Transcription

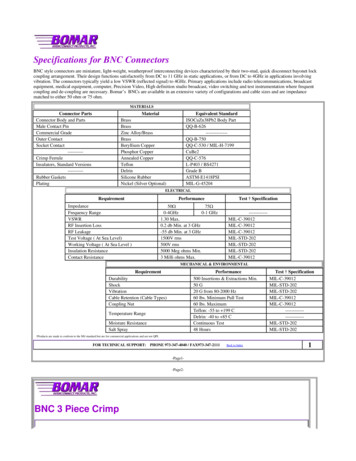

Making Crimp ConnectionsSTEP1Cut tube off square (90 )with a tube cutter.YOU’LL NEEDTube CutterSTEPSlide the PEX crimp ring over the endof the PEX tube leaving about ¼″ of thetube showing. Insert the fitting into theend of the tube. BE SURE the crimp ringis centered over the PEX barb.STEPSlide the PEX sleeve over the end ofthe PEX tube fully. Insert the fitting intothe end of the tube. BE SURE the fittingis inserted fully into the pipe.STEPCenter the jaws of the correct sizecrimp tool over the crimp ring or sleeve.Be sure the tool is held STRAIGHT andclose the jaws completely. CRIMP/PRESS ONE TIME ONLY! If you do notget a proper crimp connection the firsttime, cut the fitting off and start fromthe beginning.223Installation GuideYOU’LL NEEDCompression/Crimp ToolNote: sleeves and crimp rings are to be usedwith either ASTM F1807 or F2159 fittings alongwith the appropriate tool.STEP4BE SURE TO CHECK EVERY CRIMPJOINT! Every crimp joint should bechecked with the GO/NO GO Gauge. Ifthe designated GO slot fits over and willrotate around the crimped ring, you havemade a proper crimp. If the crimped ringwill fit in the NO GO Gauge or will not fitin the GO Gauge, you must cut the crimpjoint off and make a new connection.All of the information you’ll needto plan and install PEX plumbingin your home.YOU’LL NEEDGO/NO GO GaugeMore about PEX Crimp Connections Can be used with both hot and cold drinking water lines or withhydronic (radiant) heating. Insert fittings can be installed behind walls, but cannot be buried in concrete. Use the Home Run system or install in a continuous loop. PEX crimp rings are made of annealed copper. Sioux Chief’s PEX V-Sleeve is madeof Stainless Steel.PEX and PB fittings and crimp rings are not interchangeable.All Sioux Chief fittings and rings are manufactured to the ASTM Standard F1807Specification for Metal Insert Fittings Utilizing a Copper Crimp Ring for SDR 9 Crosslinked Polyethylene (PEX) Tubing, and are compatible with any and all fittings and ringsmanufactured to this same standard. All Sioux Chief plastic fittings are made to theASTM F2159 specification for plastic insert fittings. Sioux Chief’s V-Sleeve connection isDrainageSupportmade to the ASTM F877 standard for hot and cold PEX systems utilizing SDR plastic tubing.PEX INSTALLATION GUIDE – 10/11 2011 SIOUX CHIEF MFG.1212PEX Installation Tipswww.siouxchief.com

Why Plumb with PEX?Easy to InstallPEX tube is joined with an easy to install andtest ‘crimp’ system — no solvent welding withmessy chemicals, no chance of fire hazardpossibilities due to soldering.Cost EffectiveWhen installed using Branchmastermanifolds fewer fittings are needed to installPEX — meaning you save money in materialand time. PEX tubing also costs less thancopper tubing.For maximum flexibilitywhen servicing a line, werecommend using valvedmanifolds wherever theyare installed. Your primary manifolds shouldalways be valved.QuietWhen installed using manifolds, PEX canbe run in long lengths with smoother bends,meaning less water line noise. PEX also doesnot amplify sound as readily as copper tube.The quietest system is achieved by fasteningPEX with Sioux Chief’s full line of sound deadening hangers and brackets.Installation FlexibilityPEX systems can be installed in either aconventional ‘branch and tee’ system, or amanifold system using Branchmaster manifolds. PEX is great for quickly adding fixturesoff of your existing copper or CPVC system.Corrosion ResistantBecause of PEX’s smooth inner walls,minerals do not build up as fast as withcopper tubing. It is also more resistant tothe harmful effects of abrasive chemicalssuch as chlorine.Freeze ResistantWhile freezing conditions often cause copperand CPVC tube to break, causing thousandsof dollars in water damage, PEX tube willexpand several times its original size without damage. However, it is recommendedthat you follow all codes regarding water linefreeze prevention.2 2PEX Installation TipsPEX Installation TipsBranchmaster manifoldscan always be coupledtogether with PEX tubeto achieve the desirednumber of branches.www.siouxchief.com11

Transitioning fromCopperTransitioningfrom CopperSTEPA ‘Home Run’ installationmethod uses manifolds inone spot only (usually nearthe water heater), and givesa dedicated branch line toeach fixture in the house.This layout best minimizespressure fluctuations,which can cause scaldingand cold shocks.1Turn off water service to the entirehouse. If you have a valve installed thatwill turn off water to the affected areaonly — turn off this valve instead. Drainwater from the system by opening boththe hot and cold sides of the lowestfaucet in the house.Locate the nearest existing accessiblewater line to the new fixture (toilet,tub/shower, sink, etc.) and plan themost direct route from that line to thefixture (read ‘Running PEX Tube’for tips/precautions).YOU’LL NEEDTape measure LadderSTEP2Cut out roughly 10″ to 12″ of copperpiping. Let excess water drain fromthe system and deburr cut endsof copper tube.YOU’LL NEEDCopper cutting toolTape measureSTEP3Clean and prepare two Sweat PEXadapter fittings and solder to the twoends of the cut tube.YOU’LL NEEDSolder Soldering torchSand cloth FluxFlame retardant ragsSTEPPosition the PEX tee and two equallengths of PEX tube between the Sweat PEX fittings. Trim off excess tube andcrimp in the PEX assembly per the‘Making Crimp Connections’ sheet.(see page 11)STEPCrimp in the new supply line tothe fixture.4A ‘Semi Home Run’ installationuses Primary manifolds (usually near the water heater) andsecondary manifolds. To usea Branchmaster manifold asa secondary manifold, simplyplug one end with PEX pipe anda PEX plug.2 1010PEX Installation Tips5YOU’LL NEEDCrimp tool Crimp ringsTest gaugeGo torchless and reduce jobtime to ten minutes using theAdd-A-Line. Only compressAdd-A-line to copper tube.www.siouxchief.com3 3

sitioningfromCPVCTurn off water service to the entire house. Ifyou have a valve installed that will turn offwater to the affected area only— turn off thisvalve instead. Drain water from the systemby opening both the hot and cold sides of thelowest faucet in the house.STEP1Locate the nearest existing accessiblewater line to the new fixture (toilet, tub/shower, sink, etc.) and plan the mostdirect route from that line to the fixture(read ‘running PEX Tube’ for tips/precautions).YOU’LL NEEDTape measure LadderSTEP2Cut out roughly 10″ to 12″ of CPVC. Letexcess water drain from the systemand remove any burrs from cut ends.YOU’LL NEEDPlastic tube cutting toolTape measureSTEP3Using CPVC solvent cement, glue ontwo CPVC PEX Adapters. Wipe offexcess glue.YOU’LL NEEDCPVC Cement CPVC PrimerSTEP4STEP5Position the PEX tee and two equallengths of PEX tube between the CPVC PEX fittings. Trim off excess tubeand crimp in the PEX assembly per the‘Making Crimp Connections’ sheet.(see page 11)Crimp in the new supply line to thefixture.YOU’LL NEEDCrimp tool Crimp ringsTest gauge442 10PEX Installation TipsManifoldfromInstallationManifold InstallationTransitioningCopperOne Branch, One FixtureTo get the full benefit of manifold use, eachbranch should supply only one fixture. Supplying more than one fixture on a branchincreases the chance of pressure fluctuations, which can cause inadequate waterpressure and scalding.PlacementBecause potentially half of the crimp connections are at the manifold (the other halfat the various termination points), be sureto locate the manifold(s) in an accessiblelocation, preferably near the water heater.Locating near the water heater ensuresthat quickest delivery of hot water (percode, make sure manifold is at least 18″from water heater).Valved ManifoldsSioux Chief offers both valved and standard manifolds— valved manifolds alloweasy isolation and service of a fixture without affecting water service to the rest ofthe house.Manifold SizingThe home run manifold system allowsindividual lines for each fixture. To “size”a manifold, count the number of cold and/or hot water locations that you plan toplumb. Be sure to remember ice makersand outside hose bibs. Always purchasemanifolds with enough cold and hot waterbranches to service all planned fixtures.Branchmaster Manifolds can be linkedwith ¾″ PEX tube to allow unlimited branchconnections. Make sure to plug all unusedbranches with a 6″ stub of tube and a PEXplug (6″ should be enough to let you cutoff the plug and use the branch for futurefixtures).www.siouxchief.com39 9

sitioningfrom LocationsCPVCSave Time and MoneySioux Chief Branchmaster manifolds allowyou to make longer continuous runs ofPEX pipe— meaning you buy fewer fittingsand spend less time installing!Fewer Possible LeaksLonger continuous runs with fewer crimpconnections means fewer chances ofleaks and avoiding the possibility of thousands of dollars in water damage!Controls ScaldingWhen plumbed so that each branch linefeeds only one fixture, The Branchmastergreatly reduces pressure fluctuations andtemperature swings that cause scalding.Quiet PlumbingLonger runs of pipe using fewer fittingsmeans smoother bends and turns whichreduces line noise.Install with ConfidenceBranchmaster manifolds are guaranteedagainst defects in materials and workmanship for the life of your plumbing system.ManifoldInstallationRunning PEX me Temperatures and SunlightKeep PEX tube away from extremetemperatures — 12″ away from recessedlighting and 6″ away from gas vents.(water heater, stove pipe, etc.) Also keepaway from attics, crawl spaces, outsidewalls, or insulate per plumbing codes.Also keep out of direct sunlight.Allow for MistakesLeave extra tubing at the beginningand end of runs to simplify connection tomanifolds and end points (at wall or atfixture). Immediate connection to themanifold or transition fittings and thenmaking the run reduces the chance ofcutting tube too short.Identify Tubing RunsClearly and permanently mark each run(at the manifold) to identify the fixtureit supplies (hot or cold water, bathroomsink, kitchen sink, basement toilet, etc.).Do not apply adhesive labels to PEX pipeunless labels are approved by the tubingmanufacturer.Drilling & Notching Structural MembersNo notching or boring into top/bottom flange portionsis allowed. 1 ½″ hole allowed anywhere along web.Folow all I-Joist manufacturer’s instructions.Thermal ExpansionBecause PEX tube expands and contractsat about 1″ per 100 feet of pipe for every10 change in temperature — you mustallow for expansion and contraction inlong runs. This can be accomplished withan offset or expansion loop.PEX and ConcreteTubing installed within or under concreteslabs should be continuous lengths ofPEX tube. No fittings beneath concrete.482 10PEX Installation Tipswww.siouxchief.com95 3

PEXTubeTransitioningWhyUse ngTubingRunsFinishing Tubing RunsTransitioningCopperRunningfromPEXTubingAfter properly running and fastening the PEX tube, it’s time to terminate the run into a finished area of the house (through a flooror a wall). Although there are some situations where it makessense to crimp the tube directly to a valve or fixture (basementlaundry or sink), it is best use a copper stub out due to their rigidity and resistance to bangs and bumps that could cause leaks.Support the FittingTo prevent stress on the crimp joints,always support the tube before and afterthe fitting.HangerMinimum Bend RadiusDo not bend tube too tightly. The minimumrecommend bend radius is six times thetube size (i.e. ½″ tube 3″ bend radius).When making a 90 turn, use bendsupports.STEP1YOU’LL NEEDCrimp toolCrimp ringsPlastic HangersTube Through StudsGrommets should be used when runningtube through studs to prevent tube damageand reduce noise transfer. Tube that is runwithin 2″ of a stud nailing surface must beprotected with a metal stud guard.No Metal HangersMetal hangers can damage PEX tube,we recommend only plastic hangers beinstalled. To prevent noise transfer, onlyuse hangers that keep the tube off of thenailing surface (studs and joists).Crimp PEX tube to a straight PEX stubout or a stub out elbow depending onwhether you need to make a turn asyou come through the wall. Make surestub out is properly secured (see page6 for tips on fastening PEX tube).STEP2Cut the spun-closed end off of the stubout, then deburr and clean the outsideof the tube with sand cloth.YOU’LL NEEDCopper cutting /deburring toolSand ClothRECOMMENDED HANGERS:Tube Talon, Sioux Strap or Suspensulator.Tube Between Joists and Stud BaysTo make it easier to run tube in stud orjoist cavities, use the Power Bar, it installsquickly and is totally adjustable (USBslocated in the pipe hanger offering).Leave Room for Thermal MovementPEX needs room to expand and contract.Allow tube to dip between hangers andnever over-tighten. Many Sioux Chief hangers are designed to let the tube contractand expand without the possibility ofover–tightening.STEP3Using two wrenches, compress thestop valve onto the copper tube. Becareful not to over-tighten the joint.YOU’LL NEEDWrenches⅝″ supply stop valveHanger SpacingHangers should be used every 32″on horizontal runs and every 4′ onvertical runs.462 10PEX Installation Tipswww.siouxchief.com97 3

Slide the PEX sleeve over the end of the PEX tube fully. Insert the fitting into the end of the tube. BE SURE the fitting is inserted fully into the pipe. SupplyD rainage Support www.siouxchief.com 12 PEX Installation Tips Making Crimp Connections STEP 1 STEP 2 STEP 2 STEP 3 STEP 4 Installation Guide