Transcription

PROJECT SUMMARY

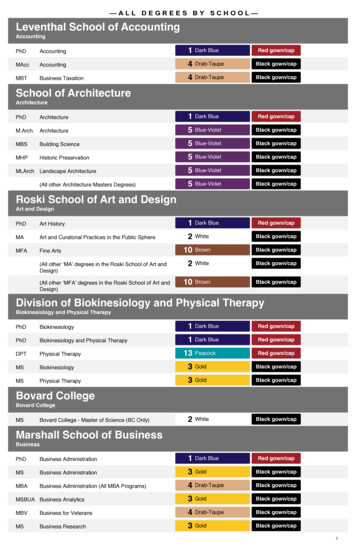

TO THE PEOPLE AND THE COMMUNITIESOF THE YUKON KUSKOKWIM REGIONWe invite you to read through this project-summary booklet to get a betterunderstanding of what we are striving to build – an environmentally responsible projectthat enriches the lives of those in the Yukon Kuskokwim (YK) region. Your insight isgreatly beneficial in helping us through our planning process. Please call, write, email orvisit any of our offices to provide us with your thoughts and get your questions answered.CAREFUL PLANNINGSince the mid-1990s, Donlin Gold has been exploring an undeveloped gold resourcelocated in the historic Kuskokwim Gold Belt of Western Alaska. During this time, we’veconducted baseline studies, held informational meetings in villages throughout theregion and gathered insight from stakeholders. All of these efforts have been directedat determining whether the Donlin Gold project is an economically and environmentallyfeasible option for natural-resource development in the YK region.OUR PROPOSALThe Donlin Gold project site, located in the mountains 10 miles north of the villageof Crooked Creek, is estimated to hold a gold deposit of more than 33 million ounces.If developed, the open-pit mine would produce 59,000 tons of ore per day, equal to118 million pounds. Construction, operation and closure of the mine would providethousands of jobs in the region for 27-plus years.PERMITTING PROCESSOver 100 local, state and federal government permits are required before constructionand operation of a large mine in Alaska can begin. We expect the process to take at leastthree years. Donlin Gold will continue to share information about the proposed projectthroughout this process.Thank you for your time and interest in this project. We look forward to hearing from you.Andy ColeGeneral ManagerDonlin Gold

TABLE OF CONTENTSPAGES3-5ABOUTTHE ENTPAGES19-25MININGPROCESSPAGES27-29CLOSINGTHE MINEPAGES31-38COMMITTED TOCOMMUNITIES

QUICK PROJECT FACTSmore than 1.5 million ounces annually forthe first five years, and 1.1 million ouncesor approximately 40 tons of gold annuallyduring the remaining years of operation.These levels would make Donlin Gold one ofthe world’s most productive gold mines.during construction and up to 1,400jobs during operation.90 percent at the Donlin Gold camp, theproject is committed to hiring residentsof the region.has been part of the project sinceexploration began in the mid-1990s tohelp fulfill Donlin Gold’s commitment toresponsible development.traffic on the Kuskokwim River, a 14-inchburied natural gas pipeline is beingrecommended as the primary source of fuelfor the generation of on-site power.1Donlin Gold exploration drilling in winter.

ABOUT USSEC TION 1: ABOUT TH E PROJEC T

ABOUT USABOUT THE PROJECTDonlin Gold is an undeveloped gold resource. Based on explorationresults, proven and probable reserves are estimated at 33.6million ounces of gold. Donlin Gold is proposing the developmentof a socially and environmentally responsible open pit gold mine.Approximately 59,000 tons (118 million pounds) of ore would beprocessed daily during the mine’s 27-plus years life.An example of an open pit mine.DONLIN GOLDPROJECTES3IL10 MDonlin Gold would be an openpit mine, approximately 2 mileslong by 1 mile wide. While acamp is currently set up at thesite, additional infrastructureplans call for a new airstrip,more on-site housing, a portnear Bethel and one port sitecloser to the mine. Otherconstruction would includean on-site power generationplant, conveyor systems, amill, truck shop, labs, wastewater treatment plant, offices,warehouses, access roads anda buried natural gas pipeline.If all the required permits areapproved, and a decision is madeto fund construction, it wouldtake three to four years toconstruct the project.M53ILESGeorgetownCrooked CreekAniakNChuathbaluk012 4 6 8NapaimuteMILESMap of the proposed Donlin Gold mine in relation to the Kuskokwim River.WHERE IS THE PROJECT LOCATED?The project site is located in the hills approximately 10 miles north ofowns the subsurface land and mineral rights in the proposed mine area.

TelidaKotlikChuloonawickBill Moore’s SloughHamiltonEmmonakAlakanukAnvikNunam IquaMountain VillagePitkas PointScammon BayHooper BayPaimiutChevakMarshallRussian MissionUpper KalskagOhogamiutLower KalskagNewtokTununakToksook BayMekoryukPilot StationGraylingShagelukNikolaiDONLIN GOLDPROJECTHoly CrossSaint Mary’sTakotnaMcGrathCrooked CreekChuathbalukAniakGeorgetownRed DevilSleetmuteStony RiverNapaimuteLime autluak kQuinhagakGoodnews BayPlatinumMap of the proposed Donlin Gold mine in relation to the YK area.HOW WOULD THE PROJECT BENEFIT RESIDENTSIN THE YUKON KUSKOKWIM REGION?owned lands and Donlin Gold is leasing the surfaceand subsurface rights, thus royalty revenue is subjectIn addition to providing revenue sharing amongof the Donlin Gold project includes jobs andeconomic growth opportunities in the YukonKuskokwim (YK) region. During construction, whichwould take three to four years, the project wouldprovide up to 3,000 jobs. Throughout the mine’s27-plus years operational life, the project wouldprovide on average, approximately 1,400 jobs.4

WHAT STAGE IS THE PROJECT CURRENTLY IN?state and federal agencies will review the permit applications and decide whether or not to approve theproject for construction and operation. Part of the process involves an Environmental Impact Statement(EIS) that will be prepared by federal permitting agencies to identify the potential project effects andmitigation needs. Throughout the process, Donlin Gold will continue with environmental studies.WHERE WE ARE NOW3-427 YEARSSCOPINGDRAFTEISProposed project is definedby Donlin GoldStudies conductedFeasibility Studies conducted(PUBLICINPUT)FINALEISUp to3,000jobsOPERATION(PUBLICINPUT)Up to1,400jobsThe proposed mine is expected to produce more than 1.5 million ouncesannually for the first five years, and 1.1 million ounces or approximately40 tons of gold annually during the remaining years of operation.THE PERMITTING PROCESS (3 YEARS)REGIONAL AND TRIBAL CONSULTATION WITH STATE AND FEDERAL REGULATORY AGENCIESABOUT DONLIN GOLDDonlin Gold is equally owned byand Barrick Gold U.S., Inc. Activitiesat the Donlin Gold project are managed by Donlin Gold, which oversees all aspectsof project development.A high percentage of Donlin Gold’s employees are shareholders and descendantsrelies on regional businesses to support the project. In addition, Donlin Gold makesmajor contributions to a variety of regional, educational and social programs.5Up to22jobsONGOING MONITORING3 CONSTRUCTIONEXPLORATION &ENVIRONMENTAL STUDIES16 YEARSCLOSURE & RECLAMATIONTimeli neUp to5 jobs

JOBSSEC TION 2: E M PLOYM E NT

EXPANDING THE REGION’S ECONOMYJOBSDonlin Gold is a mining project that has and could continue to create jobs and opportunities in theYK region as development progresses. Since exploration began in 1996, the project has employed manylocal residents in the fields of geology, environmental science, community relations, health and safety,operations, and support/administrative services at the Donlin Gold camp and in other villages.During construction and operation of the mine, the project would provideadditional economic opportunities for local retailers and suppliers as thedemand for goods and services would likely increase.HIRINGPREFERENCE7Donlin Gold is committed toAlaska hire with priority given toqualified Calista shareholders andtheir family members in additionto residents from the YK regionfor the jobs that would be availableduring construction and operationof the mine. The local hire recordat the Donlin Gold camp hasexceeded 90 percent and 9 of 10supervisors are from the YK region.

EMPLOYMENT AT DONLIN GOLDPOTENTIAL JOBSWhen construction and operation ofthe project begins, some of the typesof jobs that may be available are:HOW MANY JOBS WOULDTHE PROJECT CREATE?and RepairPlumbers, Carpenters)Construction contractors would need to fill up to 3,000 jobs tobuild the project facilities, natural gas pipeline, ports and roads. Ifdeveloped, the Donlin Gold project would be one of the largestemployers in the YK region. Approximately 1,400 jobs would beavailable during operation. During exploration, the Donlin Goldworkforce has included up to 240 employees.Just as there is now, a local hire program would be in place toprovide jobs to residents in the region.The Donlin Gold project is a drug- and alcohol-free workplace.8

JOB TRAININGDonlin Gold is creating a jobsbrochure that identifies some ofthe jobs that would be availableduring construction and operations.Donlin Gold will share informationabout jobs with communities in theregion so residents can prepare forthe employment opportunities theproject could provide.JOB LISTINGSJob openings at Donlin Goldare posted online at:www.DonlinGold.com/employeesEmployment questions can be sentby email to jobs@DonlinGold.comOr mailed to:Donlin Gold4720 Business Park Blvd., Suite G-25Anchorage, Alaska 995039

PROJECTSEC TION 3: PROJEC T DE VE LOPM E NT

SAFETYPROJECTThe safety of Donlin Gold employees is one of the company’s top priorities.Donlin Gold staff and management live by the motto “every person goinghome safe and healthy every day,” which guides their actions both on andoff the worksite. From wearing appropriate gear to understanding how tocorrectly operate tools and equipment, every employee is required to followsafety procedures to protect their wellbeing and that of their coworkers.The accomplishment of more than 1.5 million accident-free work hoursdemonstrates the dedication Donlin Gold employees have to safety.Wasillie KameroffThrough safety training programs and keeping certifications up-to-date,workers are able to maintain a safe working environment. Managers havecreated innovative methods to encourage the practice of safe behaviors andfrequently provide staff with additional safety educational opportunities.Each employee would be requiredto complete the following trainingunder Donlin Gold’s safety policy:surface miner training;Donlin Gold’s safety is alsopromoted by having employeesparticipate in additional safetytraining opportunities andsafety protocols including:refresher course;such as Barrick’s Courageousall equipment operators andmaintenance personnel;performance reviews;safety training sessions; andand remedial actions afteraccident investigations;carry out their jobs safelyand productively.standards and complyingwith all regulations; andcontractors comply with allhealth and safety standards.11Leonard Morgan

RESPONSIBLEDEVELOPMENTDonlin Gold is committed to responsibledevelopment. To provide a foundation forresponsible development, an extensiveenvironmental baseline study program has beenongoing since 1996. Resources and topics in thebaseline study program include:Resourcesand Surface WaterWHAT IS DONE WITH THEINFORMATION GATHEREDFROM THE BASELINE STUDIES?Data from these studies are used in the planning anddesign of the mine, and to establish environmentalconditions prior to project development. This datahas been submitted to regulatory agencies as part ofthe permitting process.12

SUBSISTENCE RESOURCESSubsistence hunting and fishing are a way of life for the people ofthe YK region. Donlin Gold respects this way of life and theseresources. Studies of the Kuskokwim River resources and its physicalmakeup have been conducted throughout the years to provideinformation for project planning.STUDIES OFRESOURCESRiver Use SurveysProjected Salmon Statistics13Donlin Gold has collected baselineinformation about cultural andarchaeological resources through fieldsurveys and site investigations. Thesestudies help mine planners identifycultural resources when determiningplacement for infrastructure.Archaeologists and community membershave jointly learned more about localheritage by sharing information duringclassroom visits and on archaeologicalsite field trips as well as by local residentsparticipating in community archaeology atthe Jungjuk/Angyaruaq site.

PERMITTINGPROCESSApproximately 100 permits andapproval by federal, state and localagencies before construction andoperation of the Donlin Gold minecould begin. Permitting is anticipatedto take at least three years due tothe extensive review process andconsideration by various agencies.WHO LEADS THE PERMITTING PROCESS?WHO MAKES THE DECISIONS?The permitting process is managed by federal and stateregulatory agencies. The public, agencies and the applicant willhave opportunities to comment on the project at different pointsduring the permitting process. Donlin Gold’s permit applicationswill be reviewed by federal and state regulatory agencies andpossibly amended where needed.The application for federal permits triggers a review processThe Environmental Impact Statement (EIS) is the documentthat records the details of the proposed project, alternatives,baseline information, and environmental, economic and socialeffects of the proposed project and different alternatives. The U.S.Army Corps of Engineers is the lead federal agency to overseeparticipation and manage federal coordination in conjunction withresource agencies and coordinates the state approval process.14

kQuGuFRESHWATERPONDlchGulchCrookedCreeLew iseenAmOPEN PITericanCre eCONTACTWATERPONDkORESTOCKPILEOmega GulchPROPOSEDCAMPTO PROPOSEDAIRPORTAnaco ndaC DFUELSTORAGEPIPELINEALIGNMENTTAILINGS STORAGEFACILITY(FULLY LINED)CROOKED CREEK(10 MILES)The proposed mine site layout.WHAT WOULD THEMINE LOOK LIKE?The mine would be a conventional open pitoperation with the following:15BUILDING THE MINEIt would take about three to four years to construct thefacilities and infrastructure needed to operate the mineshould all required permits be approved. In addition tobuilding access roads, a new airstrip and camp wouldbe constructed along with a port near Bethel, andanother port site, Jungjuk/Angyaruaq, located eightriver miles downstream from Crooked Creek village.Other infrastructure and mine facilities would include apower generation plant, mill, wastewater treatment plant,conveyor systems, warehouses, laboratories, offices, truckshop and a buried natural gas pipeline.

DONLIN GOLDPROJECTNR I VERPROPOSED30-MILEACCESS ROADIMRIVJungjuk/AngyaruaqPort SiteERKOKWYUKOKUSBethelDonlin Gold ProjectProposed river barge routeProposed ocean barge routeProposed port of JungjukPort of BethelProposed access roadBarges would transport supplies up the Kuskokwim River to the Jungjuk Port site.Computer rendering of river barges.SHIPPING IN SUPPLIESSupplies would be shipped to the region on ocean barges. Cargo wouldbe transferred at or near Bethel to shallow draft river barges. Duringthe summer, river barges would transport supplies and fuel fromBethel upstream to the Jungjuk/Angyaruaq Port. The shipping seasonwould last between three to four months. A 30-mile access road fromJungjuk/Angyaruaq Port to the mine site would be constructed.To help reduce barge traffic on the Kuskokwim River and the amountof diesel fuel required, Donlin Gold is proposing to build a buriednatural gas pipeline to supply on-site power generation. Personneland some supplies would be transported by air to the mine. A longerairstrip would be constructed several miles away from the site.Donlin Gold would be required to have an Oil Discharge andPrevention Contingency Plan (ODPCP). The plan would includestaged response equipment and trained response crews.trips would be made daily.used for transporting fuel andequipment, but they would notall be en-route at once.seasonal from early Junethrough early October.16

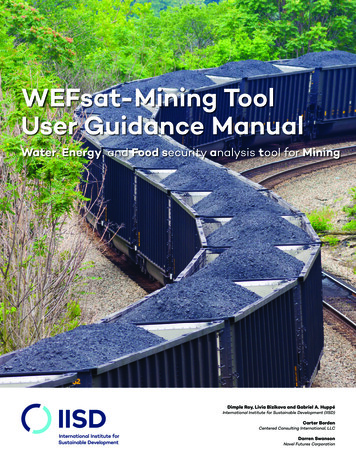

OphirMedfraTakotnaMcGrathNikolaiIditarodFlatDONLIN GOLDPROJECTCrooked CreekGeorgetownRed DevilSleetmuteStony RiverDONLIN GOLDNATURAL GAS PIPELINESTUDY ROUTELime VillageSkwentnaNHouston WasillaBig LakePalmerSusitna Knik EklutnaPoint MackenzieAnchorageTBelugaTyonekCO0 5 10 20 30 40WillowOKINLEHopeNikiskiMILESRoutes have been studied for a buried natural gas pipeline.POWERINGTHE PROJECTThe project would require anaverage of more than 150megawatts of electricity to powerthe mill and facilities. The powerwould be produced using on-sitenatural gas fired generation.NATURAL GAS PIPELINEDonlin Gold is proposing to build a buried natural gas pipelineto supply gas to the project. The 312-mile-long, 14-inch steelpipeline would transport natural gas from the Cook Inlet region,over the Alaska Range, to the project site.Temporary roads and stream or river crossings would benecessary during pipeline construction. Donlin Gold has studiedvarious pipeline routes and collected baseline data on:Temporary roads and infrastructure would be reclaimed onceconstruction of the pipeline is completed. Above-ground safety checkvalves would be located every 20 miles or more along the pipeline.17

PROCESSSEC TION 4: M IN ING PROCESS

MININGMETHODGold would require multiple stepsin processing to extract the gold.crushed and then groundin large mills to create afine silt-like powder.2. The gold bearing mineralsare then separated fromother materials using aprocess called flotation.3. A process called pressurePROCESSthe gold bearing minerals.with a cyanide solution inlarge tanks inside the mill. Thegold dissolves in the cyanide.5. The dissolved gold is thencollected onto activatedcarbon and the cyanidesolution is sent to a cyanidedetox unit. Any trace amountsof cyanide left in the tailingswould breakdown furtherunder natural conditions.6. The gold is then extractedfrom the carbon and refinedinto gold doré bars.19oxidation takes place. Bottom: Refining the gold and pouring it into gold doré bars.

e OxidationFlotationAcidificationCyanidation, Gold Leachingand Absorption onto CarbonMercuryEmissionsControlsCarbonStrippingGold ElectrowinningCyanideDetoxificationGold FurnaceGoldDoré Barsto Tailingsto Market20

MANAGINGMERCURYThe rock at Donlin Gold contains naturally occurring mercury,common in many areas of the world associated with volcanicactivity, high heat flows and plate tectonic boundaries. This mercuryis released into the atmosphere through natural processes suchgassing of the world’s oceans. According to the U.S. EnvironmentalProtection Agency (EPA), about one-half of the mercury emittedinto the air each year is from these natural processes. The U.S.Geological Survey has measured the concentration of mercuryin sediment, water, and fish collected from streams in the YKregion and their findings show higher concentrations of naturallyoccurring mercury in some areas of the region compared to others.At the Donlin Gold mine, mercury air emissions released duringthe milling process would be captured in multiple stages. DonlinGold would install and operate state-of-the-art mercury emissioncontrols, and any captured mercury would be shipped off-site to afederally regulated facility.for mercury based on maximum achievable control technology(MACT). These new limits are based on the nation’s bestperforming gold processing facilities, which are well controlledfor mercury. Donlin Gold supports the adoption of thesestrict regulations and would use state-of-the-art technologiesdeveloped at Barrick Gold to meet these standards.Page 21: Top: Cinnabar, known as red mercury,is the common ore of mercury. Bottom:The rock at the proposed Donlin Gold minesite has naturally occurring mercury.21Page 22: Top: An example of a waste rock pile abovea tailings impoundment. Middle: Testing for AcidRock Drainage at Donlin Gold. Bottom: An exampleof a mine site where potential acid-generating rockis covered with soil to reduce contact with water.

MANAGING WASTEROCK AND AIR QUALITYWASTE ROCKRock that does not go to the mills is called waste rock and would be hauledto a waste rock facility. Reclamation of the facility would take place in stagesthroughout the life of the mine, and the remaining waste rock would becontoured, covered and vegetated to facilitate stability and assist with beneficialuse after closure of the mine.METAL LEACHINGAlthough only a relatively small percentage of rock at Donlin Gold has the potentialfor Acid Rock Drainage (ARD), all of the rock is metal leaching to some extent.Metal leaching occurs when some metals can be leached from the rock bycontact with water under neutral or non-acidic conditions. Test work on therock at Donlin Gold has shown arsenic and antimony are two metals which areleachable under neutral conditions. Because of these conditions, Donlin Gold isproposing to capture and manage all of the water that contacts the waste rockfacility in a contact water pond. It will be stored on-site and will not be discharged.AIR QUALITY IN THE REGIONSince 2003, Donlin Gold has been operating an air quality and metrologicalmonitoring program. Wind speed, temperature, humidity, solar radiation,precipitation and barometric pressure are all covered and recorded under thisprogram. This information is used to assess and mitigate potential effects fromconstruction and operation of the mine.22

AQUATIC RESOURCESWater is perhaps the most valuable and important resourcein the YK region. Streams and rivers provide food andtransportation for residents. The YK region also has a plentifulsource of fresh surface water, with about 20 inches ofprecipitation annually at the Donlin Gold project site.The project has been designed for no discharge of mine-contactedwater. Any water that comes into contact with mine facilitieswould either be used in the milling process or stored on-site.Donlin Gold has been gathering surface water quality datasince 1996, and has collected surface and groundwaterquality data quarterly since 2003. Currently, Donlin Gold’sEnvironmental Department routinely collects water qualitysamples from approximately 20 surface water stations and 25groundwater wells.STUDYING FISHThere have been multiple baseline studies of the area’sstreams and rivers. Aquatic biologists have conducted salmonand resident fish surveys since 2004 to document fish species,run timing and aquatic habitat. A fish weir has been installedseasonally since 2008 to provide more definitive numbers offish entering the Crooked Creek watershed.Page 23: From Top to Bottom: EnvironmentalSpecialist Greg Sakar collecting and recordingbaseline water samples; Fish weir andunderwater video camera; Fish food (streaminsect) sampling; Aerial salmon counts.23Page 24: Top: Diagram of a lined tailings storagefacility, designed for no discharge. Middle:Typical large gold mine tailings dam. Bottom:Seepage collection system below a tailings dam.

MANAGINGTAILINGSTAILINGS POND WATERTAILINGSROCK-FILLDAMSYNTHETIC LINERDuring the process of gold extraction, wet tailingsresembling silt are a byproduct of the millingprocess. A containment dam engineered to themost stringent design standards would be built tocontain the tailings. As an additional safeguard,Donlin Gold’s tailings storage facility would havea synthetic liner similar to ones used in newlydesigned city landfills and sewage lagoons. Thebe approximately 1.75 miles long by 1 mile wide. Atclosure, the surface water would be removed fromthe tailings storage facility, and it would be coveredwith rock and soil and revegetated.WHAT WOULD HAPPEN TOTHE TAILINGS DAM IF THEREWAS AN EARTHQUAKE?The Donlin Gold site lies in a seismically activeregion. Therefore, the tailings dam would beengineered to withstand strong ground motionthat might result from an earthquake. A similar typeof dam is used at the Fort Knox gold mine nearFairbanks, Alaska, which withstood the Denali Faultearthquake of 2002 that measured a 7.9 magnitude.24

MANAGINGCYANIDEThe Donlin Gold project is designed tocomply with the International CyanideManagement Code, which covers theproduction, transport, storage and use ofcyanide as well as the decommissioningof cyanide facilities. Dry sodium cyanidebriquettes would be shipped to DonlinGold in sealed steel International Standardsbriquettes would be dissolved into a weak,The gold would be removed from the cyanidesolution during the milling process. Theremaining solution would then go through acyanide detoxification process to reduce itsconcentration. The cyanide remaining in thetailings storage facility would disintegratefurther under natural conditions.25Computer rendering of tankscontaining a cyanide solution.

CLOSURESEC TION 5: CLOSING TH E M IN E

CLOSUREInitial reclamation after mining closure.The same area after initial reclamation.RECLAMATIONCLOSING THE MINEA Reclamation and Closure Plan is required by lawto ensure that when mining activities are complete,the mine is closed and the land is returned to astable condition. The restoration plan is workedout in great detail and submitted to the permittingagencies for approval before the project isUpon completion of mining activity, the buildings andequipment would be taken apart and removed. At theend of the mine’s operation, Donlin Gold is proposingto allow the pit to fill with water and become a lake overtime. The water quality of the lake would be monitored.re-contouring and seeding the land.27After the closure of milling activities, excess waterwould be pumped from the tailings storage facilityto the pit lake and treated to meet water qualitystandards. The tailings area would then be coveredand seeded with a grass mix. The waste rock facilityand other altered areas will be re-contoured andseeded. Over time, native trees and plants wouldnaturally reclaim the area.

WASTEROCKFACILITYOPEN PITTop: Illustration of the mine site at 20 years of operation.Bottom: Illustration of the mine site after reclamation.TAILINGS STORAGEFACILITY(FULLY LINED)28

CONCURRENTRECLAMATIONWhenever possible during operations,disturbed land areas would be contouredand vegetated after they are no longerrequired for mining activity. Experienceshows better reclamation results whenMONITORINGAFTER CLOSUREmonitoring would continue, along with watertreatment when needed, to meet permittedwater quality standards.HOW DOES DONLINGOLD GUARANTEEPROPER CLOSURE OFTHE MINE?To guarantee reclamation is carried out,the law requires the mine operator toprovide financial assurance that the minewould be closed according to the permitrequirements. This can take the form of abond or other financial commitments thatare independently verified and approved byregulating agencies.29These moose were photographed in reclaimedareas of the Fort Knox mine in Alaska.

COMMUNITYSECTION 6: COMMITTED TO COMMUNITIES

EDUCATIONFrom field trips and science projects to classroompresentations and archaeological digs, Donlin Goldfor local students. The company’s support ofeducational programs and events shows DonlinGold’s commitment to creating a project thatenriches the lives of those in the YK region.By providing resources and tools to studentsto explore their interests, youth complete theireducation and the necessary training for theirdesired profession.SAFETY EDUCATIONAs a company committed to safety, Donlin Goldhas supported the Dragon Slayers programand the participation of its employees in it. Thisprogram teaches emergency response skills toteens in the region.VOCATIONAL EDUCATIONCOMMUNITYDonlin Gold has partnered with vocational31Program students tour the Donlin Gold project site. Student KevinKeyes gains hands-on work experience at Yuut Elitnaurviat. Thirdgraders in Chevak receive dictionaries provided by Donlin Gold.Association’s fisheries management program,providing internships to their participants. TheKuspuk Career Academy focuses on broadereducational and professional growth, offeringstudents instruction in math, communicationsand technological skills.

SCHOLARSHIPSDonlin Gold is providing opportunities directlyto the youth of rural Alaska as a majorKuskokwim Educational Foundation (KEF).to the Calista Region, and enables recipientsto participate in continuing educationalactivities and formal study programs. Proceedsdirectly benefited over 200 students in 2011.Educational assistance through KEF is providedthe Kuskokwim Corporation region so studentsobtain the tools, knowledge and skills tobecome successful and contributing membersof their communities.INTERNSHIPSThe Donlin Gold project has provided manyhands-on learning opportunities for studentsinterested in science and engineeringincluding the fields of geology, archaeologyand environmental conservation, in additionto water and fisheries management.Intern Marvin McDonald installing a fish weir. Intern Darien Thomas screensdirt from an archaeology site. Intern and UAF geology student Erin McComb.32

COMMUNICATINGWITH STAKEHOLDERSThrough a variety of community outreach efforts, DonlinGold has shared information about the project with residentsand provided them with many different ways to submit inputdirectly by using the following communication outlets:For several years, DonlinGold staff have been hostingproject update meetings invillages throughout the YKregion, providing residentswith the opportunity to learnabout the project directlyfrom Donlin Gold staff andgiving stakeholders thechance to be heard.Information at these meetingsis presented in Yup’ik which isthe primary language of mostresidents in the YK region.33update meeting. (Right) Donlin Gold’s Manager of Community Development & Sustainability, Mary Sattler, gives a project presentation in Akiak.

PROJECTSITE TOURSDonlin Gold sends morethan 12,000 newslettersmonthly to stakeholderswith the latest informationgive updates on the project’sprogress, safety guidelines,and highlight employeesand their contributions tosurrounding communities.The Donlin Gold newsletterRelations Society of Americawith an Award of Excellencefor an external publication.Every summer, DonlinG

Donlin Gold is equally owned by w À éj and Barrick Gold U.S., Inc. Activities at the Donlin Gold project are managed by Donlin Gold, which oversees all aspects of project development. A high percentage of Donlin Gold's employees are shareholders and descendants ¼ i § § § W Z ¼ è Î ¼ è § ¼ i è ¼ § W ¼ á ¼ A .