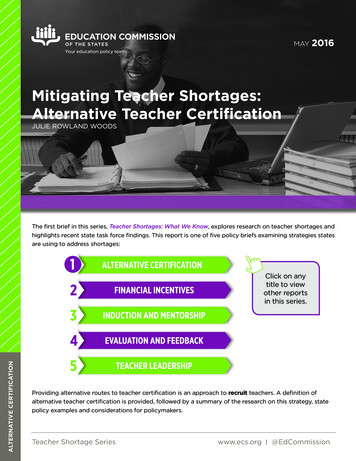

Transcription

HFC152a as the alternative refrigerantPresented by:William R. HillGeneral Motors Corporation11-FEB-20031

ContentvvvvvvvvvvBackgroundPerformanceDirect emissions issueMassCostRisk AssessmentEfficiency/LCCPService/TimingTechnical Issues RemainingConclusionsNote: Organizer questions are shown in REDAcknowledgement:v Larry Kettwichv James A. Bakerv Stella Papasaava11-FEB-2003Underwriter’s LabDelphi Automotive AC SupplierGeneral Motors Corporation2

HFC152a-backgroundChemically Similar – Environmentally Very DifferentFHCFCHFC-134aFASHRAE A1 [Non-flammable]GWP 1300HFUsed in most production vehicles todayHHFC-152aCCASHRAE A2 [flammable]Similar Materials CompatibilityHFHHFGWP 120Used in many refrigerant blends today11-FEB-20033

HFC152a-backgroundElectronicallyControlled CVCTypical HFC152a DirectExpansion SystemLayout [Initial Concept]AccumulatorCondenserSuction Line SolenoidShut off Valve(normally closed)Liquid Line SolenoidShut off ValveExpansionDevice(normally closed)Evaporator11-FEB-20034

HFC152a-PerformanceVehicle Wind Tunnel Cool-downDischarge A/C Temperature Comparison100 0F x 40% R.H. Ambient (38 0C x 40% R.H.)- Full Size Sedan 66150R-152aR-134a54130Soak Temperature0Temperature ( F) Without systemoptimization [Drop-in] HFC152a showsimproved cool-downperformance as comparedto HFC 134a43110Average Cabin Temperature3290(0C)70215010Average Outlet Temperature-1300102030405060Time (min.)40 kph(Recir. Air)City Traffic(Recir. Air)40 kph(Recir. Air)50 kph(Recir. Air)100 kph(Outside Air)Idle(Outside Air)Idle(Recir. Air)Direct Evaporation System reported by Delphi/GM/EPA at SAE Phoenix Alternate Refrigerant Symposium 200211-FEB-20035

HFC152a- Direct Emissionsv95 % Reduction in Direct Refrigerant GHGEmissions as compared to HFC134aØ GWP of HFC152a is 120 vs 1300 for HFC134a*Ø Smaller Refrigerant charge 35% less than HFC134a as demonstrated in Phoenix inSummer, 2003Ø Leakage is less than HFC134a due to molecular weightand lower system pressures with equivalent systemhardware*Engineered systems, 18(11):74-88, November,200111-FEB-20036

HFC152a-System massv System mass is expected to be similar to HFC134a systems with directexpansion nserSameCharge-0.2-0.3 kg.Plumbing/linesSameSafety system 0.2-0.4 kg.7

HFC152a Secondary Loop Optionv If secondary loop system is used, additional componentswould add to system mass/costHFC152a-Primary Refrigerant LoopCondenserCompressorA/DReservoirBlowerHVAC ModuleNew HardwareChillerExpansionDevicePumpNon-flammable coolantSecondary Loop11-FEB-20038

HFC152a-Costv How much more expensive is a current HFC152a basedsystem compared with HFC-134a?Incremental systemcost to manufactureDirect ExpansionSecondary Loop 15 [Est.] 40 [Est.]vIf secondary loop system, safety system is not needed, butthere are additional system costs11-FEB-20039

HFC152a-CostvManufacturing/Service (investment) equipmentØ New recovery/recycling equipment and serviceproceduresØ Additional safety requirements/equipment/training forvehicle assembly plant and service providersØ Use existing tooling for component suppliers11-FEB-200310

Risks Associated with HFC-152av FlammabilityØ Under the EPA SNAP program, the use of flammable refrigerants in newsystems is acceptable if necessary precautions are taken.Ø Systems will comply with SAE [Society of Automotive Engineers] J639[Refrigerant Safety Standards] and J1739 [FMEA-Failure Mode EffectsAnalysis]v Combustion production for HFC-152a/HFC-134aØ MSDS for both HFC134a and HFC152a have identical cautions fordecomposition productsv Flammability and Atmospheric Decomposition productsand their effects will be assessed in the risk assessment11-FEB-200311

HFC152a- Risk Assessmentv Comparison of flammability:LowerFlammabilityLimitLFL [%]UpperFlammabilityLimitUFL [%]Heat ofRealisticCombustionHOC *[kJ/g.]CombustionHC290propane2.1*-2.2 #9.5 #50.344.056.644*A3HFC152a3.7*-3.9 #16.9 /g]#Index[RF] # #Molecular ASHRAEClass 1Weight[g.]*Engineered systems, 18(11):74-88,November,2001# DuPont Technical Informationpresumes less than 100% combustion ofrefrigerant [3/2002] [NFPA]# #Based on DuPont numbers[Note:Numbers from Journal ofHazardous Materials, A93-2002 fall inbetween these values.]#US EPA 09-MAR-1994, Dean Smith11-FEB-2003121 ASHRAE American Society of Heating, Refrigeration and Air Conditioning Engineers

HFC152a- Risk Assessmentv Given the liability issues relating to flammability, will thevehicle manufacturers introduce HFC-152a to vehicles?Ø Use of HFC152a [with direct or indirect expansion system] will dependon the risk assessment results.v What happens if some refrigerant is mixed with HFC-152a?Ø Not likely this will occur in a vehicle system since all refrigerants haveunique service fittings per SAE J639Ø If other refrigerants are mixed with HFC152a during service, resultsdepend on properties of the refrigerant that is added. [L. Kettwich-UL]11-FEB-200313

HFC152a- Efficiency/energy consumptionv Results of HFC152a tests have shown system to be an average of 10%more efficient than HFC134a at conditions from 27 C to 46 C.Ø Use of secondary loop system will result in efficiency similar to current HFC134aMechanical COP System Air Cooling Capacity/ Measured Compressor Shaft Power81 0F x 55% R.H. (27 0C x 55%)2.500R134a2.000 3.5%R152a 8.4% 2.6% 1.8%COP1.5001.0000.5000.00030 mph (48 kph)50 mph (80 kph)70 mph (113 kph)IdleVehicle SpeedDirect Evaporation System reported by Delphi/GM/EPAat SAE Phoenix Alternate Refrigerant Symposium 200211-FEB-200314

HFC152a- Efficiency/energy consumptionv What are the potential efficiency improvements and what is the limit tothese improvements?ØØØØØØØOil SeparatorSuction line heat exchangerImproved Effectiveness of heat exchangersImproved efficiency of compressorCapacity Controlled compressor, externally controlledControlled Air Re-circulation on the evaporatorImproved lubricant compatibilityv A secondary loop needs to be assessedØ Mass and Cost will increase, efficiency similar to current HFC134asystemsv Is it possible to produce a cost vs efficiency improvement pareto?Ø Similar to those items under consideration with the enhanced R134asystem11-FEB-200315

HFC152a- LCCPR152aFrankfurtR134a-enhDirect emissionsIndirect 5000LCCP [kg. of Equivalent CO2]Direct Evaporation System reported by Delphi/GM/EPA at SAE Phoenix Alternate Refrigerant Symposium 200211-FEB-200316

HFC152a-Service Assessmentv Can leaks be identified?Ø Use of Infrared technology has been demonstrated to work similar toHFC134a leak detectors.Ø Service fittings are identified11-FEB-200317

HFC152a-Timing/feasibility for productionv What would be such a reasonable transition period?Ø 2 additional years of development are necessary to optimize systemefficiency, durability, safety, and mass and assure refrigerantmanufacturing capacityØ 2-4 additional years is necessary for a global vehicle model introductionv How mature is the technology itself?Ø Component technology developed [current HFC134a hardware]Ø System controls are still under developmentv To what extent are the problems relating to the introduction ofHFC152a systems related to technology itself, and how muchto “simply” cost?Ø Problems related to introduction are mainly technical issues aroundflammability control in operation, servicing and production.11-FEB-200318

HFC152a-Technological issuesvDual evaporator loops?Ø Secondary loop system would be used for dualevaporator loopsvDirect expansion vs secondary loop?Ø No problem to use HFC152a with secondary loopsystemsØ Secondary loop will have additional cost and reducedefficiency as compared to direct expansionvHeat pump capability?Ø Per SAE paper 2003-01-0733 System demonstrated with coolant as Heat Source– Heat capacity at -18 C is over 8 kW– Results were similar with both R134a and R152a11-FEB-200319

HFC152a-Conclusionsv Environmental ConsiderationØ 95 % reduction in direct refrigerant emissions vs. HFC-134aØ Up to 10% reduction in indirect emissions vs. HFC-134a [reduced fuelusage]v AC system considerationsØ HFC-152a and HFC-134a have nearly identical pressure / temperaturecurves-minimal component changes requiredØ Cooling performance and overall energy efficiency are better thanHFC-134aØ Current HFC-134a components, lubricants and materials can be usedwith HFC-152a Flexible component manufacturing possiblev Relative ease of industry conversionv Risk AssessmentØ Low flammabilityØ R152a is still an HFC and it could fall under any HFC regulationsØ Risk assessment results will be available when completeThank you for your kind attention!11-FEB-200320

ØSystems will comply with SAE [Society of Automotive Engineers] J639 [Refrigerant Safety Standards] and J1739 [FMEA-Failure Mode Effects Analysis] vCombustion production for HFC-152a/HFC-134a ØMSDS for both HFC134a and HFC152a have identical cautions for decomposition products vFlammability and Atmospheric Decomposition products