Transcription

Cleaning solutionsthrough dry ice blasting

45about usdry ice97environmentalprinciple10dry iceblasters26dry iceproductionmachines29dry icecontainers

› ARTIMPEX nv - 1992› Patented dry ice cleaning & production equipment› Brand : CRYONOMIC › Almost 30 years experience› In-house R&D› Quality performance equipment at competitive prices› Certified partners (agents or distributors)› World-wide team of 60 personsOur services› Worldwide assistance through certified agents› Preliminary study & feasibility analysis› Test cleaning› Start up assistance & staff trainingTo watch ourcompany movieclick herecompanyAbout us

› Frozen carbon dioxide (CO2)› Gas commonly added to water to makesoda water› Captured during industrial processes andrecycled to make dry iceApplications› Dry ice blasting› Cooled storage and transport (hospitals andlaboratories)› Technical applications: e.g. removing explosivegases from tanks for maintenance purposes,declamping metal parts etc.› Cooling process in automation› Winemaking› Airline catering› Special effects (smoke)› Fundamental and applied researchdry iceWhat is dry ice?

applicationsinline machine cleaning

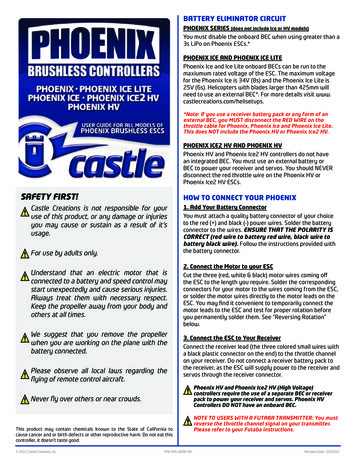

substratePrinciple of dry ice blastingcontamination layer› Dry Ice Cleaning is a blasting technique similar to sand blasting,but makes use of solid CO2 or dry ice pellets› Increase in volume by a factor of 700DuringcleaningCO2 pellets hit the surface,remove thecontaminantand turn to gas› The advantage of using dry ice pellets asblasting material is twofold:1. Thermal shock (resulting in the easydetachment of the contaminant from thesubstrate)2. Explosion lifting force (the dry ice pelletsvaporize to carbon dioxide gas on impact - the original contaminant is left for disposalSupply process of dry iceAftercleaningsubstrate not damagedcontaminationlayerremovedno additionalwasteprinciple of dry ice blastingBefore cleaning

Comparison between CRYONOMIC dry ice cleaning and traditional cleaning methods:CRYONOMIC Time saving:Cleaning in the production environmentNo need to strip down the productionmachinesShort or no production stopFast cleaning method Environmentally friendly:Generates no additional wasteNo use of agressive or dangerous productsNo noise nuisance Other advantages:Leaves the substrate intact: dry ice is soft as chalkSuitable in food industryPellets do not conduct electricityAdvantage applicable for this technique Advantage sometimes applicablefor thistechnique Advantage not applicable for this techniqueSand blastingSolvent cleaningHigh pressureManual cleaningprinciple of dry ice blastingPrinciple of dry ice blasting

Environmental facts about dry iceblasting:› Generate no secondary waste› Safe and non-toxic (e.g. food processingequipment)Other cleaning methods can be toxic:› Sand, soda, or water blasting› Chemical and solvent cleaning methodsenvironmentalEnvironmental

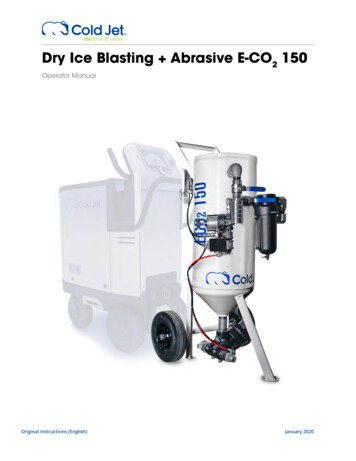

1-hose dry iceblasters·····COB 62COB 62 COB 71COB 71RCOB71A(R)1 2-hose dry iceblasters······COMBI 71COMBI 71RCOMBI 72COMBI 72RCOMBI 73COMBI 73Rdry ice blastersDry ice blasters

dry ice blastersHow to choose your CRYONOMIC dry ice blaster?One-hose vs two-hose dry iceblastersWhen to use 1-hose system? Smallerjobs More focusedcleaning Mostly end-users Light weight & compactmachine Ergonomical Less airconsumption Lowbudget Smallercompressor– Uses more dry ice at high pressure– Mainly focused on in-house blasting– Limited hose length (max 25m)When to use 1-hose 2-hose system? Bigger jobs / large projects(m²) More aggressive cleaning power (up to 16 bar) Faster cleaning (higher impact wider nozzles) Pellets stay intact, and flow and at higherspeed Contract cleaners & end-users Long distance blasting (up to100m) Vertical cleaning up to 30m high Less dry iceconsumption––––Enough compressed air requiredHeavy and less ergonomicalMainly focused on outdoorblastingBigger compressor neededfaçadecleaning

maintenanceapplications

CHARACTERISTICSCOB 62art. P20400COB 62 art. P20500dry ice blastersHow to choose your CRYONOMIC dry ice blaster?COB 71art. P20800COB 71Rart. P20850COMBI 7COMBI 7R1-hose dry ice blaster1-hose dry ice blaster1-hose 2-hose dry ice blaster MG 1004 gun Round nozzle Focus 3 5m hose set 5m power cord Manual CE certificate MG 1004(R) gun Round nozzle Focus 3 5m hose set 5m power cord Manual CE certificate Gun & nozzle: see page 21 Nozzle: see page21 Hose set 5m with quickcouplings 5m power cord Manual CE certificateHopper (capacity)14 kg dry iceIsolated hopper easily removable30 kg dry iceIsolated hopper easily removableAdvanced pneumatic hopper agitation30 kg dry iceIsolated hopper easily removableAdvanced pneumatic hopper agitationPellet consumptionAdjustable 20 – 80 kg/hBlasting without dry ice possibleAdjustable and displayed 25 – 90 kg/hBlasting without dry ice possibleStart-up value programmableAdjustable and displayed 25 – 90 kg/hBlasting without dry ice possibleStart-up value programmableStandard delivered withRemote controleNoDimensions (l x w x h)No380x570x890mmYesNo665x570x876mmWeight66 kgChassis2 fixed wheels, 2 pivoting wheelsPusch handle and hose supportTo watch anapplication videoclick hereNo68 kg90 kgYes665x570x876mm95kg2 large wheels, 2 pivoting wheelsFoldable push handle and hose supportLifting eyelets and forkling handling slot100 kg100 kg2 large wheels, 2 pivoting wheelsFoldable push handle and hose supportLifting eyelets and forkling handling slot

applicationspaint stripping

COB 62Maximal performance for repetitive cleaning jobs!The CRYONOMIC COB series is- a single hose dry ice blaster- low air consumption- powerful cleaning performance- ergonomic design: light and easy to manipulateIntuitive control panel:emergency stop andON/OFF buttons, robustsingle touch controlbuttons, blast pressureregulator and manometerTypical applications: maintenance, mould cleaning, foundry,deburring, printing machines, food industry, electrical componentscleaning, glue removal, Fast and easyconnections: quickcoupling,compressed airinlet, dry ice blasters1-hose dry ice blaster

applicationsrubberindustry

dry ice blasters1-hose dry ice blasterCOB 62 Light weight machine with grit blasting possibilities!The CRYONOMIC COB 62 takes the best of bothworlds:- single hose dry ice blaster- possibility of adding the CRYONOMIC Abrasivemodule to perform dry ice grit blasting cleaningpossibilitiesTypical applications: façade cleaning, paint stripping, car cleaning,rust removal, machine maintenance, grit blasting, Abrasive module:in addition to the dry ice blaster, thismodule allows to take advantage ofthe abrasive action of grit togetherwith the removal action of dry ice

applicationsoffsite machine cleaning

dry ice blasters1-hose dry ice blasterCOB 71(R)Top notch performance with unbeatable efficiency!The CRYONOMIC COB 71 is- the most robust single hose dry ice blaster of the COB series- a bigger hopper- more blast pressure- The Remote Control on the COB 71R gun allows you to change blastingconditions (pellet and air consumption) and gun light at distanceTypical applications: construction & renovation, contract cleaning,(Offline) machine maintenance, inline production line cleaning, automotive,rubber, metal processing, (nuclear) decontamination, robotisation, Bigger hopper:the isolated hopper is easilyremovable, an advancedpneumatic hopper agitationmakes the hopper with acapacity of 30 kg performoptimal

foundryapplications

dry ice blasters1-hose dry ice blasterCOB 71ABlaster for automated cleaning!CRYONOMIC COB 71A :- Developed for automated cleaning- Saving time- Increasing productivity- Blasting nozzles in various angle directions- Optional : giving feedback of blast parameters (COB71AR)Bent round nozzleStandard round nozzleTo watch robotisedcleaningclick hereFlat nozzleAbrasive nozzle

COMBI 7 SeriesThe perfect all-round machine for every job!The CRYONOMIC COMBI 7 Series is the only dry ice blasterallowing the:- Highest cleaning performance for every imaginable application- Industrial sites- Single hose as well as dual hoseThis blaster can be used in 6 different set-ups, each havingspecific applicationsTypical applications: contract cleaning, bigger jobs / large project cleaning, verticalcleaning, long distance cleaning, faster and more aggressive cleaning at higherimpact, dry ice blasters1-hose 2-hose dry ice blaster

applicationsmould cleaning

dry ice blastersCompose your CRYONOMIC COMBI 7 blaster according to your needsOne-hose setupMedium scale applicationsCOMBI 71(R) COMBI7One-hose setMG1004(R)Two-hose setupLarge scale applicationsLow pellet consumptionLong distance cleaningCOMBI 72(R) COMBI7Two-hose setG2001(R)Both setupsMedium scale applicationsLarge scale applicationsLow pellet consumptionLong distance cleaning(R) remote controlled gunCOMBI 73(R) COMBI7One-hose set and two-hose setMG1004(R) andG2001(R)

applicationsoffline machine maintenance

accessoriesCRYONOMIC dry ice grit blasting moduleAbrasivemoduleAdvantages compared to other cleaning techniques:· Reducing significantly the quantity of abrasive compared to sand blasting· More ecological abrasive blasting· Easier and faster cleaning up, reducing the volume of secondary waste· Extending the scope of general contract cleaning companies significantlywith one machine· No heating up or deforming of the contaminated productTypical applications: rust removal, asbestos and lead paint removal,façade cleaning, paint stripping, surface roughening before painting,coating, graffiti removal, stubborn material removal, Suitablefor:COB 62 COB 71(R)COMBI 7(R)To watch a dry icegrit blastingvideoclick here

Pelletisers····CIP 5XSCIP 5SCIP 5MCIP 5Lpellet productionDry iceproduction machines

pellet productionPellet productionCIP 5 SeriesProduction of high density dry ice pellets anddry ice sticksThe CIP 5 Series exist in 4 models:· CIP 5XS· CIP 5S· CIP 5M· CIP 5Lup to 35 kg/hup to 100 kg/hup to 180 kg/hup to 300 kg/h· Producing 3 mm pellets; 10 or 16 mm sticks· Quick and easy change of extrusion dies· Supply Liquid CO2 Pressure: 16 -21 bar storagetank· Hydraulic silent motor with fast start-up protocol· Oil entirely separated from dry ice· Ergonomic touchscreen control panelDry ice can be used for a lot of applications in different industries:› Dry ice cleaning› Cooled storage and transport (hospitals and laboratories)› Process cooling› Carbonic maceration› Fire extinguisher› Declamping of metal parts› Smoke generation for show effectsTo watch dry ice productionon different machinesclick here

pellet productionHow to choose your CRYONOMIC dry ice production machine?CHARACTERISTICSCIP 5XSart. P22800CIP 5Sart. P22700CIP 5Mart. P22600CIP 5Lart. P22500Production capacity1Up to 35 kg/hUp to 100 kg/hUp to 180 kg/hUp to 300 kg/h3 mm, 10 mm or 16 mmPellet diameterWeight (excl. hydraulic oil)Oil contentPower consumptionPower supply115 kg310 kg530 kg800 kg8l36 l54 l90 l2 kW3 kW7,5 kW9 kW400V / 50Hz / 3Ph E230V /50HzLiquid CO2 moisture: 65 ppm and completely oil freeSupply liquid CO216 – 21 barSupply pressure liquid CO2Inlet connection liquid CO2½”BSP½”BSP½”BSP¾”BSPOutlet gas CO21”BSP2”BSP2”BSP2”BSP780 x 310 x 1.000 mm1.000 x 705 x 1.035 mm1.380 x 710 x 1.785 mm1.600 x 830 x 1.805 mmDimensions excl. Outlet (l x w x h)1The production capacity depends on pellet diameter, gas tank pressure and status, liquid CO2 temperature, atmospheric conditions and user settings.

CIC-containers····CIC 85CIC151CIC370CIC550dry ice containersDry icecontainers

dry ice containersDry ice containersCIC-containersIntegrated full lengthhingeContainers for dry ice transportation· Monobloc structure in polyethylene· Enlarged wall thickness· Isolation material: polyurethane· Frame in stainless steel· Stackable and accessible at four sides· Sloping bottom with drain hole and closing dop· Lid opening assisted by gas springs· Ergonomic depth and level bottom surface· Rust proof parts for a unlimited life span· Metal components in protected positions· Exchangeable steel feet or 4 pivoting wheels· Incl. document holderLid opening assistedby gas springs2 adjustable stainlesssteel closures(lockable)CIC 85CIC 151CIC 300CIC 500Storage capacity85 litre150 litre300 litre500 litrePallet or wheelsnon or wheels (trolley)pallet or wheelspallet or wheelspallet

dry ice containersDry ice containers

www.cryonomic.cominline productionmenu33applications

THANK YOU FOR YOUR ATTENTIONArtimpex NVKleimoer 3 B-9030 Gent BelgiumTel: 32 9 216 76 90 Fax: 32 9 216 7691info@cryonomic.comwww.cryonomic.com

Dry Ice Cleaningis a blastingtechniquesimilarto sandblasting, but makes use of solid CO 2 or dry ice pellets › Increase in volume by a factor of 700 › The advantage of using dry ice pellets as blasting material is twofold: 1. Thermalshock (resulting in the . easy detachment . of the contaminantfrom the substrate) 2. Explosion lifting force (t