Transcription

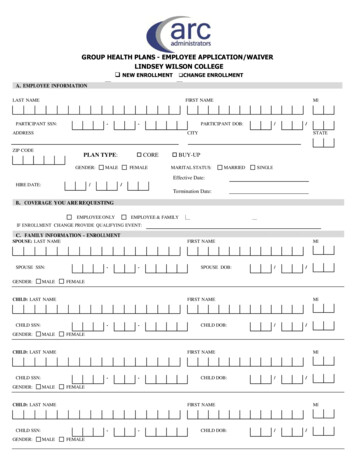

Clause 6(5) of the TBM regulations requires that EPAensures commercially sensitive information in an EMPis not published without consent.Cleanaway has not consented to publishing theredacted material on the basis that it is commerciallysensitive under the regulations. In the interests oftransparent decision making, EPA will again seekconsent to publish this material at the conclusion ofthe competitive process to select a site.Environment Management Plan - Spoil Management andReuse Facility for the West Gate Tunnel Project227 Riding Boundary Road, part 304 Riding Boundary Road, part 714 and 1198 ChristiesRoad, Ravenhall, part Christies Road and part Middle Road, Truganina.Prepared for:Cleanaway Operations Pty LtdLevel 4, 441 St Kilda RoadMelbourne, VIC 300412 May 2021

ContentsContentsIntroduction. 1General . 1Purpose and Objectives . 2Scope of the EMP . 2Format of the EMP . 31.4.1EMP Structure . 31.4.2Versions of the EMP. 31.4.3Supporting Information . 5Approval Process and Responsibilities . 6EPA Approval of an Environment Management Plan . 6Publication of the Environment Management Plan . 10Relevant Legislation, Policy and Guidelines . 10Planning Approval . 11Environmental Auditing . 112.5.1Verification of the EMP . 112.5.2Verification of Construction. 112.5.3Risk of Harm Auditing During Operations . 112.5.4Verification of Tunnel Spoil Waste Categorisation . 11Review of the EMP . 11Variations to the EMP . 12Responsibilities . 12Exclusions from the EMP . 14Project Delineation . 15Project Definition . 153.1.1Development of a Spoil Management and Reuse Facility . 153.1.2Criteria and Specifications for Containment, Reuse and Disposal. 153.1.3Criteria for Reuse and Disposal of Tunnel Spoil . 163.1.4Application of the Landfill Levy for Identified Reuses . 17Site Definition . 17Processing Area Definition . 17Containment System Definition . 18Required Separation Distance . 18SMRF Layout. 18Project Staging and Timing. 193.7.1SMRF. 193.7.2. 20Land Use and Setting . 21Planning Zoning and Easements . 21Land Ownership and Authorisation. 22Geology and Groundwater Environment. 233.11.1 Geology. 233.11.2 Hydrogeology . 243.11.3 Groundwater Elevation, Flow and Discharge . 24M18059 024 RPT Rev7 12May21ii

Contents3.11.4 Salinity and Beneficial Uses . 243.11.5 Surface Water Beneficial Uses . 25Long-Term Groundwater Level and Waste Separation . 25Expected Spoil Quantities, Locations and Characteristics. 27Expected Tunnel Spoil Quantities . 27Expected Tunnel Spoil Production Rates . 27Expected Tunnel Spoil Physical Characteristics . 29Potential for Contamination . 29Environmental Risk Assessment. 31Introduction. 31Conceptual Site Model . 315.2.1PFAS in the Environment . 315.2.2Potential Sources of PFAS . 325.2.3Contaminants of Potential Concern . 32Adopted Water and Soil Quality Criteria . 335.3.1Groundwater and Surface Water . 335.3.234Soil 34Human Health and Environmental Risks. 35Groundwater Quality Impact Assessment . 36Assessment of Potential Acid Sulfate Soils. 36Primary Risk Management and Controls. 36Facility Design . 37Introduction. 37WGTP Design . 376.2.1Design Criteria . 376.2.2Overall Facility Layout and Processing . 386.2.3Drying and Reuse of Tunnel Spoil . 406.2.4Temporary Storage of Rocky Tunnel Spoil . 41Throughput and Capacity. 416.3.1Holding Pens . 416.3.2Lined Cells . 426.3.3Dispatching Prescribed Industrial Waste . 426.3.4Impacts on Metropolitan Melbourne Existing Type 2 Licensed Landfill Capacity . 42Protection of Amenity. 436.4.1Planning and Works Approval Processes . 436.4.2Site Location and Amenity . 436.4.3Visual Impact. 436.4.4Traffic and Road Access . 446.4.5Noise. 446.4.6Dust 446.4.7Odour . 45Site Entry. 45Holding Pens. 456.6.1Loading and Unloading Holding Pens . 456.6.2Groundwater Quality Impact Assessment . 466.6.3Potentially Acid Sulphate Soils (PASS) . 476.6.4. 48M18059 024 RPT Rev7 12May21iii

ContentsLined Cells . 496.7.1Lined Cell Development . 496.7.2Cell Engineered Lining System. 506.7.3Spoil Water Collection System . 516.7.4Prevention of Free Liquid in the Lined Cells . 526.7.5Tunnel Spoil Placement in Lined Cells . 536.7.6Groundwater Quality Impact Assessment . 536.7.7Internal Separation Bunds . 536.7.8Lined Cell Capping . 54. 556.8.1Purpose. 556.8.2Spoil and Timing . 556.8.3. 566.8.4Groundwater Quality Impact Assessment . 57Spoil Water Management . 58Spoil Water Management Overview . 58Spoil Water Sources and Catchment. 58Water Storage Capacity and Design . 597.3.1Spoil Water Holding Pond and Water Treatment Plant Rationale . 597.3.2Settlement Ponds . 597.3.3Spoil Water Holding Pond . 607.3.4Contaminated Spoil Water Holding Tanks . 607.3.5Groundwater Quality Impact Assessment . 61Water Treatment Plant . 61Spoil Water Transfer. 62Surface Water Run-Off Outside of the Catchment . 62Reuse of Treated Water . 63Operations and Environmental Management . 64SMRF Operations Overview . 648.1.1Tunnel Spoil . 64SMRF Operating Hours . 65Health, Safety and Environmental Management Systems . 65Risk Management Framework . 66Environmental Management Documents and Plans. 66Operations Management Plan . 688.6.1Handling Tunnel Spoil . 698.6.2Dust Suppression and Control . 698.6.3Management of Odorous Tunnel Spoil . 708.6.4Noise Abatement . 708.6.5Prevention of Land and Groundwater Contamination Outside of Holding Pens and Lined Cells . 708.6.6Site Emergency Management Plan . 718.6.7Pollution Incident Plan . 71Incidents, Complaints and Response. 72Monitoring Program . 738.8.1Groundwater Monitoring . 748.8.2On-site Water Quality Monitoring. 758.8.3Off-site Surface Water, Sediment and Biota Sampling. 768.8.4Boundary Dust Monitoring . 778.8.5Inspection and Checklists . 78Triggers and Contingencies. 79M18059 024 RPT Rev7 12May21iv

Contents8.9.1Amenity Triggers . 798.9.2Groundwater Monitoring Triggers . 80Construction Environment Management Plan . 81Sampling Analysis and Quality Plan for Categorisation . 82Waste Categorisation Sampling Overview . 829.1.1PFAS . 829.1.2IWRG Parameters . 829.1.3EPA Publication 1828. 83Responsibility for Sampling. 83Spoil Categorisation Sampling Requirements . 849.3.1CPBJH JV Sampling Requirements. 849.3.2Cleanaway Round 1 Sampling . 849.3.3Cleanaway Round 2 Sampling . 869.3.4Sampling Methodology and Laboratory Testing Requirements . 86Cleanaway Sampling Responsibilities . 87Treatment of Tunnel Spoil . 88Proposed Treatment . 88Dewatering in the Lined Cells . 88Management of Potential Acid Sulfate Tunnel Spoil . 89Reuse of Tunnel Spoil . 90Reuse Objectives . 90Reuse Scenarios and Approval . 90Identified Reuse Options. 9011.3.1 Reuse Rationale. 9011.3.2 Identified Reuses . 90Off-Site Disposal and Treatment of Prescribed Industrial Waste Tunnel Spoil . 93Off-Site Treatment and Disposal of PIW Tunnel Spoil . 93Offsite Disposal of Category C Tunnel Spoil to MRL . 93Materials Transport and Tracking . 94Traffic Management . 96Haulage to the SMRF from WGTP Sites . 96Traffic Management at the SMRF. 9614.2.1 Delivery Trucks . 9614.2.2 Internal Haulage . 96Haulage of Category A and B Tunnel Spoil Off-site . 97Vehicle Control and Decontamination. 97Future Facility Uses. 98SMRF Reuse. 98SMRF Entrance Reuse. 98Facility Decommissioning . 9915.3.1 SMRF. 9915.3.2. 99Stakeholder Assessment and Consultation. 100Stakeholder Engagement Plan .

Environment Management Plan - Spoil Management and Reuse Facility for the West Gate Tunnel Project . 227 Riding Boundary Road, part 304 Riding Boundary Road, part 714 and 1198 Christies Road, Ravenhall, part Christies Road and part Middle Road, Truganina. Prepared for: Cleanaway Operations Pty Ltd . Level 4, 441 St Kilda Road . Melbourne, VIC 3004