Transcription

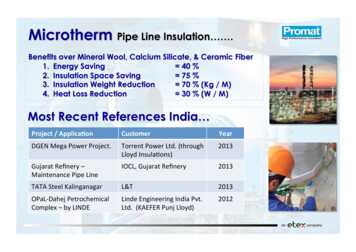

Microtherm Pipe Line Insulation .Benefits over Mineral Wool, Calcium Silicate, & Ceramic Fiber1. Energy Saving 40 %2. Insulation Space Saving 75 %3. Insulation Weight Reduction 70 % (Kg / M)4. Heat Loss Reduction 30 % (W / M)Most Recent References India .TorrentPowerLtd.(throughLloydInsula PaL- ringIndiaPvt.Ltd.(KAEFERPunjLloyd)2012

Company&BusinessCorporaten PromatHPIisadivisionofEtex,a4BillionUSDinter- ‐na onalindustrialholdinginBrussels(Belgium).n Etex affiliatedcompaniesareac veintheproduc eaderinselectedmarketsforbuildingmaterialsn asedonawiderangeofhighperformanceinsula onmaterialsandsystemsforavarietyofmarketsegments.n ula onsolu ons.PromatHPI:Leaderforthermalinsula5onsolu5ons

ormorethanPromat Insula onsolu onsthanceramicfibreandconven onalinsula gthofPromat in22countrieson5con nentsguaranteeclosecustomerandmarketin macy

Products&Proper esPorLolio:Overviewn Calciumsilicaten Microporous MICROTHERM PROMALIGHTn Otherproductsare Fibres Insula/onbricks Vermiculite bricksVermiculiteMineralWool

Products&Proper esn oper esandcharacteris csincomparisontoconven onalinsula ons: Verylowthermalconduc vity Veryhighthermalresistance Mosteffec vehightemperatureinsula on rLolio:MicropourousProductsBrands – “MICROTHERM “ & “Promalight“MEANTEMPERATURE( C)

Products&Proper esPorLolio:CalciumSilicateProductsn PromatbrandssuchasPROMATECT ,PROMASIL ,MONOLUX ,DURATEC andMONALITE arerecognisedbench- ‐marksforcalciumsilicate.n edbyPromatunderthetrademarkPROMAXON .THERMALCONDUCTIVITY(W/m.K)n .MEANTEMPERATURE( C)

Applica ons&AppliancesSolu/onsPetrochemn n n Back- ‐upinsula ocesspipingandequipmentFlareinsula onGlasn n ForehearthsMel ngfurnaceandregeneratorsMul/Metaln n n n eEnergyn n n n rsSolarpowerplantsIndoorinsula onofbuildingsFurnacesn n n n mentfurnacesCeramicfurnacesInduc onfurnacesChimneyn n n Wallprotec onoffireplacesCasingofdomes cchimneysConstruc onkitforbuildingcentresTransporta/onn n n n Mari meRailwayAutomo veAerospaceanddefenceHomeappliancesn n n StorageheatersDomes covensCoolingdevices

Spots&SpacesFactoryLoca/onsn Ourfullrangeofcalciumsilicateandmicro- esintheUK,USA,Belgium,Italy,JapanandChina.Sint- ‐Niklaas,BEAlcoa,TNn yop/misa/onoftechnologiesand“bestfit”ofproduc ontechnology.Glasgow,UKTsuCity,JPn asedoncustomerspecifica/ons.Comais,ITTisselt,BE

Microtherm LowestThermalConduc/vityMICROTHERM hasthelowestthermalconduc vityofanyhightemperatureinsula on MICROTHE RM

Comparisonwithconven/onalinsula/on 500DegCApplica/ons Remember ! The higher the operating temperature, the greater the performance differenceApproaching 1000 oC (1832 oF) MICROTHERM can be up to four times more efficient.

Microtherm.4TimesbegerthanCalSil.

Microtherm Benefits .Over Calcium Silicates, Mineral Wools, and Ceramic Fiber 1. Energy Saving 40 %2. Insulation Space Saving 75 %3. Insulation Weight Reduction 70 % (Kg / M)4. Heat Loss Reduction 30 % (W / M)

MicrothermFieldInstalla/ons

Offshoreoil–subseapipe- ‐in- ‐pipeTheapplica taintemperaturetopreventpar alsolidifica ncement.TheMICROTHERMsolu onMicrotherm FloppyPanel–speciallycreatedflexibleinsula c leproduct.Tailoredsizes–fastassembly.LowestTC.Op misedproductforevacuatedinsula on.

AsphaltpipelineThe applicationHeated transfer pipeline for asphalt from boats to refinery.320 m of pipeline routed across dock – reduce heat loss as muchas possible while maintaining maximum access space.Ambient temperature 5 oC.TheMICROTHERMsolu onBendinsula on3 layers of Microtherm MPS 2 layers of Microtherm Hydrophobic Slatted Panel – 100 mm total thickness.ThecustomerbenefitsSafe 7 oC surface temp for personnel.Minimal heat loss.Fast installation.Maximum access space.Dockpipeline

StyreneMonomerPlant–ShawGroupTheapplica OTHERMsolu onCombina onofMicrotherm uminsula onvolume.Lowestappliedwindloading.

ExhausttrainAnsaldo/Talbot

SADAFSaudiArabia

HenkelGermany

Exxon Mobil SPT Olefins-OverviewCustomerThailand Site - MESMicrotherm – Cross Over Pipe / SpaceLocation – SingaporeSegment - PetrochemApplication- Cross Over Pipe- Operating temp at 750- deg CDriver- Space ConstraintProduct- Microtherm Overstiched Panel-- Thickness t25 mm max.SpecifiersNMC – VPE ThailandNMC – SP MECHANICAL InstallersAdd Proj 1 – K Pot Inlet / OutletAdd Proj 2 – Cross Over Elbow ModsAdd Proj 3 – Tar Knock Out DrumAdd Proj 4 – Base Plant Furnace- MES Japan- Shaw Stone & WebsterManaged By-Nippon Microtherm

T12- ‐25mmfor850DegCOpera/on

Chevron-Texaco Project – GENDALO 130 km sub-sea pipe line

MicrotherminMarineexhaustsMain engine exhaust prior to insulating.Design requirement – 55oC on outer surface ofinsulated exhaust system.This was achieved by 4 layers of 15mm thickMICROTHERM Quilted Panel.

Customer:n Ourproductsareindustrybenchmarkn nta on ienceacquiredasglobalmarketleader Lowerenergycost Lowerinstalla oncost Lowermaintenancecost Con nuingproductandmaterialinnova onandperformanceevalua on Completeserviceprovider–customerandmarketdriven Focusedonop misedengineeredsolu onsandaddedvalue

Customer:n n Presenta on Problemanalysisandthermalcalcula ons Productselec onanddesign Applica onandsystemdesign Performancetes ngandverifica on Co- ‐ordina onandinstalla onsupport etous

Contact Us for Best Insulation Needs AishwarCountryManager- ‐PromatHPI,IndiaM: 91- ‐8588852431 e- ‐mail:aishwar@promat- ‐asia.comPromat(Malaysia)SdnBhd:Unit19- ‐02- raHeights,50490KualaLumpur,Malaysia.Tel: 60(3)20958555 Fax: 60(3)20952111IndiaRepOffice:610- ‐611,AnsalImperialTower,C- ‐Block,CommunityCentre,NarainaVihar,NewDelhi- ‐110028,IndiaTel: 91- ‐11- ‐25778413 Fax: 91- ‐11- ‐25778414www.promat- ‐hpi.com www.promat- ‐ap.com

-Microtherm Overstiched Panel -- Thickness t25 mm max. Managed By-Nippon Microtherm Thailand Site - MES Microtherm - Cross Over Pipe / Space NMC - VPE Thailand NMC - SP MECHANICAL Installers Add Proj 1 - K Pot Inlet / Outlet Add Proj 3 - Tar Knock Out Drum Add Proj 4 - Base Plant Furnace Specifiers - MES Japan - Shaw Stone & Webster