Transcription

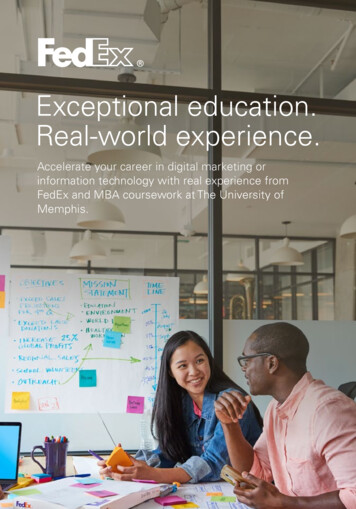

GEN2 ELEVATOR SYSTEM Experience theexceptional

Set yourbuilding apartWhether helping busy commuters get to work ordelighting people as they shop, your building shouldbe a unique experience for anyone who steps inside.The Gen2 elevator system has the style, comfort andspeed needed to ensure passengers experience yourbuilding to the fullest. With space-saving architecturalfeatures that maximize design freedom, Otis helpsyour building stand out.OTIS GEN2 OVERVIEWDescriptionMachine room-less gearlessSpeed150 – 500 fpmCapacity2100 – 5000 lbsMaximum stops32Maximum travel300’02

ARCHITECTURAL FREEDOMDesign withoutlimitsGen2 technology is sized to fit inside the wall of the topelevator landing – eliminating the need for a control room.So whether you want to impress visitors with an expansivelobby or offer tenants a larger space, Gen2 gives you theroom to bring your vision to life.COMPACT DESIGNGen2 technology eliminates machine room spaceand cost for greater architectural design freedom.COMPACT CONTROLLERSized to fit inside the wall of the top elevatorlanding, the controller can be accessed by anattractive, concealed test panel.MAXIMIZED SPACE SAVINGSFlexible coated steel belts allow a smaller machinesheave, reducing machine size by 80 percent andraising efficiency up to 50 percent.04

DESIGN STYLEYour elevator,your styleFrom modern aesthetics to classic interiors, Gen2 can betailored to fit your style. Our robust design has the abilityto carry luxury aesthetic materials, allowing you to createa cab interior to match your design style. And if you’refaced with architectural challenges such as moving largeloads or dimensional constraints, our team will work withyou to create a design solution for your project.ARCHITECT’S ASSISTANTHelps you select the right elevator solution and createdrawings and specifications tailored to your project.CABCREATE Offers choices of finishes and materials, so you can createa memorable, individual elevator with every detail.BIMCREATECreates customizable, configured 3D Revit files for integrationinto overall building plans versus selecting from pre-existing files.Access these time-saving design tools and more at www.otis.com.06

COMPASSPLUS DESTINATION MANAGEMENTA smarterway to movethroughoutyour dayEven short moments of waiting can feellike a lifetime. Otis reimagined how tonavigate seamlessly through your building.With CompassPlus destination dispatch,we put personalized technology at yourpassengers’ fingertips. CompassPlus createsan upscale, concierge-like experience thatkeeps everyone on the move.IMPROVED TRAFFICSmartGrouping organizes people to get themto their destinations up to 50 percent faster thanconventional dispatching, while making minimalstops. This system adjusts dynamically basedon your building’s needs throughout the day.INTUITIVE DESIGNOur CompassCreate software provides anarray of eye-catching screen options that intuitivelynavigate people throughout the building.SMARTPHONE ACCESSCall your elevator even before you get to theelevator bank with the eCall smartphone app.SECURITYeCall can be integrated with any third-partybuilding security system and accommodatesboth external and built-in security ID readers.CUSTOMIZATIONPersonalize your passenger experience withcustom messages – shown hourly, daily, weeklyor for special occasions. And complement yourbuilding’s style with buttons, colors, fonts andimagery of your choice.08

PERFORMANCEYour comfortis our focusWe sharpened our focus on speed and performance withoutcompromising comfort. We reduced metal-on-metal contact anddampened vibrations to ensure the Gen2 ride is smooth and quiet.SWIFT MOVEMENTHigh-performance door operators and superior car accelerationallow passengers to enter and exit elevators more quickly.SMOOTH COATED STEEL BELTSThe steel belts eliminate the noise created by themetal-on-metal contact from conventional steel ropes.LOW-NOISE GEARLESS MACHINEMounted on isolation rubber pads, the low-noise gearless machinereduces vibration and minimizes noise in adjacent rooms.10

RELIABILITYReliable,as expectedSome of the world’s most distinguished buildings trustin Gen2 technology. Manufactured exclusively at ourISO-certified factories, the Gen2 system is the result ofour most advanced thinking, global experience and deepengineering expertise. You can be sure you’re gettingexceptional Otis performance day after day.PULSEThe Pulse System continuously monitors the elevator’scoated steel belts to safeguard their integrity, ensuring safe,efficient operation and reduced inspection downtime.AUTOMATIC RESCUE OPERATIONBattery-powered systems deliver passengerssafely to the nearest floor during a power failure.‘MADE IN OTIS’From taking travelers to their next adventure tohelping commuters move about their day, Otismoves billions of people to their destinations.Our facility in Florence, South Carolina, is one ofour global manufacturing centers of excellence,serving customers across North America. Fromthis state-of-the-art facility we innovate, test andimprove the Otis equipment you’ll find in someof the world’s most iconic buildings.ENHANCED SEISMIC PROTECTIONCoated steel belts and a uniquely designedmachine sheave work together to providegreater stability during seismic activity.12

ENERGY EFFICIENCYCreate a lastingexperienceWhatever your sustainability goals – from designingnet-zero buildings to managing your energy efficiency –Gen2 is engineered to meet your needs.REGEN DRIVELED LIGHTINGLUBRICATIONSLEEP MODE75%10xZERO75%more efficient than conventionalgeared systems with non-regenerativedrives, while providing clean powerto help run other building systems.longer lifespan of Gen2 LEDlighting compared toconventional fluorescent lamp.coated steel belt and machinelubrication needed, providingfor a cleaner hoistway andelevator environment.more efficient LED energy usagewith sleep mode – lights and fansshut down when not in use andare automatically restarted withthe touch of a button.14

PARTNERSHIPWe’re with you fromconcept to completionCreating a unique experience for tenants and customers takes a lot ofthought, planning and coordination. Thankfully you don’t have to do italone. For over 160 years, we’ve helped customers all around the worldreach new heights while helping billions of passengers arrive at theirdestinations every day. So from detailed project planning to ongoingservice, we’re here to help you every step of the way.PROJECT DESIGNWe consider architectural solutions, traffic analysis, product specificationsand value engineering to help craft and deliver on your vision.SPECIALIZED INSTALLATION PLANNINGOur team helps at every step of the installation process, fromcoordinating contractors to monitoring specialized safety reviewsto delivering a smooth handover when the project is complete.16

SERVICEA commitment toexceptional serviceWE EARN YOUR TRUST — EVERY DAYOur mechanics see your building as their own.With a global team of more than 30,000, wework around the clock to keep your equipmentoperating like new. The result is truly personalizedservice that ensures we build your trust over thelifetime of your equipment.We know what it takes to keep people moving safely and smoothly.Our founders were dedicated to delivering extraordinary service,and today we’re continuing that promise with personalized andimaginative ways to meet our customers’ every need.Benefit from the industry’s leading service offering, featuring 24/7dedicated customer support through OTISLINE , more intuitiveaccess to information with the eService customer portal and ourpersonal commitment to always put your needs first.TURNING DATA INTO ACTIONAs one of the first elevator companies to usebig data and predictive analytics to improveperformance, we’re experts at getting themost out of emerging technology. Our digitalecosystem uses the “internet of things”andmobility tools to predict and diagnose issuesbefore they occur. All this to stay ahead ofyour needs and to deliver a personalizedpassenger experience.SignatureService18

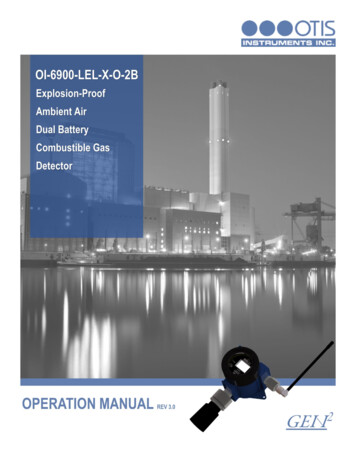

TECHNICAL DETAILSUnderslung systemsHoisting beam(not by Otis)GFCB H80’Travel height maximum(45 m)101316150(0.76 m/s)IH2100 lbs (953 kg)BClear car depth for front openingsCab height3DDoor width2500 lbs3000 lbs(1134 kg)5’-8 5 16” (1735 mm)6’-5 9 16”4’-3 16”1Clear car depth for front & rear openingsC94’-4 8”113’-0”4000 lbs(1588 kg)5’-0 16” (1528 mm)5’-5 16”(1324 mm)5’-0 4”5’-6 8“3(2362 mm)1(1543 mm)or 9’-9”3’-6”9(1665 mm)4’-0”(1067 mm)Center Opening or Single SlideSingle Slide(1219 mm)Door height7’-7”(2311 mm)8’-4”(2540 mm)9’-4”(2845 mm)Hoistway single width9,10 seismic7’-9”(2362 mm)8’-6”(2591 mm)9’-6”(2896 mm)Hoistway double width15’-6”7’-0”Hoistway double widthnon-seismicseismicHoistway depth for front openingsHoistway depth for front & rear openingsIClear overhead to hoist beam4,5AH(1.78 m/s)J17’-4”(4826 mm)5’-9”6’-4”(1753 mm)6’-3 1 4”150 fpmor 8’-0”17’-0”(4724 mm)15’-10”(2134 mm)(2438 mm)(5182 mm)19’-0”(5283 mm)19’-4”6’-11”(1930 mm)6’-11 7 8” (2130 mm)(1911mm)200 fpm(0.76 m/s)7’-5 1 4”(5791 mm)Clear car depth for front openingsCClear cab height3DDoor width5’-5 9 16”7’-4 8”171(1655 mm)(2258 mm)7’-10 16”(2273 mm)7’-11 2”151(2268 kg)25000 lbs AIA5’-11 5 16”(1811 mm)5’-8 5 16”(1735 mm)(2544 mm)9’-0 8“(2747 mm)(2559 mm)9’-0 4“(2762 mm)8’-4 16”38’-4 4”3(2426 mm)7’-9”4’-0”5000 lbs(2411 mm)(2362 mm)or 9’-9”4’-6”Door heightHoistway single width9,10 non-seismic7’-4”(2235 mm)7’-10”Hoistway single width9,10 seismic7’-6”(2286 mm)8’-0”Hoistway double width15’-0”(4572 mm)15’-4”(4674 mm)7’-0”Hoistway double width7,9,107,9,10non-seismicseismicHoistway depth for front openingsHoistway depth for front & rear openings(2267 mm)I9’-1”9’-7”(2769 mm)9’-10 1 2”(3009 mm)(2134 mm)or 8’-0”(2921 mm)10’-4 1 2”(3162 mm)16’-4” (4978 mm)16’-6”(5029 mm)10’-8”(3251 mm)Clear overhead to hoist beam4,5150 fpm(0.76 m/s)200 fpm(1.02 m/s)(4140 mm)7’-9”(2362 mm)Cab height12’-10”(3912 mm)12’-11”(3937 mm)9’-9”(2972 mm)Cab height14’-7”(4445 mm)14’-8”(4471 mm)15’-7”(4750 mm)9’-9”(2972 mm)Cab height14’-10”(4522 mm)14’-11”(4547 mm)KOptional control closet or room 7Control closetControl roomControl room–duplexIMPORTANT:To assist in your planning, we recommend that you call your Otisrepresentative at the beginning of the project.Hoistway depth x 3’-10”Hoistway depth x 5’-9”Hoistway depth x 7’-6”or 5’-6”(1676 mm)JMinimum pit depth6,8KOptional control closet or room 74’-0”(1219 mm)or 5’-0”(3073 mm)10’-9 3 4”13’-7”(1372 mm)(3295 mm)13’-7”4’-6”(1524 mm)Hoistway depth x 3’-10”(1753 mm)Control roomHoistway depth x 5’-9”(1753 mm)(2286 mm)Control room–duplexHoistway depth x 7’-6”(2286 mm)5. For seismic areas, multi-car groups, or pre 2008 ASME1. Clear car dimensions may vary depending onA17.1 Safety Code for Elevators, please contact yourinterior finishes.Otis representative for clear overhead dimensions.2. 4000P and service elevators @350 fpm require6. Some locations require a 5’-0” (1524 mm) pit.a control closet.Contact your Otis sales representative for details.3. Clear cab height varies by ceiling type and floor recess.4. Allow a minimum of 4” (102 mm) between top of safety 7. Please consult your local Otis representative regardingmulti-car groups, or smaller dimensions.beam and top of hoistway.8. A pit ladder pocket may be required. Please contactyour Otis representative for details.11’-5 11 16”350 fpmControl closet(1168 mm)(2464 mm)10’-1”(3861 mm)4’-6”8’-1”(2438 mm)(2413 mm)(4928 mm)12’-8”(1524 mm)7’-11”16’-2”(3836 mm)or 5’-0”(2388 mm)16’-0” (4877 mm)12’-7”(1219 mm)(1372 mm)(2438 mm)Cab height4’-0”3Two-SpeedFG1(2268 kg)2(2972 mm)(1219 mm)Door typeH(1.78 m/s)7’-5 2”1(2041 kg)2E(5893 mm)(2108 mm)350 fpm(1.02 m/s)B4500 lbs(1814 kg)2(2362 mm)Minimum pit depth6,8ELEVATIONK7’-9”JIDPLAN350200(1.02 m/s)4000 lbsClear car width1Center OpeningHoistway single width9,10 non-seismicH16Clear car depth for front & rear openingsF7,9,1016(0.76 m/s)A(1680 mm)(2972 mm)EG10Rated duty(1814 kg)27’-5 9 16” (2275 mm)(1970 mm)(1309 mm)(914 mm)Door type3500 lbs(1361 kg)37’-9”7,9,10(45 m)EServiceRated dutyClear car width1150’(45 m)150Speed (fpm)J150’(24 m)Maximum stopsPassengerA80’ELEVATIONK(1.78 m/s)CB HTravel height maximumAPLAN350200(1.02 m/s)ED150’(30 m)Maximum stopsSpeed (fpm)100’(24 m)Hoisting beam(not by Otis)GF(3498 mm)(1.78 m/s)(4140 mm)1115’-7”(4750 mm)(1372 mm)11or 5’-6”(1676 mm)(1168 mm)9. Hoistway widths for rises above80’-0” (24384 mm) should be increased by2” (51 mm) to allow for tolerances.10. Construction efficiencies can be realized byincreasing hoistway width dimensions by 2” (51 mm).11. Service cars with a 7’-9” (2362 mm) cab heightand 4’-6” (1372 mm) pit will require an additional8” (203 mm) of clear overhead.20

TECHNICAL DETAILSOverslung systemsHoisting beam(not by Otis)GFB HTravel heightmaximum300’Speed (fpm)(1.02 m/s)350(1.78 m/s)400(2.03 m/s)EPLAN500(2.29 m/s)PassengerRated duty2500 lbs3000 lbs(1134 kg)Clear car widthBClear car depth for front openings14’-3 1 8”(1299 mm)4’-9”Clear car depth for front & rear openings14’-3 3 4”(1314 mm)4’-9 5 8”C6’-8 16”1Clear cab height5Door width3’-6”Door heightFHoistway single width non-seismicGH(2134 mm)8’-6”(2591 mm)17’-0”(5182 mm)Hoistway double width seismic17’-4”(5283 mm)7’-0”(1981 mm)6’-2 8”200 fpm(2438 mm)Cab height15’-6”9’-7”(2921 mm)Cab height17’-1”Minimum pit depthKControl closet or room 3or 9’-7”AELEVATIONK400450(2.03 m/s)500(2.29 m/s)5’-0”7’-4 4”3(1.78 m/s)(4724 mm)16’-2”(5207 mm)17’-9”5’-6”(1524 mm)Control closetHoistway depth x 3’-10”Control roomHoistway depth x 5’-9”Control room–duplexHoistway depth x 7’-6”IMPORTANT:To assist in your planning, we recommend that you call your Otisrepresentative at the beginning of the project.7’-8 2”350 fpm(1.02 m/s)Clear car depth for front openings1H(2.54 m/s)(1219 mm)CClear cab heightDDoor width9’-4”(2845 mm)9’-6”(2896 mm)19’-0”(5791 mm)19’-4”(5893 mm)J7’-11”7’-11 5 8”(2276 mm)FHoistway single width non-seismicGI(5410 mm)8’-6”(2413 mm)8’-0”(2438 mm)or 9’-7

The Gen2 elevator system has the style, comfort and speed needed to ensure passengers experience your building to the fullest. With space-saving architectural features that maximize design freedom, Otis helps your building stand out. OTIS GEN2 OVERVIEW 02. ARCHITECTURAL FREEDOM Design without limits Gen2 technology is sized to fit inside the wall of the top elevator landing – eliminating the .