Transcription

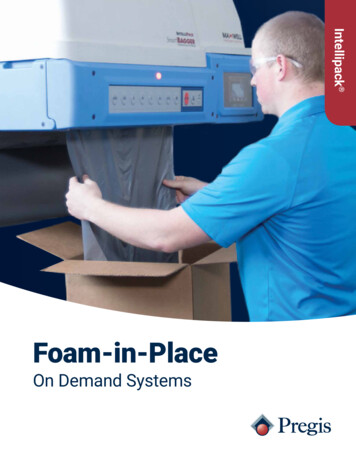

Intellipack Foam-in-PlaceOn Demand Systems

HOW IT WORKSFoam-in-place polyurethane ismolded in real-time by combiningtwo liquid foams in a high densitypolyethylene (HDPE) bag, film or apre-fabricated mold. The mixtureexpands rapidly around theproduct being protected, creatinga custom protective shell. Pack with IntelliPackFoam-In-Place and Shipwith Confidence Highest degree of productprotection available Reduce or eliminate damage costs Maximize space and costefficiencies Increase customer confidence

We’re not just in the packaging business,WE’RE IN THE “WOW” BUSINESS.WORLD CLASSSUPPORT AND SERVICEPackaging should excite customers, motivate prospects, reduce shipping and fulfillment costs, and(of course) protect your products. To ensure you’re getting the most out of your packaging, Pregisoffers unrivaled consultative and technical services and industry leading training support.Consultative Services Packaging optimized for any network – SFS, freight, ground, air, international Package design and testing center ensures packaging is FedEx, UPS orAmazon ready Specialized sales teams understands the unique challenges of your industryTechnical Service Proactively monitor packaging systems and schedule routine maintenance Highly skilled, local field technicians available for immediate needs 24/7 dedicated technical support hotlineTraining Support Standard or custom guides, placards and videos On-site employee training and educational seminars NEW Pregis 360 Virtual Reality Training Platform

Foam-in-Place SystemsAll IntelliPack systems offer long lasting mixing modules, telemetry, bar-coding andergonomic designs for operator comfort.INTELLIPACK SMARTBAGGER FOAM -IN - BAG SYSTEMIdeal for high volume, medium to large applications that require cushioning or blocking and bracing to protect goods Maxwell Intelligent Interface New Maxwell App empowers usersto add photos and videos for training Intuitive control panel Easy-to-replace sealing wires andedge seal arborsFootprint(APPROX. MACHINE DIMENSIONS)Height: 65.5"Width: 44.6"Depth: 39.1”INTELLIPACK SMARTSHOT FOAM -IN - PL ACE SYSTEMWhen your foam-in-place operation requires a handheld touch use the SmartShot.Footprint Tapered dispenser Heated dispenser minimizes cold-shots Insulated handle stays cool(APPROX. MACHINE DIMENSIONS)Hose hanger height: 8-12 ftHeated hose: 20'Feed hoses: 13'INTELLIPACK SMARTSHOT HYBRID FOAM -IN - PL ACE SYSTEMInnovative cross between handheld and bagger system.Footprint(APPROX. MACHINE DIMENSIONS) Hybrid bag stand creates a handheldand bagger machine all-in-one! Variety of bag and stand dimensionsavailable for customer needs Package a wide variety of productswith one piece of equipmentHeight: 44"Width: 24”Depth: 24"Stock Bag Sizes:14” x 18”18” x 25”24” x 32”All IntelliPack Foam-in-Place Systems Utility Requirements:ADDITIONAL BAG SIZES AVAILABLEUPON REQUESTElectrical Power: 208 or 230 VAC, 50/60 Hz, 30 Amp Dedicated CircuitReceptacle Type: L6-30IndustrialElectronicsHome and GardenAutomotiveB2B and B2C

Foam-in-Place Accessories and ConsumablesINTELLIPACK SMARTMOLD PREMOLDCreate custom molds, prefabricated for a specific product.Smartmold utilityrequirements Consistent cushioning and void-fill inplaces that need it most Reduce packaging waste Void-fill in hard to reach areasElectrical Power: 110 VAC, 50/60Hz, 10 AmpReceptacle Type: NEMA 5-15INTELLIPACK SMARTFOAM LIQUID FOAMOnly IntelliPack liquids are stored in clear outer containers allowingyou to visually see the amount of liquid in drums or totes.A-LiquidFoamB-LiquidFoam275 GallonTotes55 GallonDrums2,500 lbs500 lbs2,300 lbs450 lbsADDITIONAL SIZES AVAILABLE UPON REQUESTA formulation for every GHESTINTELLIPACK SMARTFILM The film used for foam-in-place bags arrives flat,taking up minimal space allowing customers tomaximize space and minimize costs.INTELLIPACK SMARTLUBE Cleaning solution used for maintaining andcleaning machine parts.Whether the need is protective void fill, blocking and bracing, cushioning,or pre-molded pads, IntelliPack systems feature the most cost-effective,time-efficient foam-in-place packaging.

5 DEGREESOF SEPARATION1. TelemetryCellular telemetry enables preventative maintenance24/7 eliminating costly, unexpected downtime.2. Bar-CodingBar-coding technology allows customers to create specificbags, fill rates and sequences for each product’s protectiveneeds. This removes guesswork and enables operationswith diverse product lines.3. Equipment DesignAll Pregis’ on-demand systems are designed with ergonomic features toenhance operator comfort and convenience. Multiple equipment optionsare available that meet small, medium and large application needs.4. Customer FocusAt Pregis, customers are our first priority.So, we custom design a program to meetyour specific needs.

Maxwell TechnologyMaxwell intelligent interface empowers users with greater systemcontrols, endless customization options and detailed reporting.Intuitive Interface:5. The AdvantageProgramOur program is designed tobe flexible to support yourchanging business needs.Simply put, the advantageprogram means you get highquality equipment, reliableservice and no surprises. No up-front capital investment Installation, training andongoing support Software updates to ensurestate-of-the-art performance Preventative maintenance;warranty on equipment andlabor included Customizable touchscreenSpanish language toggleEasy to use agile bag and sequence pageVirtually unlimited barcoding for consistent foamdispensed and product protection SMART features include energy conservation andself-cleaning sessions that can be scheduled duringbreaks to maximize up-timeTelemetry Detailed reporting and insights: usage, cost per pack/packer, machine perfomance Map and connect with other facility SmartBagger machinesService and Support Pregis technicians canremotely access machinesfor real-time updates andadjustments NFC cards allow usersto easily log into Maxwellwith customer controlledaccess levels Software updates pushedto Maxwell for most up-todate functionality

Products worthprotectingdeserve PregisWe are a leading manufacturer ofinnovative packaging solutions andprotective products.We solve our customer’s toughestbusiness challenges with packagingso they can create customers forlife. We do this by delivering creativesolutions to packaging challengesand leveraging a material neutralportfolio.Contact us today!www.PREGIS.COMInside the Box ProtectionReady to Use Packaging On Demand Systems – Air, Paper,Foam Foam for FabricationMail & Bagging SolutionsAutomated Poly Bagging Automated Cold Seal Packaging Shipping MailersSurface ProtectionTemporary Protective Films Interleaving Materials FoamEdge ProtectorsConsultative Services& TrainingPackage Design and Testing Custom Integration TechnicalSupport Sustainable Packaging

We're not just in the packaging business, WE'RE IN THE "WOW" BUSINESS. Packaging optimized for any network - SFS, freight, ground, air, international Package design and testing center ensures packaging is FedEx, UPS or Amazon ready Specialized sales teams understands the unique challenges of your industry Proactively monitor packaging systems and schedule routine .