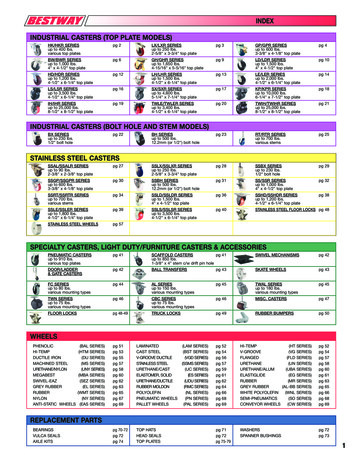

Transcription

Heavy Duty CastersKingpinless CastersCOLD FORGED CASTER RIGSRWM’s 46 series are manufactured from hotrolled pickled steel designated C1015. This steelhas a higher tensile strength than the steel used instamped casters. The cold forging process appliesenough force to the parts to cause the molecules ofmetal to flow to points of greater strength. The coldforging process also refines the grain structure ofthe steel to produce deep smooth coined ball raceswhich do not require machining.While cold forging hardens the raceway to acertain extent, To provide greater strength, RWMcase hardens all raceways of our cold forged casters.This process provides longer wearing and easierswiveling casters.Cold forging provides a caster with strengthand economy in a single product. The strength andendurance of the cold forged casters approach thatof a hot forged caster. Due to their strength, the coldforged casters are used for many applications whichhot forged casters were formerly required.HOT FORGED CASTERSRWM’s 95 series is a hot forged caster. The hotforged caster design does provide some advantagesover cold forged casters when they are built right.Hot forged casters are manufactured from mediumcarbon steel known as C1045. The increased carbonin this steel causes the metal to be harder, gives itgreater tensile strength, and enables the metal to besubjected to heat hardening processes.The advantages of hot forging are that a strongersteel can be forged into the desired shape, deeperparts can be formed, and the grain structure ofthe metal can be controlled to flow in the desireddirection to give optimum strength to the parts.The disadvantages of the hot forging process arethat close tolerances cannot be obtained and smoothfinishes cannot be controlled unless the parts aremachined. Additionally, the machined parts are ofno advantage over cold forged parts unless they arehardened. RWM flame hardens its hot forged casterball raceways which gives the raceways longerwearing characteristics and still leaves the forgedmetal in a tough state without stress risers. Thehardness of hot forged flame hardened raceways is550 Brinell vs. 500 Brinell of cold forged raceways.30PROBLEMS WITH STANDARD KINGPINCASTERSIn most industrial applications, the probabilityexists that in normal operation the casteredequipment will have to pass over cracks in thefloor, door sills, elevator entrances, and other floorobstructions. The angle and force at which a casterstrikes an obstruction will have a definite effect uponthe wear and durability of the caster rig.Factors which contribute to metal fatigue andfailure are weight, speed, and obstructions. Thehigher these factors become, the stronger thecaster must be to give a reasonable service life.Unfortunately, kingpin-style casters eventually fail inthe above conditions.HOW FAILURE OCCURSThere are two forces that continually act uponthe caster. The direct force and the thrust force.These forces increase several times in magnitudewhenever the caster receives a shock by hittingan object such as a door sill or by movement overa broken concrete surface. When this occurs,practically the entire load is supported on the rearportion of the bearing due to the lead or offset builtinto the caster. Less than five steel balls in eachrace, the load and thrust race, carry the entire load.The thrust forces transmitted to the caster try to ripoff the yoke in the counterclockwise direction. Therivet is the only thing that keeps the yoke intact withthe top plate. The thrust force is transmitted to thefront part of the kingpin. Again, one small areamust do all the work. Overstressing results inthe failure of the kingpin or bending of the metalaround the kingpin to the point where the caster isno longer usable.These problems occur with all kingpin-stylecasters eventually. Not only those made by RWM,but by our competitors as well.Cold Forged L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersSOLVING KINGPIN FAILURES WITH RWM’S UNIQUE KINGPINLESS DESIGNRWM provides a series of casters, our 65through 125 series that are different than any othercaster on the market today. These casters areKingpinless . The major factors that differentiatesthe Kingpinless casters from all the other castersis, it has no kingpin. A cross-sectional view of theRWM Kingpinless casters is shown below. Theillustrations show the bearing construction ofeach raceway. The illustrations also show RWM’spatented raceway design.The single row of balls perform a multiplefunction. They act as (1) the load carrying bearing,(2) the thrust bearing, and (3) they maintain theyoke in tight rolling contact with the inner race andtop plate.KINGPINLESS CONSTRUCTIONThe raceway is machined from bar stock steelwith RWM’s patented offset raceway configuration.This eliminates any condition of the balls havingpoint contact with the raceways and therefore,avoids ball indentation ( brinelling ) to the raceways.The large load bearing diameters eliminate theneed for heavy forged construction. In addition,the raceways are completely case hardened tofurther extend the life of the caster, a processmany manufacturers choose to skip in order to cutcosts. The rig consists of three main parts: the topplate, the inside race, and the outside race/yoke.The minimum number of parts allows for simplifiedassembly procedures, and greater flexibility insize configurations. Also, there are fewer parts towear out in the kingpinless design as compared tokingpin-style casters.Hot Forged L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009Why it’s a Superior designIn direct static loading, as a load is placed onthe caster, the forces are initially transmitted tothe rearward balls. Due to the fact that the ballsride on an incline, they tend to climb up the incline.This pulls the yoke to the rear of the caster. Asthis occurs, part of the load is transmitted aroundthe bearing to the front of the caster. This givesdistribution of the load over the entire swivel bearinginstead of just on the rear balls. When thrustforces occur as when the caster is swiveled or hitsan obstruction, these forces will push the yokebackwards in an attempt to rotate the yoke. Theyoke is pulled down on the front part of the bearingand pushed up in the back. In this way the thrust isdistributed over the entire bearing.Benefits of kingpinless design Reduction in caster failureGreater caster service lifeEasier swivel motionEliminates kingpin tightening and maintenanceReduces caster shimmy and shakeKingpinless31

Heavy Duty CastersRWM 75 SeriesOptionsFeaturesDSL Demountable Swivel LockHT High Temperature LubricationIRS Inner Race SealLT Low Temperature LubricationNY Notched YokeSL 4 - Position Swivel LockSR Sealed SwivelTG Thread GuardsWB Wheel BrakeWS Wheel SealsZP Zinc PlatedFCB Face Cam BrakeTRB Tapered Roller Bearings SWIVEL DESIGN: Patented Kingpinless SingleBall Precision Machined Raceway Hardened to50 Rockwell ’C’. Swivel Section Features a 3"diameter Raceway with 1/2" Ball Bearings. TOP PLATE: 5/16" Steel LEGS: 5/16" formed Steel FINISH: Laguna Blue Paint AXLE: 3/4" Bolt and Lock NutSee Mounting Options BelowFCB Cam BrakeSee Brakes Section on pgs. 8 - 975-UIR-0825-SIncorporating its unique and patented kingpinless design this caster is built to take continuous punishmentfrom the toughest industrial applications. The kingpinless design provides superior swivel action with a singlerow of ball bearings rolling in a mirror smooth and hardened raceway. This series of casters offers improvedswivel action, longer service life, reduced maintenance costs and down time and improved productivity.Mounting OptionsSee P65on Pg. 1364-1/2" x 6-1/2"StandardPlate32See P68on Pg. 137See P73on Pg. 1395" x 5-1/2"5-1/4" x 7-1/4"Plate Option43Plate Option76See P70on Pg. 1386" x 7"Plate Option90 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersRWM 75 SERIESWheelDiameterTreadWidthDynamicLoad5"2-1/ 2"2,000 lbs.1,600 lbs.1,620 lbs.1,800 lbs.2,300 lbs.2,500 lbs.5,000 lbs.2-1/ 2"6"2,000 lbs.3"2,500 lbs.3,000 lbs.6,000 lbs.1,800 lbs.2,000 lbs.2-1/ 2"8"2,400 lbs.3,000 lbs.4,000 lbs.1,600 lbs.2,500 lbs.3"2-1/ 2"3,100 lbs.5,000 lbs.5,500 lbs.6,000 lbs.2,370 lbs.2,500 lbs.2,000 lbs.2,900 lbs.3,600 lbs.10"3"3,000 lbs.4,000 lbs.5,000 lbs.2-1/ 2"12”3"6,000 lbs.2,700 lbs.3,000 lbs.3,400 lbs.3,500 lbs.3,900 lbs.4,300 lbs.5,000 lbs.6,000 lbs.Part 75-DLR-1230-R75-CIR-1230-R75-VIR-1230-R* Precision Ball Bearing L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009WheelMaterialSwivelRadiusLoadHeightCast Iron . Roller BearingDurastan (Phenolic)Polyurethane on IronCast Iron . Roller BearingErgo GT (Solid Elastomer) PBB*V-Groove IronForged SteelDurastan (Phenolic)Polyurethane on IronLaminated Durastan (Phenolic)Cast IronV-Groove ForgedForged SteelCast IronDurastan (Phenolic)Polyurethane on IronErgo GT (Solid Elastomer) PBB*V-Groove IronForged SteelOmega PolyurethaneDurastan (Phenolic)Polyurethane on IronCast IronLaminated Durastan (Phenolic)V-Groove IronForged SteelV-Groove ForgedPolyurethane on IronDurastan (Phenolic)Cast IronOmega PolyurethaneDurastan (Phenolic)Laminated Durastan (Phenolic)Polyurethane on IronErgo GT (Solid Elastomer) PBB*Cast IronV-Groove IronV-Groove ForgedForged SteelPolyurethane on IronDurastan (Phenolic)Polyurethane on IronDurastan (Phenolic)Ultra Thick Polyurethane on IronLaminated Durastan (Phenolic)Cast IronV-Groove Iron3- 5 / 8"6-1/ 2"4- 5 /16"7-1/ 2"6"10-1/ 8"7-3 /16"11-1/ 2"8- 5 / 8"13-1/ 2"33

Heavy Duty CastersRWM 76 SeriesFeaturesOptions Swivel Design: Patented Kingpinless Single BallBearing Precision Machined Raceway Hardened to 50Rockwell ’C’. Swivel Section Features a 3" DiameterRaceway with 1/2" Ball Bearings Top plate: 3/8" Steel Legs: 3/8" Steel Finish: Laguna Blue Paint AXLE: 3/4" Bolt and Locking NutDSL Demountable Swivel LockHT High Temperature LubricationLT Low Temperature LubricationSL 4 - Position Swivel LockPCWB Poly Cam Wheel BrakeWS Wheel SealsZP Zinc PlatedTRB Tapered Roller BearingsSee Mounting Options BelowPCWB Cam BrakeSee Brake Sectionon Pgs. 8 - 976-UOR-0830-SIncorporating RWM’s unique and patented kingpinless design this caster is built to take continuouspunishment from the toughest industrial applications. The kingpinless design provides superior swivel actionwith a single row of ball bearings rolling in a mirror smooth and hardened raceway. This series of castersoffers improved swivel action, longer service life, reduced maintenance costs and down time and improvedproductivity. Roller bearings are standard, see page 6 to determine the best bearing for your application.Mounting OptionsSee P73on Pg. 1395-1/4" x 7-1/4"StandardPlate34See P65on Pg. 1364-1/2" x 6-1/2"Plate Option75See P70on Pg. 138See P78on Pg. 1406" x 7"6-1/4" x 7-1/2"Plate Option90Plate Option95 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersRWM 76 SeriesWheelTreadDiameter Width2-1/ 2"6"DynamicLoad1,600 lbs.1,620 lbs.1,800 lbs.2,300 lbs.2,500 lbs.5,000 lbs.2,000 lbs.3"2,500 lbs.3,000 lbs.6,000 lbs.7,000 lbs.1,800 lbs.2,000 lbs.2-1/ 2 ”8"2,400 lbs.3,000 lbs.4,000 lbs.1,600 lbs.2,500 lbs.3"2-1/ 2 ”3,100 lbs.5,000 lbs.5,500 lbs.6,000 lbs.2,370 lbs.2,500 lbs.1,500 lbs.2,000 lbs.2,900 lbs.10"3,000 lbs.3"3,600 lbs.4,000 lbs.5,000 lbs.6,000 lbs.2-1/ 2 ”12"3"2,700 lbs.3,000 lbs.3,400 lbs.3,500 lbs.3,900 lbs.4,300 lbs.5,000 lbs.6,000 lbs.Part 25-RDurastan (Phenolic)76-UIR-0625-RPolyurethane on Iron76-CIR-0625-RCast Iron76-GTB-0625-RErgo GT (Solid Elastomer) PBB*76-VIR-0625-RV-Groove Iron76-FSR-0625-RForged Steel76-DUR-0630-RDurastan (Phenolic)76-UIR-0630-RPolyurethane on Iron76-DLR-0630-RLaminated Durastan (Phenolic)76-CIR-0630-RCast Iron76-FSR-0630-RForged Steel76-VFR-0630-RV-Groove Forged76-CIR-0825-RCast Iron76-DUR-0825-RDurastan (Phenolic)76-UIR-0825-RPolyurethane on Iron76-GTB-0825-RErgo GT (Solid Elastomer) PBB*76-VIR-0825-RV-Groove Iron76-FSR-0825-RForged Steel76-UOR-0830-ROmega Polyurethane76-DUR-0830-RDurastan (Phenolic)76-UIR-0830-RPolyurethane on Iron76-CIR-0830-RCast Iron76-DLR-0830-RLaminated Durastan (Phenolic)76-VIR-0830-RV-Groove Iron76-FSR-0830-RForged Steel76-VFR-0830-RV-Groove Forged76-UIR-1025-RPolyurethane on Iron76-DUR-1025-RDurastan (Phenolic)76-CIR-1025-RCast Iron76-RIR-1030-RRubber on Iron76-UOR-1030-ROmega Polyurethane76-DUR-1030-RDurastan (Phenolic)76-UIR-1030-RPolyurethane on Iron76-GTB-1030-RErgo GT (Solid Elastomer) PBB*76-DLR-1030-RLaminated Durastan (Phenolic)76-CIR-1030-RCast Iron76-VIR-1030-RV-Groove Iron76-VFR-1030-RV-Groove Forged76-FSR-1030-RForged Steel76-UIR-1225-RPolyurethane on Iron76-DUR-1225-RDurastan (Phenolic)76-UIR-1230-RPolyurethane on Iron76-DUR-1230-RDurastan (Phenolic)76-UTR-1230-RUltra Thick Polyurethane on Iron76-DLR-1230-RLaminated Durastan (Phenolic)76-CIR-1230-RCast Iron76-VIR-1230-RV-Groove Iron* Precision Ball Bearing L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009SwivelRadiusLoadHeight5-7/ 32"8"6-29 / 32"10-1/ 2"8-3 / 8"12-1/ 2"10- 5 /16"15-1/ 2"35

Heavy Duty CastersRWM 95 seriesFeaturesOptions Swivel Design: Patented Kingpinless Single BallBearing Precision Machined Raceway Hardened to50 Rockwell ’C’. Swivel Section Features a 4-1/2"Diameter Raceway with 3/4" Ball Bearings. Top plate: 1/2" Steel - SAE 1045 Hot SteelForging Legs: 3/8" Steel - Double Welded Finish: Laguna Blue Paint AXLE: 3/4", 1" or 1-1/4" Bolt and Locking NutDSL Demountable Swivel LockHDSL Heavy Duty Threaded Swivel LockHT High Temperature LubricationLT Low Temperature LubricationNY Notched YokeSL 4 - Position Swivel LockPCWB Poly Cam Wheel BrakeWS Wheel SealsZP Zinc PlatedPCWB Cam Brake95-UIR-0840-SSee Brake Sectionon Pgs. 8 - 9Incorporating RWM’s unique and patented kingpinless design this caster is built to take continuouspunishment from the toughest industrial applications. The kingpinless design provides superior swivel actionwith a single row of ball bearings rolling in a mirror smooth and hardened raceway. This series of castersoffers improved swivel action, longer service life, reduced maintenance costs and down time and improvedproductivity. Roller bearings are standard, see page 6 to determine the best bearing for your application.See P78on Pg. 1406-1/4" x 7-1/2"36 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersRWM 95 seriesWheelDiameterTreadWidthDynamicLoad2-1/ 2 ”5,000 lbs.2,000 lbs.6"3"2-1/ 2 ”3,000 lbs.6,000 lbs.7,000 lbs.3,000 lbs.4,000 lbs.1,600 lbs.2,500 lbs.8"3"4"3"10"5,000 lbs.5,500 lbs.6,000 lbs.3,500 lbs.4,000 lbs.10,000 lbs.2,000 lbs.2,900 lbs.3,000 lbs.4,000 lbs.5,000 lbs.6,000 lbs.4"5"3"12"4"5"4,200 lbs.4,500 lbs.10,000 lbs.5,000 lbs.3,400 lbs.3,500 lbs.5,000 lbs.6,000 lbs.4,800 lbs.5,300 lbs.6,000 lbs.6,500 lbs.Part 250-R L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009WheelMaterialForged SteelDurastan (Phenolic)Polyurethane on IronCast IronForged SteelV-Groove ForgedV-Groove IronForged SteelOmega PolyurethaneDurastan (Phenolic)Polyurethane on IronCast IronV-Groove IronForged SteelV-Groove ForgedPolyurethane on IronCast IronForged SteelOmega PolyurethaneDurastan (Phenolic)Polyurethane on IronCast IronV-Groove IronForged SteelV-Groove ForgedPolyurethane on IronUltra Thick PolyurethaneForged SteelPolyurethane on IronPolyurethane on IronDurastan (Phenolic)Ultra Thick PolyurethaneCast IronV-Groove IronPolyurethane on IronUltra Thick PolyurethanePolyurethane on IronUltra Thick PolyurethaneSwivelRadiusLoadHeight4-3 /4"8-1/ 2"6-3 /16"10-1/ 2 ”7-3 /16”12-1/ 2 ”7-7/16”7- 5 / 8”9- 5 / 8"15-1/ 2 ”37

Heavy Duty CastersRWM 125 seriesFeaturesOptions SWIVEL DESIGN: Patented KingpinlessSingle Ball Precision Machined RacewayHardened to 50 Rockwell ’C’. Swivel SectionFeatures a 7" Diameter Raceway with 3/4"Ball Bearings. TOP PLATE: 1/2" Steel LEGS: 1/2" Steel - Double Welded FINISH: Laguna Blue PaintDSL Demountable Swivel LockHDSL Heavy Duty Swivel LockHT High Temperature LubricationLT Low Temperature LubricationNY Notched YokeSL 4 - Position Swivel LockSR Sealed Swivel RacewayTRB Tapered Roller BearingPCWB Poly Cam Wheel BrakeWB Wheel BrakeWS Wheel SealsSee Mounting Options Below125-UIR-1040-SIncorporating RWM’s unique and patented kingpinless design this caster is built to take continuouspunishment from the toughest industrial applications. The kingpinless design provides superior swivel actionwith a single row of ball bearings rolling in a mirror smooth and hardened raceway. This series of castersoffers improved swivel action, longer service life, reduced maintenance costs and down time and improvedproductivity. Roller bearings are standard, see page 6 to determine the best bearing for your rt NumberSwivelRigid3,500 lbs.4,000 lbs.4"10,000 lbs.4,200 lbs.4,500 lbs.5,000 lbs.4"10"10,000 lbs.5"11"5"6"4"12"5"6"14"4"5"6"4"16"5,000 lbs.6,000 lbs.5,500 lbs.10,000 lbs.4,800 lbs.5,300 lbs.6,000 lbs.6,500 lbs.7,500 lbs.10,000 lbs.6,200 lbs.7,600 lbs.7,800 lbs.6,000 lbs.7,100 lbs.5"8,400 40-R125-UIR-1650-R125-UTR-1650-RWheelMaterialUltra Thick PolyurethaneCast IronV-Groove ForgedForged SteelPolyurethane on IronUltra Thick PolyurethaneCast IronForged SteelV-Groove ForgedPolyurethane on IronCast IronPolyurethane on IronCast IronPolyurethane on IronUltra Thick PolyurethanePolyurethane on IronUltra Thick PolyurethanePolyurethane on IronCast IronUltra Thick PolyurethaneUltra Thick PolyurethanePolyurethane on IronPolyurethane on IronUltra Thick PolyurethanePolyurethane on IronUltra Thick PolyurethaneSwivelRadiusLoadHeight6-3 /16"11"7-9 /16"13"8-1/ 8"8-1/4"14"9-3 / 8"15-1/ 2"10-11/16"18"11-17/ 32"19"Mounting OptionsSee P89on Pg. 1418-1/2" x 8-1/2"StandardPlate38See P85on Pg. 1418-1/2" x 11"Plate OptionLLPCWB Cam BrakeSee Brake Section on Pgs. 8 - 9 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersRWM 2-75 series Dual WheelOptionsFeaturesDSL Demountable Swivel LockHT High Temperature LubricationLT Low Temperature LubricationNY Notched YokeSL 4 - Position Swivel LockSR Sealed Swivel RacewayTG Thread GuardsWB Wheel BrakeWS Wheel SealsZP Zinc Plate Swivel Design: Patented KingpinlessSingle Ball Race Precision MachinedSwivel. Swivel is Hardened and is 3"Diameter with 1/2" Ball Bearings. Top Plate: 5/16" Steel. Legs: 5/16" Steel with Center Leg forStrength. Finish: Blue Paint. Dual Wheels: For Heavy LoadsSee Mounting Options Below2-75-UIR-0820-SIncorporating RWM’s unique and patented kingpinless design this caster is built to take continuouspunishment from the toughest industrial applications. The kingpinless design provides superior swivel actionwith a single row of ball bearings rolling in a mirror smooth and hardened raceway. This series of castersoffers improved swivel action, longer service life, reduced maintenance costs and down time and improvedproductivity. Roller bearings are standard, see page 6 to determine the best bearing for your application.WheelDiameterTreadWidthDynamicLoad800 lbs.2,000 lbs.5"2,100 lbs.2,400 lbs.820 lbs.2,000 lbs.6"2" WidthEach Wheel8"2,400 lbs.2,460 lbs.3,000 lbs.1,000 lbs.2,400 lbs.2,800 lbs.3,000 lbs.3,600 lbs.PartNumberWheelMaterial2-75-RIR-0520-SRubber on Iron2-75-DUR-0520-SDurastan (Phenolic)2-75-CIR-0520-SCast Iron2-75-UIR-0520-SPolyurethane on Iron2-75-GTB-0520-SErgo GT (Solid Elastomer) PBB*2-75-RIR-0620-SRubber on Iron2-75-UOR-0620-SOmega Polyurethane2-75-DUR-0620-SDurastan (Phenolic)2-75-CIR-0620-SCast Iron2-75-UIR-0620-SPolyurethane on Iron2-75-GTB-0620-SErgo GT (Solid Elastomer) PBB*2-75-RIR-0820-SRubber on Iron2-75-UOR-0820-SOmega Polyurethane2-75-DUR-0820-SDurastan (Phenolic)2-75-CIR-0820-SCast Iron2-75-UIR-0820-SPolyurethane on Iron2-75-GTB-0820-SErgo GT (Solid Elastomer) PBB** Precision Ball BearingSwivelRadiusLoadHeight3-15 /16"7-1/ 2"4-7/16"8"6-1/16"10 -1/ 8"Mounting OptionsSee P65on Pg. 136See P68on Pg. 137See P73on Pg. 1394-1/2" x 6-1/2"5" x 5-1/2"5-1/4" x 7-1/4"StandardPlatePlate Option43Plate Option76 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009See P70on Pg. 1386" x 7"Plate Option9039

Heavy Duty CastersDrawings Full ScaleP65Size 4-1/2" x 6-1/2"Hole Pattern 2-7/16" x 4-15/16" Slotted to 3-3/8" x 5-1/4"Hole Diameter 1/2"Found on Pages 30, 32, 33, 35, 38, 40, 45P68Size 5" x 5-1/2"Hole Pattern 4-1/8" x 4-1/2"Hole Diameter 1/2"Found on Pages 30, 32, 33, 35, 38, 4540 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersDrawings Full ScaleP70Size 6" x 7"Hole Pattern 4-3/8" x 5-5/8" Slotted to 4-5/8" x 5-1/2"Hole Diameter 1/2"Found on Pages 38, 40, 45 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/200941

Heavy Duty CastersDrawings Full ScaleP73Size 5-1/4" x 7-1/4"Hole Pattern 3-3/8" x 5-1/4" Slotted to 4-1/8" x 6-1/8"Hole Diameter 1/2"Found on Pages 38, 40, 4542 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

Heavy Duty CastersDrawings Full ScaleP78Size 6-1/4" x 7-1/2"Hole Pattern 4-1/8" x 6-1/8" Slotted to 4-1/2" x 6"Hole Diameter 1/2"Found on Pages 40, 42 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/200943

Heavy Duty CastersDrawings NOT to ScaleP85Size 8-1/2" x 11"Hole Pattern 7" x 9-3/4"Hole Diameter 5/8"Found on Page 44Please note this plate is 50% of full size.P89Size 8-1/2" x 8-1/2"Hole Pattern 7" x 7"Hole Diameter 5/8"Found on Page 44Please note this plate is 50% of full size.44 L. G. Rathbun Company Denver, CO (800)466-2713 - Your Caster Source - 01/2009

forged casters are used for many applications which hot forged casters were formerly required. HOt FOrGeD Casters RWM's 95 series is a hot forged caster. the hot forged caster design does provide some advantages over cold forged casters when they are built right. Hot forged casters are manufactured from medium carbon steel known as C1045.