Transcription

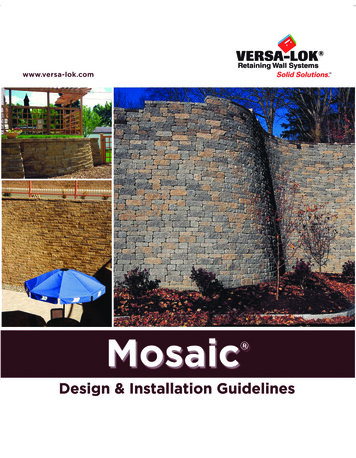

WelcomeWelcome to the VERSA-LOK Mosaic RetainingWall System Design and Installation Guidelines.This guide applies to both the Mosaic systemand its individual units. The Mosaic systemWelcome tothe VERSA-LOKMosaic RetainingWall SystemDesign andInstallationGuidelines.comprises three retaining wall units: VERSA-LOKStandard, VERSA-LOK Accent , and VERSA-LOK Technical Bulletin #1Shoreline, Waterway and Retention Pond Protection Technical Bulletin #2VERSA-LOK Stairs Technical Bulletin #3Curves and Corners Cobble . Although each is an integral part of theMosaic system, each can stand on its own as aseparate-entity retaining wall system. However,there are many variables to consider when Technical Bulletin #4VERSA-LOK Caps Technical Bulletin #5Base Installationplanning or constructing any retaining wall.Soil types, drainage, loading, topography and Technical Bulletin #6Freestanding and Vertical Wallsheight need to be addressed on each project toensure safe, trouble-free installation. Technical Bulletin #7Tiered WallsPlease note the maximum height for anunreinforced Mosaic retaining wall is 4 feet.Individual site, soil and loading conditions(including terraces) may limit unreinforced wallheights to less than 4 feet. Taller walls requiresoil reinforcement and engineering assistance.In addition to this guide, VERSA-LOK offers avariety of technical support, including in-houseengineering assistance and reference literature.Please call (800) 770-4525 with questions Technical Bulletin #8Fences, Railings and Traffic Barriers Design and Installation Guidelines- VERSA-LOK Standard Technical Documentation forVERSA-Grid Soil Reinforcement Standard and Mosaic ConstructionDetails CD-Rom containingspecifications and drawingscreated with AutoCAD softwareAutoCad is a registered trademark of Autodesk, Inc.about Mosaic, Accent or Cobble Retaining WallSystems, or to request additional literature.The following technical materials werewritten for use of VERSA-LOK Standardunits; however, the general principles applyto Mosaic walls as well. You also can downloadTechnical Bulletins from the VERSA-LOKwebsite at www.versa-lok.com1VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINESThis guide is intended to illustrate design andconstruction capabilities of the VERSA-LOKMosaic Retaining Wall System. There are manyvariables to consider, however, when planningor constructing any segmental retaining wall.Soil types, drainage, loading, topography andheight need to be addressed on every projectto ensure safe, trouble-free installation.

Table of Contents1 Introduction & Unit Specifications – Mosaic .32 Mosaic System Overview .63 Mosaic Wall Components .7 Foundation Embedment Soils and Compaction Drainage Within Walls Surface Drainage Geosynthetic Reinforcement4 Special Design Considerations .10 Shorelines Loads Behind Walls TieringThis guidedemonstrates theexceptional designcapabilities andeasy installationmethods of theVERSA-LOKMosaic RetainingWall System.5 Planning, Estimating, & Final Designs .116 Mosaic Wall Construction.14 Tools Unit Modification Excavation Leveling Pad Base Course Installing First Course of Panels Pinning Mosaic Panels Installing Additional Courses of Panels Drainage Aggregate Compacted Soil Backfill Geosynthetic Soil Reinforcement Caps7 Basic Wall Design Elements.22 Curves, Concave (Inside) Curves, Convex (Outside) Curves Corners Outside 90 o Corner Outside 90 o Corner - Vertical Side Wall at Stairs Inside 90 o Corners Stepping Top of Wall Stepping Base of Wall8 Advanced Wall Features .28 Stairs Fences/RailingsSUPPLEMENTAL INFORMATIONMosaic Material Estimation Worksheet .29VERSA-Grid Estimation Charts .30Cobble Retaining Wall System .31Accent Retaining Wall System .31Mosaic Specifications .32-38Mosaic Construction Detail Drawings .39-42VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES2

1Introduction & Unit SpecificationsVERSA-LOK Mosaic The VERSA-LOK Mosaic Retaining Wall SystemOne Standard, one Cobble, and two Accent unitsrepresents the ultimate combination of aestheticsare arranged in ten-inch-high by 24-inch-wideand performance in segmental retaining walls.panels. There are four different panel configurations that can be arranged in any order to forma random, natural stone wall appearance.Mosaic panelscreate a seeminglycomplex randompatterned, naturalstone appearancewhile still providingunmatched easein installation anddesign flexibility.The Mosaic system provides design flexibility,durability, and ease of installation. VERSA-LOKMosaic walls are quickly and economicallyassembled without mortar and do not requireWhile appearing to be randomly placed in the wall,Mosaic units are installed in simple panels.concrete footings. VERSA-LOK's uniquehole-to-slot pinning system interlocks unitsThe Mosaic system utilizes VERSA-LOK unitsand aids in alignment. Installers can easilyof varying heights and widths to achieve amodify the solid Mosaic units to create anrandom-like pattern that closely resemblesunlimited variety of curves and corners,natural stone walls. Mosaic retaining wallswithout ordering special units. Matchingconsist of three units: Standard, Accent ,concrete cap units are available to finish and Cobble .any VERSA-LOK Mosaic wall.MOSAIC PANEL ERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINESCobbleAccentStandardAccent

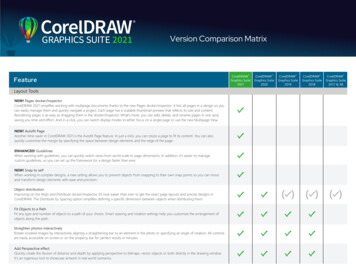

1Introduction & Unit SpecificationsVERSA-LOK MOSAIC VERSA-LOK MOSAIC UNITS(Actual unit size and weight may vary slightly by region.)VERSA-LOK Mosaic units are made from high-strength, low-absorption concrete on concrete blockmachines. VERSA-LOK Mosaic units’ solid characteristics make them resistant to damage before,during, and after construction in all climates, including shoreline applications.6"6"4"SolidVERSA-LOKMosaic unitsprovide superiordurability Accent Cobble Height:6 inches152.4 mm4 inches101.6 mm6 inches152.4 mmWidth (face):16 inches406.4 mm12 inches304.8 mm8 inches203.2 mmWidth (rear):14 inches355.6 mm8 inches203.2 mm6 inches152.4 mm12 inches 304.8 mm12 inches304.8 mm12 inches304.8 mm2/3 ft21/3 ft2Depth:Face Area:Weight:Wgt/Face Area:82 lbs123 lbs/ft20.062 m237.19 kg599.84 kg/m238 lbs108 lbs/ft20.031 m216.33 kg526.77 kg/m21/3 ft20.031 m238 lbs114 lbs/ft217.24 kg556.13 kg/m2VERSA-LOK MOSAIC WEATHERED(Available in most areas.)As an attractive alternative, all three Mosaicunits are offered with a weathered appearance(left). Weathered Mosaic units undergo aspecial process to create a rustic old-worldappearance that closely resembles natural stone.VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES4

1Introduction & Unit SpecificationsVERSA-LOK Mosaic VERSA-LOK MOSAIC PINNINGVERSA-LOK Mosaic units interlock with non-corrosive3/4"VERSA-TUFF Snap-Off Pins. VERSA-TUFF Pinsare inserted through front holes in the upper unitsVERSA-LOKMosaic units havea unique hole-toslot pin system foreasy installationand superiorstructural integrity.6"into slots in the units below. Slots allow variationin location of vertical joints (variable bond).Generally, two VERSA-TUFF Snap-Off Pins are4"used for each Standard, Accent , and Cobble Pinning Standard/Cobbleto AccentFigure Aunit—eight VERSA-TUFF Pins per panel.VERSA-TUFF Snap-Off Pins are designed to accommodatesnap offtop of pin3/4"varied heights of Mosaic units. The full length ofVERSA-TUFF Pins is used when pinning through4"six-inch-high Standard and Cobble units, (Figure A).When pinning through four-inch-high Accent units,the two-inches of the VERSA-TUFF Pin remaining6"above the unit is easily snapped off (Figure B).Figure BPinning Accent toStandard/CobbleVERSA-TUFF SNAP-OFF PINLength:6.8 inchesSnap-Off Length:4.625 inches 117.5 mmDiameter:0.48 inchesMaterial:Glass-Reinforced Nylon172.7 mm12.2 mmVERSA-TUFF Snap-offPins accommodatevaried heights ofMosaic units.VERSA-LOK CAP UNITSWeight:A Cap40 lbs18.14 kgB Cap50 lbs22.68 kg12"16"3-5/8"12"14"Cap A14"Cap BMatching cap units attractively finish VERSA-LOK walls.5VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES

VERSA-LOK Mosaic System Overview2VERSA-LOK MOSAIC–TYPICAL SECTIONSOn many projects, Mosaic retainingcap unitwalls work purely as gravity systems,where unit weight, frictional forcesbetween units, pins, and the cant of theVERSA-LOKMosaic’s uniquepanel systemprovides levelcourses every teninches to easilyaccommodategeogrid layersused in tall wallconstruction.mosaicunitswall combine to provide resistance toearth pressures. With level backfill andno excessive loading, most Mosaic wallsare stable to four feet in height.When unit weight and frictional forcesare not enough to resist soil loads,Unreinforcedhorizontal layers of geosynthetics areused to reinforce soil behind walls.With proper design and soil reinforce-cap unitment, Mosaic walls can be constructedgeosyntheticreinforcementto heights exceeding 40 feet.Each Mosaic unit is set back 3/4-inchfrom the units beneath it. There aremosaicunits12" thick min.drainageaggregatetwo units stacked in each ten-inch-highpanel—a total setback of 1.5 inchesreinforcedbackfillper panel. This results in a cant ofapproximately 8.5 degrees from vertical.ReinforcedVERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES6

3MortarlessVERSA-LOK wallsdo not requirerigid concretefootingsbelow frost.VERSA-LOK Mosaic Wall ComponentsFoundationto be taken to construct concrete pads that areFoundation soils on which walls will rest mustexactly level. In rare situations where rigid,be stiff, firm, and have sufficient capacity toreinforced concrete footings are required, theysupport wall system weight. Any loose, soft,should be placed below seasonal frost depths.or compressible material must be removed andreplaced with properly compacted backfill.The bearing capacity of the foundation soilsshould be addressed by a soils engineer.VERSA-LOK segmental retaining walls areinstalled on leveling pads consisting of wellgraded angular gravel. The most commonlyused material for leveling pads is thatwhich is used locally as road base aggregate.Granular leveling pads provide stiff yetsomewhat flexible bases to distributewall weights.Rigid concrete footings extending below frostCompacted granular leveling padsprovide stiff but flexible bases forMosaic units.are not required or recommended. BecauseVERSA-LOK units are installed without mortar,they are free to move slightly in relation to eachEmbedmentother. Flexibility of the leveling pads and wallVERSA-LOK segmental retaining walls shouldunits accommodates freeze/thaw cycles withouthave one-tenth of exposed wall heights embed-damage to structures. VERSA-LOK wallsded below grade. For example, a wall with 15installed on granular leveling pads have beenfeet of height exposed above grade should havesuccessfully used on projects throughout Northa minimum of 1.5 feet buried below grade—mak-America—including shoreline applications anding a total wall height of 16.5 feet. Embedmentwalls exceeding 40 feet in height.should be increased for special conditions suchas slope at the toe of walls, soft foundation soils,If a contractor chooses to form leveling padsor shoreline applications. Embedment providesusing concrete, unreinforced pads should beenhanced wall stability and long-term protectionmade of lean concrete mix (200-300 psi) and nofor leveling pads.more than two inches thick. To ensure correctVERSA-LOK unit alignment, special care needs7VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES

VERSA-LOK Mosaic Wall ComponentsSoils and Compactionweep through joints of installed units. For wallsWith proper design, VERSA-LOK segmentalgreater than three feet in height, a perforatedwalls can be constructed within a wide varietydrain pipe is recommended at the base of theof soil conditions. Granular soils are preferreddrainage aggregate to quickly remove largeas fill in the areas reinforced with geosynthetics;amounts of water.however, fine-grained soils such as clays areacceptable. Usually, coarse soils require lessIf high groundwater levels are anticipated or ifsoil reinforcement and are easier to compactthe wall is along a shoreline, additional drainagethan fine soils. Problem materials like expansivematerials behind and below reinforced fill may beclays, compressible soils, or highly organic soilsrequired. Filter fabric may be required to prevent(top soil) should be avoided or properlyunwanted migration of fine soil particles into theaddressed in designs.drainage aggregate.3Properlycompactedsoils anddrainage controlsare criticalcomponents ofMosaic walls.Proper compaction of foundation and backfill soilis critical to long-term performance of retainingSurface Drainagewall systems. Loose backfill will add pressure onWall sites should be graded to avoid waterwalls, collect water, cause settlement, and willflows, concentrations, or pools behind retainingnot anchor soil reinforcement materials properly.walls. If swales are designed at the top ofFoundation and backfill materials should bewalls, properly line and slope them so water iscompacted to at least 95 percent of standardremoved before it can flow down behind walls.Proctor density. (Proctor density is the maximumdensity of the soil achieved in a laboratoryGive special attention to sources of stormwaterusing a standard amount of compaction effort.)from building roofs, gutter downspouts, pavedGenerally, construction observation andareas draining to one point, or valleys intesting for proper soil type and compaction istopography. Be sure to guide flows from theseprovided by the project’s soils engineer.areas away from retaining walls. Slope thesoil slightly down and away from wall basesto eliminate water running along bases andDrainage Within Wallseroding soil. If finish grading, landscaping,Segmental retaining walls are designedor paving is not completed immediately afterassuming no hydrostatic pressure behind walls.wall installation, temporarily protect the wallDrainage aggregate (angular gravel, clear offrom water runoff until adjacent constructionfines) placed behind walls helps eliminate waterand drainage control structures are completed.accumulation. Because no mortar is used inVERSA-LOK wall construction, water is free toVERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES8

3Geosynthetics suchas VERSA-Grid reinforce backfillsoils, allowingconstruction ofstable Mosaicwalls exceeding40 feet in height.VERSA-LOK Mosaic Wall ComponentsGeosynthetic ReinforcementGeosynthetic layers must be nominallyGeosynthetics are durable, high-strength polymertensioned and free of wrinkles when placed.products designed for use as soil reinforcement.Geosynthetics are generally stronger in oneHorizontal layers of geosynthetic such asdirection, the roll direction. It is important thatVERSA-Grid provide tensile strength to holdthe high-strength direction be placed perpendicu-the reinforced soil together, so it behaves aslar to the wall face, in one continuous sheet (noone coherent mass. The geosynthetic reinforcedsplices). Along the wall length and parallel tosoil mass becomes the retaining wall. Sufficientthe face, adjacent sections of reinforcement arelength and strength of geosynthetic can createplaced immediately next to each other withouta reinforced soil mass large enough andoverlap to create 100 percent coverage withstrong enough to resist destabilizing loads.no gapping, and with special details for curvesGeosynthetic layers also connect theand corners.VERSA-LOK units to the reinforced soil.The needed type, length, vertical spacing, andGeosynthetics are made from several types ofstrength of geosynthetic vary with each projectpolymers that resist installation damage anddepending on wall height, loading, slopes, andlong-term degradation. Geosynthetics aresoil conditions. A professional Civil Engineerdesigned to interact with the soil for anchorage(P.E.) must prepare a final, geogrid-reinforcedagainst pullout and resistance to sliding.wall design for each project.Geogrids, the most common soil reinforcementfor walls, are formed with an open, grid-likeconfiguration. Geotextiles (solid fabrics) arealso used. Product specific testing determinesthe durability, soil interaction, and strengthof each type of geosynthetic. The interactionof various geosynthetics with VERSA-LOKunits (connection strength) is also tested.Geosyntheticsare designedto interactwith the soilfor anchorage.Geosynthetics provide tensilestrength to backfilled soils.9VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES

Special Design Considerations4ShorelinesVERSA-LOK segmental retaining wallsperform well in shoreline applications. However,special design considerations are often necessaryWith properdesign, Mosaicwalls can accommodate specialsite conditionssuch as waterloads, slopesor surcharges.to ensure that water pressures do not build upbehind walls. Special provisions may includegranular reinforced backfill, additional drainageaggregate, drainage behind reinforced soilmasses, and filter fabric. Protection of basesfrom water scour, wave action, and ice mayalso be necessary.See VERSA-LOK Technical Bulletin #1 for moreinformation regarding shorelines and retentionpond protection.TieringLoads Behind WallsSurcharge loads and slopes behind walls cansubstantially increase amounts of requiredsoil reinforcement. Common surcharge loadsinclude parking areas, driveways, and buildingstructures. For design purposes, permanentloads like buildings and slopes are considered tocontribute to both destabilizing and stabilizingAesthetically, it may sometimes be desirableto divide large grade changes into tiered wallsections. However, upper wall tiers can addsurcharge loads to lower walls and necessitatespecial designs. To avoid loading lower walls,upper walls must be set back horizontally atleast twice the height of the lower walls.If walls are placed closer, lower walls mustbe designed to resist the load of upper walls.forces acting on walls. Dynamic forces likevehicular traffic are considered to contributeSeveral closely spaced tiered walls can create steep,to destabilizing forces only. Often, the highestunstable slopes. If tiered walls make a grade changesurcharge loads are caused by grading or pavingsteeper than 2:1 (horizontal: vertical), global slopeequipment during construction. Heavy equipmentstability may need to be reviewed by a qualified soilsshould be kept at least three feet behind theengineer. See VERSA-LOK Technical Bulletin #7 forback of retaining wall units. Soil reinforcementmore information regarding tiered wall construction.designs should accommodate all anticipatedsurcharge loads—even if they will occurinfrequently or just once.VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES10

5VERSA-LOK’stechnical staff isavailable to assistin planning, layout,estimating, andreferrals for finalengineering.Planning, Estimating& Final DesignsPlanningEstimatingCareful planning is critical to successful projects.Accurately estimate and order required materialsPrior to design, accurate information needs toincluding VERSA-LOK units, VERSA-TUFF be gathered including soil conditions, proposedSnap-Off Pins, cap units, VERSA-LOK Concretewall heights, topography, groundwater levels,Adhesive, imported backfill, leveling padand surface water conditions. Proper permits,materials, VERSA-Grid geosynthetic soilowner approvals, utility clearances, andreinforcement, drainage aggregate, andtemporary easements should also be obtainedadditional drainage materials. The Mosaic in advance.Unit Estimation Chart on page 12 shows howto determine quantities of the various MosaicPlanned wall alignments should be reviewedunits. See the Material Estimation Worksheetfor feasibility. Make sure that layouts accounton page 29 to help determine quantities of allfor minimum curve radii, wall setback, andVERSA-LOK products.area needed for geosynthetic soil reinforcement.Be sure that all wall components fit withinFor reinforced-wall projects, the VERSA-Gridproperty constraints. Verify that temporaryestimation charts on page 30 provide approximateconstruction excavations will not underminefoundation supports of any existing structuresor utilities. Considerations should also begiven to site access for equipment and materials.11VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINESamounts of geogrid soil reinforcement necessary toconstruct walls in various soil and loading conditions.For tall walls or complex situations, VERSA-LOK staffengineers can prepare project-specific preliminarydesigns for geogrid estimation purposes.

Planning, Estimating& Final Designs5Mosaic Unit Estimation ChartEach Mosaic panel is 1.66 square feet in wall-face area. For each panel, there is one Standard unit,two Accent units, and one Cobble unit. The following formulas and table may be used to estimatequantities of units required for a Mosaic retaining wall project.6"6"4"12"12"12"12"16"No. of STANDARD UNITS Wall Square Footage 1.668"No. of ACCENT UNITS Wall Square Footage 1.66 x 2EACH PANEL REQUIRES 8 PINSNo. of COBBLE UNITS Wall Square Footage 1.66VERSA-LOK MOSAIC QUANTITY ESTIMATION CHART t10 inchesStandard5678910111213141520 inches30 inches40 472808896104112120VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES*This chartdoes not includeestimates forembedded(buried) units.The quantity ofembedded units(generally allStandard units)should also beadded to thesequantities.12

5Planning, Estimating& Final DesignsFinal DesignsFor walls overfour feet high,a licensedprofessional civilengineer (P.E.)should preparethe finalwall design.Final wall designs may be provided prior toFor assistance in specifying, designing, andputting projects out for bidding. Alternatively,engineering VERSA-LOK walls, sample wallwall portions of projects can be specifiedspecifications are provided on pages 32 to 38design/build. With design/build projects, engi-and sample construction details are providedneers/architects provide wall layout informationon pages 39 to 42. Additional details and(line and grade) but not final engineering forspecifications are available in electronic format:the wall. Contractors submit bids based onCall (800) 770-4525 for more information or visitthis layout including estimated labor, materials,our website at www.versa-lok.com. VERSA-LOK’sand final engineering costs. Contractors whotechnical staff is also available to assist withare awarded projects retain licensed engineersplanning, layout, preliminary engineering, andto prepare final wall designs and submit shopreferrals for final engineering.drawings for approval from projectengineers/architects.For walls more than four feet in height, most buildingcodes require a final wall design prepared by aAs with all proposed construction, a soils reportlicensed Civil Engineer (P. E.) registered in that state.prepared by a qualified geotechnical engineer isVERSA-LOK and its manufacturers have a networkrequired to provide adequate information forof licensed Civil Engineers who are familiar withproper design. The soils report should addresssegmental retaining wall design. These individualsoverall stability of planned grade changes andare available for referrals to architects, engineers,allowable bearing capacity of foundation soils.The report should also include information aboutreinforced and retained soil properties.13VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINESor contractors with final wall design needs.

Mosaic Wall Construction6ToolsThe following tools may be helpful duringconstruction of Mosaic segmental retaining walls:VERSA-Lifter Block SplitterSafety ProtectionVibratory Plate CompactorDiamond-Blade Concrete SawCaulking GunBackhoe or Skid-Steer LoaderThe VERSA-Lifter helps installers constructVERSA-LOK Standard retaining walls bymaking it easier to lift and place units —especially on the base course. Two prongs onFour-Foot LevelString LineHand Tamperthe Lifter are inserted into pin holes in eachVERSA-LOK Standard unit. Lifting the handlesecures the Lifter to the unit and makes foreasy, balanced lifting and placement.Transit or Site LevelFinishing TrowelTape MeasureFour-Pound Sledge HammerBroomBrick HammerShovelThree-Inch Masonry ChiselVERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES14

6VERSA-LOKMosaic units areeasily modifiedby splitting fora textured face,or by saw-cuttingfor a smooth side.Mosaic Wall ConstructionUnit ModificationExcavationDuring wall construction, it may be necessaryExcavate just deeply enough to accommodate theto split or cut VERSA-LOK Mosaic units.leveling pad (which is normally 6 inches thick)Splitting creates an attractive textured faceand the required unit embedment below grade.on any visible sides of a Mosaic unit thatWhen necessary, also excavate areas wherematches the split-face on the front of the unit.geosynthetic soil reinforcement will be placed.Saw-cutting creates a smooth straight edgeRequired unit embedment varies with wall heighton a partial unit, so it can fit tightly next toand site conditions. Generally, if grade in frontadjacent units. Remember to always wearof the wall is level, one-tenth of the exposed wallproper safety protection when performingheight should be buried below grade.splitting or cutting operations.To split units with a masonry chisel and hammer,mark a path on the unit’s top, bottom, andback. Score along the top and bottom pathsusing the chisel and a heavy hammer. Place theunit on its face and strike along the back path.It is easier to split units on the ground than ona hard surface. The unit should fracture nicelyalong the paths. If many splits will be requiredfor a project, it may be helpful to rent a mechanicalor hydraulic block splitter from your blockAdditional embedment may be required forsupplier or rental center.special conditions including slopes in front ofwalls, soft foundation soils, and shorelineSaw-cuts are normally made using a gas-poweredapplications. Compact soil at the bottom ofcut-off saw with a diamond blade. Before youexcavation—do not place Mosaic units on loose,saw-cut a unit, mark a line on each side to besoft, wet, or frozen soil—settlement may result.cut. Place the unit face toward you with the topIf the wall will set on previously backfilledside up, at a comfortable height on a stable workexcavations, such as utility line trenches, besurface. Make a straight cut down and two tosure the entire depth of existing backfill is wellthree inches into the face. Move saw to top ofcompacted. If necessary, over-excavate soft soilsunit, and cut through top using successivelyand replace with properly compacted backfill.deeper cuts. Flip unit over and finish by cuttingcompletely through the bottom of the unit.15VERSA-LOK MOSAIC DESIGN AND INSTALLATION GUIDELINES

Mosaic Wall ConstructionLeveling PadBase CoursePlace granular leveling pad material andMake sure that the leveling pad is level andcompact to a smooth, level surface. Levelingbegin placing base course units. For ease ofpad should be at least six inches thick and 24installation, use only VERSA-LOK Standardinches wide. It should consist of crushed stone.units for the base course. This will create aThe most commonly used material for levelinguniform “platform” on which to build thepads is what is used locally as road base aggre-Mosaic panels.gate. To construct long sections of leveling pad,create forms by leveling and staking rectangularmetal tubing along both sides of the plannedpad. Place and compact granular material withinthese leveled forms and screed off excess.6Take time toensure a level basecourse—minorunevenness in thebase course willbe amplified anddifficult to correctafter severalcourses ofpanels havebeen installed.Always begin at the lowest level and workupward in situations where the planned gradealong the wall front changes elevation. Use athin layer of fine sand on top of the levelingpad for final leveling.Align base units using their backs or slots,rather than their irregularly textured front f

VERSA-LOK Mosaic units are made from high-strength, low-absorption concrete on concrete block machines. VERSA-LOK Mosaic units' solid characteristics make them resistant to damage before, during, and after construction in all climates, including shoreline applications. 12" 4" 12" 12" 6" 16"