Transcription

Durable Pothole Repairs POTHOLE11th December 2012Dipl.-Ing. Kathrin Kubanek & Dr.-Ing. Carsten Karcher

ConsortiumCo-ordinator Karlsruhe Institute of Technology (KIT-ISE), Institute ofHighway and Railroad Engineering, GermanyMembers Danish Road Institute (DRI), Denmark Forum Des Laboratoires Nationaux EuropeensDe Recherche Routiere (FEHRL), Belgium Transport Research Laboratory (TRL), UK University of Zilina (UNIZA), Slovakia University of Twente (UT), Netherlands Slovenian National Building and Civil EngineeringInstitute (ZAG), SloveniaTrust. Understand. Commit.Picture: CSIR2

Motive All European countries have potholes Potholes cause increasing numbers of crashes,injuries and deaths How to repair them?– Many approaches only durable on short-term basis– Therefore not cost-effectiveFoto: C. NicollsTrust. Understand. Commit.3

Motive Main objective to address the need of road agencies– Durable construction and maintenance methods– Repair damage occurs after hard winters– Repeated frost-thaw cycles Evaluation methods using existing European Standards Comparison with trial sitesTrust. Understand. Commit.4

Workpackages WP1 – Definition of the term “pothole” WP2 – Selection of tests and evaluation methods for usein the laboratory and in situ WP3 – Study of existing standards, techniques, materials& experience with them on the European Market WP4 – Evaluation of techniques and materials fromexisting trial sitesIn Progress WP5 – Laboratory testing of selected materials WP6 – Life Cycle Cost and Benefit Analysis (LCCBA) WP7 – Development of guidelines including cataloguesof materials – Final ReportTrust. Understand. Commit.5

Workpackage 1PotholeA deterioration of the pavement surface in which the materialsbreaks down in a relatively short time and is lost causing a steepdepression. Notes (1):Generally, potholes require rapid remedial action to maintain the safety ofroad users.Potholes will also need to be reinstated to maintain the functionalrequirements and comfort, but the requirement will be as immediate.Potholes will typically have a depth of at least 30 mm and an areaequivalent to a diameter between 100 mm and 1 m with the values for aspecific situation depending on several factors including the traffic speedand intensity, the type of vehicle (particularly the presence of bicycles andpedestrians) and the climate.Trust. Understand. Commit.6

Workpackage 1PotholeA deterioration of the pavement surface in whichthe materials breaks down in a relatively shorttime and is lost causing a steep depression. Notes (2):Potholes can grow once they have emerged, but generally stop growingafter a certain time. However, other potholes can after appear close to anexisting one has appeared.Potholes can occur due to several mechanisms (such as fracture, attritionand seasonal), not all of which are fully understood.Trust. Understand. Commit.7

Workpackage 2Principal requirements of the materials in order toensure durability and the test methods to assess them1. Standard properties for surfacing materials2.in adverse(by CompactibilityDeformation resistanceconditionswheel-tracking or 3.prior to trafficcycliccompression) Dependentmaterial type or test to develop4.toonconditions SensitivityTexture depthsteel balldepressiontesttemperaturesindirecttensile Repeatedtestsfor differentand5.(includingthe useofortack/bondcoat) test (ITT) e.g.AdhesionAir voidscontentand/orfreeze/thawcycles (an adaptation prEN6.Recyclability(buttensileonlyasoptiona considerationat this stage) humiditiesWater12697-48,sensitivityan existingnon-asphalt Chemicalevaluation/data test)sheet ofBinderaffinity Tests referred to in EN 13108 to the levels appropriate to theoriginal specificationTrust. Understand. Commit.8

Workpackage 3Study of existing standards, techniques, materials& experience with them on the European Market Two main elements of quality pothole repair:– Selection of material– Pothole repair techniquesTrust. Understand. Commit.9

Workpackage 3Study of existing standards, techniques, materials& experience with them on the European Market Different types of materials– Bitumen-based cold-mix materials– Bituminous hot mixed materials– Cement-based materials Different repair techniques:– Temporary repairs– Semi-permanent procedures– Permanent/ more durable repairTrust. Understand. Commit.10

Workpackage 3Conclusions– Materials and methods are similar in the differentcountries– Materials (1):A few test methods were found, but no requirementsfor properties.Aggregate size of the repair material depends on thedepth of the pothole.Dense-graded asphalt materials is supposed toperform well at warm and hot temperatures.Open-graded asphalt mixtures are normally moreworkable at freezing temperatures.Trust. Understand. Commit.11

Workpackage 3Conclusions– Materials (2):Cold-mix materials as a temporary solution but canalso be more durable with proper installation.Limitations of cold-mix materials: It can’t becompacted to the same level as hot-mix asphalts.Hot-mix asphalt as a more durable solution.Cement-based materials as fast-hardening solutionsfor rapid repair. But different deflections ofsurrounding asphalt leads to cracking at the jointsand ingress of water. Therefore not recommended.Trust. Understand. Commit.12

Workpackage 3Conclusions– Pothole Repair techniques:Cold-mix asphalts as an emergencymethod and often only possibilities dueto low temperatures. But here are also differentmethods which lead to different durabilities.Semi-permanent procedures: Use of hot or coldmaterial with preparation of pothole.Permanent/ more durable repair: Use of hot materialswith preparation of pothole, including use of propercleaning, preparation of edges and use of bond coat.Trust. Understand. Commit.13

Workpackage 4Evaluation of techniques and materials fromexisting trial sites 3 trial sites– Denmark: in Tulso (2008/09)– Slovenia: in Ljuljana/Slovenia (1999, repaved 2011)New Trial Sites in Novo mesto & Nova Gorica (2012)– UK: Trial Site in UK, restrictions due to confidentialityagreements.but: existing approval scheme in the UK for materialsthat evaluates/ certifies materialsTrust. Understand. Commit.14

Workpackage 4Trial site in TulsoTrust. Understand. Commit.15

Workpackage 4Spring 2011Autumn 2011Trial site in Ljuljana/SloveniaTrust. Understand. Commit.16

Workpackage 4Trial site in Novoe mesto and Nova GoricaTrust. Understand. Commit.17

Workpackage 4Conclusions– Different evaluations methods were used at the trialsites, a common evaluation system should bedeveloped.– This needs to involve different climate zones anddifferent traffic classes according to the differentconditions in Europe.– Generic types of materials couldn’t be divided indurability categories based on this evaluation becauseof great variations in the estimated durability.– Suggestion of categorizing pothole repair materials indifferent durability categories.Trust. Understand. Commit.18

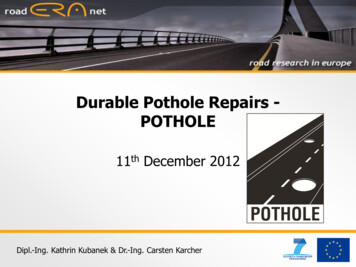

Workpackage 4Synthetic tmaterialsCat. I, Cat. IICat. I, Cat. IICat. I, Cat. II, Cat. IIICat. I, Cat. II, Cat.IIIComprehensiveLimitedLimitedDurabilityless than 1 Limitedyear (short-termdurability)NoneNonePothole ½ m Temperature 10 CEstimateddurabilityEquipmentCategory I:LimitationsCategory II: Durability between 1-3 years (medium-term durability)forCategory III: Durability more than 3 years (long-term durability)application 3 h after applicationReady forShortly afterShortly after 3 h sNoNoPossibility ofrecyclingTypical typeCracks in repair, Loss of material, Cracks in repair,Cracks in repair,frettingadhesion failureof damage for adhesion failure,adhesion failure,the genericimmersedcracks in thechippingspotholepavement, loss ofrepairedchippings, loss ofmaterialsmaterialTrust. Understand. Commit.19

Workpackage 4Typical damagesCracks (hot asphalt)Trust. Understand. Commit.Loss of material (cold asphalt)20

Workpackage 4Typical damagesFailure of adhesionCracks(Cement-based materials)Trust. Understand. Commit.21

Workpackage 5 & 6WP 5: Laboratory testing of selected materials Currently in Progress Testing of materials– Basic testings: Aggregate gradation, binder content,air void content– Further testing of selected materials: compactability(workability), indirect tensile test (stiffness strength),water sensitivity, sensitivity to conditions (freeze/thaw)WP 6: LCCBA is in preparationTrust. Understand. Commit.22

POTHOLEThank you for your attention!Dipl.-Ing. Kathrin KubanekKathrin.kubanek@kit.eduTel.: 49 721 6084 3869Dr.-Ing. Carsten KarcherCarsten.karcher@kit.eduTel.: 49 721 6084 2245Trust. Understand. Commit.23

None None Pothole ½ m Temperature 10 C Ready for traffic Shortly after application Shortly after application 3 h after application 3 h after application Possibility of recycling Yes Yes No No Typical type of damage for the generic pothole repaired materials Cracks in repair, adhesion failure, immersed chippings Loss of material,