Transcription

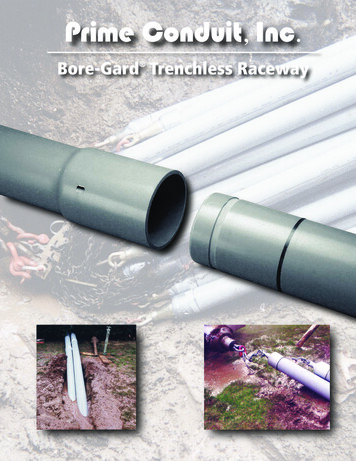

Bore-Gard Trenchless Raceway

Print Bore-Gard TrenchlessRaceway.qxp Layout 1 3/11/16 2:25 PM Page 2Prime Conduit Bore-GardPrecision engineered design has matching groovesand nylon locking strap to provide a secure connection.Positive stop automaticallyaligns strap grooves.Insertiondepth indicatortells at a glanceif pipe ends areinserted to thecorrect depth.Heavy walls and deepinsertion make the jointimmune to the effects ofnormal bending.Triple-lobedgasket designed toprovide ease ofassembly anda watertightseal. The Preferred Trenchless SolutionENGINEERED RACEWAYSYSTEMADVANTAGES OVER HDPEThe Easiest InstallationPRODUCT INSTALLATIONHDPE ovalizes which reduces the internalcapacity of the ducts. Bore-Gard is packagedin bundles, not wound on reels, so it doesnot collapse into an oval shape.1. Position Bore-Gard with the print line facing up.The Bore-Gard bundles are also easier totransport and results in less material waste.Because Bore-Gard does not use reels likeHDPE, reel handling equipment is notneeded, there aren’t any costly reels toreturn, and there isn’t the safety risk ofuncoiling reels.4. Insert pulling eye into spigot end of Bore-Gard.LABOR - TIME - MONEYSAVERUSES STANDARD SCHEDULE 40FITTINGS7. Take next piece of Bore-Gard and insert spigot end into belled end of thefirst piece until the insertion line is no longer visible.Bore-Gard is a PVC trenchlessraceway system utilizing horizontaldirectional drilling for electricaland datacom applications.Bore-Gard eliminates the costlyproblems of HDPE pipe on a reel,minimizes environmentaldisruptions in tight and confinedspaces, and is easy to install.Purchasing special Bore-Gard fittings isNOT required. In fact, they don’t even exist!Bore-Gard uses standard, off the shelf,Schedule 40 fittings, making transitionsfaster, easier, and less expensive.8. Slide the plastic locking strap into slot on the side of the bell. Push thestrap in completely. It is not necessary to remove or cover the handle onthe strap.The unique design incorporates aproprietary water-tight seal andlocking ring that enables fast,cement-free assembly, strongenough for 1000 foot bores.The belled end will not snag whenpulled into a bore.2. Remove plastic locking strap and set it aside.3. Remove end caps. On first stick only, trim spigot end of Bore-Gard at thegroove before attaching the pulling eye/gripping attachment.5. Tighten pulling eye so that it expands against the interior of the conduit.Use of sleeve over O.D. of conduit is recommended.6. The installer should use appropriate instrumentation to ensure thatmaximum pull rating is not exceeded. *Note: lbf (pounds-force) is NOTequivalent to psi (lbf/in2). It is the responsibility of the customer to makethat conversion (if needed) based on installation/equipment conditions.10. Bore-Gard is now ready for installation.FAST, EASY WATER-TIGHTCONNECTIONSPrime Conduit’s locking strap provides a fast,easy and secure connection. No cement ortools required. It also eliminates costly fusionwelding. The locking strap is shipped installedwith product. The factory installed gasketkeeps out ground water and drilling fluid andhas been tested to 80 psi.ELECTRICAL, UTILITY ANDTELECOMMUNICATIONMARKETSBore-Gard is perfect for underroads, highways, airport runways,railways and waterways,metropolitan/urban areas, or anyother buried conduit application.AGENCY APPROVALS ANDMARKET ACCEPTANCE Bore-Gard has been tested to UL651 standardand received ETL approval. It can be used foruse with electrical conductors per TheNational Electrical Code articles 300 and 352.Bore-Gard is also proudly Made in the USA.PERFORMANCE SPECIFICATIONSBore-Gard is tested to a rigorous Pull test at 80 psi and a Bend & Pull test at a65' radius and 80 psi.Short Fold9. Repeat with remaining sections as space allows.

The Preferred Trenchless SolutionADVANTAGES OVER HDPEHDPE ovalizes which reduces the internalcapacity of the ducts. Bore-Gard is packagedin bundles, not wound on reels, so it doesnot collapse into an oval shape.The Bore-Gard bundles are also easier totransport and results in less material waste.Because Bore-Gard does not use reels likeHDPE, reel handling equipment is notneeded, there aren’t any costly reels toreturn, and there isn’t the safety risk ofuncoiling reels.USES STANDARD SCHEDULE 40FITTINGSPurchasing special Bore-Gard fittings isNOT required. In fact, they don’t even exist!Bore-Gard uses standard, off the shelf,Schedule 40 fittings, making transitionsfaster, easier, and less expensive.FAST, EASY WATER-TIGHTCONNECTIONSPrime Conduit’s locking strap provides a fast,easy and secure connection. No cement ortools required. It also eliminates costly fusionwelding. The locking strap is shipped installedwith product. The factory installed gasketkeeps out ground water and drilling fluid andhas been tested to 80 psi.AGENCY APPROVALS ANDMARKET ACCEPTANCE Bore-Gard has been tested to UL651 standardand received ETL approval. It can be used foruse with electrical conductors per TheNational Electrical Code articles 300 and 352.Bore-Gard is also proudly Made in the USA.

The Easiest InstallationPRODUCT INSTALLATION1. Position Bore-Gard with the print line facing up.2. Remove plastic locking strap and set it aside.3. Remove end caps. On first stick only, trim spigot end of Bore-Gard at thegroove before attaching the pulling eye/gripping attachment.4. Insert pulling eye into spigot end of Bore-Gard.5. Tighten pulling eye so that it expands against the interior of the conduit.Use of sleeve over O.D. of conduit is recommended.6. The installer should use appropriate instrumentation to ensure thatmaximum pull rating is not exceeded. *Note: lbf (pounds-force) is NOTequivalent to psi (lbf/in2). It is the responsibility of the customer to makethat conversion (if needed) based on installation/equipment conditions.7. Take next piece of Bore-Gard and insert spigot end into belled end of thefirst piece until the insertion line is no longer visible.8. Slide the plastic locking strap into slot on the side of the bell. Push thestrap in completely. It is not necessary to remove or cover the handle onthe strap.9. Repeat with remaining sections as space allows.10. Bore-Gard is now ready for installation.PERFORMANCE SPECIFICATIONSBore-Gard is tested to a rigorous Pull test at 80 psi and a Bend & Pull test at a65' radius and 80 psi.

Bore-Gard Trenchless Raceway Specifications PA C K A G I N GPart Number10'20'WallTypeBG340SP-010BG340SP-020Sch 40BG440SP-010BG440SP-020Sch eQuantity (ft./bundle)Bundles perTruckloadFeet perTruckload20'Approx.Wt. per100 ft. 560234Sch 405"23046040209,200317BG640SP-020Sch 406"20040040208,000418BG840SP-010BG840SP-020Sch 408"14028032164,480647-BG280SP-020Sch 802"-2800-1542,000101BG380SP-010BG380SP-020Sch 803"350700562819,600210BG480SP-010BG480SP-020Sch 804"260520562814,56030810 ft lay length 9' 6"; 20 ft. lay length 19' 6"T E C H N I C A L D ATA1 Min.WallThickness(in.)4 Min.&Pull (lbf)Crush(lbs)ListingsPart NumberWall TypeTradeSizeBG340SPSch 403"3.5000.2167,5007,0001,000ETL, CSABG440SPSch 404"4.5000.2379,2008,700900ETL, CSABG540SPSch 405"5.5630.25811,80011,300900ETL, CSABG640SPSch 406"6.6250.28014,50014,000850ETL, CSABG840SPSch 408"8.6250.32218,500*18,000850N/ABG280SPSch 802"2.3750.2183,1503,0002,000ETLBG380SPSch 803"3.5000.3009,8009,3002,000ETLBG480SPSch 804"4.5000.33712,50012,0002,000ETL1 Avg.OD(in.)1Average OD & Minimum Wall Thickness per UL651 & NEMA TC-2.2Pull Test UL651 6.12.2.1 - @ 80 psi3 Bend2 PullTest (lbf)3Bend & Pull UL651 6.12.2.2 - 65' Bend Radius @ 80 psi* 8" Bend & Pull tested at 60 psi/72' Bend RadiusThe Bend & Pull and Pull test results are recorded in lbf (pounds-force). This is NOT equivalent to psi (lbf/in2). It is the responsibility ofthe customer to make that conversion (if needed) based on installation/equipment conditions.4 Schedule 40 - Meets UL651 6.9, NEMA TC-2, & CSA C22.2 No.211.2 6.3 ; Schedule 80 – Meets UL651 6.9US Patent 6,789,629ACCESSORIESGasketsPulling G8PESizeLocking Strap

Product SummaryVisit www.primeconduit.com for more informationProductSpecificationsSchedule 40 PVCHeavy Wall ETL Certified to UL651, NEMA TC-2, Federal Specification WC1094A ½", ¾", 1", 1¼", 1½", 2", 2½", 3", 3½", 4", 5", 6" Concrete encased & direct burial underground applications; exposed or concealed applications aboveground Rated for use with 90 C conductorsSchedule 80 PVCExtra Heavy Wall ETL Certified to UL651, NEMA TC-2, Federal Specification WC1094A ½", ¾", 1", 1¼", 1½", 2", 2½", 3", 4", 5", 6" Listed for aboveground & belowground applications including areas subject to physical damage [352.12 (C)] Rated for use with 90 C conductorsSchedule 40 HeavyWall PVC Utility Non-UL Listed, Designed for power utility applications 1½", 2", 2½", 3", 4", 5", 6", 8" Concrete encased, direct burial, power utility applications; Rated for use with 90 C conductors or cableTelephone Duct NEMA TC-10 & Bellcore CAO8546 (Types B and C) 4” PVC: Type B & Type B Heavy Wall, Type C, Type C Tel-Gard, Type D Concrete encased (Types B & C), Direct Bury (Type C), Exposed Applications (Type D)TypeP&C DuctSize90 CableTC 6 & 8ASTMF-512ConcreteEncasedDirectBurial* EB-202", 3", 4", 5", 6" EB-35 Heavy Wall2", 3", 4", 5", 6" DB-602", 3", 31/2", 4", 5", 6" DB-120 Heavy Wall1", 11/2", 2", 3", 4", 5", 6" DB-1004", 5", 6" DB-100 DWP3", 4", 5" * EB-20 is ETL Certified to sPVCOutdoor - Direct Bury, ConcreteEncasedType C, Type 40,Type 803-Way 11/2",4-Way 11/4"FiberglassOutdoor (UV Resistant) - BridgeCrossings, Areas Subject toPhysical Damage (Bullet-Proof)Heavy or BulletResistant3-Way 11/2",4-Way 11/4"SteelOutdoor - Bridge Crossings, AreasSubject to Physical Damage(Vandalism & Crush)Galvanized orPVC Coated Steel3-Way 11/2",4-Way 11/4"Conforms to NEC Article 300.22 and NFPA 90Afor installation of communication cables insidebuildingsEMTIndoor - Inside BuildingsEMT3-Way 11/2",4-Way 11/4"UL Listed EMT Outer Shell, Conforms to NFPA90A for installation of communication cablesinside buildingsBoreableOutdoor - Horizontal DirectionalDrilledType 40 PVCOuter Duct3-Way 11/2",4-Way 11/4"Minimum Crush per CSA C22.2 No.211.2,UL 651 & NEMA TC-2UL Listed, ETL Certified to UL651Intra-Gard Schedule 40 & Type C: 1¼", 1½", 2” 4-Way, 6-Way, and 4-Way Hybrid Direct bury & concrete encased applications; Bellcore GR-356 CoreBore-GardTrenchless Raceway ETL Certified to UL651, CSA Certified (Schedule 40) 2", 3", 4", 5", 6" & 8" Horizontal directional drilling for electrical and datacom applicationsPV Mold Exceeds NESC requirements, Designed in accordance with NEMA TC-19 Standard Duty: 1", 2", 3", 4", 5" Heavy Duty Schedule 40: 1½", 2", 3", 4", 5", 6" Extra Heavy Duty Schedule 80: 2" - 3" Pole riser system designed to protect communications power cable installed on polesSplit Duct & Kits Schedule 40 Duct & Kits: 2", 2½", 3", 3½", 4", 5", 6"; Schedule 80 Duct: 2", 4"; C Duct & Kits: 4" Repair brokenductworkFittings & Accessories Couplings, adapters, junction boxes, end bells, reducers, clamps, switch boxes, access fittingsElbows & Sweeps Schedule 40, Schedule 80, DB Sweeps, and Telephone Duct Sweeps23240 Chagrin Blvd., Suite 405 Cleveland, OH 44122 216-464-3400 www.primeconduit.comPCBGTR PP 06/16 2016 PrimeConduit, Inc.

Bore-Gard is also proudly Made in the USA. PRODUCT INSTALLATION 1. Position Bore-Gard with the print line facing up. 2. Remove plastic locking strap and set it aside. 3. Remove end caps. On first stick only, trim spigot end of Bore-Gard at the groove before attaching the pulling eye/gripping attachment. 4. Insert pulling eye into spigot end of .