Transcription

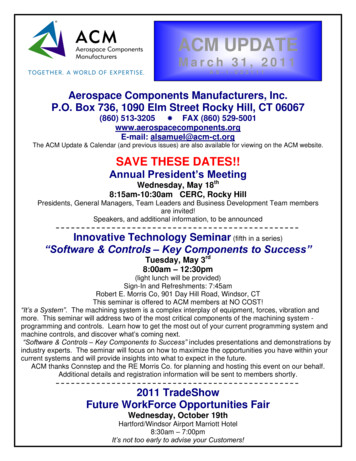

ACM UPDATEMarch 31, 2011A S - 1 - 0 3 3 1 1 1Aerospace Components Manufacturers, Inc.P.O. Box 736, 1090 Elm Street Rocky Hill, CT 06067(860) 513-3205 FAX (860) 529-5001www.aerospacecomponents.orgE-mail: alsamuel@acm-ct.orgThe ACM Update & Calendar (and previous issues) are also available for viewing on the ACM website.SAVE THESE DATES!!Annual President’s MeetingWednesday, May 18th8:15am-10:30am CERC, Rocky HillPresidents, General Managers, Team Leaders and Business Development Team membersare invited!Speakers, and additional information, to be announcedInnovative Technology Seminar (fifth in a series)“Software & Controls – Key Components to Success”Tuesday, May 3rd8:00am – 12:30pm(light lunch will be provided)Sign-In and Refreshments: 7:45amRobert E. Morris Co, 901 Day Hill Road, Windsor, CTThis seminar is offered to ACM members at NO COST!“It’s a System”. The machining system is a complex interplay of equipment, forces, vibration andmore. This seminar will address two of the most critical components of the machining system programming and controls. Learn how to get the most out of your current programming system andmachine controls, and discover what‘s coming next.“Software & Controls – Key Components to Success” includes presentations and demonstrations byindustry experts. The seminar will focus on how to maximize the opportunities you have within yourcurrent systems and will provide insights into what to expect in the future.ACM thanks Connstep and the RE Morris Co. for planning and hosting this event on our behalf.Additional details and registration information will be sent to members shortly.2011 TradeShowFuture WorkForce Opportunities FairWednesday, October 19thHartford/Windsor Airport Marriott Hotel8:30am – 7:00pmIt’s not too early to advise your Customers!

Business Development Bruce Fiedorowicz (Volvo Aero CT), Business Development Team Leader, welcomed members tothe Team‘s March 29th meeting. Firth-Rixson LLC, headquartered in East Hartford, joined ACM at theend of 2010 and Mike Sweeney and Bob Gabaldon attended their first Business Development Teammeeting. ―We make forgings‖ was their brief, but all-encompassing description of the company whichoperates four ring rolling facilities in the U.S. along with closed-die forging plants in the UnitedKingdom, Hungary and at a new plant in Savannah, GA.The meeting‘s guest speaker, from Northeast Utilities (NU), wasRich Asselin, Senior Energy Engineer, who was accompanied byCarl Santoro, Program Administrator; both are from NU‘sConservation & Load Management Dept. In introducing Rich,Bruce Fiedorowicz commented on a ‗change of pace to bottomline cost savings from the Team‘s usual interest in top line sales.Rich briefed NU‘s Conservation & Load Management programswhose purpose is to advance the efficient use of energy, bothThe Benefits of PRIME / Leanelectric and natural gas. This program, financially supported byManufacturingthe Connecticut Energy Efficiency Fund, has varied elements Reduced energy consumption per productintended to provide assistance in reducing energy usage and are Lower operating costsapplicable to both new construction and replacement of older, Improved manufacturing productivityinefficient equipment. Cash incentives for the installation of higher Reduced inventory Reduced floor spaceefficiency equipment can provide as much as 75% of the Reduced wasteincremental cost between standard and high efficiency equipment. Safer and cleaner workplaceFinancing is also available at low interest rates for relatively shortterm loans.Rich also discussed NU PRIME (Process Reengineering for Increased Manufacturing Efficiency), aprogram offering financial support for Kaizen activities which promote energy efficiency throughincreased productivity. PRIME provides support, at no cost, for two (pre-approved) Kaizen eventsand a 50% cost-share of two additional follow-on events; savings are qualified through the estimatedreduction of electric consumption per unit of product produced.Rich Asselin may be reached at 860-665-3292 or asselrw@nu.com. Detail information on all of NU‘sconservation programs may be found at www.ctsaveserergy.org/programs/business.php.The Team discussed current Industry Meetings and Tradeshows:--Lockheed-Martin held their fifth F-35 Supplier Conference in Washington DC on March 9th.Bruce Fiedorowicz of Volvo Aero CT and Jason Jarvis of Jarvis Airfoil represented their firmsand advised, in addition to hearing informative program briefings, of attendees having anopportunity to visit and brief CT‘s congressional and senatorial delegation. It was suggested,with the great value from the information obtained in these briefings, ACM members plan toattend future F-35 Supplier Conferences; even if ‗not invited‘, invitations may be obtained bycontacting Lockheed-Martin.Although not discussed at the F-35 meeting, the Department of Defense issued a formal stopwork order in regard to development of the F-136 engine. Subsequent to the release of this 90day stop work order, GE Aviation advised of their intent to continue the program, self-fundedby themselves and Rolls-Royce, until a final resolution is reached.--Off Shore Technology Conference, May 2-5th, Houston, TX.--AHS (American Helicopter Society) Vertical Flight Forum, May 3-5th, Virginia Beach, VA.--Army Aviation Exhibition and Conference, June 7-8th, Redstone Arsenal, Huntsville, AL.--Paris Airshow, June 20-26th, Le Bourget, France. Members having previously attended thisShow described it as an outstanding ―opportunity to benchmark the global competition‖.Contact Wayne Sumple at 860-282-4222 for information on available display space in theConnecticut State display.

ACM‘s Tradeshow is scheduled for Wednesday, October 19th at the Marriott Hotel in Windsor.Format for the Tradeshow will be similar to that of last year and will again be preceded by themorning‘s ―Future WorkForce Opportunities Fair‖, which attracted over 400 students.Bruce requested members step up to the responsibility of inviting their customers, and consideringtheir limited travel budgets, suggested now would be a great time to ask them to ‗save the date‘In a brief discussion of other aerospace business related matters,-orders were reported for new commercial airliners from Cathay Pacific, Lufthansa, TAN andothers. These orders indicate likely added commercial engine business for Pratt & Whitney.Additionally, with the U.S. Air Force award of the K-46A aerial refueling tanker contract toBoeing, P&W will benefit with orders to produce PW4000 engines.-raw material prices and delivery lead times continue upward. Nickel, having dropped slightlyin February, was reported as having increased to the 12- 13/lb. range on the LME. Dramaticdelivery pushouts by the mills was reported, reaching up to 40 weeks for Inconel alloys.―Demand is not being met by the mills and will likely get worse, as the aerospace industry hasnot yet reached its peak!‖ The next Business Development Team meeting will be held on Wednesday, April 20th at 8:15am atCERC, Rocky Hill. On March 29th, CT Governor Dannel Malloy visited ACM member firms Volvo Aero CT (Newington)and Adchem Manufacturing Technologies (Manchester). The following link is video coverage of hisvisit to Volvo Aero: 4133. Announced on March 31st, Indian low cost carrier IndiGo selected the Pratt & Whitney PW1000G topower up to 150 of their AirBus A320neo aircraft. IndiGo has become the launch customer for theA320neo, due to enter service in 2016.Consolidated Purchasing The Purchasing Team met at Yarde Metals in Southington on March 3rd and Team membersdiscussed their current business situation and related procurement issues. Metal raw materials arealways a key topic and both Aerodyne Alloys and Yarde reported continued projections of higherprices. ―Inventory of nickel based alloys has climbed, yet prices on the LME (London MetalsExchange is the premier world market trading non-ferrous metals) did not drop!‖ Lead times onstainless steel alloys are increasing, prices are increasing, yet mills are not increasing their output. Itwas also reported mills were no longer producing certain ‗boutique‘ alloys due to poor margins onthese unusual, low volume materials.While mills were not adding capacity, Aerodyne Alloys and Yarde both advised of their firms havinginvested in increased capability at their facilities. Aerodyne recently added three new saws for cuttingbar and Yarde Metals is constructing a building to house a new coil flattening line in Southington,targeted to open in July. Thank you Aerodyne Alloys!! Rebate checks have been sent to 14 ACM firms who qualified forsales volume rebates from Aerodyne Alloys, which for 3 ACM firms provided a significant portion, orexceeded the cost, of their annual ACM dues. Aerodyne‘s agreement with ACM provides a 3%rebate on the amount a firm‘s current year sales exceed their total sales from the prior year. ACMdistributes 75% of the rebate to each qualifying firm. For information regarding this agreement,please contact Aerodyne‘s Kirk Smallidge (see, below). The Purchasing Team will hold its next meeting on Thursday, April 14th at 8:00am atHar-Conn Chrome Co, West Hartford.

Suppliers having Agreements with ACM are:Supplier:Turtle & HughesKey Contact:Dave HowardTelephone:203-497-1555Shop Supplies, Abrasives,Cutting Tools, etcRaw Materials: Nickel, Cobalt,Aerodyne Alloys Kirk Smallidge 860-508-1271Titanium – Sheet, Plate & Bar StockProgressive Manufacturing The Progressive Manufacturing Team met on March 8th. Connstep‘s Lean consultant, Roy Laun,led the Team‘s discussion on Value Stream Mapping (VSM) and the benefits of using software tosupport the process.Roy began his discussion of Value Stream Mappingreflecting on a recent United Technologies initiativethat helped introduce eVSM, a PC based graphicalmapping and analysis tool. The software requires bothMicrosoft‘s Visio and Excel be installed and works inconjunction with these programs to provide the‗classical‘ Value Stream Map. Calculations for flowtime, based on inputs of cycle time, setup time, nonvalue added processes, etc appear immediately andallow the lean practitioner to see the effect of processchange. The software also produces ‗spaghettidiagrams‘ to chart the flow of product thru the factoryfloor. Groups of machines can be storedgraphically, allowing reuse without having to redo allthe inputs.Aero Gear‘s Brian Moriarty and Roderigo Garzadescribed their positive experience with eVSM.Aero Gear mapped a 180 step process and usedthe output to develop what was called a ―smartinventory‖. This was described as having made asignificant improvement in on-time delivery; also,customer service went up dramatically! Briansuggested ―using MRP to order raw material, but touse VSM to actually schedule the shop‖.Roy summarized his discussion of the eVSM software describing it as a ―living analytical tool,allowing process improvements to be tested which offer cost and inventory reductions as well asreduced distances travelled‖. Additional information on eVSM is available at www.evsm.com. Royadvised the software is licensed on a per-seat basis, costing approx. 350 per seat, and requiresapprox. 16 hours of training to become proficient. MS Visio’s cost is approx. 560. Roy Laun maybe reached at rlaun@connstep.org or 860-539-4909.

John Kornegay, former ACM President, and long-time President of Kamatics and Kaman PrecisionProducts, has retired and is offering his service and experience in assisting ACM member firms withthe application of Lean in their businesses. John said ―I don‘t believe I would have survived the earlyyears of lean transformation without the support of ACM President‘s and the ACM Lean Team‖ andthis is now ―the give-back period of my career‖.John will visit your company, tour the facility and meet with the company president (or otherappropriate individuals) to offer his suggestions and/or a different viewpoint of how Lean might beapplied (for new adopters) or accelerated (for on-going programs). He has also offered a briefpresentation and/or will lead a group discussion in support of a firm‘s pursuit of Lean implementation.John is offering this assistance to ACM firms at NO COST! For those interested in discussing hisservices or to schedule a meeting, please contact John Kornegay directly at 252-402-8587 (cellphone) or jckornegay@earthlink.net. And many thanks for offering this service to the ACM!! The Progressive Manufacturing Team will hold its next meeting on Tuesday, April 19th at 8:00amat the Trumpf Inc Customer and Technology Center in Farmington, CT. Please RSVP your plan toattend this meeting.This meeting will continue the theme of advanced software tools to assist in Lean deployment.The Swedish firm Solme will present an on-line briefing of their AviX Method software, currently intrial usage at Trumpf. “AviX Method is time and motionanalysis software used to increase productivity and reducecycle times in manufacturing processes. Its information canbe used for cost calculations, balancing of production linesand investment decisions. Using video technology to speedup analysis, separating productive from unproductive work, itenables you to involve everyone in the continuousimprovement process.” For more information about AviX Method, please see their website tml. ACM member John Kravontka, President, Fuss & O‘NeillManufacturing Solutions (Manchester, CT) offers a ‗singlepoint lesson‘ (right) as a visual best practice to fosterspreading of ideas leading to improved safety, quality, leadtimes and profit. John may be reached atJKravontka@FandO.com or 800-286-2469x5399.

Workforce Development The WorkForce Development Team met on March 17th at Aerex Mfg in South Windsor.John Murphy, an educational consultant with the Connecticut Technical High School system attendedthis meeting to discuss ho

ACM UPDATE March 31, 2011 AS- 1 - 0 33111 Aerospace Components Manufacturers, Inc. P.O. Box 736, 1090 Elm Street Rocky Hill, CT 06067 (860) 513-3205 FAX (860) 529-5001 www.aerospacecomponents.org