Transcription

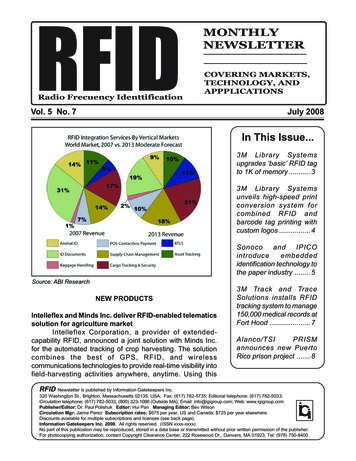

RFIDRadio Frecuency IdenttificationMONTHLYNEWSLETTERCOVERING MARKETS,TECHNOLOGY, ANDAPPPLICATIONSVol. 5 No. 7July 2008In This Issue.3M Library Systemsupgrades ‘basic’ RFID tagto 1K of memory . 33M Library Systemsunveils high-speed printconversion system forcombined RFID andbarcode tag printing withcustom logos . 4Sonoco and IPICOintroduceembeddedidentification technology tothe paper industry . 5Source: ABI ResearchNEW PRODUCTSIntelleflex and Minds Inc. deliver RFID-enabled telematicssolution for agriculture marketIntelleflex Corporation, a provider of extendedcapability RFID, announced a joint solution with Minds Inc.for the automated tracking of crop harvesting. The solutioncombines the best of GPS, RFID, and wirelesscommunications technologies to provide real-time visibility intofield-harvesting activities anywhere, anytime. Using this3M Track and TraceSolutions installs RFIDtracking system to manage150,000 medical records atFort Hood . 7Alanco/TSIPRISMannounces new PuertoRico prison project . 8RFID Newsletter is published by Information Gatekeepers Inc.320 Washington St., Brighton, Massachusetts 02135, USA; Fax: (617) 782-5735; Editorial telephone: (617) 782-5033;Circulation telephone: (617) 782-5033, (800) 323-1088 (Outside MA); Email: info@igigroup.com; Web: www.igigroup.comPublisher/Editor: Dr. Paul Polishuk Editor: Hui Pan Managing Editor: Bev WilsonCirculation Mgr: Jaime Perez Subscription rates: 675 per year, US and Canada; 725 per year elsewhere.Discounts available for multiple subscriptions and licenses (see back page).Information Gatekeepers Inc. 2008. All rights reserved. (ISSN xxxx-xxxx)No part of this publication may be reproduced, stored in a data base or transmitted without prior written permission of the publisher.For photocopying authorization, contact Copyright Clearance Center, 222 Rosewood Dr., Danvers, MA 01923, Tel: (978) 750-8400.

RFID NewsletterJuly 2008solution, growers and harvesters can track theexact location, timing, and efficiency of eachharvester, as well as the arrival, loading, anddeparture times of crop transport vehicles.The harvesting of crops is a timesensitive operation that requires ation vehicle operators to obtain themaximum yield from each harvest.Reliance on current manual trackingmethods can hinder coordination and slow workflows in the field, adversely affecting productquality.“In the crunch of harvest time, people arefocused on the task at hand (i.e. the harvestingof crops), and not the tracking, recording andcommunications of operational data. As a result,there is often a lack of the information requiredto ensure the most efficient operation,” saidPierre Vidaillac, president of Minds Inc.“Leveraging our success with Intelleflex intracking hot mix asphalt for the road constructionindustry, we were able to develop a solution thatis specifically designed to track the harvestingof crops in the field.”“This is a great example of how today’sbusiness needs are driving the usage of RFIDand complementary technologies. While GPSprovided exact location finding capabilities forthe harvester, it did not by itself deliver a costeffective, event-driven solution to track thearrival and departure of transport vehicles at theharvester,” said Sam Liu, marketing director atIntelleflex.“By adding our Extended Capability RFIDinto the solution mix, we fill that need, and deliversignificant incremental value.”Using the Intelleflex and Minds’ solution,GPS units and RFID readers are mounted onharvesters to track their whereabouts in the fieldas well as the arrival, loading, and departuretimes of transport vehicles.The information is then transmittedwirelessly for immediate access anywhere,anytime — over the Web and mobile phones.Alien Technology introduces intelligent tagradar software to enable new applicationsfor RFIDAlien Technology, a provider of RFIDultrahigh-frequency (UHF) products andservices, announced the availability of its newIntelligent Tag Radar (ITR) software developedfor the ALR-9900, ALR-9800, and ALR-8800Enterprise-Class reader platform. ITR is the firstRFID reader software to provide comprehensiveinformation about the position and direction ofUHF RFID tags in addition to the contents ofthe tag memory.The Intelligent Tag Radar reader platformincludes the following:- ITR-Singulation, a technology thatenables the reader to easily discriminate amongadjacent tagged objects on a conveyor such asitems, cases, or airline baggage, without theneed for specialized antennas, sensors, or nearfield equipment;- ITR-Velocity, which provides real-timeinformation on the speed of a tagged object,enabling discrimination between stationary andmoving objects and automated decision-makingbased on speed and location;- ITR-Directionality, which identifieswhether an item is coming or going as well asthe direction of the item;- ITR-Range, which enables thesystem to isolate tagged items to a given zone,with sufficient precision for most applications,but with much lower cost than competitivetechnologies like active and Wi-Fi tags.“With this new ITR platform, our partnersand their customers can derive new value fromtheir existing investments in RFID,” said ScotStelter, director of reader product marketing withAlien Technology. “This extension of the AlienReader Protocol enables our partners toaddress unsolved business problems usingexisting Alien readers and Gen 2 tags as wellas to expand RFID into new growth applicationsand segments.”ITR application examples:Copyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com2

RFID NewsletterJuly 2008- ITR for airline baggage andmanufacturing — One of the challenges of usingRFID with conveyor belts is the difficulty inisolating individual tagged objects as they passthe antenna. Standard solutions to this problementail reducing conveyor speed or creatinggreater separation between tagged objects. ITRSingulation enables the isolation of the one tagthat is “top-dead-center” with respect to theantenna. This allows the system to keep trackof the order of the tagged objects and to takespecific action with respect to each one. Aliensubsidiary Quatrotec is using ITR, in addition toits airport RFID solution, in baggage-handlingapplications being evaluated now by severalairports and baggage handling companies.- ITR for retail — Retail users of RFIDneed to know not only that a given reader hasdetected a certain tag, but in which direction thetag is traveling when it was detected. Knowingwhether a case of product has moved from theback room to the store floor or the reverse helpsprovide more-accurate inventory informationand supplements shrinkage-control systems.Retailers will also be able to discern movinginventory items from stationary ones with ITRVelocity. This information provides retailers withtimely and specific information on the productthe user is examining, while collecting dataabout how long the customer interacted with theitem. This valuable marketing data will helpretailers to optimize merchandizing displays andto know which products are hot in real time.- ITR for asset tracking — In manyasset-tracking applications, passive RFID isreplacing the more expensive active RFIDsolution. ITR-Range enables the system toisolate the tag to a given zone, which in manycases is sufficient precision for the user, whoretains all of the cost benefits of passive RFID.Alien developed this application to aid in theloading process for cargo helicopters.“The availability of Alien’s ITR softwarepoints to continued passive UHF applicationenablement in the industry,” said Michael Liard,research director for RFID and contactlesstechnologies and markets at ABI Research. “Theability to understand where an item is going,where its exact location is among other items,while on a conveyer or passing through a readzone, opens up the door for application use ofRFID that’s well beyond the supply chain,manufacturing and simple asset tracking.Enterprises such as airlines and airports, largepackage and postal service companies, andothers can benefit from the use of the IntelligentTag Radar.”Alien’s software for the patent-pendingITR can be downloaded by existing and newcustomers from the Alien Partner Portal. Thenew firmware includes an updated softwaredevelopment kit with sample code for severalof the applications described above. For moreinformation about the Alien reader portfolio andthe ITR software upgrade, including datasheetsand pictures, go to www.alientechnology.com/readers.3M Library Systems upgrades ‘basic’ RFIDtag to 1K of memory3M Library Systems introduced anupgraded “basic” RFID tag with 1K of memory,a fourfold increase over the former basic tag, atthe American Library Association annualconference, held at the Anaheim ConventionCenter.The new tag can be imprinted withcustom logos and barcodes by library staff andis fully rewriteable to allow compliance with afuture ISO tag data standard and countryspecific standards. The new basic tag continuesto meet ISO 15693-3 and 18000-3 standards,as do all other 3M RFID tag options.“The purpose of this upgrade is to provideour customers with peace of mind in knowingthat their investment in RFID technology haslongevity and a better price/value option forlibrary system customers,” said Jacob Haas,market development manager, 3M LibrarySystems.Copyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com3

RFID NewsletterJuly 2008“The memory capacity is large enoughfor future applications, and users are providedwith another tag option to meet their price needs.These are very high-value advantages for abasic tag option.”Added Haas, “This new basic tag optionfits into a complete line of RFID tags (premiumand enhanced) that 3M provides to libraries. Itis part of a complete portfolio of RFID tags thatgives the library a choice of tag options that willbest fit its needs.”The tags, which are affixed to circulatingitems, are employed in a host of easy-to-use3M Library Systems RFID applications thatboost performance and productivity in circulationmanagement, inventory control, and security.3M Library Systems’ new basic tag hasbeen accelerated-age-tested and is guaranteedfor the life of the item to which it is affixed. Italso has a “fast-read multiblock” feature thatprovides high performance when multiple tagsmust be read simultaneously. Moreover, theability to custom print on the tags right at thelibrary also enables rapid conversion.Lem Amen, vice president, 3M Track andTrace Solutions, which include RFIDapplications, says the new 3M basic RFID tag“is another big step forward in helping librariesadopt the productivity enhancing benefits ofRFID.Libraries face mounting pressures todayto provide more services to growing populationswithout substantial increases in human orfinancial resources. RFID technology is a staffand-customer-friendly, cost-efficient means offilling the gap.”3M Library Systems provides security,productivity, and information-managementsolutions that harness technology to enable amore human library, freeing librarians to spendmore time doing what they do best — helpingpeople. 3M also partners with libraries to supporttheir technological advancement and ensuretheir success through numerous industrysponsorships and programs. For moreinformation about the 3M Library Systems, visithttp://www.3M.com/library.3M Library Systems unveils high-speed printconversion system for combined RFID andbarcode tag printing with custom logos3M Library Systems introduced its 3MPrint Conversion System for high-speedconversion to RFID collection managementsystems and subsequent tag printing at theAmerican Library Association’s annualconference.The 3M Print Conversion System, withits easy-to-use intuitive interface, fast reader,and automatic tag printer, enables staff tosimultaneously print barcodes and custom logoson the RFID tags, while weeding the collectionat the same time.“The resulting productivity increase andcost savings are substantial,” said Jacob Haas,market development manager, 3M LibrarySystems. “Even after RFID conversion, librarieswant to retain barcodes to have a visible numberon their collection items for various uses, and alogo to identify items that are loaned to otherbranches and libraries.The 3M Print Conversion Systemhandles all of that in one step, plus weeding.It’s one of the most efficient conversion systemsavailable, and eliminates the cost of buyingbarcodes for future additions to the librarycollection.”Haas also noted that the 3M PrintConversion System, as with all 3M LibrarySystems RFID products, gives the user accessto 3M Tag Data Manager, which empowers thelibrary to change its data format to ISO tag datawithout changing tags, if future needs make thatdesirable or necessary.“We don’t lock our customers into ourdata format,” he said. “We want libraries to havethe freedom to make changes as easily andcost-effectively as possible, especially becausean ISO standardized format may be issued inthe not-too-distant future.”Copyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com4

RFID NewsletterJuly 2008The 3M Print Conversion System workswith a library’s own PCs so the user can takeadvantage of its advantageously priced PCcontracts and maintain standardized computerusage. The system is available with high-volumeand regular-volume options to suit individuallibrary requirements. It also can reprogram RFIDtags as items change.“The 3M Print Conversion System isanother important step forward for theproductivity gains that RFID is bringing tolibraries around the world,” said Rory Yanchek,business manager, 3M Track and TraceSolutions. “As the demand for library servicesincreases at a time when budgets are static, atbest, we are making this technology easy to useso that every library staff member can performhis or her tasks with greater efficiency and jobsatisfaction.”The new workstation meets the EURoHS (European Union’s Restriction ofHazardous Substances) directive. RoHSrestricts the use of certain hazardoussubstances in electrical and electronicequipment, including that sold to the librarymarket. To learn more about how 3M LibrarySystems products meet the EU RoHS directive,visit http://www.3M.com/us/library and clickRecycling/Regulatory.this process to produce its new Intellicoreengineered carriers which are specificallydesigned to meet the unique needs of papermanufactures,” said John Colyer, Sonoco vicepresident, Industrial Products — North America.“This technology can be read through any sizeof paper roll, which allows for easy managementthroughout the product’s life cycle.”Sonoco is the world’s largestmanufacturer of fiber-based tubes and cores,many of which are used by companies aroundthe world to package various grades and typesof paper.“Until now, the paper industry hasn’t beenable to seamlessly provide real time trackingand location for the hundreds of millions of rollsit produces annually,” said Gordon Westwater,president and chief executive officer of IPICO.“Working with Sonoco and using IPICO’s leadingidentification technology, we have created whatwe believe will quickly become the RFIDstandard for the paper industry.”Leading paper manufacturers have longsought reliable and cost-effective tools to helptheir customers instantly track exact paper rolllocation, recognizing that paper gradeidentification, storage visibility, and wastereduction are key opportunities for cost savingsand profit enhancement.This new technology shows potential todeliver important financial and environmentalbenefits to customers around the world, and isdesigned as an end-to-end managementsolution dedicated to improving the user’sbottom line.“The RFID-enabled paper rolls representa step-change in material management for oursite. We have a solution that is actually workingand enables automatic goods receipt andmatching against order and shipping documentwithout any manual intervention,” said MikeRamsay, managing director, Mondi MarchCorrugated Packaging.“The system gives the site real-time, foolproof data that enables us to determine exactlySonoco and IPICO introduce embeddedidentification technology to the paperindustrySonoco, one of the largest diversifiedglobal packaging companies, and IPICO Inc.announced the availability of the world’s firstRFID enabled core solution specificallydesigned for the paper industry.UsingIPICO’sdual-frequencytechnology, the new fiber cores allow customersto automatically identify, track, and locate paperrolls at any point in the supply chain.“IPICO and Sonoco have developed aunique process by which RFID technology isembedded in fiber-based cores. Sonoco is usingCopyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com5

RFID NewsletterJuly 2008which reel has been used for each customerproduct. This, for the first time, gives us fulltraceability so that we can guarantee to acustomer that the correct type and source ofpaper has been used.The technology is so simple to use thatit provides a win-win solution with accurate datareporting and at less cost to acquire throughsavings in labor, waste, stock levels and stockouts.”the oil & gas market space to achieve successfuland value-added deployment of this technologyby supporting these organizations through ourcomprehensive set of field-experts, our RFIDlab facilities, real-world test environments, andstandards development roadmaps,” said Dr. BenZoghi, director of the Oil & Gas Solution Groupand professor at Texas A&M University.The solution group offers an arena forthe petroleum industry to communicate theirunderlying needs and align them with thetechnology. It offers petroleum companies theability to voice their requirements for specificapplications of RFID and have the experts inthe solution group deliver on theserequirements. It also offers a way of building aconsolidated methodology of exchanging andinterpreting information related to the collectedRFID data.“One of the objectives of our group is toprovide a concise and clear direction for howthe petroleum market can use radio frequencyidentification technology. This entails definingbest-practices, operational processes, datamodels, and application architectures. Outliningthese steps is a critical precursor to industryadoption.Building this foundation provides a clearview of where and how RFID technology canbe used,” said Konrad Konarski, a foundingmember of the Oil & Gas Solution Group andvice-president of Merlin Concepts andTechnology.Standards development can embodydefining the data-schema of an RFID tag, but itcan also involve understanding operationalconditions, for instance, how the cocktail ofchemicals inserted into a drill string affectsreadability and survivability of a tag.Hydrochloric acid for acid fracturing, hydrogensulfide from down-hole corrosive gases, or baritein the drilling mud are all factors that determinehow RFID technology can be used and how itneeds to be designed and developed to workeffectively.CONTRACTSOil & Gas RFID Solution Group: Petroleumindustry turns to Texas for RFIDExceptionally high crude prices andsurging global demand have led the oil and gasindustry to seek out technologies such as RFIDas a means of gaining operational insight withintheir organizations. Everything from streamliningproduct procurement to enhancing safety andreliability of field equipment can be automatedor improved through an RFID technologybackbone.Leading this wave of industry support isthe Oil & Gas RFID Solution Group, an allianceof subject-matter experts, academicresearchers, and technology providersconsisting of Texas A&M University, Universityof Houston, Avery Dennison, Merlin Concepts& Technology, Shipcom Wireless, Motorola Inc.,and a handful of leading petroleum companies.This multi-disciplinary field of experts is helpingexploration, drilling, and productionorganizations identify, define, develop, anddeploy RFID systems to address fundamentalissues that are inherent to their respective fields.“The group has been created as a meansto unify the industry’s direction and synchronizeits efforts with respect to product and standardsdevelopment.Serving as a think-tank and research anddevelopment center to build the next generationof RFID systems for the petroleum industry. Weare here to assist and work hand-in-hand withCopyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com6

RFID NewsletterJuly 2008Understanding these environmentalfactors helps define best practices thatintegrators can use to interpret criticalcomponents of system development andthereby successfully build RFID technologies forthese application areas.EPC Global, the international standardsboard for RFID technology, is also playing anactive part in accelerating this industry’s movetowards RFID.The standards board is currently workingin collaboration with the Oil & Gas SolutionGroup to achieve these underlying objectivesand develop the next-generation in RFIDSystems for this industry.“A thriving [petroleum] market spacebrings with it great complexity. Supplier networkshave become more intricate, drilling locationsmore diverse, and consumer markets morewide-spread. As such, there is fundamentalneed to leverage next-generation technologiessuch as RFID to enhance asset utilization andstreamline operational processes. RFIDtechnology clearly possesses the ability tosupport the industries growth and address someof its critical pain-points,” added Alex Heredia,vice-president of Oil & Gas for Shipcom Wirelessand member of the Oil & Gas Solution Group.With these new RFID systems capableof storing more information in extremeenvironmental surroundings while being read atlonger distances and maintaining lower pricepoints, the industry is in line for a variety of newand revolutionary application areas of thetechnology.Current uses of the technology includedrill-pipe validation, circulation subactuation,perforating gun triggering, personnelgeofencing, and supply chain visibility, amongothers. The list will continue to grow, and theadoption rate increase as the Oil & Gas SolutionGroup and others drive RFID as a business toolthat enables process intelligence byrevolutionizing procurement, production, andprocess control.The Oil & Gas RFID (OGR) SolutionGroup brings together select industry subjectmatter experts, academic researchers, andtechnology service providers to identify, define,develop, and deploy cutting-edge solutions forexploration, production, drilling, and productmanufacturing in the oil and gas market. Byeducating and refining the customersunderstanding of what the technology can dofor them and developing systems with the helpof a consolidated effort of oil and gasprofessionals, the solutions group is creatingscalable application systems and datastandards and helping generate understandingand adoption of RFID within the oil and ngroup.com.3M Track and Trace Solutions installs RFIDtracking system to manage 150,000 medicalrecords at Fort Hood3M has completed the development andinstallation of an RFID Smart Shelf System totrack and manage the more than 150,000medical files of US Army personnel and theirfamily members at Fort Hood, Texas. Under theterms of a three-year, 3.76 million contract, 3MTrack and Trace Solutions will provide trainingand maintenance services over the next year.Fort Hood, situated about 60 miles northof Austin, the state capital, is the nation’s largestactive-duty domestic armed forces facility. Itoccupies 340 square miles.The custom-designed 3M RFID SmartShelf System is the centerpiece of a pilotprogram that may be extended to other militaryinstallations after a period of evaluation.The system is intended to substantiallyreduce errors and inefficiencies associated withmanual tracking, retrieval, filing, and file mergingmethods of medical records management atFort Hood, where thousands of files may be inuse at the base’s six clinics during any givenmonth. In turn, such improvement would makeCopyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com7

RFID NewsletterJuly 2008a positive impact on operational efficiencies inhealth care delivery, the troop deploymentprocess, and the management of medical datacollection.One of the top priorities of the system isto provide virtually instant accessibility tocomplete medical records for soldiers and theirfamily members requiring intensive and complexhealthcare services.“The cost-efficiency and far-reachingversatility of RFID is prompting an expandingrange of innovative applications in almost allfacets of society,” observed Lem Amen, vicepresident, 3M Track and Trace Solutions. “As aleader in this emerging technology, 3M is veryproud to help introduce this powerful tool to theArmy.”The program to track and manage Armymedical records using radio frequencyidentification technology is being led by theTelemedicine and Advanced TechnologyResearch Center (TATRC), a unit of the US ArmyMedical Research and Materiel Command(USAMRMC).The Army becomes the first branch of theUS Armed Forces to deploy this RFID systemfrom 3M for medical records management.Three other federal government entities areusing RFID systems from 3M Track and TraceSolutions for applications not requiring SmartShelf technology. David Erickson, 3M programmanager for the Fort Hood project, saidapproximately 300 cabinets have been installedwith “smart shelves” to accommodate the morethan 150,000 medical files, whose movementsare continuously monitored.“The system is designed to provideautomatic inventory monitoring and automaticerror notification, and thereby essentiallyeliminate human compliance issues,” he said.“The problems that arise in manually managingvast numbers of medical records are not only awaste of time and money, but, more important,they can adversely affect the delivery of medicalservices.And on a major military installation, theycan also have an impact on the timelydeployment of personnel to their assignmentsto other parts of the world.”Erickson said 3M’s Fort Hood contractcovered the tasks of choosing and optimizingthe best radio frequency technology for thisapplication, developing a cost-effective systemthat includes shelf-based reading capabilitiesand specialized software tailored specifically tomeet the military’s processes and the installationand training of personnel for its use andmaintenance.Sirit Inc. is providing INfinity 510 UHF tagreaders for the Fort Hood RFID installation.“This application presented a number ofenvironmental, technological and performancechallenges, and 3M has implemented severalunique concepts to achieve remarkable results,”says Tony Sabetti, Sirit vice president, RFSolutions.“We are pleased that the IN 510, whichwas selected as the top performing reader inthe ODIN technologies Reader Benchmarkreport, provides the reader managementflexibility, read accuracy, and high tag read ratesneeded to meet the stringent requirements forthe application.”Alanco/TSI PRISM announces new PuertoRico prison projectAlanco Technologies Inc. announced thatits Alanco/TSI PRISM Inc. subsidiary has beenawarded a contract by the Weil Group Inc. todesign a TSI PRISM RFID inmate trackingsystem for a prison complex located inBayamon, Puerto Rico, operated by the PuertoRico Department of Corrections andRehabilitation. Current project plans call forincorporation of TSI PRISM into one, andpossibly two, 500-bed facilities of similar designand architecture within the Bayamon complex.The Weil Group, a security systems consultingfirm located in Caguas, Puerto Rico, is the primecontractor on the Bayamon project.Copyright 2008 Information Gatekeepers Inc. 320 Washington St. Brighton, MA 02135 Tel: (617) 782-5033 Web: www.igigroup.com8

RFID NewsletterJuly 2008The total value of the project, to beconfirmed in early August 2008 upon completionof the system design, will be in the range of 800,000 for both 500-bed facilities. The projectcontract is anticipated to be finalized andawarded in the August/September 2008 timeperiod.Greg M. Oester, president of Alanco/TSIPRISM, commented, “Puerto Rico is the fourthcontract awarded to TSI PRISM this year, threeof which have been attained through the effortsof security integrators such as the Weil Group,which provide a high degree of expertise andstrong customer relationships. This newintegrator involvement is indicative ofaccelerated interest and acceptance of RFIDtracking’s value proposition throughout thecorrections industry.”For more information, please visitwww.alanco.com.Robert Urwiler, chief information officer for VailResorts.The Intermec CN3 mobile computerswith IP30 handheld RFID readers combine thesmallest, most advanced, rugged computer inthe world with a powerful, modular passive UHFRFID handle.The modularity of the IP30 and the RFIDreadiness of Intermec mobile computers meanthe power of RFID can be literally added in asnap today or at any point in the future. TheIntermec CN3 also integrates GPS andBluetooth to increase efficiency and safety byenabling hands-free turn-by-turn voicenavigation. With 3G WAN and Cisco CompatibleWi-Fi and Bluetooth radios, users are connectedwith voice and high-speed data (GSM/EDGE orCDMA/EV-DO) anywhere they go.“Vail Resorts is a leader in providingexceptional experiences for their guests,” saidIntermec’s vice president of RFID, Ray Cronin.Vail Resorts improves season ski pass “We are pleased that Intermec CN3 mobileholder experience with Intermec RFIDcomputers with IP30 RFID readers helpIntermec Inc. announced that its CN3 continue that history of excellence by giving theirmobile comp

RFID Newsletter July 2008 - ITR for airline baggage and manufacturing — One of the challenges of using RFID with conveyor belts is the difficulty in isolating individual tagged objects as they pass the antenna. Standard solutions to this problem entail reducing conveyor speed or creating greater separation between tagged objects. ITR-