Transcription

Manufacturing Execution Systemin Automotive Supply ChainAnalytical Framework for Data IntegrationOleg GusikhinFord Scientific Research Labe-Technology ResearchICEIS 2002

Ford Research Laboratorye-Technology Research(Information Science, Operations Research,Data-mining, Neural Nets, Statistics)ICEIS 2002

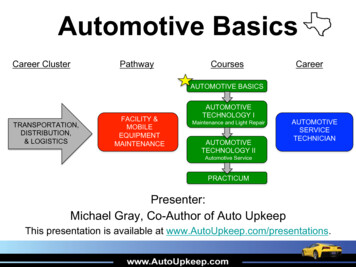

Presentation Outline BackgroundManufacturing Execution System (MES)Data Integration IssuesData Integration Analytical FrameworkMES Functional Diagram ReviewSummaryICEIS 2002

Automotive Supply ChainAP1APNtier 2supplierstier 2supplierstier 1suppliersBodyShopStampingPaintShoptier 1suppliersAP15ICEIS 2002Dealerstier 2suppliersFinalAssembly

Environment Business First-tier automotive supplier with establishedbusiness practices Mixed-volume commodity products Over 100 End Items supplied to several dozenscustomers IT Infrastructure TCP/IP Network Interface to corporate MRPII Numerous Plant Floor Automation Systemsof different types and vendors evolved over timeICEIS 2002

Production Systemfor 1st Tier SupplierArea ASupplyUncertainties:Rate, Yield, DowntimeICEIS 2002Area BAssemblyDistributionDemandvariability

DistributionTruckRailICEIS 2002

Premium FreightAirTruckRailICEIS 2002

Cost Savings Opportunities ICEIS 2002Premium FreightInventoryOvertimeExcessive Material Handling

Manufacturing Execution CycleCustomerRequirementsResource Allocationand SchedulingDispatchingBalance on Hand,Work in ProcessPlant FloorResource StatusPlant Floor DataICEIS 2002MonitoringProduction Rate,Downtime, Yield

IT InfrastructureMRPManufacturing ExecutionRaw MaterialWork in ProcessEnd ItemsEnd ItemsIn blyPlant Floor AutomationICEIS 2002ShippingCustomer

IT InfrastructureMRPManufacturing ExecutionRaw MaterialWork in ProcessEnd ItemsEnd ItemsIn blyPlant Floor AutomationICEIS 2002ShippingCustomer

Data Integration EnvironmentMRPIIPlant HUBAS/RSPLCICEIS 2002Bar codeScannerAGVRobotSpecial-purposesoftware system

Data Integration Issues Asynchronies in Snapshot Data RetrievalTransactional Data OnlyDisjointed DataInaccurate and/or Incomplete DataLack of DataInformation System FailuresICEIS 2002

Asynchronies in SnapshotData RetrievalMissed CountsSystem ASystem BProductionStatus SnapshotICEIS 2002

Asynchronies in SnapshotData RetrievalDouble CountsSystem ASystem BProductionStatus SnapshotICEIS 2002

Transactional Data OnlyWork In Process ?Work In Process ?Bar CodeReaderCycle CountICEIS 2002Cycle Count

Disjointed DataPart-CPart-AAPart-BPart-AICEIS 2002?

Inaccurate DataIncomplete containerIncomplete containerComplete containerContainer ScanPart Count: 4ICEIS 2002Part Count: 4Part Count: 4

Incomplete Data (No Part Number)Batch CBatch BBatch AReaderPart 1Part 2Part 3Part 1Part 2Part 3Batch NumberBatch CBatch BBatch AStyle and Paint CodesICEIS 2002

Lack of DataWorkstation AAGVWorkstation BAGVShipping DockNo DataAvailablePLCAGV ControlAGV ControlData CollectionICEIS 2002Scanner

MES Functionality HierarchyExecution ControlDecision SupportManagerial InformationIntegration and InterpretationPlant Floor DataICEIS 2002MRP Data

Operation Management vs.Information TechnologyWhat information isneeded, When, andBy WhomOperationsManagementICEIS 2002How to get theinformationInformationTechnology

Integrated ApproachWhat information isneeded, When, andBy WhomOperationsManagementICEIS 2002How to get theinformationMESInformationTechnology

Data Integration Framework1. Design Material Flow Model (MFM)2. Map Data Sourcesa. Snapshotb. Transaction3. Design Internal LogicICEIS 2002

Petri Net Model of Material Flowp1t1p4p2NotationPTMICEIS ufferEventPart, Tool, Container

Petri Net Data MappingSnapshotPlant Floor TransactionsICEIS 2002

Modeling ExampleInput BufferWorkstationReader AReader Bt1p1ICEIS 2002Output Buffert2p2p3

Model Executionp1t1p2t2Message FromReader At1t2t1t2Message FromReader BICEIS 2002p3

Firing Rulep1t1p2t2Message FromReader At1ICEIS 2002t2p3

Attribute MappingAttribute MappingPartICEIS 2002Msg Color Attribute Mapping /Color MsgPart

Information Mapping ExampleAS/RSWork CenterShippingScrapAssembly PlantICEIS 2002

Material Flow ModelShippingWCP1P2P3In TransitAssemblyDemandP4ReworkICEIS 2002

Initial State MappingBOHWCP1P2AS/RSP3AssemblyDemandPhysical CountsReworkICEIS 2002In TransitP4MRP

Transaction MappingWCP1AGV ControlBOHP2P3PLCReworkICEIS 2002In TransitScannerAssemblyDemandP4

Data Sources MappingBOHWCP1P2P3AssemblyDemandP4ReworkICEIS 2002

Internal Logic Design UsingTime ParametersICEIS 2002

Timing ParametersTimerCurrent TimeToken Time Stamp 16:54:12 ICEIS 2002 16:32:08 Input Arc Delay00:40:00

Availability Delay IllustrationParts trackedby the modelParts not trackedby the modelArea AACBCBAReaderArea B6 parts3 partsICEIS 2002

Modeling without delayACBCBA6 parts3 parts3 partsICEIS 2002

Modeling with delayAvailability DelayACBCBA6 parts3 parts4 partsICEIS 2002

Token Clean UpArea ACBScrapt3t2ReaderArea BCCt1Clean Up TimetcCurrent Time - t1 Clean Up Timet3t2Clean Up TimetcICEIS 2002

Place StatusTimerCurrent TimeToken Time StampInput Arc DelayPlace Status{up, down} 16:54:12 ICEIS 2002 16:32:08 00:40:00

Place Status Trigger(Direct Information)Status: UpStatus: Downt1Machine Upt2Machine DownICEIS 2002t1Status: Upt2 Msg Machine Down /Msg t1t2 Msg Machine Up /Msg

Place Status Trigger(Indirect Information)T2 – T1 STCurrent Time T2 Current Time T1 t1p1 Msg p2ICEIS 2002Timestamp T1 STp1t1 Timestamp T1 t2t2STp2Current Time T3 p1t1Timestamp T3 t2 Msg STp2

Workstation Modelw11200t1p27200source AGVtransfer type RECEIVEtransfer to IM100ICEIS 2002c1t2source PLCI M100operation COMPLETE

Final Modelw1t11200p2P16007200c1ScrapICEIS 2002t2BOHP3t3 In TransitAssemblyDemandP4

Actual Inventory vs. ModelInventoryActualModelICEIS 2002Time

Use of the Framework System Specification Implementation Tool– (example: G2 with Petri Nets libraries)ICEIS 2002

MES ArchitectureMRP InterfaceWWW Real-TimeStatus DisplaySchedulingMESDatabasePlant FloorData IntegrationpageEvent ManagementDispatchingPlant Floor AutomationICEIS 2002E-mail

Summary Increase in dynamics and complexity ofmanufacturing environment creates the needto bridge the gap between corporateplanning systems and plant floor processcontrols The success of MESs depends on theavailability of accurate, consistent andtimely data.ICEIS 2002

Summary (Cont.) The data integration function is oftenoverlooked: this is a primary source ofMES projects failures The design of MES information supportrequires integral analysis of material andinformation flowICEIS 2002

Summary (Cont.)The proposed analytical framework1. Provides a systematic approach to analyzeand integrate the critical sources of data formanufacturing (supply chain) execution2. Emphasizes the possibilities and benefits ofincorporating the knowledge of productionprocess to compensate for incomplete and/orinaccurate dataICEIS 2002

ICEIS 2002

Manufacturing Execution System (MES) Data Integration Issues Data Integration Analytical Framework MES Functional Diagram Review Summary. ICEIS 2002 Automotive Supply Chain Final Assembly Paint Shop Body Shop Stamping AP1 AP15 APN tier 1 suppliers tier 2 suppliers tier 1 suppliers tier 2 suppliers tier 2