Transcription

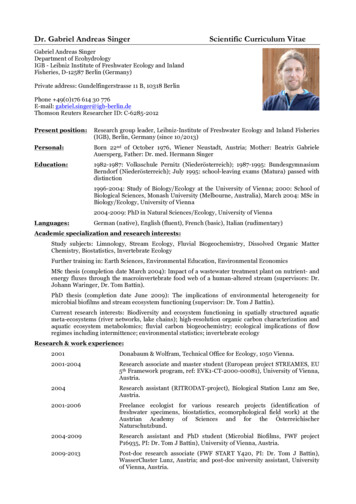

ForewordWhen Andreas Stihl developed his first chain saw 90 years ago, his aim and vision was to “ease people’s workwith and in nature.” Today, STIHL is the world’s bestselling brand of chain saw and leads the market time andagain with outstanding innovations. Our chain saws and outdoor power tools provide significant support topeople’s daily work in forestry and agriculture, in gardening and landscape maintenance, and in construction.We specifically design our products to meet our customers’ needs. Our most important partners are theauthorized dealers, who provide advice, instruction and service. With more than 40,000 authorized dealersin over 160 countries, we are close to the customers and know what the users need.Anyone who wants to be a global leader may never be satisfied with what has been achieved. Sustained successis only possible when one continuously develops further and focuses one’s company on lasting principles. Wehave had a long-term approach and have set the highest quality standards for our products ever since thecompany was founded. Andreas Stihl, the founder, already manufactured many of the components for hischain saws himself. That was the only way for him to maintain the quality he needed for his tools. Out of thisambition, grew a worldwide manufacturing network with production facilities in seven countries. Proprietaryknow-how and first-class workmanship down to the smallest detail typify the quality that is “made by STIHL.”Since the company was founded by Andreas Stihl in 1926, it has developed from a one-man operation intoan internationally active manufacturer of chain saws and outdoor power tools. As a family-owned companywith its roots in forestry, we feel a special responsibility to people and nature. This strong bond gives us thestrength to continue growing. We are proud to look back on 90 years of STIHL.Dr. Nikolas StihlChairman of the Supervisory Board of STIHL AGDr. Bertram KandzioraChairman of the Executive Board of STIHL AGTHE BEGINNINGSThe first gasoline-powered chainsaw from Andreas Stihl (1929)was successfully tested in theBlack Forest. One of the firstcustomers was a sawmill.23

1926 – 1945Pioneering spirit and the firstfoundations of success19401937“I AM A STIHLER”A PIONEER OF GLOBALIZATIONSTIHL exports to the United States andThe company’s own apprentice department withCanada as of the mid 1930s.workshop is set up in 1940.Andreas Stihl develops his first chain saw and manufactures the components himself. He exports to international markets from an early stage. And he trains his skilled workers himself. STIHL continues to build onthese principles today.When Andreas Stihl opens hisengineering office in Stuttgart in1926, forestry work is still hardand difficult. Trees are felled withan axe or handsaw and then transported to sawmills. Only there arechain saws used.Stihl graduated in mechanicalengineering before starting hisown business as a dealer forwood-processing machines, sohe often visits sawmills. One day,he has an idea: The saw shouldbe carried to the tree, and not thetree to the saw. He thinks moreand more about designing a transportable, powerful chain saw. Thisidea ultimately leads to a product.The first chain saw from the“A. Stihl Engineering Office” isa two-man electric saw. The firstgasoline-powered saw follows in1929. As the suppliers cause himtechnical problems, he manufactures the parts himself. Successis not long in coming: As he sayshimself, the saws are “grabbedout of his hands.”In the following years, he regularlylaunches new models on themarket. The small engineeringoffice turns into a sizeable factory.A major relocation takes place: fromthe center of Stuttgart to the moreindustrial suburb of Bad Cannstatt.Business at first goes well, evenduring the Great Depression thatstarts in 1929. The inventivebusinessman offsets falling salesof chain saws in the early nineteen-thirties by producing washingmachines for example. His firstexports are also good for business.Andreas Stihl prioritizes the exportbusiness and enters new marketsin the United States and Canada.Then, the Second World War starts.The factory in Bad Cannstatt iscompletely destroyed in an airraid in October 1944. The Alliesdetain Andreas Stihl for a while ina labor camp in Bavaria. However,he is discharged in a trial before adenazification tribunal.19411926FOCUS ON THE WORKFORCETHE “FATHER OF THE CHAIN SAW”By 1941, Andreas Stihl employs 340Andreas Stihl develops his first chainpeople. Even then, the employeessaw in his small workshop in Stuttgart.benefit from a Christmas bonus and apension fund.1929LIGHTER, BETTER, HANDIERThe first two-man gasoline chainsaw (46 kg / 6 hp) eases forestrywork considerably.»We want to make people’s work easier.That was my father’s vision 90 years ago.And that is still our main motivation today.«HANS PETER STIHL4SOCIAL RESPONSIBILITYToday, STIHL employs approximately15,000 people. The company providesdual training in Germany and at itsinternational sites.And its voluntary employeebenefits go far beyond the provisions of collective-bargainingagreements.5

1945 – 1970Big plans and setting the rightcourse for the futureIn the post-war years, STIHL masters the crisis. Personnel changes also occur: Andreas Stihl’s childrenjoin the company and guide it to more growth.After the war, Andreas Stihl is confronted with difficult challenges.His trustee, Karl Gutjahr, is able torestart operations at today’sheadquarters in Waiblingen-Neustadt in 1945, but just 80 of theprevious 500 employees are stillthere. The saw business is in aslump because people are repairing used tools and not buying newones. STIHL is in a crisis.STIHL works its way back tosuccess with highly motivatedemployees, some of them fromthe founding years, and with newproducts. The legendary “Contra”model is launched in 1959. STIHLachieves double-digit revenuegrowth with this gearlessgasoline-powered chain saw.The entry of Hans Peter Stihl andhis sister Eva into the company isat first unremarkable, but is laterhighly formative for its entirefurther development. In 1960,Andreas Stihl, now 64 yearsold, changes the form of thecompany to a limited partnership (KG) and includes his fourchildren with equal shares aslimited partners. STIHL now has640 employees and generates1959A STRONG FAMILY CONNECTIONHans Peter Stihl and his sister Eva gradually gain1964experience in important positions. They consultCONTINUAL INNOVATIONin 1973, they take charge of business operations.STIHL is the first manufacturer to equip its chainTheir brother, Dr. Rüdiger Stihl, joins the companysaws with an anti-vibration handle in 1964.in 1978. Gerhild Schetter (née Stihl) is also atheir father on all major decisions. After his deathlimited partner.revenue of approximately 25million deutschmarks.Operations at the factory still requires a high degree of manualwork, but the rapid growth – twonew plants are already underconstruction – requires a newapproach. The siblings Eva andHans Peter Stihl want to restructurethe firm and to create a modernindustrial company. Major steps inthis direction are the expansion ofthe production facilities and thedevelopment of a sales organization.STIHL makes a start in this directionwith a sales branch in Austria.1965QUALITY FROM A SINGLE SOURCEIn 1965, an ultramodern plant for the production of sawchains and guide bars is built in Waiblingen-Neustadt. STIHLcontinues to produce these components itself to this day.1959A SAW TRAVELS AROUND THE WORLDThe “Contra,” a gearless gasoline-powered chainsaw, revolutionizes forestry work. With 12 kgand 6 horsepower, it is lighter and more efficientA special sense of responsibility – for employees, nature and societythan all other products on the market. Forestryoperations can increase their productivity by up toTo this day, the company sees itself asstrongly committed to its employees, societyand the environment. The corporate culturethat has grown over decades is marked by afeeling of trusting partnership, responsibility,respect and fairness. Voluntary employeebenefits have a long tradition at STIHL, goingback to the time of Andreas Stihl. Under the6management of his children Hans Peter Stihland Eva Mayr-Stihl, various models of employeeparticipation in the company’s success arecreated. But commitment and responsibilityare demonstrated also by the workforce. Forexample, numerous donation campaigns andemployee deployments for social and ecologicalprojects take place – worldwide.200 percent.SOCIAL COMMITMENTToday, STIHL supports social, environmental and cultural projects aroundthe world, such as the “Pró-Florescer”project in Rio de Janeiro. In the city’sbotanical gardens, young peoplefrom precarious backgrounds areable to undertake occupationaltraining as gardeners.7

1970 – 1995A strategy and courageto go through great changesOwn manufacturing and sales – founding production and sales companies in Germany and abroad is the key tosuccess. STIHL has been the world’s bestselling chain-saw brand since 1971.PERSONAL ADVICE FROM ANAUTHORIZED DEALERRight from the start, STIHL hasplaced importance on advice,instruction and service fromauthorized dealers. Today, morethan 40,000 of them sell STIHLproducts in over 160 countries.In the late nineteen-sixties,Andreas Stihl increasingly withdraws from the company forreasons of health. His son, HansPeter Stihl, becomes the personally liable general partner in 1971.He and his sister, Eva, have already been pursuing a clear strategyfor some years: They want totake control of sales operations.The contact points for customersare to be the authorized dealerships, which can provide expertadvice, as well as reporting backto the founding company on anyproblems that might arise withnew developments. The siblings’entrepreneurial vision and thepersistently pursued sales strategy pay off. STIHL has been theworld’s bestselling chain-sawbrand since 1971. The company’sown sales organization is continuously developed.Along with rising demand, newproduction sites are establishedin Brazil, Switzerland and theUnited States. A magnesium diecasting plant is also built. Thenew plants not only supply theirown domestic markets, they alsocompete with each other. Thismeans that on the one hand,production becomes more costeffective; on the other hand,STIHL achieves a high degreeof vertical integration and canmanufacture key componentsitself. The worldwide productionnetwork makes STIHL into aglobal player, but without losingits family-owned structure.1992ENTRY OF THE THIRD GENERATIONDr. Nikolas Stihl, the son of Hans Peter Stihl, joins the1973STIHL Group. From 1993 until 2011, he is the ChiefSTIHL EXPANDSSetting up a pro-In 2012, he becomes Chairman of the Advisory Boardduction and salesand of the Supervisory Board. Hans Peter Stihl becomescompany in Brazil isthe Honorary Chairman. Eva Mayr-Stihl continues as theDeputy Chairwoman of the Advisory Board.one of the first stepsin establishing aQuality standards also rise: STIHLengineers systematically optimizethe tools’ performance and workon enhancing product safety andoperating comfort, while reducingemissions.Executive of VIKING GmbH in Langkampfen, Austria.world-wide pro-1988duction and salesINCREASING IMPORTANCE OFnetwork.ENVIRONMENTAL PROTECTIONSTIHL develops the world’s first catalyticconvertor for two-stroke engines.1977SAWING, GRINDING, CUTTINGSTIHL continues expanding its product range.Product diversity – growth in all respects, but not at any priceThe first trimmers for private customers areadded in the mid-seventies.The STIHL product range has been steadilygrowing since the mid-sixties. In addition tochain saws, numerous other hand-heldoutdoor power tools are developed: cut-offmachines, brushcutters, hedge trimmers,grass trimmers and earth augers, as well asblowers and sprayers – today powered bygasoline, electricity or rechargeable batteries.8In addition to performance and weight, anincreasing role is played by operating comfort,operating safety and environmental protection.The range is completed with lubricants and protective clothing. And with the acquisition in 1992of VIKING, a manufacturer of gardening powertools, STIHL covers the gardening segment inaddition to forestry and construction.ENVIRONMENTAL PROTECTIONToday, STIHL has its own ultramodern development center.Approximately 500 developmentengineers work there, for exampleon reducing the tools’ emissions to atechnical minimum. The investment volume for environmentallyacceptable engine technologiesamounted to more than half abillion euros in the past ten years.9

1995 – 2016A new structure and thestrength to growOn a sound basis and largely independent of the fluctuating capital markets, the family-ownedSTIHL group is well positioned to meet the challenges of the future.THE PARTNERSFront (from left to right): Dr. Rüdiger Stihl, Eva Mayr-Stihl, Hans Peter Stihl, GerhildThe entry of the third generationtakes place along with greatstructural changes. In 1995, theSTIHL companies are placedunder the roof of a holding company. A far-reaching partnershipagreement ensures that the groupcontinues to be 100-percentfamily owned. This is an importantstep, because the Stihl familywithdraws from the operationalbusiness.For the first time, the STIHLGroup is managed by an ExecutiveBoard without any members ofthe Stihl family, since 2003 underExecutive Board Chairman Dr.Bertram Kandziora. The family isinvolved in all strategic decisionsthrough the Advisory Board of theholding company and through theSupervisory Board of STIHL AG,which was founded in 1997.“Innovation and a focus on corecompetencies are our greatstrengths. Our most importantbenchmark is quality. It involvesthe entire lifecycle of a product –from production to service.”Dr. Bertram KandzioraIn this form, the STIHL Groupcontinues to grow, and todaygenerates annual revenue of morethan three billion euros. Withan equity ratio of 70 percent, allinvestments can be financed fromits own resources. In order tocreate the right conditions forfurther growth, one billion euroswill be invested worldwidebetween 2015 and 2018.STIHL aims to achieve continuallong-term growth. In addition tocontinuity, the company’s greatstrengths include its focus on corecompetencies. This means thatSTIHL has a consistent orientation towards the needs of itscustomers, produces no less thantop quality for them, and makessure that advice, instruction andservice are at the same level as itsproduct quality. This reflects themotto of the company’s founder:“Every chain saw is only as goodas its service.”Schetter; rear (from left to right): Kathrin Stihl, Markus Schetter, Susanne Müller-Schöll,Dr. Nikolas Stihl, Christina Berger, Selina Stihl, Karen Tebar.THE EXECUTIVE BOARDDr. Bertram Kandziora (middle) is the Chairman of the Executive Board of STIHL AG and the Executive Board member for2016Production and Materials. The other members of the ExecutiveSTIHL CONTINUES TO GROWBoard are (from left to right) Norbert Pick (Marketing and Sales),In Waiblingen, STIHL opens a newWolfgang Zahn (Development) and (from right to left) Dr. Michaelproduction logistics center and a newProchaska (Human Resources and Legal Affairs) and Karl Anglerbuilding for the development center(Finance, Controlling, Information Systems and Service).with floor space of 12,600 squaremeters (135,000 square feet). The2014production network is furtherANOTHER WORLD FIRST FROM STIHLcarburetor plant in the Philippines.expanded with the new ZAMAThe STIHL TSA 230 is the world’sfirst battery-powered2009cut-off machine.STRONG AND QUIET: BATTERYTECHNOLOGYThe range of battery tools is startedin 2009 with cordless hedgetrimmers. The first cordless chainsaw follows a year later.»The desire to grow is natural.For a company that has its roots in forestry,this ambition is well established. We always aim to grow above ourselvesin everything we do. Because only when we improve ourselves,are we able to pass on this capability to others.«DR. NIKOLAS STIHL10SUSTAINABLE BUSINESSOPERATIONSAlso today, STIHL prioritizes a downto-earth and long-term approach. Jobsecurity is very important. Between2015 and 2018, STIHL will investapproximately 300 million euros inthe German founding company –the highest volume to beinvested at a site of the STIHLGroup and a clear commitmentto the home country.11

ANDREAS STIHL AG & Co. KGBadstraße 11571336 WaiblingenDeutschlandwww.stihl.de

Their brother, Dr. Rüdiger Stihl, joins the company in 1978. Gerhild Schetter (née Stihl) is also a limited partner. 1959 1965 QUALITY FROM A SINGLE SOURCE In 1965, an ultramodern plant for the production of saw chains and guide bars is built in Waiblingen-Neustadt. STIHL continues to produce these components itself to this day. 1945 - 1970