Transcription

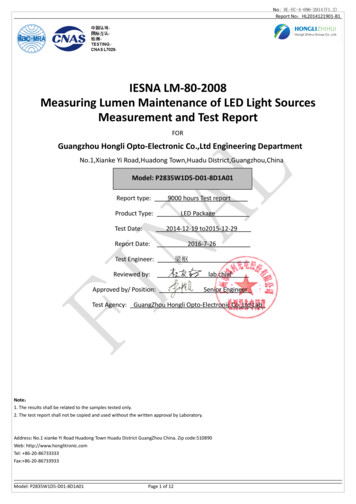

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008Measuring Lumen Maintenance of LED Light SourcesMeasurement and Test ReportFORGuangzhou Hongli Opto-Electronic Co.,Ltd Engineering DepartmentNo.1,Xianke Yi Road,Huadong Town,Huadu District,Guangzhou,ChinaModel: P2835W1D5-D01-8D1A01Report type:9000 hours Test reportProduct Type:LED PackageTest Date:2014-12-19 to2015-12-29Report Date:Test Engineer:2016-7-26梁枢Reviewed by:Approved by/ Position:lab chiefSenior EngineerTest Agency: GuangZhou Hongli Opto-Electronic Co.,Ltd LabNote:1. The results shall be related to the samples tested only.2. The test report shall not be copied and used without the written approval by Laboratory.Address: No.1 xianke Yi Road Huadong Town Huadu District GuangZhou China. Zip code:510890Web: http://www.honglitronic.comTel: 86-20-86733333Fax: 86-20-86733933Model: P2835W1D5-D01-8D1A01Page 1 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORTContent1.General Information . . 31.1 Description of LED Light Sources . 31.2 Standards Used . 31.3 Test Facility . . .31.4 Description of Auxiliary Equipment . .31.5 Operating Cycle . .31.6 Test interval . .31.7 Ambient Conditions . . 31.8 Photometry Measurement Uncertainty . 31.9 Sample Set. . . 32.Summary Of Test Result. . 43. Test Data . 53.1 Data sheet 1:85 ,150mA (Lumen Maintenance) . . 53.2 Data sheet 1:85 ,150mA (Chromaticity Shift) . . 63.3 Data sheet 1:105 ,150mA (Lumen Maintenance) 73.4 Data sheet 1:105 ,150mA (Chromaticity Shift) . 84. Appendix . . 94.1 Mechanical Dimensions( Ta 25 ) . . 94.2 EUT Photo . . .10Appendix A-Family Declaration letter .11Appendix B- REVISION HISTORY .12Model: P2835W1D5-D01-8D1A01Page 2 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORT1.General Information1.1 Description of LED Light SourcesModel: P2835W1D5-D01-8D1A01Product Type: LED PackageNominal CCT:2700KFamily products covered by this report :According to ENERGY STAR Program Guidance Regarding LED Package, LED Array and LED Module Lumen Maintenance Performance DataSupporting Qualification of Lighting Products, the following products can be covered by this report base on the declaration letter of manufacturer[Engineering Department] ( see attachment A for more information). The information of these models Shows that the covered products meet allsection 3 item 3 requirements of ENERGY STAR Program Guidance Regarding LED Package, LED Array and LED Module Lumen MaintenancePerformance Data Supporting Qualification of Lighting Products( September 9, 2011)Model typePackage 2835 seriesModel laimer:The truthfulness and accuracy of all the technical information above for the covered LED products is ensure by manufacturer ofLED light source (Engineering Department). GuangZhou Hongli Opto-Electronic Co.,Ltd Lab isn’t responsible or gives any guaranteesfor the truthfulness of the technical information.1.2 Standards Used IESNA LM-80-08:IES Approved Method for Measuring Lumen Maintenance of LED Light Sources. ENERGY STAR Program Guidance Regarding LED package, LED Array and LED Module Lumen Maintenance Performance Data Supporting Qualificationof Lighting Products.(* The standard is not in the scope of accreditation)1.3 Test FacilityThe testing Facility used by Guangzhou Hongli Opto-electronic Co., Ltd lab, is located at No.1 xianke Yi Road Huadong Town Huadu District GuangZhouChina.1.4 Description of Auxiliary EquipmentDeviceManufactureIntegral SphereEVERFINEModel NoDiameter0.5MEquipment NoTest RangeCalibrationDateCalibrationdue mmabletest Power el: P2835W1D5-D01-8D1A01Page 3 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST r LM-80aging -15DC regulatedPower 60V/6A2015-6-152016-6-141.5 Operating CycleSamples are driven with a constant direct current (DC).1.6 Test intervalSamples are tested in every 1000 hour.1.7 Ambient conditionsFor lumen maintenance test ,samples were operated in thermal chambers with minimal ambient airflow. for long term reliability test .The case temperature was controlled by mounting several thermocouples on a sample reliability stress board at the designated thermalmeasurement point ,as shown in APPENDIX .The ambient temperature Ta was measured by several thermocouples at a distance of 1.5mmabove the reliability test board. The relative humidity within chamber was less than 65%.For photometry measurement ,temperature was set to 25 2 ,RH 65%1.8 Photometry Measurement UncertaintyThe uncertainty of the light output measurements is U 2.52%(k 2),at the95% confidence level.The uncertainty of the correlated color temperature measurements is U 21.5K(K 2),at the95% confidence level. This calibration resultstraceable to the CHINA CEPREI LABORATORY .1.9 Sample SetSampling Method:LED samples for IESNA LM-80 testing consist of units built from a minimum of three manufacturing lots with each manufacturing lot built fromdifferent wafer lots built on non-consecutive days.These manufacturing lots are picked to represent a wide parametric distribution.Each Sample is soldered to all of the reliability stress boards for a given set of IESNA LM-80 tests.Sample Size:Total 60 Pcs;Status: Normal;Each Ts test condition 25Pcs for sampling ,The other 10pcs samples were retain;The samples tested at Ts 85 and 105 were received at 2014-12-19 and tested during 2014-12-19 to 2015-12-29.The Samples were numbered from 1# to 25#, 26# to 50#.(1) Data set : 85 ,150mAPart Number: P2835W1D5-D01-8D1A01Number of Units: 25PcsActual Case Temperature(Ts):TS 84.8 Actual Ambient Temperature(Ta): TA 83.2 Life Test Drive Current: IF 150mAMeasurement Current: IF 150mA(2) Data set : 105 ,150mAPart Number:P2835W1D5-D01-8D1A01Number of Units: 25PCSActual Case Temperature(Ts):Model: P2835W1D5-D01-8D1A01TS 104.5 Page 4 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORTActual Ambient Temperature(Ta): TA 103.7 Life Test Drive Current: IF 150mAMeasurement Current: IF 150mA2. Summary Of Test Result(1) Data set:Data Set 1 85 150mANumber of Units:25 PcsNumber of Failures :0 PcsAverage. Lumen Maintenance at 9000 hours :95.39%Average Chromaticity Shift at 9000 hours ( u'v'): 0.00442 54000 HReported TM-21 L70 Life time:(2) Data set:Data Set 1 105 150mANumber of Units:25 PcsNumber of Failures :0 PcsAverage. Lumen Maintenance at 9000 hours :94.99%Average Chromaticity Shift at 9000 hours ( u'v'): 0.00434Reported TM-21 L70 Life time:53000H3. Test Data3.1 Data Set 85 ,150 mA (Lumen Maintenance)NoVF(V)Ф(lm)0hrsLumen 96.87%96.52%95.58%95.24%95.06%Model: P2835W1D5-D01-8D1A01Page 5 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST 95.71%95.37%st 40%97.73%TM-21 Projection:Test Duration: 9000hoursα : 5.640E-06β : 1.003Calculated L70: 64000HReported L70 : 54000H3.2 Data Set,85 , 150mA(Chromaticity Shift)Nou'CCTv'(K)Chromaticity Shift( .00444st 6130.00654Model: P2835W1D5-D01-8D1A01Page 6 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORT3.3 Data Set 105 ,150 mA (Lumen Maintenance)NoVF(V)Ф(lm)0hrsLumen t 3%96.83%TM-21 Projection:Test Duration: 9000hoursα : 6.993E-06β : 1.011Calculated L70: 53000HReported L70: 53000HModel: P2835W1D5-D01-8D1A01Page 7 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORT3.4 Data Set,105 , 150mA(Chromaticity Shift)Nou'CCTv'(K)Chromaticity Shift( 003040.003270.003710.003980.004250.004570.00483st 0.00586Model: P2835W1D5-D01-8D1A01Page 8 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORT4. Appendix A-EUT PHOTO4.1 Mechanical Dimensions( Ta 25 )All dimensions are in millimeter4.2 Eut PhotoModel: P2835W1D5-D01-8D1A01Page 9 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORTModel: P2835W1D5-D01-8D1A01Page 10 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORTAppendix A-Family Declaration letterDeclaration of SimilarityCurrent Date: March 7, 20161, an officer of (engineering department), do hereby attest, that our LED package with the model number P2835W1D5-D01-8D1A01 was tested byhongli lab. The covered family models are in below table:Model typePackage 2835 seriesModel 1-8D1A01650080150P2835W8F4-D01-8D1A01350080150The family models P2835WXDX-DXX-XDXAXX and P2835WXFX-DXX-XDXAXX, tested model P2835W1D5-D01-8D1A01 could meetall the requirements listed as below:a. the tested model has been conducted on the largest LED package and have the largest per chip current;b. the family models have the equal or fewer LED dies than the tested model;c. die spacing greater than or equal to the tested model;d. identical materials used;e. identical construction processes used;f. identical performance attributes.Certified by: contact name Title Date 2016/7/26Model: P2835W1D5-D01-8D1A01Page 11 of 12

No: HL-EC-4-096-2014(V1.2)Report No:HL2014121901-B1IESNA LM-80-2008 TEST REPORTAppendix B- REVISION HISTORYReport NumberReport DateContentsHL20141219012016-1-5Original reportHL2014121901-B2016-3-7Add Family products coveredHL2014121901-B12016-7-26Add Family models P2835WXFX-DXX-XDXAXX******************END OF REPORT******************Model: P2835W1D5-D01-8D1A01Page 12 of 12

IESNA LM-80-08:IES Approved Method for Measuring Lumen Maintenance of LED Light Sources. ENERGY STAR Program Guidance Regarding LED package, LED Array and LED Module Lumen Maintenance Performance Data Supporting Qualification of Lighting Products.(* The standard is not in the scope of accreditation)