Transcription

EMBA 245 QS Ultima fpe oahesThationinnov

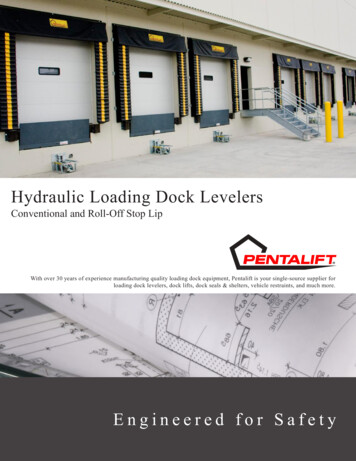

Experience the geometry of success– with ultimate paper utilisationThe strength of corrugated board lies hidden in the smoothSuperior performance right down the linestill a flat sheet, without the angular rigidity of a box, themised to sustain the integrity of corrugated board inclu-sine curve or profile of its fluting. During conversion, whileintegrity of this profile is at risk. And compressed corrugatedboard is weak board. Worried? No need: the new EMBA 245QS Ultima eliminates the problem.World’s first non-crush converting inline machineMarking a radical advance in technology, this state-of-the-artmachine features EMBA’s unique Ultima Feeder and va c- uum transport throughout the complete machine, mak ingit the world’s first inline converting machine to featureEMBA’s patented non-crush technology. Full corrugatedboard integrity and quality is now assured throughout theprocess – from initial feed through printing, slotting, diecutting and folding to stacking. True non-crush, from startto finish – shaped by innovation.Each stage and unit of the EMBA 245 QS Ultima is optiding light grade materials. This ensures an end productthat satisfies the most stringent BCT/FCT/ECT standardswith exceptional print quality. The machine’s modularopen-access design, servo-operated drive and sensorcontrol systems ensures safe and simple monitoring ofperformance parameters. The exceptionally functionaland logical operator interface also makes productionquick and easy.Non-crush feedingThanks to innovative vacuum servo technology, the UltimaFeeder needs no feed roller. This means crush-free perfor-mance and enhanced feeding register accuracy, even withlight grade corrugated board at high speeds. The all-servo

EMBA’s patented Non-Crush Converting technology preservesthe geometry and strength of the corrugated profile for optimumbox performance and significant savings in material costs.five axis feed table, featuring an extended feeding stroke,ensures trouble-free feeding of all types of sheet.Crystal-clear print qualityEMBA top-print technology, with its practical open-accessformat allowing kiss touch printing, is already an industrybenchmark. With the introduction of the EMBA 245 QSUltima comes RDD (Real Direct Drive) technology. Thisinnovation integrates the servo motor with the printingcylinder, for enhanced print register accuracy, print lengthum Slotter Creaser). EMBA’s unique vacuum trans portsystem ensures superior sheet control throughout theunit. Combined with larger diameter creasing heads, thisprovi des excellent folding and very close die-cut register.The many benefits of this unique design include open-topaccess to ease maintenance, creasing profiles that areeasily changed to accommodate different corrugatedboard grades and dual slotting shafts; – all advantagespossible with the Magna VSC Slotting unit.compensation and printing plate height variation correction.Smooth folding and stacking for a fast finish!self-adjusting chamber-blade and sheet-cleaning system.medium and large sheets – unless equipped with the EMBAOther benefits include a reversible ink pump and optionalState-of-the-art slotting unitThe EMBA 245 QS Ultima incorporates the world’s mostadvanced slotting unit, the Magna VSC Slotting unit (Vacu-Today’s high speeds pose a real challenge when foldingAPS Folding unit (Automatic Panel Support), designed forthe highest production speeds. Last, but not least, the high-performance Counter-Stacker effortlessly handles all gradesof corrugated board in the most complex die-cut formats.

The intelligent way to speed productionIn the capital-intensive converting industry, speed is goodexceptionally user-friendly operator interface, the highlymercial success, flexibility is the key. The industry’s sub-setting time to a minimum. Though easy to use, the EMBAand intelligence even better. However, for long-term com stantial equipment costs make high capacity utilisationessential. The speed, intelligence and flexibility of the EMBA245 QS Ultima enable rapid and precise adjustment tothe latest market trends and demands. Whatever the sizeor grade of corrugated board to be converted, howeveradvanced the print requirement, the EMBA 245 QS Ultima will handle it superbly. This means satisfied customers withoptimised machine utilisation.automated and servo controlled EMBA 245 QS Ultima cutsOperator Interface is highly sophisticated, permittingprecision setting of operating parameters. The machine caneasily be set for 50 or more separate orders during a singleeight-hour shift! The Operator Interface provides onlineadjustment of machine settings, comprehensive processmonitoring and access to a database of 100,000 repeatorders. This is the sort of speed and flexibility that guarantees success. It’s fast, intelligent and flexible.Minimal set-up timeHigh-speed productionproduction output with the shortest set-up time, making itthinking. With its unique vacuum transport system provi-The EMBA 245 QS Ultima is designed for maximumideal for short order sizes required by just-in-time demands.Combining advanced digital communication with anThe EMBA 245 QS Ultima is fast moving, as well as fastding converting speeds of up to five sheets per second, itgives the highest productivity on the market.High productivity thanks to outstandingproduction speeds and the shortest set-up times.

Intelligent design One of the most technically advanced machine platformson the market, the EMBA 245 QS Ultima ’s short set-uptimes, high running speeds and consistent product qualitymake it the intelligent choice.The user-friendly Operator Interface, digital control servo-driven technology and advanced communication interfaceenables integration into a broader interactive network. Thisopens up a wide range of communication possibilities. and smart communicationsA direct link between the EMBA 245 QS Ultima and thefactory’s production control system enables an exchangeof data on queued orders, job schedules and productionstatistics via the EmBase interface. An interactive networkallows access to EMBA’s online support, securing the entireproduction process. Whatever the geographical location,EMBA will be right there, via a secure Internet link.Servo technology and advanced communication throughout the entireproduction process.

Designed for sustainable evolutionTransforming a vision into industrial excellence is an organicplatform, designed to evolve with industry’s needs.EMBA 245 QS Ultima features a whole range of technicalperfect harmony. The EMBA 245 QS Ultima is future-ready.process – like creating a pearl from a grain of sand. Theimprovements that enhance productivity and productTechnical innovation and commercial development inquality. A powerful reason to invest. But, like the oyster,Leanindustrial climate is constantly evolving. Success has alwaystechnology continuously monitors and optimises all opera-its true value – though less obvious – is much greater. Thebeen about transforming challenges into opportunities:for industry, these challenges now include sustainability,energy efficiency, environmental impact and occupationalsafety. The pearl at the heart of the EMBA 245 QS Ultima is EMBA’s evolutionary Non-Crush Converting technologyIntelligent and fully-integrated, EMBA 245 QS Ultima servotional parameters. This intelligent machine platform, withits advanced servo motor technology, minimises materialcosts, reduces waste and energy costs, all vital factors forenhanced profit. EMBA 245 QS Ultima technology offersthe lowest operational costs on the market.

Cost-efficient: minimal waste and optimal boardutilisation for consistent raw material cost savings.Sustainable: strong focus on reduced energy and rawmaterial consumption.Ergonomic: designed to be easy to use with enhancedoperator safety.CleanThe EMBA 245 QS Ultima is a clean machine. Its advancedtechnology cuts waste, effluents, emissions and other fac-tors affecting environmental impact. A reversible ink pumpand high-efficiency washing system reduces ink loss, waterconsumption and also waste ink treatment costs.SafeThe user-friendly EMBA 245 QS Ultima combines ergo-nomic design with same-side access, enabling operatorsto maintain visual contact at all times. Enhanced operatorsafety is provided by a comprehensive interlocking safetysystem and elimination of the feed roller inlet nip point,marking a major safety improvement for feed unit operators. Modular design, top-access, safety systems andNon-Crush Converting technology ensures the EMBA 245QS Ultima is safe and easy to operate.

can produce all types of boxes, from the simplest brown boxto the highest quality printing and most complex die-cutformats. The EMBA Operator Interface provides compre hensive control throughout the entire converting process,offering optional interfacing with auxiliary equipment,from pre-feeder to bundling machine and palletiser.The Automatic Panel Support (APS) folder with vacuum transporttroughout the section contributes to the Non-Crush Converting concept. This combination ensures superior folding accuracy,from lightest to heaviest corrugated board qualities andsmallest to largest box sizes, for unchallenged productivity.the EMBA 245 QS Ultima offers outstanding capa-city andAPS FolderThe Operator Interface is the link between the operator and themachine, consisting of monitor and keyboard controls for quick andsimple use. The easy to learn and use software makes the operationof the machine extremely user-friendly, a must for real Quick-Set setting of new orders or repeat orders instantly downloaded from thearticle database. During production, the operator will supervise andcontrol the entire machine through the interactive Operator Interface.Support menus for operation, service and maintenance instructions,together with logging and diagnostics of machine data are alsoincluded, providing an intelligence platform for comprehensivemachine and production management. The Operator Interfaceoptionally also features communication access to factory productioncontrol network systems, auxiliary equipment and VPN-internetconnection for remote EMBA online support.Operator InterfaceThe production of complicated die-cut layouts and highquality printing at top speed is ensured by the CounterStacker unit, featuring counting, squaring and stacking of theboxes, performed in a smooth single downstacking motion.This provides the accuracy and reliability required for theoutstanding productivity achieved in the EMBA 245 QS Ultima .Counter-StackerEMBA 245 QS Ultima The online inline machineThe fully integrated servo platform and modular design ofFrom the high-speed non-crush Ultima Feeder to theflexibility. Fast and cost-efficient, the EMBA 245 QS Ultima is optimised for consistent high productivity. High paperefficient Counter-Stacker unit, the EMBA 245 QS Ultima utilisation, low energy consumption, extreme reliability,minimal waste generation and self-diagnostic capabilitymake it exceptionally cost efficient. And the EMBA Comfortprogram is your assurance that the EMBA 245 QS Ultima will continue to be an excellent investment, throughout itsentire life cycle.

QSD Die-CutterThe EMBA Ultima Feeder is the revolutionary innovationfor non-crush feeding of sheets without a feed roller,making true Non-Crush Converting possible.Advanced servo and vacuum design solutions ensurehigh-speed performance with superior feed register for allpaper qualities and sheet sizes.Ultima Feeder The EMBA RDD – Real Direct Drive servo technology integrates the servomotor with the print cylinder for excellent print register accuracy, alsofeaturing print length and printing plate height compensation. The EMBAtop printing concept with space and access between units for premountingof printing plates enables true Quick-Set setting of the machine .RDD PrinterThe Magna VSC-Vacuum Slotting Creasing unit with the unique vacuumtransport of sheets through the unit produces optimised clean slottingand creasing of all corrugated board qualities. This state-of-the-arttechnology breakthrough for corrugated board conversion representsanother EMBA milestone innovation, making Non-Crush Converting throughout the EMBA 245 QS Ultima machine a reality.Magna VSC SlotterHigh speed die-cutting of sheets with complex layouts for all sizes andcorrugated board configurations is easily accomplished in the sturdy QuickSet Die-Cutting unit. An optional waste evacuation unit is available for thetoughest jobs, and pre-mounting of tools on the tool cylinder in the standbyposition makes the unit fully Quick-Set . For complex internal die-cuttingrequirements there is an optional bottom Die-Cutting unit available with anintegral waste evacuation unit and quick-change tool-mounting system.

An investment in the futureInstallation and commissioning mark only the first steps instays that way. When combined with the EMBA ProfessionalEMBA converting inline machine, you invest in the future!The EMBA Original Parts Program is your guarantee thata creative and ongoing partnership. When you invest in anWith the EMBA Comfort customer support program, youcan be certain that your EMBA 245 QS Ultima will performto full capacity throughout its entire life cycle, benefitingfrom the latest know-how and technical innovations.The EMBA Upgrade Program, featuring the latest techni-cal upgrades from the EMBA research team, makes sure itService Program, production optimisation is assured.all spare parts supplied are designed for your EMBA 245 QSUltima , to the most stringent manufacturing specifications and standards, for trouble-free replacement. Onceyour production team has completed its EMBA AcademyTraining, you can rely in the knowledge that your EMBA 245QS Ultima is being operated by EMBA-trained specialists.The shape of innovationThis brochure addresses benefits such as speed, Quick-Set ,By preserving the geometry of the corrugated profile,bottom line, and all contributing to greater cost-efficiency,tion, producing significant savings in material costs.flexibility and energy efficiency: all crucial to a healthyenvironmental sustainability and operator safety.However, the outstanding benefit of EMBA’s new Non-CrushConverting technology is improved box performance.EMBA 245 QS Ultima technology optimises paper utilisaThis redefines operational excellence, reasserting the shapeof innovation – and securing the future of the ultimatesustainable packaging material: corrugated board.We reserve the right to change the design or specification of the equipment without notification.

www.emba.com

The EMBA top printing concept with space and access between units for premounting of printing plates enables true Quick-Set setting of the machine . Ultima Feeder The EMBA Ultima Feeder is the revolutionary innovation for non-crush feeding of sheets without a feed roller, making true Non-Crush Converting possible. Advanced servo .