starting pointwas set at 2000. The paper sample was compiled byconducting a literature search based on the combinationsof descriptors (1) “green” and “environmental” (bothhaving to be present in the respective paper jointly), (2)“supply chain” or “logistics” as well as (3)“environmental management” and/or “EMS”. Theseissues had to be found in title, keywords or abstract for apaper being included in the subsequent review.Assessing the classification context to be adopted inthe literature review helps to structure and classify thematerial. There are two contexts: context 1 refers to apaper’s descriptive characteristics; context 2 addressesdetailed paper contents at the interface of supply chainmanagement/logistics, environment and environmentalmanagement. The material is reviewed and analyzedaccording to the classification context.Much of the literature focuses on revised logistics,environmental management practices, or green supplychain management as among the important managementtopics of today (Gold et.al. 2010, Montabon et al. 2007;Srivastava 2007). Skjoett-Larsen (2000) views greensupply chain management as Europe’s most importantchallenge of the 21 century. Zhu and others, in a seriesof studies (Zhu et al., 2005, 2007a,b, 2008, 2010a,b)contended that green supply chain management in the‘‘workshop of the world,’’ that is, China, will becomeincreasingly important. For this reason, in theforeseeable future, “green”, or “environment”, will, insupply chain management systems, become an important

competitive element (Skjoett-Larsen, 2000; Abukhaderand Jönson, 2004 etc.).Before 2000, there was relatively little research onlogistics management/supply chain management and theenvironment; research of the sort represented byAbukhader and Jönson (2004) who revealed eight typesof logistics management and supply chain managementperiodicals published between 1992 and 2001.Their views indicated that, compared to other themes,such as commercial logistics management, logistics andmanagement, and logistics management and informationtechnology, there was much less research on logisticsmanagement/supply chain management and theenvironment. However, due to global warming andsurging oil prices, more emphasis has been placed onenvironmental protection and many researchers havebegun to explore the development of green supply chainmanagement concepts or theories. Most research effortshave focused on investigating the relationship between“green”/ environmental factors and environmental/organizational performance (Bowen et al., 2001; Wangerand Schaltegger, 2004; Menguc and Ozanne, 2005; Raoand Holt, 2005; Ann et al., 2006; Clemens and Douglas,2006; Vachon and Klassen, 2006 a,b; Simpson et al.,2007; Vachon, 2007; Aragón-Correa et al., 2008;), whilerelatively little has focused on the issue of identifyinggreen supply chain management taxonomy.2. LOGISTICS AND THE ENVIRONMENTBefore discussing the environmental concerns of thelogistics, it is necessary to first define the term“environment” as there are several definitions. Acomprehensive definition is presented in the frameworkof the ISO 14001 Environmental Management System,and is also the definition the authors elect to use in thispaper. “Surroundings in which an organization operates,including air, water, land, natural resources, flora, fauna,humans, and their interrelations. NOTE – Surroundingsin this context extend from within an organization to theglobal system” (ISO 14001, 2004).The most widely accepted definition for sustainabledevelopment was given by the World Commission onEnvironment and Development in 1987, andsubsequently endorsed by the United Nations at theEarth Summit in 1992: “Sustainable development isdevelopment that meets the needs of the present withoutcompromising the ability of future generations to meettheir own needs” (WCED, 1987).The Brundtland Commission shaped one of the mostwell-known definitions of sustainability, highlighting theequal right of present and future generations to meettheir respective needs (WCED, 1987). Elkington (1997)posits the integration of the intensely interrelatedeconomic, ecological and social aspects of sustainabilityin a “triple-bottom line”. It is, however, indispensable toconsider organizational and social aspects as well whenaiming for overall sustainable development (. AlsoDyllick and Hockerts (2002) point to the three facets ofsustainability, conceiving corporate sustainability as thebusiness case (economic), the natural case(environmental), and the societal case (social).“To answer, as far as possible how society intends toprovide the means to meet economic, environmental andsocial needs efficiently and equitably, while minimizingavoidable or unnecessary adverse impacts and theirassociated costs over relevant space and time scales”(UK Roundtable on Sustainable Development, 1996).Many authors have formulated their own definitionsof sustainability, with consideration for these underlyingconcepts. Three recurring considerations are found to beespecially important:1. economic development;2. environmental preservation;3. social development.In the case of logistics systems, economicdevelopment can be thought of as relating to the profitsand in turn the benefits to the employees of logisticscompanies and the indirect effects on the economy.Second, environmental preservation considers ecologicalimpacts which can range from effects on local wildlife tothose of global warming depending on analysisboundaries. Finally, social development accounts for theeffects of logistics activities on human society, includingthe detrimental impact that pollution can have on thepublic. Most all studies pertaining to logistics and theenvironment have long-term implications based on oneor more of these three considerations.The U.K. Round Table on Sustainable Developmenthas summarized the externalities of logistics activities.Corresponding to the aforesaid common considerationsfor sustainability they have divided their list into similarcategories. Table 1 provides an adapted version of theirlist.Table 1: Impacts of logistics systems (Adapted from UK Roundtable onSustainable Development, 1996)Type ofimpactEconomicImpactsParadox1.Traffic Congestion2. Resource wasteEcologicalImpacts1. Greenhouse Gases Cause Climate Change2. The use of non-renewable fossil fuel3. The effects of waste products such as tiresand oil4. Ecosystem destruction and speciesextinctionSocialImpacts1. Negative public health impacts of pollution2. Crop destruction3. Injuries and deaths resulting from trafficaccidents4. Noise5. Visual intrusion6. Congestion deterring passenger travel7. Loss of Greenfield sites and open spaces8. Deterioration of Buildings/Infrastructure

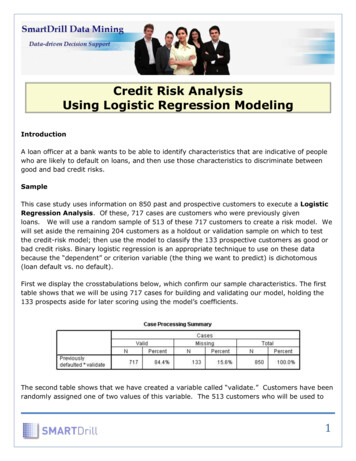

Different categorization schemes could be used toorganize these impacts, for instance climate changeresulting from greenhouse gases has economic and socialimplications.Green logistics is a form of logistics which iscalculated to be environmentally and often sociallyfriendly in addition to economically functional. As earlyas the 1980s, several companies were concerned withdeveloping green logistics, and interest in the conceptsoared with increased consumer concerns about howproducts were manufactured and delivered in the early21st century. Many modern companies pride themselveson their environmentally friendly policies and practices,and companies which are interested in adopting greenlogistics can utilize the services of logistics consultantswho specialize in helping companies convert, reform,and streamline their existing logistics systems.Logistics is the integrated management of all theactivities required to move products through the supplychain. For a typical product this supply chain extendsfrom a raw material source through the production anddistribution system to the point of consumption and theassociated reverse logistics. The logistical activitiescomprise freight transport, storage, inventorymanagement, materials handling and all the relatedinformation processing.The main objective of logistics is to co-ordinate theseactivities in a way that meets customer requirements atminimum cost. In the past this cost has been defined inpurely monetary terms. As concern for the environmentrises, companies must take more account of the externalcosts of logistics associated mainly with climate change,air pollution, noise, vibration and accidents. Thisresearch project is examining ways of reducing theseexternalities and achieving a more sustainable balancebetween economic, environmental and social objectives,as illustrated lelogisticsENVIRONMENTClimate changeAir qualityNoiseLand useBiodiversityWasteFigure 1: Three pillars of sustainable logistics (Adapted from Green Logistics)The Council of Supply Chain ManagementProfessionals (CSCMP) defines logistics management as“that part of supply chain management that plans,implements, and controls the efficient, effective forwardand reverses flow and storage of goods, services andrelated information between the point of origin and thepoint of consumption in order to meet customers’requirements”.Mentzer et.al. (2001) coined commonly used andwell-adopted definitions of supply chains and supplychain management (SCM). They define the supply chainas “a set of three or more entities (organizations orindividuals) directly involved in the upstream anddownstream flows of products, services, finances, and/orinformation from a source to a customer”. SCM means“the systemic, strategic co-ordination of the traditionalbusiness functions and the tactics across these businessfunctions within a particular company and acrossbusinesses within the supply chain, for the purposes ofimproving the long-term performance of the individualcompanies and the supply chain as a whole”.Green or sustainable logistics is concerned withreducing environmental and other negative impactsassociated with the movement of supplies. Sustainabilityseeks to ensure that decisions made today do not have anadverse impact on future generations. Green supplychains seek to reduce negative impact by redesigningsourcing, distribution systems and managing reverselogistics so as to eliminate any inefficiency, unnecessaryfreight movements and dumping of packaging.A good example of one logistics aspect that posesgreat risk to the environment is packaging. Packagingrepresents one of the greatest challenges toenvironmental friendly logistics while at the same timebeing vital in shipping and storage. Correct or incorrectpackaging has consequences for how much of a productcan be stored, how it is stored and or transported in agiven space. This can increase to the unit cost if thepackaging hinders optimization of storage space.Many industries have developed forms of packagingthat do all that is required of them in transit but do notjustify the expense of returning them to the point oforigin. This packaging is only used once and thendiscarded. This principle goes all the way down to thelevel of individual tins or cartons of food. It is this typeof packaging that presents the greatest challenge tologisticians as, increasingly, there is a responsibility forthe supplier and the buyer to recover and recycle oreffectively dispose of packaging.Logistics and transport activities have been identifiedas having a major impact on the environment in whichwe all live. For example, excess carbon emission haschanged the environmental landscape, by destroying theecosystem. Indigenous forests have thinned out andchanged rain patterns thus impacting farming and foodproduction. Consequently logistics and transport haveattracted significant legislation at both national andinternational level. Targets for improving environmentalperformance have been set by the international

community via the Rio, Kyoto and the Copenhagensummit meetings.As Wu and Dunn (1995) stated in “Environmentallyresponsible logistics systems”, the challenge of today’slogistics managers is to determine how to incorporateenvironmental management principles into their dailydecision-making process. Different activities in alogistics system lead to different environmental impacts.Figure 2 shows how logistics decisions that affect theenvironment.Resources inputRaw materialacquisition:InboundlogisticsTransformation Purchasing Consolidation Inventorymanagement Vendor selection Mode selection Packaging Vendor location Carrier selection Material’s handling Warehousing Backhaul managementOutboundlogistics Network design Inventory decision Packaging Consolidation Mode selection Carrier selection Warehousing BackhaulmanagementMarketingAfter-salesservice Service level Returns handling Channel decision Parts management Service networkPollutants (negative environmental impact)Fig. 2 Logistics decisions that affect the environment (source: Wu and Dunn 1995)From figure 2, decisions which made in differentactivities in logistics system has directly or indirectlyaffected environmental performance. It is can besummarized from below categories: Vendor selection and location. Different vendorshave different requirements for raw onmental impact on delivering raw materials. Warehousing. The size and location of thewarehouses directly result in disparate consumptionin energy and land usage. Packaging. The materials used in packaging lead todifferent levels in wasting. Also it will show unlikeweight in transportation. Mode and carrier selection. It is directly embodied inemissions through distribution channels both ininbound and outbound logistics. Service level and network design. Different servicelevel and network distinguish the distance fromdistribution centers to the market. It also brings ondistinct pollution and emissions to environment.Every stage of product manufacturing and deliveringcan benefit from green logistics, from developing bettermethods to extract raw materials to reducing packagingon products when they are prepared for delivery.Consumers are sometimes willing to pay more forproducts bearing labeling which indicates that the parentcompany practiced environmental and socialresponsibility when making the product, which makesgreen logistics appealing from a business standpoint aswell as an ethical one.Some examples of green logistics include: shippingproducts together, rather than in smaller batches; usingalternative fuel vehicles for manufacturing andshipping; reducing overall packaging; utilizing rawproducts which are harvested in a sustainable way;building facilities for manufacturing and storage whichare environmentally friendly; and promoting recyclingand reuse programs.4. ENVIRONMENTAL MANAGEMENTSYSTEMS (EMS)The priorities of the 21st century were outlined in1992 in Rio de Janeiro (Brazil), by declaring that“environmental management is to be considered thedominant of sustainable development and at the sametime the highest priority of production process andentrepreneurship” (Agenda 21, 1992). Environmentalmanagement is part of the concept of strategicmanagement and involves safe management ofeconomic activities that helps attain optimal correlationwith efficient environmental protection.

Environmental management can be defined as theway in which companies deal with environmental issues(Kolk and Mauzer, 2002). One of the authors inprevious research offer her own definition of the term:“Environmental management is the planning,implementation and control of strategic, tactical andoperational measures for prevention, reduction andelimination of damage caused to the environment aswell as purposeful usage of market advantages gainedthereof” (Tambovceva, 2008).The goal of environmental management is to lessenthe negative impact of economic activity onenvironment and to ensure ecological safety ofproduction processes, as well as production ofenvironmentally and to human health friendlyproduction. Implementation of the given tasks has to gohand in hand with attainment of other priority goals ofthe company, including preservation of its current andlong-term competitiveness. Environmental managementincreases the liability of the company not only throughproduction of safe and harmless products, but also usingreasonable use of natural resources and selection ofenvironmentally friendly technologies.Normally, environmental management is facilitatedby an Environmental Management System (EMS), atool that organizes and facilitates environmental workand tracks progress towards organizational goals(Ammenberg 2001). An EMS enables companies todemonstrate sound environmental management tostakeholders, which can lead to improved brand imageand increased market opportunities (Welford 1998).The two main accredited EMS standards today areISO 14001 and the EU Eco-Management and AuditScheme (EMAS). Both standards were voluntarilydeveloped during the 1990s with the possibility of beingverified by an external body. Developed by theInternational Organization for Standardization (ISO) in1996, ISO 14001 adoptions require certification by anindependent third party auditor, who helps to ensure thatthe EMS conforms to the ISO 14001 standard. Inpreparation for certification, an organization mustcharacterize the procedures and plans that form its EMS.ISO 14001 is an international standard developed byindustry, trade associations, governments andnongovernmental organizations while EMAS is aEuropean standard developed by the European Union.ISO 14001 applies to all organizations in anyindustry, while the EMAS is primarily focused on themanufacturing and energy industry. In the past, theEMAS standard contained other specific requirements;however, in 2001 EMAS was revised and is now basedon ISO 14001. The largest remaining differencebetween the two is that EMAS requires anenvironmental report, which is reviewed by an external,independent, third party (Ammenberg 2001), while ISO14001 does not.There are many benefits for a company that choosesto implement an EMS (Welford 1998). For example,measures taken to reduce the company’s environmentalimpact can also directly reduce costs, e.g. energysavings in a factory will result in lower energy expensesand increasing carrier fill rates will reduce the numberof trucks on the road thus, reducing the shipper’stransportation costs. There are also competitiveadvantages such as the benefit of staying ahead of thecompetition and legislation. Relationships withgovernmental agencies can also be improved which canlead to regulatory advantages for the firm (Kolk andMauzer, 2002). Lastly, the company can experiencemarket benefits since the company image can besignificantly improved by an EMS certification. AnEMS certification is often seen as a sign of a company’scommitment to environmental issues. However, inreality an EMS says very little about a company’s actualperformance. It is important to remember that an EMSonly provides a standard at the organizational level andit does not set specific levels for emissions reductions orperformance requirements. In theory, a company couldset low targets with a slow improvement rate and stillreceive an EMS certification. On the other hand, acompany could also perform well in the environmentalarea without having an EMS. As Ammenberg (2001)asserts, it is not possible to answer the general questionas to whether an EMS actually improves environmentalperformance. Although an EMS certification does notnecessarily decrease the company’s environmentalimpact, it helps them achieve a better understanding oftheir ecological footprint. This is the first step towards aprogressive change in corporate culture.Based on this, operations, purchasing and supplychain managers have seen the integration ofenvironmental and social issues, including thoseembedded in related standards (e.g., ISO 14001) intotheir daily tasks (Beske et.al., 2008). Such triggers haveincreased interest in green/environmental or sustainablesupply chain management. The literature is still limitedin quantity, and no major reviews of the field have beenpresented. Among the papers identified in the relatedsearch, following papers that attempt to review part ofthe literature were found (Zsidisin and Siferd, 2001;Baumann et.al., 2002; Abukhader and Jönson, 2004;Kleindorfer et.al., 2005; Seuring and Müller, 2007;Srivastava, 2007). deal with environmental performanceas an operation's objective, where supply chain issuesare only secondarily addressed. Zisdisin and Siferd(2001) provide a review on environmental purchasingwhich is based on only 38 publications, i.e., they do notaim to cover all related publications. With only limitedcoverage of supply chain issues, Baumann et al. (2002)centre their review on green product development.Abukhader and Jönson (2004) look at the intersection ofenvironmental issues with logistics. Their review hastwo major limitations: first, they only focus on logisticsmanagement journals. Second, supply chain issues aretreated as a subset of logistics management. The recentpaper by Kleindorfer et al. (2005) comes closest to whatis attempted here. In their contribution they reviewpapers in the field of “Sustainable OperationsManagement” published in the first 50 issues of“Production and Operations Management”. While they

title their paper as operations, they cover related supplychain issues. The emphasis of their paper is more ondiscussing individual issues, but they only providelimited insights into the overall development and statusof the field. Seuring and Müller (2007) also provide aspecific literature review only. They address theemergence and development of integrated chainmanagement (Stoffstrommanagement) in Germany.While this has close links to sustainable supply chainmanagement, the different schools also identifiedincorporate close links to industrial ecology and closedloop supply chain management. A much wider attemptis made in the paper of Srivastava (2007), but, as theauthor already states in the introduction “primarilytaking a reverse logistics angle”.Large number of organizations are running whethercertified EMS or uncertified EMS today. The possibilityof using environmental management systems as a toolfor the logistic management became an interestingresearch problem. Why the organizations want to adoptEMS had been described before, turn the discussionback to their business. The market competition wasalways described as hard, when the customers muchconcerned the environment issues today, environmentalrequirements were taken seriously as a precondition fororganizations (Nawrocka D. 2008a,b). The EMSadopters have to “Green” their business since theymarketed themselves as environmental proactivecompanies.On the other hand, questions remain about whethercompanies are using their EMSs to challenge theirsupplier networks to become more environmentalsustainable. (Darnall and Jolley, 2008) Under thepressure of fierce competition, for the purpose ofreducing the cost and optimizing the resource, thecompanies need outsourcing to help them cut someweakness and concentrate in their core business. Thatmeans the companies have to build a relationship withtheir suppliers, because supplier is a part of companiesbusiness now which has the influence on their rement, the companies have to take action tocontrol the environmental performance in their supplychain.Rao and Holt (2005) also summed up someenvironmental elements should be considered in logisticmanagement from a transportation system such as typeof transport, fuel sources, infrastructure, operationalpractices and organization: Environmental-friendly waste management. Environmental improvement of packing. Taking back packing. Eco-labeling. Recovery of company’s end-of-life products. Providing consumers with information onenvironmental friendly products and/ or productionmethods. Use of environmentally-friendly transportation.Nawrocka (2008a,b) wrote papers for investigatingthe possibility of using environmental managementsystems (EMS) as a tool for the environmentalmanagement of supply chains, the use of EMS, thecredibility of ISO 14001 and the role of supplier controlin environmental management were analyzed. Since thecompanies adopted the outsourcing business, theirsupply chains are growing larger and much complex forfacing the various suppliers. Supplier control is seen asa risk for companies’ environmental performance. Theuse of EMS is obviously showed in the relationshipbetween buyers and suppliers. EMS would be not onlyimproving the environmental performance from theinternal environmental work, but also stretched tosupplier outside the company’s limits meanwhilefacilitating the communication between companies.5. THE PARADOXES OF GREEN LOGISTICSIn the past, planning and research related to freightlogistics systems has primarily been focused towards theobjective of increasing the efficiency of industryactivities with respect to timing and profits. However,within the last 15 years growing concern overenvironmental impacts has spawned the concept ofgreen logistics as a stimulus for developing methodswhich can reduce the environmental impacts of freighttransportation. As a result researchers and industry havebegun assessing mitigation options for planning freighttransportation with consideration for environmentalexternalities. For the purposes of this document and toprovide a general definition, green logistics can bethought of as an approach for planning freight logisticssystems that incorporates sustainability goals with aprimary focus on the reduction of environmentalexternalities. In accordance with this description,various studies provide some background on the currentstate of green logistics practice

LOGISTIC SYSTEM INTEGRATION WITH ENVIRONMENTAL MANAGEMENT SYSTEM: A CASE STUDY OF INTERNATIONAL COMPANY A. TAMBOVCEVS1, T. TAMBOVCEVA2 1 Riga Technical University, ata2000@inbox.lv 2 Riga Technical University, tatjana.tambovceva@rtu.lv The aim of the research is to investigate potential of integrating environment issues into logistic system by literature review and case