Transcription

ADVANCEDDRY ICECLEANINGSOLUTIONSMinimizes production downtimeNo waterNo chemicalsNo secondary wasteNo abrasion of treated surfacesEnviromentally friendyAIR BLASTING SHOT PEENING WET BLASTING PAINT STRIPPING DRY ICE & DRY SNOW CLEANINGSODA BLASTING ULTRA HIGH PRESSURE WATER JETTING ENAMELING & COATING SOLUTIONSin partnership with

FerroECOBlastis a leader in thedevelopment andproduction of surfacetreatment technologiesand machinery.We shape the surfacetreatment industry withour constant researchand developmentWe area problemsolversWe strive for asuperior customerexperience Over 55 years of know-how, tradition of innovation and excellence More than 1.000 successfully installed custom made solutions worldwide Highly motivated, educated and experienced team Our own laboratory and research center Prompt after sales activities Satisfied customers in the most demanding global companiesOur philosophy is keeping trackof new technologies andconstantly develop throughinnovation and research. Thisenables us to be one of the topsuppliers of technologicalsolutions in the fields of airblasting, shot peening andindustrial surface cleaningtechnologies. We are present atall the most importantexhibitions in the world and weattend and hold lectures aboutsurface treatment technologiesand solutions.

What isDRY ICEDry ice cleaning is indispensable in the modern production process. Cleaning or removingdirt and residues can be done directly on machines, hot tools, etc., without wastingprecious time and money dismantling and reassembling.This type of cleaning technology is very similar to sandblasting,where a medium is accelerated with a pressurized air stream toimpact a targeted surface, except that the effect is doubled. Withthe difference in temperature, dry ice creates tensions andfractures on the surface layer, and with the kinetic energy of itspellets removes deposits without damaging the base material.Due to its soft means of application, dry ice cleaning is in manyways superior to sandblasting. It does not pit or damage theunderlying surface and sublimes quickly into the air. It leaves nosecondary residue and does not erode or wear away the targetedsurface. Tolerances are preserved and most equipment andmachinery can be cleaned while in place, no transport needed.DRY ICE can be usedfor cleaning, in thefood and wineprocessingindustry, cooling,catering, etc.Environmentallyfriendlyprocess withnet zerocarbon footprint.DRY ICE advantages: Cleans numerous objects with varying complex geometries in one go Equipment is cleaned on location, thus minimizing production downtime Quick evaporation that leaves no waste - only removed material Dry ice transforms into harmless carbon dioxide gas No water - no possibility for microorganism growth No chemicals Non-abrasive, no damage to the surface

AUTOMATED DRY ICEIN-LINE ROBOTIZEDDRY ICE CLEANING CELLFully automatic line with a robotic system for cleaning with dry ice pelletsbefore painting. The system has a lot of unique features The automaticblaster filling system enables constant and precise dry ice pellets flow forthe best cleaning result, the automatic dosing unit with built-in dispensingscrew conveyor for in-time dosing and dry ice quality loss prevention, aunique adjustable vertical loader for cold boxes and the whole system isautonomous, there is no operator needed. All the features described aboveguarantee 100% cleaning results every day. In-line automatic cleaning system Automatic blaster filling Automatic dosing unit Insulated dry ice storage Adjustable vertical loader User-friendly “FerroSmartPanel”ROBOTIC CLEANING CELLFOR CLEANING ENGINE PARTSFully automatic robotized solution for permanent cleaning of engine parts.With all the built-in systems our cell is the most advanced, effective andeconomical solution for the cleaning of engine parts in the world. Pre-setprograms along with the use of a robotic arm ensure 100% clean productseach time. The system has dual dry ice blasting nozzles for maximumefficiency of the cleaning process. Fully automatic cleaning process Completely closed system In-sync with other production processes Pre-set cleaning programs for 100% clean products On-site dry ice production with pelletizer PE80 Recovery unit RE80 enables big savings in energy costs, cost of liquid CO²Each of our dry ice automatic cleaning solutions is unique and well configured tosolve the biggest problems and satisfy even the most demanding clients.

CLEANING SOLUTIONSAUTOMATIC DRY ICECLEANING CELLFOR SMALL AUTOMOTIVE PARTSThis dry ice cleaning cell is used for cleaning gear pumps and is designed toclean large quantities of products, with full automation for the best cleaningresult. The system is cleverly designed to ensure maximum hygiene with aseparate entrance and exit for cleaned parts. To maximize efficiency, theoperator can adjust the height of the blasting nozzle, its speed and the numberof passes over the surface. Fast cleaning process for large-scale production Cleaning process is 100% controlled Clean / unclean compartments for maximum cleanliness Maximal efficiency of cleaning with minimal worker input On-site dry ice production with pelletizer PE80DRY ICE CLEANING ROOMThe safe and user-friendly dry ice cleaning room is very useful for cleaninglarger components in an enclosed space, which prevents dirt, oils, liquids, etc.,from entering the production lines and halls. The room is soundproofed toprevent sound pollution in the production process Sound-absorbing insulation panels, soundproof doors Sensor and alarm system for measuring CO² concentration Suction system with filter unit with cassettes and ventilator Electronic control panelThe most important task of every automatic or robotic cleaning solution is the permanentand continuous supply of a controlled amount of dry ice pellets to the nozzle.

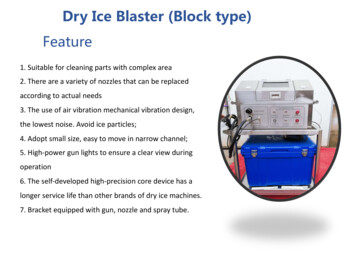

DRY ICE EQUIPMENTBLASTER BL25 MINIThe BL25 is a high-performance dry ice blasting machine that isdeveloped for the small but frequent cleaning jobs in factories andworkshops. The BL25 is used for both heavy contaminations as well asdelicate cleaning tasks. Its small size makes it very mobile in confinedspaces. It can operate with limited air supply (as low as 70L per minute)BLASTER BL60A new generation of blasters with improved rotary air-lock system and alarge hopper with a capacity of 23kg which enables continuous dry iceflow. The emphasis was put on sustainability, affordability, and efficiency.A powerful and reliable machine for everyday jobs.PELLETIZER PE80The pelletizer enables users to manufacture dry ice directly into theblaster or into a storage container. High-density pellets can beproduced in any size from 1,7mm to 16mm.RECOVERY UNIT RE80The revert gas that would otherwise go to waste is collected, chilled,compressed to liquid CO2, and sent back to the pelletizer to producemore dry ice pellets. Low energy and CO2 consumption (saves up to 0,8kg of LCO2 per kg of produced dry ice) significantly reduce your dry iceproduction costs.

What is DRY SNOW blastingSimilar to the dry ice blasting/cleaning process,the special feature of snow blasting is thatliquid CO2 is first converted into standardpellets and immediately after to verysmall solid CO2 snow particles at atemperature of -78.5 C. Uniform micro crystalshave better density in the airflow and muchless kinetic energy, making the impact on thesurface of the object being cleaned extremelygentle. Working pressure can be significantlylower and the consumption of dry snowcrystals is easily controlled. Our snow cleaningmethod is the next step of cleaning verydemanding and precise objects that are toosensitive for classic cleaning processes.WHEREdo weapply it?FerroECOBlast’s snow blasting technology is best applied in the cleaning ofdemanding and sensitive components, like electronics, fine mechanical parts etc. It isalso becoming increasingly popular for final pre-cleaning or activating surfaces priorto painting metal or plastic parts of any size both in individual and serial production.We offer our own know-how, procedures and equipment for cleaning of very sensitiveand delicate surfaces with innovative, manual or automated/robotized snow blastingtechnologies in the mass production of automotive, aerospace or medical instrumentsand components.DRY ICE advantages:DRY SNOW advantages: The only system on the market that provides85% efficiency in obtaining dry icepellets from liquid CO² Fast, cost-efficient and safe cleaning process Easy automation and process monitoringwith reproducible features High cleaning and pre-cleaning efficiencyof a wide range of materials

DRY ICE / SNOWIS APPLICABLE TRYDEBURRINGPLASTIC & RUBBERINDUSTRYEverydaycleaning ofdies/moldsdirectly on diepress machinesis a necessity formodern-dayfoundries.Surfacepreparationbefore paintinghas never beeneasier than todaywith dry ice/drysnow cleaning.From landing gearsystems to cargobays, dry iceblasting hasproven to be anideal solution formany cleaningapplications in theaircraft andaerospace industry.Dry ice blastingis an effectivesolution toremove burrsand flash frommachined andmolded parts.Dry ice cleaningtechnologyprovides plastic& rubbermanufacturerswith a nonabrasive andenvironmentallyfriendly methodof cleaning theirmolds.FerroČrtalič d.o.o.Sela pri Dolenjskih Toplicah 478350 Dolenjske TopliceSLOVENIA - EUROPET: 386 (0)7 384 51 00F: 386 (0)7 384 51 15info@ferrocrtalic.comwww.ferroecoblast.comDry ice cleaningreduces productiondowntime and costs.

On-site dry ice production with pelletizer PE80 FOR SMALL AUTOMOTIVE PARTS AUTOMATIC DRY ICE CLEANING CELL This dry ice cleaning cell is used for cleaning gear pumps and is designed to clean large quantities of products, with full automation for the best cleaning result. The system is cleverly designed to ensure maximum hygiene with a