Transcription

Detecting Pipeline Leaks – What’sthe Right Approach?October 20, 2016 Pipeline Safety Trust ConferenceNew Orleans, LA

Leak Detection§ Best Defense is Preventing Leaksfrom Occurring in First Place– Proactive pipeline integrity and damageprevention programs§ Leak Detection–––Focuses on how to detect promptly tominimize size and consequenceOne approach does not fit allVarious pipeline systems and operatingconditions call for different approaches

Detecting Leaks – One approach does not fit all§ Ruptures – quicker detection– Pressure & Flow deviation alarms– Computational pipeline monitoring (CPM)§ Seepers – slower detection– Visual surveillance – air and ground– Facility gas monitoring & thermal imaging– Line balancing & tightness tests§ Everything In-Between– Computational pipeline monitoring (CPM)– Pressure wave & statistical patterns– Fiber optic cable technology research throughPRCI using acoustic & thermal sensing–––Complicating FactorsCompressibility of various fuelsElevation differences & changing pressure patternsPipeline size and operating pressure

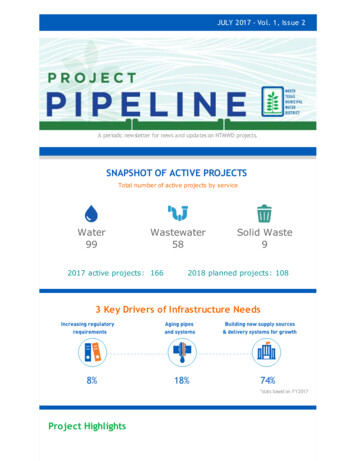

Typical Liquid Pipeline Leak Detection Using CPM in FlowingConditionsLeak Size as a Percentage of Flow Rate25%Short-term leak detection driven byinstrument accuracy, type of CPMused, line pressures, andcommunication speed and reliability20%Industry is striving to detect smaller leaks,more quickly, and more reliably15%Longer-term leak detection limitedby equipment capabilities. Moreindustry work is needed10%5%0%0369Time to Detect Leak (hr)Typical CPM PerformanceTypical RTTM PerformanceTechnology Human Factors12

Effective LD is More than Great Technology§ Technology Needs StrongControl Center Operations§ Control Center Operations NeedStrong Technology1.Recognizing abnormalconditions is not always obvious1.2.“Think Leak” safety culture2.3.Focusing on continuousimprovement using risk-basedpriorities3.Normal dynamic operatingconditions cause pressure/flowchangesSlack line conditions due to startsand stopsHigh false alarm rates cause fatigueand distractionPipeline Operators need effective LD ProgramManagement – API RP 1175

API RP 1175 Leak Detection Program Management§ Identifies all detection methods, policies, processes, andhuman element.§ December 2015 - Published RP 1175––––––Culture & StrategySelection of Leak Detection MethodsPerformance Targets & MetricsProcedures, Training, MaintenanceAlarm Management & TestingManaging Changes§ 2016 – Formed Implementation Team– Hosting Webinars– Workshop planned at 2017 API PipelineConference– Developing training and assessment tools

Keys to Success1.2.3.Have a Continuous Improvement Mindset regarding People, Procedures,& Technology– RP 1173 Safety Management Systems– RP 1175 Leak Detection Program ManagementHave a “Think Leak” Safety-First Culture– Leadership support– Training and operating disciplineHave a collaborative and proactive approach– Industry engagement to share best practices, lessons learned, andtechnology research (PRCI)Shared Mission:Provide reliable energy supply to meet our society’s needs inthe safest & environmentally responsible manner possible.

- Fiber optic cable technology research through . 20% 25% 0 3 6 9 12 Time to Detect Leak (hr) Typical Liquid Pipeline Leak Detection Using CPM in Flowing Conditions Typical CPM Performance Typical RTTM Performance Technology Human Factors Longer-term leak detection limited by equipment capabilities. More